Abstract

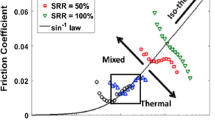

We present a realistic elastohydrodynamic lubrication (EHL) simulation in point contact using a Carreau-like model for the shear-thinning response and the Doolittle-Tait free-volume viscosity model for the piezoviscous response. The liquid lubricant modeled is a high-viscosity polyalphaolefin which has been shown by high-pressure viscometry to possess a relatively low threshold for shear-thinning as a single-component liquid lubricant. As a result, the measured EHL film thickness is about one-half of the Newtonian prediction. We derived and numerically solved the two-dimensional generalized Reynolds equation for the modified Carreau model based on Greenwood. In this simulation, viscosity was not treated as an adjustable parameter; the models used for the pressure and shear dependence of viscosity were obtained entirely from viscometer measurements. Truly remarkable agreement is found in the comparisons of simulation and experiment for traction coefficient and for film thickness in both pure rolling and sliding cases.

Similar content being viewed by others

Abbreviations

- a :

-

Hertzian contact radii, [m]

- B :

-

Doolittle parameter

- \(E^\prime\) :

-

Reduced Young’s modulus of two surfaces, [Pa]

- G :

-

Modulus or critical stress, [Pa]

- h, H :

-

Film thickness, [m], and dimensionless, H = h/a

- h 0, H 0 :

-

Normal approach, [m], and dimensionless, H 0 = h 0 /a

- h cen, h min :

-

Central and minimum film thickness, [m]

- k :

-

Traction coefficient

- K 0 :

-

Bulk modulus at p = 0, [GPa]

- K ′0 :

-

Pressure rate of change of bulk modulus at p = 0

- n :

-

Power law exponent

- p, P :

-

Pressure, [Pa], and dimensionless, P = p/p h

- p h :

-

Maximum Hertzian pressure, [Pa]

- p x , p y :

-

Dimensionless pressure gradients, \(p_x =\frac{h}{G}\frac{\partial p}{\partial x}, p_y =\frac{h}{G}\frac{\partial p}{\partial y}\)

- u, v :

-

Velocities in two directions, [m/s]

- \(\bar{u},\bar{v}\) :

-

Entrainment velocity, \(\bar{u}=\frac{u_1 +u_2}{2}\), \(\bar{v}=\frac{v_1 +v_2}{2}\), [m/s]

- U, V :

-

Dimensionless velocities, U = uμ/(hG), V = vμ/(hG)

- v :

-

Volume, [m3]

- v 0 :

-

Volume at ambient pressure or p = 0, [m3]

- v occ :

-

Occupied volume, [m3]

- w :

-

Load, [N]

- X, Y, ξ:

-

Dimensionless coordinates X = x/a, Y = y/a, ξ = z/h

- \(\dot{\gamma}\) :

-

Shear rate

- \(\dot{\gamma}_x, \dot{\gamma}_y, \dot{\gamma}_e\) :

-

Shear rate in two directions, and composite, \(\dot{\gamma}_e =\sqrt{\dot{\gamma}_x^2 +\dot{\gamma}_y^2}\)

- ɛ:

-

Dimensionless coefficients for Poiseuille flow

- λ:

-

Characteristic time, [s]

- \(\mu,\bar{\mu}\) :

-

Low-shear viscosity, [Pa*s], and dimensionless, \(\bar{\mu}=\mu/\mu_0 \)

- μ o :

-

Low-shear viscosity at ambient pressure, [Pa*s]

- \(\rho, \bar{\rho}\) :

-

Density of lubricant, [kg/m3], and dimensionless, \(\bar{\rho}=\rho/\rho_0 \)

- ρ0 :

-

Density at ambient pressure, [kg/m3]

- σ x , σ z :

-

Normal stresses in two directions, tensile is positive, [Pa]

- \(\tau, \bar{\tau}\) :

-

Shear stress, [Pa], dimensionless shear stress, \(\bar{\tau}=\tau/G\)

- \(\bar{\tau}_x,\bar{\tau}_y, \bar{\tau}_e\) :

-

Dimensionless shear stresses in two directions and combined, \(\bar{\tau}_e =\sqrt{\bar{\tau}_x^2 +\bar{\tau}_y^2}\)

- \(\bar{\tau}_a,\bar{\tau}_b\) :

-

Dimensionless shear stresses on the middle layer

- ϕ x ,ϕ y :

-

Two flow factors in two directions

- Ω:

-

Solution domain

References

Dyson, A., Naylor, N., Wilson, A.R.: The measurement of film thickness in elastohydrodynamic contacts. In Symposium on Elastohydrodynamic Lubrication (Leeds), Instn. Mech. Engrs., London, pp. 76–91 (1965)

Greenwood, J.A., Kauzlarich, J.J.: Elastohydrodynamic film thickness for shear-thinning lubricants. Proc. Instn. Mech. Engrs. Part J – J. Eng. Tribol. 212(J3), 179–191 (1998)

Bair, S., Khonsari, M.: An EHD inlet zone analysis incorporating the second Newtonian. ASME J. Tribol. 118(2), 341–343 (1996)

Bair, S., Vergne, P., Marchetti, M.: The effect of shear-thinning on film thickness for space lubricants. STLE Tribol. Trans. 45(3), 330–333 (2002)

Bair, S., Qureshi, F.: The generalized newtonian fluid model and elastohydrodynamic film thickness. ASME J. Tribol. 125(1), 70–75 (2003)

Dyson, A., Wilson, A.R.: Film thickness in elastohydrodynamic lubrication by silicone fluids. Proc. Instn. Mech. Engrs. 180(Part 3K), 97–105 (1965–1966)

Chapkov, A.D., Bair, S., Cann, P., Lubrecht, A.A.: Film thickness in point contacts under generalized Newtonian EHL conditions: numerical and experimental analysis. Tribol. Int. available online, (2007)

Bair, S., McCabe, C., Cummings, P.T.: Calculation of viscous EHL traction for squalane using molecular simulation and rheometry. Tribol. Lett. 13(4), 251–254 (2002)

Bair, S., Kotzalas, M.: The contribution of roller compliance to elastohydrodynamic traction. STLE Tribol. Trans. 49(2), 218–224 (2006)

Bair, S., Kottke, P.: Pressure-viscosity relationships for elastohydrodynamics. STLE Tribol. Trans. 46(3), 289–295 (2003)

Liu, Y., Wang, Q.J., Wang, W., Hu, Y., Zhu, D., Krupka, I., Hartl, M.: EHL simulation using the free-volume viscosity model. Tribol. Lett. 23(1), 27–37 (2006)

Bair, S., McCabe, C., Cummings, P.T.: Comparison of nonequilibrium molecular dynamics with experimental measurements in the nonlinear shear-thinning regime. Phys. Rev. Lett. 88(5), 058302-1–0508302-4 (2002)

Bair, S., Vergne, P., Querry, M.: A unified shear-thinning treatment of both film thickness and traction in EHD. Tribol. Lett. 18(2), 145–152 (2005)

Bair, S., Khonsari, M.M.: Generalized Reynolds equations for line contact with double-Newtonian shear-thinning. Tribol. Lett. 18(4), 513–520 (2005)

Bair, S.: A Reynolds–Ellis equation for line contact with shear-thinning. Tribol. Int. 39(4), 310–316 (2006)

Bair, S., Khonsari, M.M.: Reynolds equations for common generalized Newtonian models and an approximate Reynolds–Carreau equation. Proc. Instn. Mech. Engrs. Part J – J. Eng. Tribol. 220(J4), 365–374 (2006)

Greenwood, J.A.: Two-dimensional flow of a non-Newtonian lubricant. Proc. Instn. Mech. Engrs. Part J – J. Eng. Tribol. 214(J1), 29–41 (2000)

Holmes, M.J.A., Evans, H.P., Snidle, R.W.: Comparison of transient EHL calculations with start-up experiments. In: Dowson, D. et al (eds.) Proceedings of the 29th Leeds-Lyon Symposium on Tribology, Elsevier, Amsterdam, pp. 79–89 (2002)

Venner, C.H, Kaneta, M., Nishikawa, H., Jacod, B.: Effects of waviness on the film thickness in a circular EHL contact under rolling sliding. In: Ichimaru, K., et al. (eds.) Proceedings of the International Tribology Conference, Vol. I, JAST, pp. 631–636 (2001)

Felix-Quinonez, A., Ehret, P., Summers, J.L.: Numerical analysis of experimental observations of a single transverse ridge passing through an elastohydrodynamic lubrication point contact under rolling/sliding conditions. Proc. Instn. Mech. Engrs. Part J – J. Eng. Tribol. 218(J2), 109–123 (2004)

Felix-Quinonez, A., Ehret, P., Summers, J.L.: On three-dimensional flat-top defects passing through an EHL point contact: a comparison of modeling with experiments. ASME J. Tribol. 127(1), 51–60 (2005)

Carreau, P.J.: Rheological equations from molecular network theories. Trans. Soc. Rheol. 16(1), 99 (1972)

Cook, R.L., King, H.E., Herbst, C.A., Herschback, D.R.: Pressure and temperature-dependent viscosity of 2 glass-forming liquids – Glycerol and dibutyl phthalate. J. Chem. Phys. 100(7), 5178–5189 (1994)

Hu, Y.Z., Zhu, D.: A full numerical solution to the mixed lubrication in point contacts. ASME J. Tribol. 122(1), 1–9 (2000)

Liu, S.B., Wang, Q., Liu, G.: A versatile method of discrete convolution and FFT (DC-FFT) for contact analyses. Wear 243(1–2), 101–111 (2000)

Wang, W.Z., Wang, H., Liu, Y.C., Hu, Y.Z., Zhu, D.: A comparative study of the methods for calculation of surface elastic deformation. Proc. Instn. Mech. Engrs. Part J – J. Eng. Tribol. 217(J2), 145–153 (2003)

Liu, Y.C., Wang, Q.J., Wang, W.Z., Hu, Y.Z., Zhu, D.: Effects of differential scheme and mesh density on EHL film thickness in point contacts. ASME J. Tribol. 128(3), 641–653 (2006)

Hamrock, B.J., Dowson, D.: Isothermal elastohydrodynamic lubrication of point contacts, part III – fully flooded solution. ASME J. Lubr. Tech. 99(2), 264–275 (1977)

Ehret, P., Dowson, D., Taylor, C.M.: On lubricant transport conditions in elastohydrodynamic conjunctions. Proc. Roy. Soc. Lond. A 454, 763–786 (1998)

Bair, S., Khonsari, M., Winer, W.O.: High-pressure rheology of lubricants and limitations of the Reynolds equation. Tribol. Int. 31(10), 573–586 (1998)

Bair, S.: High-Pressure Rheology for Quantitative Elastohydrodynamics, Elsevier Science, Amsterdam, p. 174 (2007)

Bair, S.: Normal stress difference in liquid lubricants sheared under high pressure. Rheol Acta 35(1), 13–23 (1996)

Tanner, R.I.: Engineering Rheology, Clarendon Press, Oxford (1985)

Acknowledgments

Yuchuan Liu and Q. Jane Wang would like to express their gratitude for the support from Office of Naval Research and Department of Energy. Scott Bair acknowledges the support of the Timken Company for high-pressure rheology research over many years.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, Y., Wang, Q.J., Bair, S. et al. A Quantitative Solution for the Full Shear-Thinning EHL Point Contact Problem Including Traction. Tribol Lett 28, 171–181 (2007). https://doi.org/10.1007/s11249-007-9262-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11249-007-9262-5