Abstract

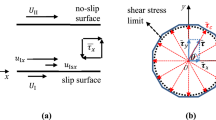

Elastohydrodynamic lubrication (EHL) point contact occurs between two rough surfaces at the mesoscopic level, while the interaction of rough surfaces involves contact between asperities at the microscale level. In most cases, the contact between asperities within an interface takes the form of lateral contact rather than peak contact. Regions devoid of contact asperities are filled with lubricating oil. However, conventional models often oversimplify lateral contact forms as interactions between asperities and a smooth, rigid plane. These simplifications fail to accurately represent the true contact conditions and can lead to inaccuracies in the analysis of EHL’s contact performance. To address this issue, we have developed a novel EHL interface model comprising two rough surfaces. This model allows us to explore the influence of asperity height, contact angle, and contact azimuth angle on EHL interface performance.

Similar content being viewed by others

Data Availability

Data will be made available on request.

Abbreviations

- \(A_{n}\) :

-

The nominal contact area

- \(W\) :

-

The normal load

- \(R\) :

-

The radius of asperity

- \(z\) :

-

The height of asperity

- \(h\) :

-

The average gap (the mean film thickness)

- \(\varphi\) :

-

The asperity contact angle

- \(\theta\) :

-

The contact azimuth angle

- \(F_{in}\) :

-

The normal force on asperity

- \(n_{i}\) :

-

The normal component force

- \(\tau_{i}\) :

-

The tangential component force

- \(h_{i}\) :

-

The horizontal component force

- \(\delta\) :

-

The asperity deformation

- \(\delta_{c}\) :

-

The critical deformation

- \(\delta_{m}\) :

-

The amplitude of the deformation

- \(S_{k}\) :

-

The hardness coefficient

- \(\nu\) :

-

The equivalent Poisson’s ratio

- \(E\) :

-

The composite Young’s modulus

- \(G\) :

-

The shear modulus

- \(\omega\) :

-

The angular frequency

- \(t\) :

-

The time

- \(T\) :

-

The period

- \(k_{in}\) :

-

The asperity contact stiffness

- \(k_{idn}^{{}}\) :

-

The average contact stiffness

- \(e_{in}^{{}}\) :

-

The asperity contact energy dissipation

- \(\delta^{*}\) :

-

The asperity deformation (The superscript asterisk (*) denotes dimensionless quantities.)

- \(\zeta^{*}\) :

-

The asperity displacement

- \(\zeta_{m}^{*}\) :

-

The displacement amplitude

- \(\mu_{s}\) :

-

The friction coefficient

- \(c_{i\tau }^{*}\) :

-

The tangential contact damping

- \(k_{i\tau }^{*}\) :

-

The tangential contact stiffness

- \(\phi (z)\) :

-

The distribution of asperity heights

- \(\sigma_{z}\) :

-

The standard deviation of the asperity height distribution

- \(\eta_{a}\) :

-

The density of asperities

- \(\Gamma (\varphi ,\theta )\) :

-

The joint probability density function of asperity contact angles and contact azimuth angles

- \(M\) :

-

The asperity number

- \(m\) :

-

The number of contacting asperities

- \(\sigma_{\varphi }\) :

-

The standard deviations of asperity contact angles

- \(\sigma_{\theta }\) :

-

The standard deviations of asperity contact azimuth angle

- \(\Delta^{*}\) :

-

The normal deformation of the interface

- \(F_{s}^{*}\) :

-

The solid asperity contact force

- \(K_{s}^{*}\) :

-

The solid contact stiffness

- \(C_{s}^{*}\) :

-

The solid contact damping

- \(A_{l}\) :

-

The total area of the closed oil pits

- \(p_{l}\) :

-

The normal dynamic force of the squeeze oil film

- \(p_{l}\) :

-

The normal dynamic force of the squeeze oil film

- \(\overline{{p_{l} }}\) :

-

The mean pressure

- \(B\) :

-

The width of contact area

- \(\eta_{l}\) :

-

The lubricating oil viscosity

- \(\phi_{x} ,\phi_{y}\) :

-

Two pressure flow factors

- \(\phi_{c}\) :

-

The contact factor

- \(\overline{h}_{T}^{*}\) :

-

The expectation of dimensionless local film thickness

- \(\chi\) :

-

The end leak coefficient

- \(F_{l}^{*}\) :

-

The dimensionless liquid contact force

- \(K_{l}^{*}\) :

-

The liquid contact stiffness

- \(C_{l}^{*}\) :

-

The liquid contact damping

References

Zhao Y, Liu HC, Morales-Espejel GE, Venner CH. Effects of solid viscoelasticity on elastohydrodynamic lubrication of point contacts. Tribol Int. 2022;171:107562.

Greenwood JA. Elastohydrodynamic lubrication. Lubricants. 2020;8:1–30.

Ren G. Hypo-elastohydrodynamic lubrication of journal bearings with deformable surface. Tribol Int. 2022;175:107787.

Simo KL, Meffert D, Magyar B, Oehler M, Sauer B. Simulative investigation of the influence of surface texturing on the elastohydrodynamic lubrication in chain joints. Tribol Int. 2022;171:107564.

Tsuha NAH, Cavalca KL. Finite line contact stiffness under elastohydrodynamic lubrication considering linear and nonlinear force models. Tribol Int. 2020;146:106219.

Wang Z, Pu W, Pei X, Cao W. Nonlinear dynamical behaviors of spiral bevel gears in transient mixed lubrication. Tribol Int. 2021;160:107022.

Lv FR, Zhang XJ, Ji CC, Rao ZS. Theoretical and experimental investigation on local turbulence effect on mixed-lubrication journal bearing during speeding up. Phys Fluids. 2022;34:113104.

Bi C, Han D, Wu Y, Li Y, Yang J. Thermohydrodynamic investigation for supercritical carbon dioxide high speed tilting pad bearings considering turbulence and real gas effect. Phys Fluids. 2021;33:125114.

Hutchings I, Shipway P. Surface topography and surfaces in contact. Oxford: Butterworth-Heinemann; 2017.

Masjedi M, Khonsari MM. Film thickness and asperity load formulas for line-contact elastohydrodynamic lubrication with provision for surface roughness. J Tribol. 2012;134:011503.

Johnson KL, Greenwood J, Poon SY. A simple theory of asperity contact in elastohydro-dynamic lubrication. Wear. 1972;19:91–108.

Xu J, Zhu J, Xia W, Liu B. Micro-asperity contact area considering strain hardening for metallic materials. J Tribol. 2021;144(4):041503.

Zhu L, Chen J, Zhang Z, Hong J. Normal contact stiffness model considering 3D surface topography and actual contact status. Mech Sci. 2021;12:41–50.

Sepehri A, Farhang K. On elastic interaction of nominally flat rough surfaces. J Tribol. 2007;130:011014.

Sepehri A, Farhang K. Closed-form equations for three dimensional eastic-plastic contact of nominally flat rough surfaces. J Tribol. 2009;131:041402.

Hua DY, Qiu L, Cheng HS. Modeling of lubrication in micro contact. Tribol Lett. 1997;3:81–6.

Chong WW, Hamdan SH, Wong KJ, Yusup S. Modelling transitions in regimes of lubrication for rough surface contact. Lubricants. 2019;7(9):77–121.

Hu Y, Wang H, Wang W, Zhu D. Computer model of mixed lubrication in point contacts. Tribol Int. 2001;34:65–73.

Du Y, Lan J, Quan H, Sun C, Liu X, Yang X. Journal bearing properties and dynamic responses under transient impact load and elastic deformation. Phys Fluids. 2021;33:065118.

Lv FR, Shang GYQ, Zou DL, Ji AM. Transient mixed-lubrication analysis of low-viscosity lubricated bearings under impact load with consideration of turbulence. Phys Fluids. 2022;34:033108.

Gao ZQ, Xi YP, Peng LX, Fu WP, Wang W, Hu WP, Wei X. Normal and tangential contact models for mixed lubrication of mechanical interface. Phys Fluids. 2022;34:112112.

Patir N, Cheng HS. An average flow model for determining effects of three-dimensional roughness on partial hydrodynamic lubrication. J Lubr Technol. 1978;100:12–7.

Masjedi M, Khonsari MM. On the effect of surface roughness in point-contact EHL: formulas for film thickness and asperity load. Tribol Int. 2015;82:228–44.

Zhao Y, Maietta D, Chang L. An asperity microcontact model incorporating the transition from elastic deformation to fully plastic flow. J Tribol. 2000;122:86–93.

Xiao H, Sun Y, Xu J. Investigation into the normal contact stiffness of rough surface in line contact mixed elastohydrodynamic lubrication. Tribol Trans. 2018;61:742–53.

Kogut L, Etsion I. A finite element based elastic-plastic model for the contact of rough surfaces. Tribol Trans. 2003;46:383–90.

Krupka I, Hartl M, Matsuda K, Nishikawa H, Wang J, Guo F, et al. Deformation of rough surfaces in point EHL contacts. Tribol Lett. 2019;67(33):1–16.

Cornelio C, Spagnuolo E, Di Toro G, Nielsen S, Violay M. Mechanical behaviour of fluid-lubricated faults. Nat Commun. 2019;10:1274.

Aghababaei R, Warner DH, Molinari JF. Critical length scale controls adhesive wear mechanisms. Nat Commun. 2016;7:11816.

Zhao B, Zhang S, Keer LM. Semi-analytical and numerical analysis of sliding asperity interaction for power-law hardening materials. Wear. 2016;364–365:184–92.

Shi X, Zou Y, Fang H. Numerical investigation of the three-dimensional elastic–plastic sloped contact between two hemispheric asperities. J Appl Mech. 2016;83:101004.

Verma NN, Mazumder S. Quantifying the effect of asperity size and shape on thermal contact conductance of metal-metal contacts through direct numerical simulations. Int J Heat Mass Transf. 2017;115:336–46.

Xu H, Komvopoulos K. A fracture mechanics analysis of asperity cracking due to sliding contact. Int J Solids Struct. 2019;171:1–9.

Zhang K, Li G, Gong JZ, Zhang M. Normal contact stiffness of rough surfaces considering oblique asperity contact. Adv Mech Eng. 2019;11:1687814018824471.

Greenwood J, Williamson J. Contact of nominally flat surfaces. Proceedings of the Royal Society of London (A). 1966;295:300–19.

Wang QJ, Zhu D. Hertz theory: contact of spherical surface. Boston: Springer; 2013.

Mindlin RD, Deresiewicz H. Elastic spheres in contact under varying oblique forces. J Appl Mech. 1953;20:327–44.

Brizmer V, Kligerman Y, Etsion I. Elastic–plastic spherical contact under combined normal and tangential loading in full stick. Tribol Lett. 2007;25:61–70.

Thomson WT, Dahleh MD. Theory of vibration with applications. 5th ed. Peking: Prentice-Hall; 2005.

Misra AK. Mechanistic model for contact between rough surfaces. J Eng Mech-Asce. 1997;123:475–84.

Misra A, Huang S. Effect of loading induced anisotropy on the shear behavior of rough interfaces. Tribol Int. 2011;44:627–34.

Greenwood J, Tripp J. The contact of two nominally flat rough surfaces. Arch Proc Inst Mech Eng. 1970;185:625–34.

Jackson RL, Green I. A statistical model of elasto-plastic asperity contact between rough surfaces. Tribol Int. 2006;39:906–14.

Durst F. Fluid mechanics: an introduction to the theory of fluid flows. Heidelberg: Springer; 2022.

Wu C, Zheng L. A contact factor and its application in studying partial hydrodynamic lubrication. Lubr Eng. 1989;3:1–6 (in chinese).

Cameron A. Basic lubrication theory. London: Ellis Horwood Press; 1981.

Wen S, Huang P. Principles of tribology (second edition). Peking: Tsinghua University Press; 2017.

Pei JX, Han X, Tao YR. An improved stiffness model for line contact elastohydrodynamic lubrication and its application in gear pairs. Ind Lubr Tribol. 2022;72(5):703–8.

Qin WJ, Chao J, Duan LJ. Study on stiffness of elastohydrodynamic line contact. Mech Mach Theory. 2015;86:36–47.

Funding

This research is supported by the National Natural Science Foundation of China (No. 52005401, No. 52375127), the Cultivation Scientific Research Project of Panzhihua University (2021PY001), the Opening Project of Material Corrosion and Protection Key Laboratory of Sichuan province (2022CL15), and the Project for Science and Technology Plan of Henan Province (212102210445).

Author information

Authors and Affiliations

Contributions

ZG: Formal analysis, Writing original draft, Funding acquisition, Writing review & editing; YZ: Investigation; XW: Software, Visualization, Funding acquisition. YZ: Conceptualization, Methodology; WF: Validation, Visualization, Supervision; WW: Project administration.

Corresponding author

Ethics declarations

Conflict of interests

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Consent for Publication

All authors have approved the final manuscript and submission to the journal.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Gao, Z., Zhang, Y., Wei, X. et al. Elastohydrodynamic Lubrication Interface Stiffness and Damping Considering Asperity Lateral Contact. Acta Mech. Solida Sin. 37, 109–123 (2024). https://doi.org/10.1007/s10338-023-00441-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10338-023-00441-9