Abstract

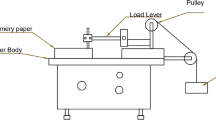

Aluminum is widely used in electrical contacts due to its electrical properties and inexpensiveness when compared to copper. In this study, we investigate the influence of operating conditions like contact load (pressure), sliding speed, current, and surface roughness on the electrical and tribological behavior of the interface. The tests are conducted on a linear, pin-on-flat tribo-simulator specially designed to investigate electrical contacts under high contact pressures and high current densities. Control parameters include sliding speed, load, current, and surface roughness. The response of the interface is evaluated in the light of coefficient of friction, contact resistance, contact voltage, mass loss of pins, and interfacial temperature rise. As compared to sliding speed, load, and roughness, current is found to have the greatest influence on the various measured parameters. Under certain test conditions, the interface operates in a “voltage saturation” regime, wherein increase in current do not result in any increase in contact voltage. Within the voltage saturation regime the coefficient of friction tends to be lower, a result that is attributed to the higher temperatures associated with the higher voltage (and resulting material softening). Higher interfacial temperatures also appear to be responsible for the higher wear rates observed at higher current levels as well as lower coefficients of friction for smoother surfaces in the presence of current.

Similar content being viewed by others

References

Bond, N.T.: Aluminum contact surfaces in electrical transition interfaces. IEEE Trans. Parts Mater. Packag. 5, 104–111 (1969)

Jackson, R.L.: Electrical performance of aluminum/copper bolted joints. IEE Proc. Gener. Transm. Distribution 129 (Part C), 177–184 (1982)

Braunovic, M.: Fretting damage in tin-plated aluminum and copper connectors. IEEE Trans. Compon. Hybrids Manuf. Technol. 12, 215–223 (1989)

Ben Jemaa, N., Carvou, E.: Electrical contact behaviour of power connector during fretting vibration. In: Proceedings of the Fifty-Second IEEE Holm Conference on Electrical Contacts (2006)

McNab, I.R.: Advances in electrical current collection. Wear 78, 1–6 (1982)

Ma, X.C., He, G.Q., He, D.H., Chen, C.S., Hu, Z.F.: Sliding wear behavior of copper-graphite composite material for use in maglev transportation system. Wear 265, 1087–1092 (2008)

Reichner, P.: Metallic brushes for extreme high-current applications. IEEE Trans. Compon. Hybrids Manuf. Technol. 3, 21–26 (1980)

Groth, K., Heidenfelder, F., Holinski, R.: Advancements of tribological performance of carbon brushes in electrical motors. Ind. Lubr. Tribol. 53, 5–10 (2001)

Bonwitt, W.F.: An experimental investigation of the electrical performance of bolted aluminum-to-copper connections. Trans. Am. Inst. Electr. Eng. 67, 1208–1219 (1948)

Runde, M., Magnusson, N., Lenes, A.: Bolted connectors for stranded aluminum power conductors. IEEE Trans. Power Deliv. 23, 523–530 (2008)

Rabinowicz, E.: The temperature rise at sliding electrical contacts. Wear 78, 29–37 (1982)

Lawson, D.K., Dow, T.A.: Sparking and wear of high current density electrical brushes. Wear 102, 105–125 (1984)

Bansal, D.G., Streator, J.L.: Behavior of copper-aluminum tribological pair under high current densities. IEEE Trans. Magn. 45, 244–249 (2009)

Davidson, R.F., Cook, W.A., Rabern, D.A., Schnurr, N.M.: Predicting bore deformations and launcher stresses in railguns. IEEE Trans. Magn. MAG-22, 1435–1440 (1986)

Persad, C., Peterson, D.R.: High energy rate modification of surface layers of conductors. IEEE Trans. Magn. MAG-22, 1658–1661 (1986)

Greenwood, J.A., Williamson, J.B.P.: Electrical conduction in solids II. Theory of temperature-dependent conductors. Proc. R. Soc. Lond. Ser. A 246, 13–31 (1958)

Timsit, R.: Electrical contact resistance: fundamental principles. In: Electrical Contacts: Principles and Applications, pp. 1–88. Marcel Dekker, New York (1999)

ASM Specialty Handbook: Aluminum and Aluminum Alloys. ASM International, Materials Park, OH (1993)

Bansal, D.G., Streator, J. L.: Voltage saturation in electrical contacts. In: Proceedings of STLE/ASME International Joint Tribology Conference, IJTC 2009. American Society of Mechanical Engineers, New York (2009)

Bansal, D.G., Streator, J.L.: Voltage saturation in electrical contacts via viscoplastic creep. Acta Mater. 59, 726–737 (2011)

Timsit, R.S.: Electrical contact resistance: properties of stationary interfaces. IEEE Trans. Compon. Packag. Technol. 22, 85–98 (1999)

Holm, R.: Electric Contacts: Theory and Applications, p. 482. Springer-Verlag, Berlin (1967)

Tabor, D.: The Hardness of Metals. Oxford University Press, Oxford (1951)

McLean, D.: The physics of high temperature creep in metals. Rep. Prog. Phys. 29, 1–34 (1966)

Frost, H.J., Ashby, M.F.: Deformation-Mechanism Maps: The Plasticity and Creep of Metals and Ceramics. Pergamon Press, Oxford, UK (1982)

Ueno, T., Kadono, K., Yamaguchi, S., Aoyagi, M., Tanaka, A., Morita, N.: Relationship between contact voltage drop and frictional coefficient under high-current sliding contact. IEEJ Trans. Electr. Electron. Eng. 5, 486–492 (2010)

Acknowledgments

This research was conducted at Georgia Institute of Technology, and supported in part through the Department of Defense Multidisciplinary Research Program of the University Research Initiative as Office of Naval Research Grant N00014-04-1-0601, entitled “Friction & Wear under Very High Electromagnetic Stress.” Information conveyed in this manuscript does not necessarily reflect the position or policy of the Government, and no official endorsement should be inferred.

Author information

Authors and Affiliations

Corresponding author

Additional information

The research was conducted at Georgia Institute of Technology when the author Dinesh G. Bansal was a graduate student.

Rights and permissions

About this article

Cite this article

Bansal, D.G., Streator, J.L. Effect of Operating Conditions on Tribological Response of Al–Al Sliding Electrical Interface. Tribol Lett 43, 43–54 (2011). https://doi.org/10.1007/s11249-011-9784-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11249-011-9784-8