Abstract

The effects of temperature, pressure and shear stress on the viscosity of simplified automotive lubricants—polymer-thickened base oil solutions—were investigated. Various polymers—with different molecular weights and conformations (comb, linear and star)—were used at low concentration (1.2 % w/w) in a hydrocracked mineral base oil: a poly(alkylmethacrylate), an olefin copolymer and a poly(isoprene-styrene hydrogenated). Their rheological behavior was studied and modeled with a Vogel-Tamman and Fulcher equation, a modified Williams-Landel-Ferry-Yasutomi relationship and a Carreau-Yasuda-like formula. Then, the Einstein’s law was used to rapidly and simply determine the hydrodynamic radii of polymers as a function of temperature and pressure. Calculations from Flory equations, intrinsic viscosities and direct measurements confirmed the relevance of this methodology. Finally, molecular considerations allowed a good understanding of the rheological response of polymer solutions.

Similar content being viewed by others

Abbreviations

- a, n :

-

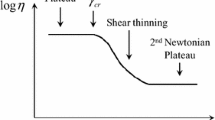

Parameters for the Carreau-Yasuda model

- C 1, C 2, A 1, A 2, B 1, B 2 :

-

WLF constants

- c :

-

Concentration in weight of active polymer (g cm−3)

- c*:

-

Critical concentration (g cm−3)

- D F :

-

Fragility parameter

- F :

-

Dimensionless relative thermal expansion of the free volume

- G :

-

Shear modulus (kPa)

- h :

-

Film thickness (nm)

- k :

-

Liquid thermal conductivity (W m−1 K−1)

- l :

-

Mean monomer size (cm)

- M :

-

Mass of one molecule (g)

- m0 :

-

Molecular mass of one monomer (g mol−1)

- M n :

-

Number average molecular mass (g mol−1)

- M w :

-

Weight average molecular mass (g mol−1)

- N :

-

Number of monomers (N = M w/m0)

- N a :

-

Avogadro number (mol−1)

- Na :

-

Nahme-Griffith number

- N experiment :

-

Number of experimental data

- N parameter :

-

Number of parameters in the model

- n :

-

Refractive index

- PDI:

-

Polydispersity index

- p :

-

Pressure (Pa)

- R g :

-

Radius of gyration (nm)

- R h :

-

Hydrodynamic radius (nm)

- Relative root mean square error:

-

\(\sqrt {\frac{{\sum {\left( {\frac{{\eta_{\text{experiment}} - \eta_{\text{model}} }}{{\eta_{\text{experiment}} }}} \right)^{2} } }}{{N_{\text{experiment}} - N_{\text{parameters}} }}}\)

- T :

-

Temperature (°C)

- \(T_{\infty }\) :

-

Vogel temperature at which the viscosity diverges (°C)

- T g(0):

-

Glass transition temperature at atmospheric pressure (°C)

- T g(p):

-

Glass transition temperature depending on pressure (°C)

- α :

-

Local pressure–viscosity coefficient (GPa−1)

- α*:

-

Reciprocal asymptotic isoviscous pressure coefficient (GPa−1)

- β :

-

Temperature–viscosity coefficient (K−1)

- Φ :

-

Volume fraction

- Φ 0 :

-

Universal Flory constant (mol−1)

- [η]:

-

Intrinsic viscosity (L g−1)

- η :

-

Viscosity (Pa s)

- η experiment :

-

Experimental viscosity (Pa s)

- η model :

-

Modeled viscosity (Pa s)

- η red :

-

Reduced viscosity (L g−1)

- η r :

-

Relative viscosity (cm3 g−1)

- \(\eta_{0}\) :

-

Low shear viscosity (Pa s)

- \(\eta_{\infty }\) :

-

Viscosity extrapolated to infinite temperature (Pa s)

- \(\eta_{g}\) :

-

Viscosity at the glass transition (Pa s)

- τ :

-

Shear stress (Pa)

References

Andrade, E.N.D.C.: The viscosity of liquids. Nature 125, 309–310 (1930)

Angell, C.A.: Formation of glasses from liquids and biopolymers. Science 276, 1924–1935 (1995)

Asme pressure–viscosity report. American Society of Mechanical Engineers I & II (1953)

Bair, S.: Measurements of real non-newtonian response for liquid lubricants under moderate pressures. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 215(3), 223–233 (2001)

Bair, S.: High-pressure rheology for quantitative elastohydrodynamics. Elsevier Science B.V., Amsterdam (2007)

Bair, S., Khonsari, M.: An ehd inlet zone analysis incorporating the second newtonian. J. Tribol. 118(2), 341–343 (1996)

Bair, S., Mary, C., Bouscharain, N., Vergne, P.: An improved Yasutomi correlation for viscosity at high pressure. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 227(9), 1056–1060 (2013)

Bair, S., Winer, W.: Some observations on the relationship between lubricant mechanical and dielectric transitions under pressure. J. Lubr. Technol. 102(2), 229–234 (1980)

Bair, S., Kottke, P., Winer, W.: Cavitation in creeping shear flows. Am. Inst. Chem. Eng. AIChE J 51, 2150–2170 (2005)

Bair, S., Vergne, P., Querry, M.: A unified shear-thinning treatment of both film thickness and traction in EHD. Tribol. Lett. 18(2), 145–152 (2005)

Barlow, A.J., Erginsav, A., Lamb, J.: Viscoelastic relaxation in liquid mixtures. Proc. R. Soc. Lond. Math. Phys. Sci. A309(1499), 473–496 (1969)

Barnes, H., Hutton, J., Walters, K.: An introduction to rheology. Elsevier B.V., Amsterdam (1989)

Berthe, D., Vergne, P.: High pressure rheology for high pressure lubrication: a review. J. Rheol. 34(8), 1387–1414 (1990)

Boutris, C., Chatzi, E., Kiparissides, C.: Characterization of the LCST behaviour of aqueous poly(n-isopropylacrylamide) solutions by thermal and cloud point techniques. Polymer 38(10), 2567–2570 (1997)

Brandrup, J., Immergut, E.H., Wohlfarth, C.: Handbook of chemistry and physics—upper critical (UCST) and lower critical (LCST) solution temperatures of binary polymer solutions, vol. 88th ed. CRC (2007–2008)

Briant, J., Denis, J., Parc, G.: Propriétés rhéologiques des lubrifiants. Publications de l’institut français du pétrole (1985)

Colby, R.H.: Structure and linear viscoelasticity of flexible polymer solutions: comparison of polyelectrolyte and neutral polymer solutions. Rheol. Acta 49(5), 425–442 (2010)

Cowie, J., Arrighi, V.: Polymers: Chemistry and physics of modern materials, vol. 50. Taylor & Francis, Contemporary Physics (2009)

De Gennes, P.G.: Scaling concepts in polymer physics. Cornell University Press, Ithaca, NY (1979)

Eyring, H.: Viscosity, plasticity, and diffusion as examples of absolute reaction rates. J. Chem. Phys. 4(4), 283–291 (1936)

Flory, P.J.: Principles of polymer chemistry. Cornell University Press, Ithaca, NY (1953)

Fujimatsu, H., Ogasawara, S., Kuroiwa, S.: Lower critical solution temperature (LCST) and theta temperature of aqueous solutions of nonionic surface active agents of various polyoxyethylene chain lengths. Colloid Polym. Sci. 266, 594–600 (1988)

Glass, J.E., Schulz, D.N., Zukoski, C.F.: Polymers as rheology modifiers. ACS, Washington, DC (1991)

Habchi, W., Vergne, P., Bair, S., Andersson, O., Eyheramendy, D., Morales-Espejel, G.: Influence of pressure and temperature dependence of thermal properties of a lubricant on the behaviour of circular TEHD contacts. Tribol. Int. 43(10), 1842–1850 (2010)

Hansen, C.M.: The three dimensional solubility parameter and solvent diffusion coefficient: their importance in surface coating formulation. Copenhagen Danish Technical Press, Copenhagen (1967)

Harris, K., Bair, S.: Temperature and pressure dependence of the viscosity of diisodecyl phthalate at temperatures between (0 and 100) °C and at pressures to 1 GPa. J. Chem. Eng. Data 52, 272–278 (2007)

Huggins, M.L.: The viscosity of dilute solutions of long-chain molecules. IV. Dependence on concentration. J. Am. Chem. Soc. 64(11), 2716–2718 (1942)

Kraemer, E.O.: Molecular weights of celluloses and cellulose derivates. Ind. Eng. Chem. 30(10), 1200–1203 (1938)

Macosko, C.: Rheology Principles, Measurements and Applications. Wiley-VCH, New York (1994)

Martin, A.F.: Cellulose and cellulose derivatives. In: Memphis Meeting of the American Chemical Society, p. 966 (1942)

Mortier, R., Fox, M., Orszulik, S.: Chemistry and technology of lubricants. Springer Science (2010)

Petera, D., Muthukumar, M.: Brownian dynamics simulation of bead–rod chains under shear with hydrodynamic interaction. J. Chem. Phys. 111(16), 7614–7623 (1999)

Taylor, R.I.: Tribology and energy efficiency: from molecules to lubricated contacts to complete machines. R. Soc. Chem. 156, 1–22 (2012)

Williams, M.L., Landel, R.F., Ferry, J.D.: The temperature dependence of relaxation mechanisms in amorphous polymers and other glass-forming liquids. J. Am. Chem. Soc. 77(14), 3701–3707 (1955)

Wolf, B.A.: Improvement of polymer solubility: influence of shear and of pressure. Pure Appl. Chem. 69(5), 929–933 (1997)

Wolf, B.A.: Polyelectrolytes revisited: reliable determination of intrinsic viscosities. Macromol. Rapid Commun. 28(2), 164–170 (2007)

Yasutomi, S., Bair, S., Winer, W.: An application of a free volume model to lubricant rheology. I: dependence of viscosity on temperature and pressure. II: variation in viscosity of binary blended lubricants. ASME J. Tribol. 106, 291–312 (1984)

Acknowledgments

The authors are deeply grateful to Total for its financial and technical support. We would like to thank Dr. J. Eckelt and Prof. Dr. B.A. Wolf from WEE-Solve (Auf der Burg 6, D-55130 Mainz, Germany) for having performed LCST measurements. We also acknowledge Prof. C. Chassenieux, Prof. J.-F. Tassin and D. Chaveroux from the laboratory Polymères, Colloïdes, Interfaces (UMR Université du Maine CNRS-6120, 72085 Le Mans Cedex 9, France) for having kindly provided chromatography and light scattering results.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mary, C., Philippon, D., Lafarge, L. et al. New Insight into the Relationship Between Molecular Effects and the Rheological Behavior of Polymer-Thickened Lubricants Under High Pressure. Tribol Lett 52, 357–369 (2013). https://doi.org/10.1007/s11249-013-0214-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11249-013-0214-y