Abstract

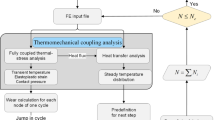

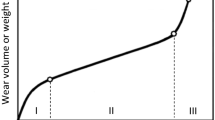

The photoelastic technique was applied to capture in situ plane stress in a block-on-cylinder contact. This method allows researchers to qualitatively visualize the distribution of principal stress difference during wear processes. Additionally, numerical simulation of the evolution of wear was conducted. The conjugate gradient method together with fast Fourier transform was employed to solve the pressure distribution. Based on the computed pressure, the block wear was solved with Archard’s wear law. The subsurface stress was computed using the influence coefficient method. The simulated results of wear and stress were compared with the experimental results; the similarities and differences between the results highlight the usefulness and limitations of the numerical method. However, the photoelastic technique together with the numerical method casts light on the nature of wear.

Similar content being viewed by others

Notes

There is a typo in Eq. (31b) of the reference; it should be pij ← (P0/P) pij.

Abbreviations

- d :

-

Thickness of a birefringence specimen

- E * :

-

Equivalent Young’s modulus,\({1 \mathord{\left/ {\vphantom {1 {{E^*}}}} \right. \kern-0pt} {{E^*}}}={{\left( {1 - \nu _{1}^{2}} \right)} \mathord{\left/ {\vphantom {{\left( {1 - \nu _{1}^{2}} \right)} {{E_1}}}} \right. \kern-0pt} {{E_1}}}+{{\left( {1 - \nu _{2}^{2}} \right)} \mathord{\left/ {\vphantom {{\left( {1 - \nu _{2}^{2}} \right)} {{E_2}}}} \right. \kern-0pt} {{E_2}}}\)

- f σ :

-

Material stress fringe value

- G * :

-

Equivalent shear modulus, \({1 \mathord{\left/ {\vphantom {1 {{G^*}}}} \right. \kern-0pt} {{G^*}}}={{\left( {1 - 2{\nu _1}} \right)} \mathord{\left/ {\vphantom {{\left( {1 - 2{\nu _1}} \right)} {{G_1}}}} \right. \kern-0pt} {{G_1}}} - {{\left( {1 - 2{\nu _2}} \right)} \mathord{\left/ {\vphantom {{\left( {1 - 2{\nu _2}} \right)} {{G_2}}}} \right. \kern-0pt} {{G_2}}}\)

- g :

-

Gap between two contact bodies

- g 0 :

-

Initial gap between two contact bodies

- I c :

-

The set of all nodes that are in contact

- I g :

-

The set of all nodes in the calculation domain

- k :

-

Wear coefficient

- p :

-

Normal pressure distribution

- P :

-

External normal loads

- q :

-

Tangential pressure distribution, q = µp

- s :

-

Total sliding distance

- u̅ z :

-

Elastic deformation along the z direction

- x, z :

-

Spatial coordinates

- x 1,2 :

-

Domain of contact

- Δh :

-

Wear depth increment

- Δs :

-

Sliding distance increment

- Δx :

-

The size of one mesh grid

- δ :

-

‘rigid-body’ approach

- σ x,z, τ zx :

-

Stress component

References

Marshall, D.B., Shaw, M.C., Morris, W.L.: Measurement of interfacial debonding and sliding resistance in fiber reinforced intermetallics. Acta Metall. Mater. 40(3), 443–454 (1992). https://doi.org/10.1016/0956-7151(92)90392-R

Hu, Z., Lu, W., Thouless, M.D.: Slip and wear at a corner with Coulomb friction and an interfacial strength. Wear. 338–339, 242–251 (2015). https://doi.org/10.1016/j.wear.2015.06.010

Dally, J.W., Chen, Y.M.: A photoelastic study of friction at multipoint contacts. Exp. Mech. 31(2), 144–149 (1991). https://doi.org/10.1007/BF02327567

Bryant, M.D., Jau-Wen, L.: Photoelastic visualization of contact phenomena between real tribological surfaces, with and without sliding. Wear. 170(2), 267–279 (1993). https://doi.org/10.1016/0043-1648(93)90247-J

Burguete, R.L., Patterson, E.A.: A photoelastic study of contact between a cylinder and a half-space. Exp. Mech. 37(3), 314–323 (1997). https://doi.org/10.1007/BF02317424

Fang, Y., He, J., Huang, P.: Experimental and numerical analysis of soft elastohydrodynamic lubrication in line contact. Tribol. Lett. 65(2), 42 (2017). https://doi.org/10.1007/s11249-017-0825-9

Fernández, M.S.-B., Calderón, J.M.A., Díez, P.M.B., Segura, I.I.C.: Stress-separation techniques in photoelasticity: a review. J. Strain Anal. Eng. Des. 45(1), 1–17 (2009). https://doi.org/10.1243/03093247JSA583

Solaguren-Beascoa Fernández, M.: Data acquisition techniques in photoelasticity. Exp. Tech. 35(6), 71–79 (2011). https://doi.org/10.1111/j.1747-1567.2010.00669.x

Yoneyama, S., Arikawa, S., Kobayashi, Y.: Linear and nonlinear algorithms for stress separation in photoelasticity. Exp. Mech. 52(5), 529–538 (2012). https://doi.org/10.1007/s11340-011-9512-1

Narayanamurthy, C.S., Pedrini, G., Osten, W.: Digital holographic photoelasticity. Appl. Opt. 56(13), F213-F217 (2017). https://doi.org/10.1364/AO.56.00F213

Zhan, W., Huang, P.: Numerical analysis of time-varying wear with elastic deformation in line contact. Friction (2018). https://doi.org/10.1007/s40544-017-0195-1

Andersson, J., Almqvist, A., Larsson, R.: Numerical simulation of a wear experiment. Wear. 271(11–12), 2947–2952 (2011). https://doi.org/10.1016/j.wear.2011.06.018

Meng, H., Ludema, K.: Wear models and predictive equations: their form and content. Wear. 181, 443–457 (1995). https://doi.org/10.1016/0043-1648(95)90158-2

Archard, J.: Contact and rubbing of flat surfaces. J. Appl. Phys. 24(8), 981–988 (1953). https://doi.org/10.1063/1.1721448

Hegadekatte, V., Huber, N., Kraft, O.: Finite element based simulation of dry sliding wear. Modell. Simul. Mater. Sci. Eng. 13(1), 57–75 (2004). https://doi.org/10.1088/0965-0393/13/1/005

Mukras, S., Kim, N.H., Sawyer, W.G., Jackson, D.B., Bergquist, L.W.: Numerical integration schemes and parallel computation for wear prediction using finite element method. Wear. 266(7), 822–831 (2009). https://doi.org/10.1016/j.wear.2008.12.016

Hu, Z., Lu, W., Thouless, M.D., Barber, J.R.: Simulation of wear evolution using fictitious eigenstrains. Tribol. Int. 82, 191–194 (2015). https://doi.org/10.1016/j.triboint.2014.10.015

Arjmandi, M., Ramezani, M., Giordano, M., Schmid, S.: Finite element modelling of sliding wear in three-dimensional woven textiles. Tribol. Int. 115, 452–460 (2017). https://doi.org/10.1016/j.triboint.2017.06.015

Flodin, A., Andersson, S.: Simulation of mild wear in spur gears. Wear. 207(1–2), 16–23 (1997). https://doi.org/10.1016/S0043-1648(96)07467-4

Põdra, P., Andersson, S.: Wear simulation with the Winkler surface model. Wear. 207(1), 79–85 (1997). https://doi.org/10.1016/S0043-1648(96)07468-6

Sfantos, G., Aliabadi, M.: Wear simulation using an incremental sliding boundary element method. Wear. 260(9), 1119–1128 (2006). https://doi.org/10.1016/j.wear.2005.07.020

Polonsky, I.A., Keer, L.M.: A numerical method for solving rough contact problems based on the multi-level multi-summation and conjugate gradient techniques. Wear. 231(2), 206–219 (1999). https://doi.org/10.1016/S0043-1648(99)00113-1

Johnson, K.L.: Contact mechanics. Cambridge University Press, Cambridge (1985)

Theocaris, P.S., Gdoutos, E.E.: Matrix theory of photoelasticity, vol. 11. Springer, Berlin (1979)

Lei, Z., Yun, H., Zhao, Y., Pan, X.: Automatic determination of fringe constant in digital photoelasticity. Eng. Mech. 26(12), 40–45 (2009)

Zhan, W., Huang, P.: Numerical analysis of elastic wear in line contact. J. South China Univ. Technol. 45(5), 45–51 (2017). https://doi.org/10.3969/j.issn.1000-565X.2017.05.007

Mo, Y., Turner, K.T., Szlufarska, I.: Friction laws at the nanoscale. Nature. 457(7233), 1116–1119 (2009). https://doi.org/10.1038/nature07748

Acknowledgements

The authors would like to acknowledge the financial support of the National Natural Science Foundation of China (Grant No. 51575190).

Author information

Authors and Affiliations

Corresponding author

Appendices

Appendix A

The surface deflection distribution produced by a given contact pressure p(x) is shown in Eq. (1). As the ‘rigid-body’ approach δ in Eq. (5) can be determined based on the load balance condition, the constant C in Eq. (1) can be merged with it. Equation (1) can be expressed as the Green function:

where Ig is the grid area and K(x) represents the surface displacement distribution produced by a unit concentrated normal force acting at the origin. Comparing Eq. (A.1) with (1), the kernel K(x) is given by

where H(x) is the Heaviside step function. Under the assumption of stepwise constant distribution of contact pressure, the influence coefficient Ki−j is given by

Integrating Eq. (A.3) yields an explicit formula for Ki−j, which can be expressed as

where \(f\left( x \right)=x\left( {\ln \left| x \right| - 1} \right)\).

Appendix B

where

Rights and permissions

About this article

Cite this article

Zhan, W., Fang, Y., Van Hoang, C. et al. Instantaneous Plane Stress Observation and Numerical Simulation During Wear in an Initial Line Contact. Tribol Lett 66, 90 (2018). https://doi.org/10.1007/s11249-018-1042-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11249-018-1042-x