Abstract

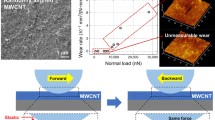

Nano-textured surfaces (NTSs) can reduce adhesion and friction and thus have potential to increase the reliability of micro-electro-mechanical systems and nano-electro-mechanical systems. However, deformation of the nanotextures severely limits the effectiveness of using NTSs. This article presents a novel concept of nano-surface-engineering by texturing the surface with core–shell nanostructures to produce deformation-resistant nanotextures. The NTSs were produced by thermal evaporation of Al on Si substrates to form Al nanostructures and then depositing amorphous silicon on top of Al by plasma-enhanced chemical vapor deposition. Friction and deformation of the NTSs were studied using a TriboIndenter and a scanning electron microscope. The results show that the novel NTS significantly reduced the coefficients of friction of the surface without any detectable plastic deformations of the nanotextures even after heavy scratches.

Similar content being viewed by others

References

Kim, S.H., Asay, D.B., Dugger, M.T.: Nanotribology and MEMS. Nano Today 2, 22–29 (2007)

Komvopoulos, K.: Adhesion and friction forces in microelectromechanical systems: mechanisms, measurement, surface modification techniques, and adhesion theory. J. Adhes. Sci. Technol. 17, 477–517 (2003)

Maboudian, R., Howe, R.T.: Critical review: adhesion in surface micromechanical structures. J. Vac. Sci. Technol. B Microelectron. Process. Phenom. 15, 1–20 (1997)

Williams, J.A., Le, H.R.: Tribology and MEMS. J. Phys. D Appl. Phys. 39, 201–214 (2006)

Bhushan, B.: Tribology Issues and Opportunities in MEMS, pp. 109–119. Kluwer, Dordrecht (1998)

Douglass, M.R.: Lifetime estimates and unique failure mechanisms of the Digital Micromirror Device (DMD). In: 1998 IEEE International Reliability Physics Symposium Proceedings 36th Annual, Anonymous IEEE, New York, NY, USA, pp. 9–16 (1998)

Hornbeck, L.J.: The DMDTM projection display chip: a MEMS-based technology. MRS Bull. 26, 325–327 (2001)

Zou, M., Seale, W., Wang, H.: Comparison of tribological performances of nano- and micro-textured surfaces. Proc. Inst. Mech. Eng. N (J. Nanoeng. Nanosyst.) 219, 103–110 (2005)

Zou, M., Wang, H., Larson, P.R., Hobbs, K.L., Johnson, M.B., Awitor, O.K.: Ni nanodot-patterned surfaces for adhesion and friction reduction. Tribol. Lett. 24, 137–142 (2006)

Zou, M., Cai, L., Wang, H.: Adhesion and friction studies of a nano-textured surface produced by spin coating of colloidal Silica nanoparticle solution. Tribol. Lett. 21, 25–30 (2006)

Wang, H., Premachandran Nair, R., Zou, M., Larson, P.R., Pollack, A.L., Hobbs, K.L., Johnson, M.B., Awitor, O.K.: Friction study of a Ni nanodot-patterned surface. Tribol. Lett. 28, 183–189 (2007)

Nair, R.P., Zou, M.: Surface-nano-texturing by aluminum-induced crystallization of amorphous silicon. Surf. Coat. Technol. 203, 675–679 (2008)

Song, Y., Premachandran Nair, R., Zou, M., Wang, Y.A.: Adhesion and friction properties of micro/nano-engineered superhydrophobic/hydrophobic surfaces. Thin Solid Films 518, 3801–3807 (2010)

Yoon, E.-S., Singh, R.A., Kong, H., Kim, B., Kim, D.-H., Jeong, H.E., Suh, K.Y.: Tribological properties of bio-mimetic nano-patterned polymeric surfaces on silicon wafer. Tribol. Lett. 21, 31–37 (2006)

Burton, Z., Bhushan, B.: Hydrophobicity, adhesion, and friction properties of nanopatterned polymers and scale dependence for micro- and nanoelectromechanical systems. Nano Lett 5, 1607–1613 (2005)

Jin, Z., Yang, D.-h., Ou, X.-b.: Microstructures and properties of aluminum film and its effect on corrosion resistance of AZ31B substrate. Trans. Nonferr. Metals Soc. China 18, 312–317 (2008)

Stone, D., LaFontaine, W.R., Alexopoulos, P., Wu, T.-W., Li, C.-Y.: An investigation of hardness and adhesion of sputter-deposited aluminum on silicon by utilizing a continuous indentation test. J. Mater. Res. 3, 141–147 (1988)

Shan, Z.W., Adesso, G., Cabot, A., Sherburne, M.P., Syed Asif, A.S., Warren, O.L., Chrzan, D.C., Minor, A.M., Alivisatos, A.P.: Ultrahigh stress and strain in hierarchically structured hollow nanoparticles. Nat. Mater. 7, 947–952 (2008)

Zheng, B., Wang, Y.N., Qi, M., Williams, E.H.: Phase boundary effects on the mechanical deformation of core/shell Cu/Ag nanoparticles. J. Mater. Res. 24, 2210–2214 (2009)

Gerberich, W.W., Mook, W.M., Perrey, C.R., Carter, C.B., Baskes, M.I., Mukherjee, R., Gidwani, A., Heberlein, J., McMurry, P.H., Girshick, S.L.: Superhard silicon nanospheres. J. Mech. Phys. Solids 51, 979–992 (2003)

Gerberich, W.W., Mook, W.M., Cordill, M.J., Cartera, C.B., Perreya, C.R., Heberleinb, J.V., Girshickb, S.L.: Reverse plasticity in single crystal silicon nanospheres. Int. J. Plasticity 21, 2391–2405 (2005)

Suh, N.P., Sin, H.-C.: The genesis of friction. Wear 69, 91–114 (1981)

Komvopoulos, K., Saka, N., Suh, N.P.: The mechanism of friction in boundary lubrication. J. Tribol. 107, 452–461 (1985)

Komvopoulos, K., Saka, N., Suh, N.P.: Plowing friction in dry and lubricated metal sliding. J. Tribol. 108, 301–303 (1986)

Acknowledgments

We thank the Arkansas Biosciences Institute and the University of Arkansas for major equipment funding support. We also thank the US National Science Foundation (NSF) for the support under grants CMS-0600642, CMS-0645040, and the support of the Center for Semiconductor Physics in Nanostructures (C-SPIN), an OU/UA NSF-funded MRSEC (DMR-0520550).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Morton, B.D., Wang, H., Fleming, R.A. et al. Nanoscale Surface Engineering with Deformation-Resistant Core–Shell Nanostructures. Tribol Lett 42, 51–58 (2011). https://doi.org/10.1007/s11249-011-9747-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11249-011-9747-0