Abstract

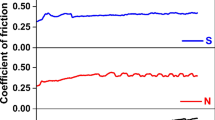

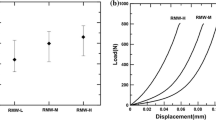

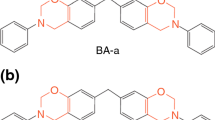

The heat resistance of the multiphase friction materials made with straight phenolic resin (ST), boron–phosphorous (B–P)-modified phenolic resin (BP), or polyimide (PI) was investigated using a Krauss-type friction tester. Thermal analysis of the cured resins was also carried out to examine the chemical and mechanical properties of the resin and their effects on the wear rate and the coefficient of friction. The results showed that the fade and wear of the friction materials were closely related to the thermal decomposition of the binder resin and durability of the contact plateaus, which were produced by the compaction of wear debris around hard ingredients on the rubbing surface. The friction material containing the B–P modified resin was more resistant to wear and fade than the other binder resins. On the other hand, the friction material with polyimide showed good fade resistance but exhibited excessive wear despite its good thermal resistance.

Similar content being viewed by others

References

Jang, H., Kim, S.J.: Brake friction materials. In: Sinha, S.K., Briscoe, B.J. (eds.) Polymer Tribology, pp. 521–549. Imperial College Press, London (2009)

Jacko, M.G., Lee, S.K.: Brake lining and clutch facings. In: Kirk-Othmer Encyclopedia of Chemical Technology, vol. 4, pp. 523–536, 4th edn. Wiley, New York (1992)

Anderson, A.E.: ASM Handbook, Friction, Lubrication and Wear Technology, vol. 18, pp. 569–577. ASM International, Metals Park (1992)

Nicholson, G.: Facts about friction, pp. 167–186. P & W Price Enterprises Inc, Gedoran America Limited, Winchester (1994)

Cho, M.H., Kim, S.J., Kim, D.H., Jang, H.: Effects of ingredients on tribological characteristics of a brake lining: an experimental case study. Wear 258, 1682–1687 (2005)

Auerbach, I.: Decomposition kinetics of a phenolic-carbon composite. I. Resin available for volatilization. J. Appl. Polym. Sci. 14, 747–756 (1970)

Auerbach, I.: Decomposition kinetics of a phenolic-carbon composite II. Rate relationship. J. Appl. Polym. Sci. 15, 91–103 (1971)

Cho, M.H., Cho, K.H., Kim, S.J., Kim, D.H., Jang, H.: The role of transfer layers on friction characteristics in the sliding interface between friction materials against gray iron brake disks. Tribol. Lett. 20, 101–108 (2005)

Cho, K.H., Cho, M.H., Kim, S.J., Jang, H.: Tribological properties of potassium titanate in the brake friction material; morphological effects. Tribol. Lett. 32, 59–66 (2008)

Cho, K.H., Jang, H., Hong, Y.-S., Kim, S.J., Basch, R.H., Fash, J.W.: The size effect of zircon particles on the friction characteristics of brake lining materials. Wear 264, 291–297 (2008)

Nam, J.-D., Seferis, J.C.: Viscoelastic characterization of phenolic resin-carbon fiber composite degradation process. J. Polym. Sci. B Polym. Phys. 37, 907–918 (1999)

Kim, S.J., Jang, H.: Fricition and wear of friction materials containing two different phenolic resins reinforced with aramid pulp. Tribol. Int. 33, 477–484 (2000)

Anderson, A.E.: Proceedings of Fibers in Friction Materials Symposium, pp. 2–49. The Asbestos Institute, Phoenex, AZ (1987)

Bijwe, J., Nidhi, Majumdar, N., Satapathy, B.K.: Influence of modified phenolic resins on the fade and recovery behavior of friction materials. Wear 259, 1068–1078 (2005)

Nidhi, Bijwe, J.: NBR-modified resin in fade and recovery module in non-asbestos organic (NAO) friction materials. Tribol. Lett. 27, 189–196 (2007)

Nidhi, Bijwe, J., Mazumdar, N.: Influence of amount and modification of resin on fade and recovery behavior of non-asbestos organic (NAO) friction materials. Tribol. Lett. 23, 215–221 (2007)

Hong, U.S., Jung, S.L., Cho, K.H., Kim, S.J., Jang, H.: Wear mechanism of multiphase friction materials with different phenolic resin matrices. Wear 266, 739–744 (2009)

Eriksson, M., Bergman, F., Jacobson, S.: On the nature of tribological contact in automotive brakes. Wear 252, 26–36 (2002)

Rabinowicz, R.: Friction and Wear of Materials, 2nd edn. Wiley, New York (1995)

Acknowledgments

This study was supported by the Korea Science and Engineering Foundation (KOSEF) through the National Research Lab. Program funded by Ministry of Science and Technology (R0A-2007-000-10011-0).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shin, M.W., Cho, K.H., Lee, W.K. et al. Tribological Characteristics of Binder Resins for Brake Friction Materials at Elevated Temperatures. Tribol Lett 38, 161–168 (2010). https://doi.org/10.1007/s11249-010-9586-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11249-010-9586-4