Abstract

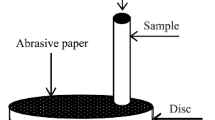

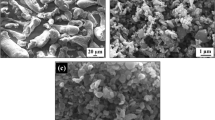

Wear properties of a nanostructured matrix of Al prepared via mechanical milling and hot extrusion were investigated before and after incorporation of B4C nanoparticles. The sample powders were milled for a period of 20 h to produce nanopowders. Mechanical milling was used to prepare nanocomposite samples by addition of 2 and 4 wt% of B4C nanoparticles into the Al matrix. A pin-on-disk setup was used to evaluate the wear properties of the hot extruded samples under dry condition. The results revealed a lower friction coefficient and a lower wear rate for the nanostructured matrix of Al in contrast to a commercial coarse grained Al matrix. The same pattern was also observed in the nanocomposite samples with respect to the base matrix. Hardness values were used to discuss the observed results. Scanning electron microscopy (SEM) was used to analyze the worn surface and wear debris.

Similar content being viewed by others

References

Kimura, Y.: Recent trends in tribology in Japan. J. Euro. Rib. 931, 1–9 (1993)

Raghumatham, N., Ioannidis, E.K., Sheppard, T.: Fabrication, properties and structure of a high temperature light alloy composite. J. Mater. Sci. 26, 985–992 (1991)

Shibata, K., Ushio, H.: Tribological application of MMCs for reducing engine weight. J. Tribol. Int. 27, 39–41 (1994)

Chellman, D.J., Langenbeck, S.L.: Aerospace applications of advanced aluminum alloys. J. Key Eng. Mater. 77–78, 49–60 (1993)

Chawla, N., Chawla, K.K.: Metal matrix composites, pp. 1–5. Springer-Verlag, New York (2006)

Rohatgi, P.K.: Cast metal matrix composites. In: Metal Hand Book, vol 15. 9th edn. ASM International, Metals Park (1988)

Sannino, A.P., Rack, H.J.: Tribological investigation of 2009Al-20 vol.% SiCp/17-4 PH, Part I: composite performance. Wear 197, 151 (1996)

Sharma, S.C.: The sliding wear behavior of Al6061–garnet particulate composites. Wear 249, 1036 (2001)

Jiang, J.Q., Tan, R.S., Ma, A.B.: Dry sliding wear behaviour of Al2O3–Al composites produced by centrifugal force infiltration. Mater. Sci. Technol. 12, 483–488 (1996)

How, H.C., Baker, T.N.: Characterisation of sliding friction-induced subsurface deformation of Saffil-reinforced AA6061 composites. Wear 232, 106 (1999)

Ipek, R.: Adhesive wear behaviour of B4C and SiC reinforced 4147 Al matrix composites (Al/B4C–Al/SiC). J Mate Proc Tech 162–163, 71–75 (2005)

Rosenberger, M.R., Schvezov, C.E., Forlerer, E.: Wear of different aluminum matrix composites under conditions that generate a mechanically mixed layer. Wear 259, 590–601 (2005)

Hemanth, J.: Tribological behavior of cryogenically treated B4Cp/Al–12% Si composites. Wear 258, 1732–1744 (2005)

Kaczmar, J.W., Pietrzak, K., Wlosinski, W.: The production and application of metal matrix composite materials. J. Mater. Process. Technol. 106, 58–67 (2000)

Mohanty, R.M., Balasubramanian, K., Seshadri, S.K.: Boron carbide-reinforced aluminum 1100 matrix composites: fabrication and properties. Mater. Sci. Eng. A 498, 42–52 (2008)

Topcu, I., Gulsoy, H.O., Kadioglu, N., Gulluoglu, A.N.: Processing and mechanical properties of B4C reinforced Al matrix composites. J. Alloys Comp. 482, 516–521 (2009)

Shorowordi, K.M., Haseeb, A., Celis, J.P.: Tribo-surface characteristics of Al–B4C and Al–SiC composites worn under different contact pressures. Wear 261, 634–641 (2006)

Lee, K.B., Sim, H.S., Cho, S.Y., Kwon, H.: Tensile properties of 5052 Al matrix composites reinforced with B4C. Metall. Mater. Trans. A 32, 2142–2147 (2001)

Lashgari, H.R., Zangeneh, Sh, Shahmir, H., Saghafi, M., Emamy, M.: Heat treatment effect on the microstructure, tensile properties and dry sliding wear behavior of A356–10% B4C cast composites. Mater. Des. 31, 4414–4422 (2010)

Vintila, R., Charest, A., Drew, R.A.L., Brochu, M.: Synthesis and consolidation via spark plasma sintering of nanostructured Al-5356/B4C composite. Mater. Sci. Eng. A 528, 4395–4407 (2011)

Ye, J.C., He, J.H., Schoenung, J.M.: Cryomilling for the fabrication of a particulate B4C reinforced Al nanocomposite: Part I. Effects of process conditions on structure. Metall. Mater. Trans. A 37A, 3099–3109 (2006)

Li, Y., Zhao, Y.H., Ortalan, V., Liu, W., Zhang, Z.H., Vogt, R.G., Browning, N.D., Lavernia, E.J., Schoenung, J.M.: Investigation of aluminum-based nanocomposites with ultra-high strength. Mater. Sci. Eng. A 527, 305–316 (2009)

De Castro, C.L., Mitchell, B.S.: Crystal growth kinetics of nanocrystalline aluminum prepared by mechanical attrition in nylon media. Mater. Sci. Eng. A 396, 124–128 (2005)

Keblinski, P., Phillpot, S.R., Wolf, D., Gleiter, H.: Amorphous structure of grain boundaries and grain junctions in nanocrystalline silicon by molecular-dynamics simulation. Acta Mater. 45, 987–998 (1997)

Suryanarayana, C.: Nanocrystalline materials. Int. Mater. Rev. 40, 41 (1995)

Kong, X.L., Liu, Y.B., Qiao, L.J.: Dry sliding tribological behaviors of nanocrystalline Cu–Zn surface layer after annealing in air. Wear 256, 747 (2004)

Du, L., Xu, B., Dong, S., Yang, H., Wu, Y.: Preparation, microstructure and tribological properties of nano-Al2O3/Ni brush plated composite coatings. J. Surf. Coat. Technol. 192, 311–316 (2005)

Dao, M., Lu, L., Asaro, R.J., De, J.T.M., Ma, E.: Toward a quantitative understanding of mechanical behavior of nanocrystalline metals. J. Acta Mater. 55, 4041–4065 (2007)

Lv, X., Wang, R.S.G., Liu, Y., Long, K., Li, S., Zhang, Z.D.: Effect of nanocrystallization on tribological behaviors of ingot iron. Wear 264, 535–541 (2008)

Thakur, S.K., Dhindaw, B.K.: The influence of interfacial characteristics between SiCp and Mg/Al metal matrix on wear, coefficient of friction and microhardness. Wear 247, 191–201 (2001)

Suryanarayana, C., Grant Norton, M.: X-ray Diffraction: A Practical Approach. Plenum Press, New York (1998)

Prabhu, B., Suryanarayana, C., Ana, L., Vaidyanathan, R.: Synthesis and characterization of high volume fraction Al–Al2O3 nanocomposite powders by high-energy milling. J. Mater. Sci. Eng. A 425, 192–200 (2006)

Durai, T.G., Das, K., Das, S.: Al (Zn)–4Cu/Al2O3 in situ metal matrix composite synthesized by displacement reactions. J. Alloys Compd. 457, 435–439 (2008)

Srinivasa, Rao, C., Upadhyaya, G.S.: 2014 and 6061 aluminium alloy-based powder metallurgy composites containing silicon carbide particles/fibres. Mater. Des. 63, 59–66 (1995)

Archard, J.F.: Contact and rubbing of flat surface. J. Appl. Phys. 24, 981–988 (1953)

Clarke, J., Sarkar, A.D.: Wear characteristics of as-cast binary aluminium–silicon alloys. Wear 54, 7–16 (1979)

Kumar, S., Chakraborty, M., Sarma, V.S., Murty, B.S.: Tensile and wear behavior of in situ Al–7Si/TiB2 particulate composites. Wear 265, 134–142 (2008)

Alpas, A.T., Embury, J.D.: Sliding and abrasive wear behaviour of aluminum (2024)–SiC particle reinforced composite. Scr. Metall. 24, 931–935 (1990)

Suh, N.P.: The delamination theory of wear. Wear 25, 111–124 (1973)

Ma, T., Yamaura, H., Koss, D.A., Voigt, R.C.: Dry sliding wear behavior of cast SiC-reinforced Al MMCs. Mater. Sci. Eng. A 360, 116–125 (2003)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Alizadeh, A., Taheri-Nassaj, E. Wear Behavior of Nanostructured Al and Al–B4C Nanocomposites Produced by Mechanical Milling and Hot Extrusion. Tribol Lett 44, 59–66 (2011). https://doi.org/10.1007/s11249-011-9825-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11249-011-9825-3