Abstract

The energy dissipation in the contact regions between solids in sliding contact can result in high local temperatures which may strongly affect the friction. This is the case for rubber sliding on road surfaces at speeds above 1 mm/s. I derive equations which describe the frictional heating for arbitrary (non-uniform) motion, taking into account that some of the frictional energy is produced inside the rubber due to the internal friction in rubber. Numerical results are presented for one limiting case for steady sliding.

Similar content being viewed by others

References

Jaeger, J.C.: Moving source of heat and the temperature at sliding contacts. J. Proc. R. Soc. NSW 76, 203 (1942)

Archard, J.F.: The temperature of rubbing surfaces. Wear 2, 438 (1959)

Holm, R.: Calculation of the temperature development in a contact heated in the contact surface, and application to the problem of the temperature rise in a sliding contact. J. Appl. Phys. 19, 361 (1948)

Block, H.: The flash temperature concept. Wear 6, 483 (1963)

Bansal, D.G., Streato, J.L.: On estimations of maximum and average interfacial temperature rise in sliding elliptical contacts. Wear 278–279, 18 (2012)

Putignano, C., Le Rouzic, J., Reddyhoff, T., Carbone, G., Dini, D.: A Theoretical and experimental study of viscoelastic rolling contacts incorporating thermal effects. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. (2014). doi:10.1177/1350650114530681

Liu, Y., Barber, J.R.: Transient heat conduction between rough sliding surfaces. Tribol. Lett. 55, 23 (2014)

Persson, B.N.J.: Rubber friction: role of the flash temperature. J. Phys. Condens. Matter 18, 7789 (2006)

Rowe, K.G., Bennet, A.I., Krick, B.A., Sawyer, W.G.: In situ thermal measurements of sliding contacts. Tribol. Int. 62, 208 (2013)

Persson, B.N.J., Lorenz, B., Volokitin, A.I.: Heat transfer between elastic solids with randomly rough surfaces. Eur. Phys. J. E 31, 3 (2010)

Persson, B.N.J., Volokitin, A.I., Ueba, H.: Phononic heat transfer across an interface: thermal boundary resistance. J. Phys. Condens. Matter 23, 045009 (2011)

Persson, B.N.J.: Thermal interface resistance: crossover from nanoscale to macroscale. J. Phys. Condens. Matter 26, 015009 (2014)

Persson, B.N.J.: Sliding Friction: Physical Principles and Applications, 2nd edn. Springer, Berlin (2000)

Persson, B.N.J.: Theory of friction: stress domains, relaxation, and creep. Phys. Rev. B51, 13568 (1995)

Barel, I., Urbakh, M., Jansen, L., Schirmeisen, A.: Multibond dynamics of nanoscale friction: the role of temperature. Phys. Rev. Lett. 104, 066104 (2010)

Gnecco, E., Bennewitz, R., Meyer, E.: Abrasive wear on the atomic scale. Phys. Rev. Lett. 88, 215501 (2002)

Schallamach, A.: A theory of dynamic rubber friction. Wear 6, 375 (1963)

Persson, B.N.J., Volokitin, A.I.: Rubber friction on smooth surfaces. Eur. Phys. J. E 21, 69–80 (2006)

Eyring, H.: The activated complex in chemical reactions. J. Chem. Phys. 3, 107 (1935)

Persson, B.N.J.: Theory of rubber friction and contact mechanics. J. Chem. Phys. 115, 3840 (2001)

Almqvist, A., Campana, C., Prodanov, N., Persson, B.N.J.: Interfacial separation between elastic solids with randomly rough surfaces: comparison between theory and numerical techniques. J. Mech. Phys. Solids 59, 2355 (2011)

Scaraggi, M., Persson, B.N.J.: Submitted to PRL. arXiv:1406.7236

Persson, B.N.J.: (unpublished)

Israelachvili, J.: Intermolecular and Surface Forces, 2nd edn, Academic Press (1992), Sec. 11.10, p. 203

Barber, J.R.: Bounds on the electrical resistance between contacting elastic rough bodies. Proc. R. Soc. Lond. A 459, 53 (2003)

Campana, C., Persson, B.N.J., Müser, M.H.: Transverse and normal interfacial stiffness of solids with randomly rough surfaces. J. Phys. Condens. Matter 23, 085001 (2011)

Pastewka, L., Prodanov, N., Lorenz, B., Mser, M.H., Robbins, M.O., Persson, B.N.J.: Finite-size effect in the interfacial stiffness of rough elastic contacts. Phys. Rev. E 87, 062809 (2013)

Greenwood, J.A.: Constriction resistance and the real area of contact. Br. J. Appl. Phys. 17, 1621 (1966)

Timoshenko, S., Goodier, J.N.: Theory of Elasticity. McGraw-Hill, New York (1951)

Fortunato, G., Giustiniano, M.: Bridgestone Technical Center Europe, Rome (2014) (unpublished)

Acknowledgments

I thank J.A. Greenwood and J.R. Barber for discussions and useful comments on the manuscript.

Author information

Authors and Affiliations

Corresponding author

Appendix

Appendix

The heat transfer coefficient \(\alpha _1\) depends on the interaction potential between the rubber and the road surface. This interaction potential is certainly not very well defined, but depends on the location and road contamination. For hydrocarbons (rubber molecules) in contact with hydrocarbons (e.g., tar or organic contamination), one expect mainly a weak Van der Waals interaction and interfacial binding energies of the order of \(\gamma _{12} \approx 0.06 \, {\rm{ J/m}}^2\). For Van der Waals interaction, one have

where the last term in the [\(\cdots \)] is a repulsive interaction and \(z_0\) the equilibrium surface separation. Writing \(z=z_0+u\) and expanding to second order in \(u\) gives

where \(K=12 \gamma _{12} / z_0^2\). For many systems [24], \(z_0 \approx 0.16 \ {\rm{nm}}\) giving \(K\approx 2.6\times 10^{19} \ {\rm{J/m}}^2\). For this interfacial coupling parameter, one can estimate [10] \(\alpha _1 \approx 10^7 \ {\rm{W/m}}^2{\rm{K}}\)

We now address how the spreading resistance depends on the sliding speed. We are interested in the spreading resistance associated with the thermal interaction between the microasperity contact regions inside the macroasperity contact regions. The spreading resistance associated with the thermal interaction between the macroasperity contact regions occur at so low a sliding speed that it is not relevant for rubber friction problems in most cases. At zero sliding speed (\(v=0\)), the heat transfer coefficient [25–27]

where \(p\) is the nominal contact pressure in the macroasperity contact regions and \(u_0\) a length parameter equal to \(u_0 = \gamma h_{\rm rms}\), where \(\gamma \approx 0.5\), and where \( h_{\rm rms}\) is the root-mean-square roughness including only roughness components with wavelengths smaller than the size of the macroasperity contact regions, i.e., the rms roughness measured over a length scale of the order of the radius \(R\) of the macroasperity contact regions. \(\kappa _0\) and \(\kappa _1\) are the heat thermal conductivity of the two materials (here rubber and road, respectively).

To determine the velocity dependency of \(\alpha _{\rm{spread}}\), we use the (approximate) equation for \(\alpha _{\rm{spread}}\) derived by Greenwood [10, 28]:

Here, \(N\) is the number of microasperity contact regions within a macroasperity contact area, and \(A_0\) is the nominal contact area (which in the present case equal the macroasperity contact area \(A_0=\pi R^2\)). At zero sliding speed, the sum in (42) is over all the \(N\) microasperity contact regions (where the prime on the summation symbol indicates that the \(n=m\) term is excluded) with the center at positions \(\mathbf{x}_m\) (\(m=1,\ldots ,N\)). We can approximately write

where \(1/a^2\) is the number of microasperity contact regions per unit surface area. A more accurate treatment (see [29]), which takes into account that a point near the edge of the macroasperity contact region has less than half the number of the neighbor’s as the one at the center, results in an additional factor \(8/3\pi \approx 0.85\) in (43).

Now let us consider finite sliding speed. We can write

The first term on the right-hand side describes the thermal coupling between the hot contact spots on the rubber side of the contact and the second term on the road side of the contact. For \(v>D/R\) the thermal coupling on the rubber side is limited to \(|\mathbf{x}_m-\mathbf{x}_n| < D/v\) so that

For a sliding speed with \(v>D'L/R^2\) (where \(D'\) is the thermal diffusivity of the road), the thermal coupling on the road side is limited to \(|\mathbf{x}_m-\mathbf{x}_n| < (D'L/v)^{1/2}\) (where \(L\) is the sliding distance that the road macroasperity is in contact with the rubber) and, in this case, we get

This treatment is only approximate and a more accurate treatment should take into account the sliding distance \(s(t)\) at time \(t\), rather than the total slip distance \(L\). Let us define

Using this result and Eq. 41 gives the velocity-dependent heat transfer coefficient

where

are the effective elastic modulus. We note that both \(E^*\) and \(p=p_0/A_{\rm{m}}\) in Eq. 47 depend on the sliding speed, but in a first approximation the velocity dependency cancels so we can (approximately) evaluate these quantities using the low-frequency modulus. For the system studied in Sect. 4, we have \(\kappa \approx 0.1 \ {\rm{W/Km}}\), \(E^*\approx 10 \ {\rm{MPa}}\), \(p \approx (0.065/0.18) \ {\rm{MPa}} \approx 0.36 \ {\rm{MPa}}\) and \(h_{\rm{rms}} \approx 0.036 \ {\rm{mm}}\) giving \(\alpha _{\rm{spread}} \approx 400 \ {\rm{W/m}}^{2}\,{\rm{K}}\) for \(v=0\). The total heat transfer coefficient the the macroasperity contact regions is given by

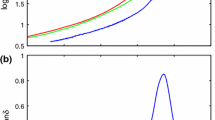

Figure 12a shows the heat transfer coefficient \(\alpha (v)\) calculated from Eqs. 47 and 48, assuming again that the substrate heat conductivity is infinite so that \(1/\kappa _1 = 0\). Note that \(\alpha \) varies from \(400 \ {\rm{W/m}}^{2}\,{\rm{K}}\) at low sliding speed to \(\approx 0.6\times 10^6 \ {\rm{W/m}}^{2}\,{\rm{K}}\) at high speed. Figure 12b shows the temperature at the rubber surface \(z=0\), and at depth into the rubber \(z\approx 1/q_1 \approx 1 \ \upmu {\rm{m}}\) and \(z \approx 1/q_0 \approx 1 \ {\rm{mm}}\), as a function of the sliding speed. The calculation is for the same parameters as in Fig. 9, i.e., the rubber heat conductivity \(\kappa = 0.23 \ {\rm{W/m\,K}}\), heat capacity \(C= 1{,}650 \ {\rm{J/kg\,K}}\) and mass density \(\rho = 1{,}200 \ {\rm{kg/m}}^3\). The road (or substrate) and the rubber background temperatures are \(T_0 = 20\) and \(40\,^\circ {\rm{C}}\), respectively. The substrate surface was assumed to be a self-affine fractal with the power spectrum shown in Fig. 5.

a The heat transfer coefficient \(\alpha (v)\), and b the temperature at the rubber surface \(z=0\), and at depth into the rubber \(z\approx 1/q_1 \approx 1 \ \upmu {\rm{m}}\) and \(z \approx 1/q_0 \approx 1 \ {\rm{mm}}\), as a function of the sliding speed. The rubber–road heat transfer coefficients which varies from \(400 \ {\rm{W/m}}^{2}\,{\rm{K}}\) at low sliding speed to \(\approx \alpha _1 (A_1/A_{\rm{m}})\approx 0.6 \times 10^6 \ {\rm{W/m}}^{2}\,{\rm{K}}\) at high speed according to Eqs. 47 and 48. The rubber heat conductivity \(\kappa = 0.23 \ {\rm{W/m\,K}}\), heat capacity \(C= 1{,}650 \ {\rm{J/kg\,K}}\) and mass density \(\rho = 1{,}200 \ {\rm{kg/m}}^3\). The road (or substrate) and the rubber background temperatures are \(T_0 = 20\) and \(40\,^\circ {\rm{C}}\), respectively. The substrate is assumed to have infinite heat conductivity and a surface which is a self-affine fractal with the power spectrum shown in Fig. 5. The calculation is for a standard rubber tread compound

When comparing Fig. 12b with Fig. 9b, we note the following. The velocity dependency of the flash temperature ≈\(1 {\rm{mm}}\) inside the rubber is very similar in both cases, starting at a temperature just slightly above the road temperature at very low velocities, and increasing to the rubber background temperature for very high sliding speeds. However, the rubber surface temperature \(z=0\) and the rubber temperature just inside the rubber surface for \(z \approx 1 \ \upmu {\rm{m}}\) behaves rather differently. Thus, in both cases, as expected, the temperature is close to the road temperature for \(v < 10^{-6} \ {\rm{m/s}}\) and then start to increase. In Fig. 9b, the temperature increases continuously with increasing speed, while in Fig. 12b, it decreases for \(v > 10^{-4} \ {\rm{m/s}}\) and then starts to increase again for \(v > 10^{-1} \ {\rm{m/s}}\). The decrease in the temperature results from the strong increase in the heat transfer coefficient (see Fig. 12a), while in Fig. 9, the heat diffusion constant was assumed to be velocity-independent.

Rights and permissions

About this article

Cite this article

Persson, B.N.J. Role of Frictional Heating in Rubber Friction. Tribol Lett 56, 77–92 (2014). https://doi.org/10.1007/s11249-014-0386-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11249-014-0386-0