Abstract

In this study, a twin-disc test machine was used to simulate a rolling/sliding gear contact for three surface finishes, each run with two types of lubricants, thus seeking to develop insight into the tooth flank/lubricant tribological system. The test disc surfaces were case-carburised before the surfaces were produced by: transverse grinding followed by a mechanical abrasive polishing process; transverse grinding only; and transverse grinding followed by preheating as a final finishing step (intended to enhance the build-up of an easily sheared surface boundary layer using a sulphur additive). The twin-disc contact was lubricated with an ester-based environmentally adapted lubricant or a polyalphaolefin-based commercial heavy truck gearbox lubricant. To obtain information about the composition of chemically reacted surface layers, the specimens used were analysed using glow discharge-optical emission spectroscopy. The results indicate that the interactions between different surface finishes and lubricants have different impacts on friction behaviour, wear and the reacted surface boundary layer formed by the lubricant. Running a smooth (polished) surface with the appropriate lubricant drastically reduces the friction. Surface analysis of the ground surfaces gives clear differences in lubricant characteristics. The commercial lubricant does not seem to react chemically with the surface to the same extent as the EAL does. Micropitting was found on all ground discs with both lubricants, though at different rates. The highest amount of wear but less surface damage (i.e. micropits) was found on the preheated surface run with the commercial lubricant.

Similar content being viewed by others

References

ISO 6336-1:2006(E), Calculation of the load capacity of spur and helical gears. Part 1 Basic principles introduction, and general influence factors

Bergseth, E., Torbacke, M., Olofsson, U.: Wear in environmentally adapted lubricant with AW technology. J. Synth. Lubr. 25, 137–158 (2008). doi:10.1002/jsl.57

Kleemola, J., Lehtovaara, A.: Experimental simulation of gear contact along the line of action. Tribol. Int. 42, 1453–1459 (2009)

Castro, J., Seabra, J.: Coefficient of friction in mixed film lubrication: gears versus twin-discs. Proc. Inst. Mech. Eng. J. Eng. Tribol. 221, 399–411 (2007). doi:10.1243/13506501JET257

Brandão, J.A., Seabra, J.H.O., Castro, J.: Surface initiated tooth flank damage. part I Numerical model. Wear 268, 1–12 (2010)

Brechot, P., Cardin, A.B., Murphy, W.R., Theissen, J.: Micropitting resistant industrial gear oils with balanced performance. Ind. Lubr. Tribol. 52(3), 125–136 (2000)

Sjöberg, S., Björklund, S., Olofsson, U.: The influence of manufacturing method on the running-in of gears. Proc. Inst. Mech. Eng. J. Eng. Tribol. 225, 999–1012 (2011). doi:10.1177/1350650111414471

Widmark, M., Melander, A.: Effect of material, heat treatment, grinding and shot peeing on contact fatigue life of carburized steels. Int. J. Fatigue 21, 309–327 (1999)

Höhn, B.-R., Michaelis, K., Doleschel, A.: Frictional behaviour of synthetic gear lubricants. Tribol. Series 39, 759–768 (2001)

Björling, M., Larsson, R., Marklund, P., Kassfeldt, E.: Elastohydrodynamic lubrication friction mapping—the influence of lubricant, roughness, speed, and slide-to-roll ratio. Proc. Inst. Mech. Eng. J. Eng. Tribol. 225, 671–681 (2011)

Patir, N., Cheng, H.S.: An average flow model for determining the effects of three-dimensional roughness on partial hydrodynamic lubrication. J. Lubr. Technol Trans. ASME 100, 12–17 (1978)

Höhn, B.-R., Michaelis, K., Kreil, O.: Influence of surface roughness on pressure distribution and film thickness in EHL-contacts. Tribol. Int. 39, 1719–1725 (2006)

Petry-Johnson, T.T., Kaharaman, A., Anderson, N.E., Chase, D.R.: Experimental investigation of spur gear efficiency. J. Mech. Des. 130, 0626011–06260110 (2008)

Dizdar, S., Andersson, S.: Influence of the pre-formed boundary layers on wear transition in sliding lubricated contacts. Wear 213, 117–122 (1997)

Fletcher, D.I., Beynon, J.H.: Development of a machine for closely controlled rolling contact fatigue and wear testing. J. Test. Eval. 28, 267–275 (2000)

Lewis, R., Dwyer-Joyce, R.S.: Wear mechanisms and transitions in railway wheel steels. Proc. Inst. Mech. Eng. J. Eng. Tribol. 218, 467–478 (2004)

Krantz, T.L., Alanou, M.P., Evans, H.P., Snidle, R.W.: Surface fatigue lives of case-carburized gears with an improved surface finish. J. Tribol. 123, 709–716 (2001)

Gallardo-Hernandez, E.A., Lewis, R.: Coating and treatment solutions for rolling/sliding component contacts. Wear 267, 1009–1021 (2009)

Martins, R., Locatelli, C., Seabra, J.: Evolution of tooth flank roughness during gear micropitting tests. Ind. Lubr. Tribol. 63, 34–45 (2011)

Hamrock, B.J.: Fundamentals of Fluid Film Lubrication. McGraw-Hill, New York (1994)

Guideline for Testing of Chemicals, Information Taken From Organisation for Economic Co-Operation and Development (OECD). http://www.oecd.org (2011). Accessed 26 June 2011

Torbacke, M., Kassman Rudolphi , Å., Kassfeldt, E.: Lubricants—Properties and Performance. Universitetstryckeriet, Luleå (2012)

Godfrey, D.: In: Ku, P.M. (ed.) Interdisciplinary Approach to Friction and Wear, p. 335. Southwest Institute, Washington DC (1968)

McFadden, C., Soto, C., Spencer, N.D.: Adsorption and surface chemistry in tribology. Tribol. Int. 30, 881–888 (1997)

ISO 14707:2000 (E), Surface chemical analysis: glow discharge optical emission spectroscopy (GD-OES)—introduction to use, first edition 2000-08-15

Veronesit, V.: Influence of a low temperature sulphurizing process on lubricants in standard EP and FZG tests. Tribol. Int. 18(4), 203–208 (1985)

Oila, A., Bull, S.J.: Assessment of the factors influencing micropitting in rolling/sliding contacts. Wear 258, 1510–1524 (2005)

Olver, A.V., Tiew, L.K., Medina, S., Choo, J.W.: Direct observations of a micropit in an elastohydrodynamic contact. Wear 256, 168–175 (2004)

Hannes, D., Alfredsson, B.: Rolling contact fatigue crack path prediction by the asperity point load mechanism. Eng. Fract. Mech. 78, 2848–2869 (2011)

Höglund, E.: Influence of lubricant properties on elastohydrodynamic lubrication. Wear 232, 176–184 (1999)

Acknowledgments

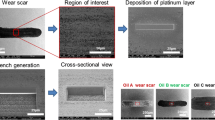

We would like to thank Statoil Lubricants, Primateria, Alexander Drott at Volvo Powertrain Köping for analysing the material structure and providing the photos for 13b, and Vinnova’s KUGG research programme for the opportunity to carry out this study.

Author information

Authors and Affiliations

Corresponding author

Appendices

Appendix

Film thickness equations for elliptical and rectangular conjunctions are applied to specific machine elements, other than the rolling-element bearings, by Hamrock [20] to illustrate how fluid film lubrication conditions can be analysed. Two disc pairs, i.e. ground/ground (elliptical contact, crowning set to 25 μm) reference discs and polished/polished (rectangular contact), are used as input with the set load. Note that the pressure viscosities were not measured at lubricant bulk temperature and pure rolling is assumed in the calculations. The EAL (ester) is assumed to have a similar pressure viscosity coefficient as the commercial lubricant (PAO), for which the pressure viscosity coefficient is taken from Höglund [30].

The minimum film thickness for the elliptical conjunction is given by:

The minimum film thickness for the rectangular conjunction is given by:

The specific film parameter for the elliptical conjunction, the EHD film thickness for an ideal smoothness of the surfaces divided by the composite surface roughness, is given by:

The specific film parameter for the rectangular conjunction, the EHD film thickness for an ideal smoothness of the surfaces divided by the composite surface roughness, is given by:

List of Symbols

- b :

-

Disc width, m

- E :

-

Effective Young’s modulus, E = 2[(1−ν 2a )/E a + (1−ν 2b )/E b]−1, Pa

- E a, b :

-

Young’s modulus, Pa

- G :

-

Dimensionless material parameter, G = Eα

- h :

-

Minimum film thickness, m

- h′:

-

Minimum film thickness for rectangular conjunction, m

- H :

-

Dimensionless film thickness, h/R

- H′:

-

Dimensionless film thickness for rectangular conjunction, h′/R′

- k :

-

Ellipticity parameter, k = (R y /R x)2/π

- R :

-

Effective radius ground discs, R −1 = [r −1ax + r −1bx ]−1 + [r −1ay + r −1by ]−1, m

- R′ :

-

Effective radius polished discs, R −1 = [r −1ax + r −1bx ]−1, m

- Rq:

-

RMS roughness, μm

- U :

-

Dimensionless speed parameter, U = uη 0 /E′R

- u :

-

Mean surface velocity on the pitch line, u = (ω a ·r a + ω b ·r b )/2, m/s

- W :

-

Dimensionless load parameter, W = w z /E′R 2

- W′:

-

Dimensionless load parameter, W′ = w z /E′Rb

- w z :

-

Normal load component, N

- α :

-

Pressure–viscosity coefficient at 40 °C, Pa−1

- Λ :

-

Specific film parameter for elliptical conjunction

- Λ′:

-

Specific film parameter for rectangular conjunction

- η 0 :

-

Dynamic viscosity at 40 °C, Pa s

- ω:

-

Angular velocity, rad s−1

2.1 Index

- a, b :

-

Body a, b

- 0:

-

Reference value at atmospheric pressure

- x :

-

Direction of motion

- y:

-

Direction perpendicular to motion

- z :

-

Normal direction

2.2 Input data

-

b = 0.010 m

-

E a, b = 207 GPa

-

r a, b = 0.0253 m

-

R = 0.01120 m

-

R′ = 0.0118 m

-

Rq = 1.1 μm

-

Rq′ = 0.06 μm

-

u = 1.04 m/s

-

α = 15.5 GPa−1

-

ν a, b = 0.293

-

w z = 7140 N

-

η0 = 0.0692 Pa s (EAL)

2.3 Results

-

E = 226 Pa

-

G = 3510

-

h = 0.27 μm

-

h′ = 0.19 μm

-

H = 2.41 × 10−5

-

H′ = 1.60 × 10−5

-

k = 7.0

-

U = 2.82 × 10−11

-

U′ = 2.70 × 10−11

-

W = 2.18 × 10−4

-

W′ = 2.5 × 10−4

-

Λ = 0.17

-

Λ′ = 2.2

Rights and permissions

About this article

Cite this article

Bergseth, E., Olofsson, U., Lewis, R. et al. Effect of Gear Surface and Lubricant Interaction on Mild Wear. Tribol Lett 48, 183–200 (2012). https://doi.org/10.1007/s11249-012-0004-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11249-012-0004-y