Abstract

Tribology of small inorganic nanoparticles in suspension in a liquid lubricant is often impaired because these particles agglomerate even when organic dispersants are used. In this paper we use lateral force microscopy to study the deformation mechanism and dissipation under traction of two extreme configurations (1) a large MoS2 particle (~20 μm width) of about 1 μm height and (2) an agglomerate (~20 μm width), constituting 50 nm MoS2 crystallites, of about 1 μm height. The agglomerate records a friction coefficient which is about 5–7 times that of monolithic particle. The paper examines the mechanisms of material removal for both the particles using continuum modeling and microscopy and infers that while the agglomerate response to traction can be accounted for by the bulk mechanical properties of the material, intralayer and interlayer basal planar slips determine the friction and wear of monolithic particles. The results provide a rationale for selection of layered particles, for suspension in liquid lubricants.

Similar content being viewed by others

References

Bowden, F.P., Tabor, D.: The Friction and Lubrication of Solids, Part II. Oxford University Press, London (1964)

Bhushan, B., Gupta, B.K.: Handbook of Tribology. McGraw-Hill, New York (1991)

Black, A.L., Dunster, R.W., Sanders, J.V.: Comparative study of surface deposits and behavior of MoS2 particles and molybdenum dialkyl-dithio-phosphate. Wear 13, 119–132 (1969)

Gansheimerand, J., Holinsky, R.: A study of solid lubricants in oils and greases under boundary conditions. Wear 19, 439–449 (1972)

Bell, M.E., Findlay, J.H.: Molydenite as a new lubricant. Phys. Rev. 59, 922–927 (1941)

Braithwaite, E.R., Rowe, G.W.: Principles and applications of lubrication with solids. Sci. Lubr. 15, 92–96 (1957)

Winer, W.O.: Molybdenum disulphide as a lubricant: A review of the fundamental knowledge. Wear 10, 422–452 (1967)

Spalvins, T.: Morphological and frictional behavior of sputtered MoS2 films. Thin Solid Films 96, 17–24 (1982)

Holinski, R., Gansheimer, J.: A study of the lubricating mechanism of molybdenum disulphide. Wear 19, 329–342 (1972)

Buck, V.: Morphological properties of sputtered MoS2 films. Wear 91, 281–288 (1983)

Fleischauer, P.D., Tolentino, L.U.: Effects of crystallite orientation on the environmental stability and lubrication properties of sputtered MoS2 thin films. ASLE Trans. 27, 82–88 (1984)

Roberts, E.W.: Thin solid lubricants in space. Tribol. Int. 23, 95–105 (1990)

Miyoshi, K., Honecy, F.S., Abel, P.B., Pepper, S.V., Spalvins, T., Wheeler, D.R.: A vacuum (10–9 Torr) friction apparatus for determining friction and endurance like that of MoSx films. Tribol. Trans. 36, 351–358 (1993)

Suzuki, M.: Comparison of tribological characteristics of sputtered MoS2 films coated with different apparatus. Wear 218, 110–118 (1998)

Wang, D.Y., Chang, C.L., Chen, Z.Y., Ho, W.Y.: Microstructural characterization of MoS2-Ti composite solid lubricating films. Surf. Coat. Technol. 121, 629–635 (1997)

Killeffer, D.H., Linz, D.: Molybdenum Compounds: Their Chemistry and Technology. Wiley Interscience, New York (1952)

Bowden, F.P., Tabor, D.: Friction: An Introduction to Tribology, vol. 91. Anchor, Garden City, New York (1973)

Singer I.L.: In: Singer, I.L., Pollock, H.M. (eds.) Fundamentals of Friction: Macroscopic and Microscopic Processes. Kluwer, Dordrecht (1992)

Dickinson, R.G., Pauling, L.: The crystal structure of molybdenite. J. Am. Chem. Soc. 45, 1466–1471 (1923)

Bragg, W.: The investigation of the properties of thin films by means of X-rays. Nature 115, 266–269 (1925)

Rapoport, L., Bilik, Yu., Feldman, Y., Homyonfer, M., Cohen, S.R., Tenne, R.: Hollow nanoparticles of WS2 as potential solid-state lubricants. Nature 387, 791–793 (1997)

Rapoport, L., Feldman, Y., Homyonfer, M., Cohen, S.R., Solan, J., Hutchison, J.L., Tenne, R.: Inorganic fullerene-like material as additives to lubricants: structure–function relationship. Wear 225–229, 975–982 (1999)

Tenne, R., Margulis, L., Genut, M., Hodes, G.: Polyhedral and cylindrical structures of tungsten disulphide. Nature 360, 444–446 (1992)

Feldman, Y., Wasserman, E., Srolovitz, D.J., Tenne, R.: High-rate gas-phase growth of MoS2 nested inorganic fullerenes and nanotubes. Science 267, 222–225 (1995)

Joly-Pottuz, L., Martin, J.M., Dassenoy, F., Belin, M., Montagnac, G., Reynard, B., Fleischer, N.: Pressure-induced exfoliation of inorganic fullerene-like WS2 particles in a Hertzian contact. J. Appl. Phys. 99, 023524 (2006)

Sahoo, R.R., Biswas, S.K. to be communicated

Gubarevich, A.V., Usuba, S., Kakudate, Y., Tanaka, A., Odawara, O.: Diamond powders less than 100 nm in diameter as effective solid lubricants in vacuum. Jpn. J. Appl. Phys. II 43, L920–L923 (2004)

Shafiei, M., Alpas, A.T.: Friction and wear mechanisms of nanocrystalline nickel in ambient and inert atmospheres. Metall. Mater. Trans. A 38, 1621–1631 (2007)

Gubarevich, A.V., Usuba, S., Kakudate, Y., Tanaka, A., Odawara, O.: Frictional properties of diamond and fullerene nanoparticles sprayed by a high-velocity argon gas on stainless steel substrate. Diam. Relat. Mater. 14, 1549–1555 (2005)

Moshkovith, A., Perfiliev, V., Lapsker, I., Fleischer, N., Tenne, R., Rapoport, L.: Friction of fullerene-like WS2 nanoparticles: Effect of agglomeration. Tribol. Lett. 24, 225–228 (2006)

Singer, I.L.: Mechanics and chemistry of solids in sliding contact. Langmuir 12, 4486–4491 (1996)

Wahl, K.J., Singer, I.L.: Quantification of a lubricant transfer process that enhances the sliding life of a MoS2 coating. Tribol. Lett. 1, 59–66 (1995)

Wahl, K.J., Belin, M., Singer, I.L.: A triboscopic investigation of the wear and friction of MoS2 in a reciprocating sliding contact. Wear 214, 212–220 (1998)

Devaprakasam, D., Khatri, O.P., Shankar, N., Biswas, S.K.: Boundary lubrication additives for aluminium: a journey from nano to macrotribology. Tribol. Int. 38, 1022–1034 (2005)

Green, C.P., Lioe, H., Cleveland, J.P., Proksch, P., Mulvaney, P., Sader, J.E.: Normal and torsional spring constants of atomic force microscope cantilevers. Rev. Sci. Instrum. 75, 1988–1996 (2004)

Cleveland, J.P., Manne, S., Bocek, D., Hansma, P.K.: A nondestructive method for determining the spring constant of cantilevers for scanning force microscopy. Rev. Sci. Instrum. 64, 403–404 (1993)

Ogletree, D.F., Carpick, R.W., Salmeron, M.: Calibration of frictional forces in atomic force microscopy. Rev. Sci. Instrum. 67, 3298–3306 (1996)

Ma, S., Wang, X., Xing, Y., Zhang, X., Xu, K., Teer, D.G.: Microstructure and mechanical properties of MoS2/titanium composite coatings with different titanium content. Surf. Coat. Technol. 201, 5290–5295 (2007)

Watanabe, S., Noshiro, J., Miyake, S.: Tribological characteristics of WS2/MoS2 solid lubricating multilayer films. Surf. Coat. Technol. 183, 347–351 (2004)

Maugis, D.: Contact, Adhesion and Rupture of Elastic Solids. Springler-Verlag, Berlin, Germany (2000)

Briscoe, B.J., Biswas, S.K., Sinha, S.K., Panesar, S.S.: The scratch hardness and friction of a soft rigid-plastic solid. Tribol. Int. 26, 183–193 (1993)

Scharf, T.W., Prasad, S.V., Dugger, M.T., Kotula, P.G., Goeke, R.S., Grubbs, R.K.: Growth, structure, and tribological behavior of atomic layer-deposited tungsten disulphide solid lubricant coatings with applications to MEMS. Acta Mater. 54, 4731–4743 (2006)

Simha, K.R.Y.: Fracture Mechanics for Modern Engineering Design. Universities Press, Hyderabad, India (2001)

Acknowledgments

The authors are grateful to Hindustan Petroleum Corporation Limited (HPCL), Mumbai, India for their support in carrying out this work. Our sincere thanks to Ms. P. Savitha for the help in carrying out this work.

Author information

Authors and Affiliations

Corresponding author

Appendix: Calculation of Mode II Stress Intensity Factor

Appendix: Calculation of Mode II Stress Intensity Factor

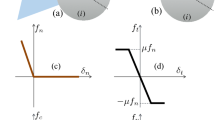

We model a particle being scratched by a conical indenter of β half cone angle under a normal load P (Fig. 12) we assume that slip occurs in a direction parallel to the scratch direction, as a mode II fracture. We situate a crack of length ‘2c’ in the slip plane at a variable depth δ and determine the δ* where K II = K IIc. Noting that there is a compressive stress σz which is a monotonic function of the normal load which decays in moving normally, and which acts normal to the crack length, we expect δ* to vary as a function of normal load.

We have estimated K II for sliding of the layers under both compressive and shear stress assuming a pre existing flaw of 0.1 μm at the interface. The stress intensity factor is calculated assuming the pre-existing crack is under a pure shear (σ = 0) and the interfacial shear strength of MoS2 = 25 MPa [42].

For a conical indenter, Normal stress is given by,

where, p m and \( \zeta \) are defined in Eqs. 6 and 8, respectively.

Let us assume a crack of length ‘2c’ at the interface of two layers under the action of a uniform normal compressive stress σz and a uniform shear stress τ. The mode II stress intensity factor, K II, for propagation of this crack can be written [43]

where, (a) k = 3 − 4 v, for plane strain and (b) k = (3 − v)/(1 + v), for plane stress.

Figure 13 shows that, with increase in normal load, we can shear more material from peak of the particle, where K II becomes equal to K IIC. However, the figure gives only a qualitative estimate of the stress intensity factors and this validates the experimental finding of material removal qualitatively (Fig. 5).

Rights and permissions

About this article

Cite this article

Sahoo, R.R., Math, S. & Biswas, S.K. Mechanics of Deformation under Traction and Friction of a Micrometric Monolithic MoS2 Particle in Comparison with those of an Agglomerate of Nanometric MoS2 Particles. Tribol Lett 37, 239–249 (2010). https://doi.org/10.1007/s11249-009-9504-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11249-009-9504-9