Abstract

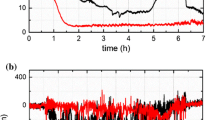

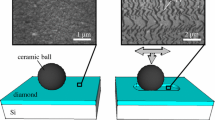

We studied the formation of tribologically induced nanocrystalline layers in lubricated contacts during running-in using a pin-on-disk tribometer coupled to a radionuclide high-resolution wear measurement system. The experiments were stopped after different running times and the sliding surfaces were analysed by atomic force microscopy, auger electron spectroscopy and focused ion beam analysis. Initially, at very high wear rates, zinc phosphate anti-wear films are formed in the contact regions of the surfaces, which slow down the wear process. During rubbing the formed films will submerge below the surface of the materials as result of large plastic deformations. This process affects the friction coefficient and the wear rate and is considered to be a key mechanism for the running-in.

Similar content being viewed by others

References

Kehrwald, B.: Einlauf tribologischer Systeme. Ph.D. thesis, University of Karlsruhe (1998)

Poon, C.Y., Sayles, R.S.: The classification of rough surface contacts in relation to tribology. J. Phys. D 25, A249–A256 (1992)

Rigney, D.A.: Transfer, mixing and associated chemical and mechanical processes during the sliding of ductile materials. Wear 245, 1–9 (2000)

Shakhvorostov, D., Pöhlmann, K., Scherge, M.: An energetic approach to friction, wear and temperature. Wear 257, 124–130 (2004)

Scherge, M., Shakhvorostov, D., Pöhlmann, K.: Fundamental wear mechanism of metals. Wear 255, 395–400 (2003)

Spedding, H., Watkins, R.C.: The anti-wear mechanism of zddp’s. Tribol. Int. 15, 9–15 (1982)

Martin, J.M.: Antiwear mechanisms of zinc dithiophosphate: a chemical hardness approach. Tribol. Lett. 6, 1–8 (1999)

Mosey, N.J., Müser, M.H., Woo, T.K.: Molecular Mechanism for the Functionality of Lubricant Additives. Science 307, 1612–1615 (2005)

Smith, G.C.: Surface analytical science and automotive lubrication. J. Phys. D 33, R187–R197 (2000)

Neville, A., Morina, A.: Wear and chemistry of lubricants. In: Stachowiak, G. (ed.) Wear—Materials, Mechanisms and Practice, pp. 71–94. Wiley and Sons, London (2005)

So, H., Lin, Y.C.: The theory of antiwear for ZDDP at elevated temperature in boundary lubrication condition. Wear 177, 110–115 (1994)

Scherge, M., Pöhlmann, K., Gervé, A.: Wear Measurement using Radio-Nuclide-Technique (RNT). Wear 254, 801–818 (2003)

Canning, G.W., et al.: Spectromicroscopy of tribological films from engine oil additives. Part I. Films from ZDDP’s. Tribol. Lett. 6, 159–169 (1999)

Rigney, D.A.: In: Proc. Materials Solutions ’97 on Wear of Engineering Materials. ASM Intl., Materials Park, OH (1998)

Bec, S., et al.: Relationship between mechanical properties and structure of zinc di thiophosphate anti-wear films. Proc. Roy. Soc. Lond. A 455, 4181–4203 (1999)

Chokshi, A.H., Rosen, A., Karch, J., Gleiter, H.: On the validity of the Hall-Petch relationship in nanocrystalline materials. Scripta Metall. 23, 1679–1684 (1989)

Schiøtz, J., Tomalla, F.D.D., Jacobsen, K.W.: Softening of nanocrystalline metals at very small grain sizes. Nature 391, 561–563 (1998)

Schuh, C.A., Nieh, T.G., Yamasaki, T.: Hall-Petch Breakdown Manifested in the Abrasive Wear Resistance of Nanocrystalline Nickel. Scripta Mater. 46, 735–740 (2002)

Shakhvorostov, D., Pöhlmann, K., Scherge, M.: 14th International Colloquium Tribology, January 13-15, Esslingen (2004)

Scherge, M., Martin, J.M., Pöhlmann, K.: Characterization of wear debris of systems operated under low wear-rate conditions. Wear 260, 458–461 (2006)

Acknowledgements

We thank Eberhard Nold (Forschungszentrum Karlsruhe) and Erich Müller (Karlsruhe University) for experimental assistance and Matthias Scherge for discussions and advice. The authors are pleased to acknowledge financial support from the Taiho Kogyo Tribology Research foundation and support from the ESF Nanotribo program.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dienwiebel, M., Pöhlmann, K. Nanoscale Evolution of Sliding Metal Surfaces During Running-in. Tribol Lett 27, 255–260 (2007). https://doi.org/10.1007/s11249-007-9216-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11249-007-9216-y