Abstract

This paper reports and discusses some of our recent advances in surface science research on a silica film supported on a Ru(0001) substrate. This system is unique, as the silica is bound to the metal surface by dispersive forces only, and thus opens the possibility to study reactions in the confined space between the metal substrate and the silica film, acting as a permeable membrane. We demonstrate that this system allows for detailed insights into the complexity of reactions in confined space, including phenomena due to the response of the confined space to the presence of the reactants, and direct comparison to the situation when the same reaction occurs in open space.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Model studies in heterogeneous catalysis, based on surface science techniques, have been instrumental to reach a basic understanding of processes and reactions at solid surfaces at the atomic level [1, 2]. Starting from nanoparticles and clusters in the gas phase, as the least complex species, via single crystalline metal surfaces, those studies have been developed to study single crystalline metal oxide surfaces, i.e. epitaxially grown single crystalline metal oxide thin films, as models for catalysts supports and increasing the complexity to deposit and grow metal nano particles on those model supports to approach the complex structure and morphology of real catalysts [3,4,5,6,7]. Those systems may be studied with surface science techniques to study the connection between geometric and electronic structure and their relation to reactions at those open surfaces. In order to provide more information on supported nanoparticles new techniques are being developed. For instance, a technique termed Surface Action Spectroscopy (SAS) has recently been developed [8], based on ideas established in gas phase metal cluster studies, where rare gas messengers are attached to clusters and infrared laser radiation is used to detach those and record the desorbing rare gas by mass spectrometry as a function of laser frequency. This provides information on the vibrational spectrum, and, in comparison to calculations determine the structure. Such techniques are under development but provide a perspective for future studies [9]. However, there are many important heterogeneously catalyzed reactions, such as those catalyzed by zeolites and molecular organic frameworks (MOFs), where the reactions occur within the volume of the catalysts in confined space [10, 11]. Here the possibility to contribute basic understanding using surface science techniques is rather limited at first sight.

In recent years, however, efforts have been started to investigate molecular adsorption and intercalation between metal surfaces and weakly bound overlayers, such as graphene, hexagonal-Boron-Nitrides (h-BN), but also within carbon nanotubes, mainly initiated and reviewed by Fu, Bao [12, 13] and others [14]. Our group had worked in this direction by using thin silica layers on single crystal metal surfaces [15]. There is a modification of silica, i.e. a silica bilayer, which is only bound to the metal substrate by dispersive forces, thus leaving the space between metal surface and silica film accessible for reactions [16]. We have studied the intercalation of CO between the silica bilayer and a Ru(0001) surface [16]. Figure 1 shows some schematic structures of samples studied. The graphene and h-BN samples expose openings through their hexagonal carbon and boron-nitride structures, which are too small for molecules, such as CO, to penetrate. However, it is obvious that the carbon and boron-nitride materials come in flakes or islands and allow for intercalation from the island edges. The silica ring openings, though slightly larger, might allow for CO penetration. Nevertheless, in order to mimic the situation found in the above-mentioned zeolites, where the reactants diffuse to the reaction site through a, mostly, silica membrane, a model system fulfilling the requirements is needed. As we will explain in the following this can be achieved employing the bilayer-silica/Ru(0001) system, using hydrogen as the molecule to permeate the membrane to start the reaction with adsorbed oxygen on the metal surface to form water.

Presentation of materials, where confined catalytic reactions are being discussed. a Pores in metal loaded zeolites, metal loaded carbon nanotubes, intercalation between a metal surface and 2D cover [13]. b Low energy electron micrographs of graphene flakes on Pt(111) to study CO oxidation. Wrinkles in the flakes, where CO may enter the flake between 2D materials and metal surfaces are marked with an arrow [12, 17]. c Interplay between nanotube diameter and the size organic educt and product molecules to determine selectivity [14]. d CO intercalation between a silica bilayer and a Ru(0001) surface as a function of pressure [15]

2 Model Systems to Approach the Study of Reactions in Confined Space

Before we discuss the results on reactivity measurements [18, 19], we will elaborate on the structure of the bilayer silica film, which is a prerequisite to understand our approach. The studies started about 13 years ago [16], and a summary, of what has been achieved so far, has recently been published in a review paper [20]. Figure 2 shows two large scale scanning tunneling microscopy (STM) images of the bilayer film, exposing in Fig. 2a (left) the crystalline and in Fig. 2a (right) the vitreous phase. Figure 2b shows a comparison of crystalline and vitreous phase at higher resolution, and reveals Si–O hexagonal rings formed from SiO4 tetrahedra, as shown by a schematic of the bilayer film in its crystalline form in Fig. 3a, also indicating, that there is no chemical bond between the film and the substrate. The vitreous film differs from the crystalline film only by the distribution of various ring sizes, ranging from four to nine membered rings. In addition to the bilayer film, there is also a monolayer film (Fig. 3b), which, in contrast to the bilayer film, does form a strong bond to the substrate, as is revealed via a comparison of the infrared reflection absorption spectroscopy (IRAS) spectra [21], also shown in Fig. 3c. The blue spectrum refers to the bilayer film, for both the crystalline as well as the vitreous film, and exposes only Si–O vibrations, while the red spectrum shows the strong Si–O–Ru vibration at 1135 cm−1, characteristic for the monolayer film. STM images themselves do not provide identification of chemical speciation. However, if we compare non-contact-Atomic Force Microscope (NC-AFM) and STM data from the same region, as done in Fig. 4, we can see that NC-AFM emphasizes the Si-species, while STM emphasizes the O-species [23].

a Schematic structure of the silica bilayer film as viewed from the top (above) and the side (below); b Schematic structure of the silica monolayer film as viewed from the top (above) and the side (below); c Infrared (IRAS) spectra of the monolayer and bilayer films in comparison [21]

High resolution non-contact AFM (left) and STM images of the same region. While nc-AFM images the Si atoms, STM preferentially images the oxygen atoms of the hexagonal network [23]

The combination of all those studies provides convincing evidence that we know the structure of the material. By the way, it also proves a proposal by Zachariasen [24], published in 1932, for the structure of vitreous silica for the first time by real space imaging. We also have started to understand the transformation between the crystalline and the vitreous phase. A first indication can be deduced from Fig. 5, where a color coded STM image of an area is shown, where the two phases coexist [25]. Counting the number of silica rings (colored differently for different sizes, see figure captions) within increments, and plotting those numbers as one moves from the crystalline phase on the left to the vitreous phase on the right, provides a statistical indication which ring sizes appear first near the area where the transition from 6-membered rings only to the coexistence of different ring sizes occurs. Clearly, a combination of 5- and 7-membered rings occur first, and this is consistent with theoretical studies by Klemm et al. [26], who have shown that the initial breaking of Si–O bonds in an arrangement of four 6-membered rings leads to the formation of two 5- and two 7-membered rings, as indicated in Fig. 6. It shows a series of structures based on density functional calculation, that correspond to the various extrema of the shown potential energy curve. The black line shows the electronic energy landscape for the free, i.e. unsupported, silica film, and the red line for the potential energy surface of the metal supported film. The rate determining step is connected to the transition across the first transition state, about 4 eV above the crystalline ground state. The defect of two 5- and two 7-membered rings, finally formed by the described process out of 4 6-membered rings, is called Stone–Wales defect [27]. Parallel to the theoretical calculations an experimental study has been performed [26]. Using our low-energy electron microscopy (LEEM)/photoemission electron microscopy (PEEM) instrument [28, 29] we have studied the temporal behavior of the low-energy electron diffraction (LEED) pattern as a function of temperature. Figure 7 shows on the left the LEED patterns of the crystalline and the vitreous phases. On the right, the temperature and time dependent normalized intensity of the (0,0) reflex during the transformation are displayed [26]. The normalization factor is the difference of reflectivities, before and after the transformation. Both, data for measurements in ultrahigh vacuum, as well as under an oxygen pressure are presented, and, based on those data, Arrhenius plots are produced. From the slope an apparent activation energy of 4.1–4.2 eV may be deduced. This value is fully consistent with the predicted activation energy for the rate determining step for the defect formation on the metal supported silica film by theory.

STM image of co-existing crystalline and vitreous regions in the bilayer film. a Color coded ring sizes as given in the figure. b Counting rings of different sizes per slice, where the slice is defined as the area covered by 1 row of 6-membered rings on the left of the figure from top to bottom. c Probability of finding 6-membered rings per slice going from left to right in the STM image [26]

Results of density functional theory (DFT) calculations [26]. The shown structures in a are associated with the energies marked in the energy diagram in b. b Potential energy diagram as function of the reaction coordinate with marked bilayer arrangements 1, 2, 3, intermediate states I1, I2, I3, as well as the transition states TS1 through TS4. The black line corresponds to the bilayer silica film without a substrate, and the red line with a metal substrate [26]

Set of experimental data derived from the LEEM study of the thermal transformation of the crystalline into a vitreous silica bilayer film. Top left: LEED pattern of the crystalline film (left) and the vitreous film; Top and bottom right: Normalized intensity of the (0,0) reflex as a function of time while the system is heated to the given temperatures (color coded), (top right) in an oxygen ambient, and (bottom right) in ultrahigh vacuum; Bottom left: Arrhenius plot derived from the two data sets shown on the right. The apparent activation energy of the process involved are given in eV [26]

Based on this knowledge of the film structure we may now proceed to establish a simple model system to study reactions in confined space. Small molecules, such as H2 may diffuse through the narrow 6-membered ring pores of the crystalline film and reach the interface. The way how the confinement affects H2 adsorption has been addressed in the literature [30]. Given that it is possible to adsorb oxygen atoms at the interface during the preparation procedure, the hydrogen reaching the surface may react with the adsorbed atomic oxygen after dissociation and form water. Since the silica film typically spans across entire substrate terraces that are few 100 nm wide [18], the water then has to desorb through the silica membrane [19]. If we consider the vitreous structure, also reactions involving bigger di- or tri-atomic molecules may be used.

3 Water Formation Under a Bilayer Silica Film

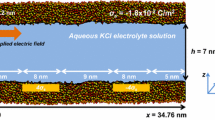

Figure 8 schematically shows the situation we are dealing with: Molecular hydrogen diffuses through the ring openings in the crystalline silica film and reacts with the oxygen adsorbed on the Ru(0001) surface [18, 19]. The reaction is followed using a LEEM/PEEM instrument installed at the Berlin Synchrotron Facility BESSY II, which has been described in detail in the literature [28, 29]. Here we only mention the general experimental set up, which is shown in Fig. 9. The sample may be probed either with synchrotron radiation or by scattering electrons, which are generated by an electron source and guided to the sample via an electron guide set up. Either the electrons, emitted via ionization by the synchrotron radiation, or the scattered electrons are then guided into an aberration correcting mirror, transferred to an electron analyzer, where the electron energy is selected, and the spatial distribution is visualized on a projector screen. This set up allows to record videos to follow the spatial progress of the reaction [18, 19]. For further information on LEEM, see also Refs. [31,32,33,34].

Schematic structure of the system investigated. The bilayer silica film is shown as red (oxygen) and yellow (silicon) spheres. The Ru(0001) surface as grey spheres. Oxygen adsorbed on the metal surface are shown as red spheres and their concentration varies as the reaction proceeds. 3O represents the highest concentration of oxygen atoms per unit cell, 1O and 2O represent less oxygen coverages correspondingly. The micrograph shown on top represents the oxygen coverage, as will be discussed below (dark: oxygen free, bright: oxygen rich) [20]

Schematic representation of the LEEM/XPEEM instrument operated at BESSY II. The various components are indicated [29]

Figure 10a shows a set of electron scattering (LEEM) micrographs, where the field of view is divided into a darker and a brighter region. As time progresses, the dark area covers the entire field of view. Stopping the reaction at a given time, allows us to take X-ray photoelectron spectra (XPS) using synchrotron radiation, and identify the chemical constitution of the surface, comparing the dark and the bright area. In Fig. 10b the O1s XPS spectra comparing both areas are displayed, indicating that in the bright area there is oxygen adsorbed on the Ru surface as shown by the small peak around 529 eV binding energy, while in the dark area this oxygen feature is missing. The intense oxygen derived peak around 532 eV in both areas, of course, stems from the oxygen in silica film. The XPS Si 2P spectra are consistent with this observation. The small shift of 0.5 eV is due to the change in work-function between the oxygen rich and oxygen poor area, and is the reason why electron scattering leads to intensity differences between the two areas. Obviously, the movement of the dark area across the screen represents a reaction front, which removes the oxygen adsorbed on the Ru surface. In order to understand how such a reaction front occurs, we have to consider the oxygen coverage in more detail. There are a number of ordered atomic oxygen structures on Ru(0001), which may be identified via LEED patterns. The silica bilayer film is usually prepared by evaporation of Si in an oxygen atmosphere, which leaves the highest coverage 3O(2 × 2)/Ru(0001) on the surface. It has been proven early on, that on this structure molecular hydrogen cannot dissociate, as hydrogen needs two adjacent adsorption sites, and thus water formation is not possible. However, this is only true if the high oxygen coverage is continuous across the entire surface. Realistically, however, there are defect areas in such an oxygen layer, where the coverage is lower, and, there molecular hydrogen may dissociate and induce water formation. As water formation progresses, more oxygen is removed and a reaction front is induced, which moves across the surface, leaving an oxygen free surface behind. This phenomenon leads to the observed intensity contrast in Fig. 10. The time dependence of the intensity in the micrograph is therefore a measure for the progress of the reaction at a given temperature. Figure 11a shows such a data set recorded for different temperatures. This transforms into an Arrhenius plot of the reaction velocity against inverse temperature. Figure 11b compares the data for the crystalline silica film, the vitreous film and the water formation at the Ru(0001) surface without the silica film coverage. It should be mentioned that the latter reaction had been studied in the past using temperature programmed desorption data by the group of Dietrich Menzel. The data in Fig. 11b allow us to deduce the apparent activation energy for the water formation reaction. The results from the present study are collected in Fig. 11b. The difference between the reaction confined by a crystalline silica film and the vitreous film are marginal (0.32 eV and 0.27 eV), while with respect to the value measured for the reaction without confinement (0.59 eV), the activation energy is reduced by close to a factor of 2. It should be noted, that equivalent data for the non-confined reaction had been reported before by the Menzel group [35]. Such a decrease of the apparent activation energy in confinement against the non-confined reaction is typically connected with a change in the reaction mechanism towards a diffusion-controlled reaction. The similarity of the values between crystalline and vitreous film cover is indicative that the larger ring openings in the vitreous film do not influence the reaction considerably.

a Set of LEEM micrographs taken in 10 s steps during the water formation reaction, acquired with the LEEM/PEEM setup described in Ref. [18]. Annealing in 1 × 10–6 mbar H2 at 550 K. Ekin = 14 eV. On the right a micrograph is shown where the oxygen coverage is indicated. b Two sets of XPS spectra taken in the range of O1s ionizations and Si2p ionizations. The black lines are spectra taken in the area indicated as O-rich, and the red lines are taken in the area indicated as oxygen-poor [18]

a Intensity of the micrographs as a function of time for different temperatures between 550 and 661 K for crystalline bilayer film. b Arrhenius plots derived from the data in a and equivalent data for a vitreous film, as well as the apparent activation energies derived from those data on the left of b. This may be compared with the equivalent analysis for the reaction without confinement [20]

4 Theoretical Studies on Water Formation and Kinetic Analysis

In order to understand the observation in greater detail, a theoretical effort has been started to try to simulate a reaction mechanism based on detailed density functional calculations. The four elementary reaction steps for water formation are shown as Eqs. 1–4, and identifies the reaction constants k1 through k4 [19]. Figure 12 shows an energy diagram including those for three situations; i.e. the non-confined reaction, the confined reaction for the crystalline film cover,

assuming the layer is fixed during all reaction steps, and allowing the film to adopt to different oxygen coverages during reaction. The solid lines refer to the pure electronic energy values, the broken lines to the Gibbs Free Energy calculated at 500 K taking hydrogen in the gas-phase as reference. The black lines refer to the reaction on the open Ru(0001) surface, the blue line to the confined space reaction with a constrained silica layer, and the red line to the confined space reaction with optimized silica layer positions. Obviously, optimizing the silica layer position considerably affects the energy landscape. In addition, the schematic shows the various steps, starting with hydrogen adsorption for an oxygen coverage (2O) initially, and the oxygen free surface (black) up to reaction coordinate 12 and (1O) and the oxygen free surface past reaction coordinate 12, as well as the reaction steps following according to the reaction equations as numbered. As hydrogen cannot assume its most stable adsorption position after dissociation, the reaction profile on the 2O surface is considerably less exothermic. It is interesting to note that the rate determining step, i.e. the OH formation, with the highest activation energy, does not change comparing the free Ru(0001) surface and the confined space reaction. This hints to the fact that, different from transition state effects observed in zeolites, where the formation of transition state complexes is responsible for the changes in reactivity [36,37,38], other steps of the reaction must be rate determining. Water formation and water desorption are considerably affected by the confinement, and, in fact, depending as strongly on whether the silica bilayer remains fixed in space or is allowed to optimize its position with respect to the oxygen covered Ru(0001) surface. Based on the observations and calculations, we may explain the dark and the bright regions observed in connection with the reaction front as follows: The bright region corresponds to a fully oxygen covered (3O) surface, the dark area to a less oxygen covered (1O) surface with a coverage of 0.25 monolayers of oxygen. The hydrogen only dissociates on the dark area and has to diffuse to a region with higher oxygen coverage. This is where the water formation occurs and the reaction front progresses.

Energy diagrams of the water formation reaction for the non-confined reaction (black), and the confined reaction with a fixed silica film (blue) and with tuned silica film position with respect to the metal surface. The full lines refer to the pure electronic energy, and the broken lines to the Gibbs Free Energy at 500 K [19]

In order to proceed towards a kinetic modelling of the reaction, we consider the four elementary reactions summarized in Eqs. 1–4, as well as the diffusion of hydrogen atoms on the surface. The diffusion of OH and water on the surface can be excluded due to the high diffusion barriers, as revealed by the electronic structure calculations. Also, based on the theoretical results we calculate the kinetic constants utilizing the transition state theory, and the Eyring equation. A set of differential equations has been set up to describe the spatio-temporal dependence of the surface concentrations, where the only diffusion process considered is the one for hydrogen atoms. Figure 13 compares concentration profiles for the three cases considered, i.e. the uncovered surface, the surface covered with a fixed silica bilayer, and the surface covered with a silica bilayer that is tuned in its position depending on the oxygen concentration. Hydrogen, oxygen, hydroxyl and water concentrations are given, and it is obvious, that in all cases a reaction front forms based on the kinetic model. When the front velocities are calculated based on this model it is apparent, that the front moves faster for the open reaction in comparison to the confined reaction. The reaction profiles tell us, that the active area of water production is in the region of the moving front, where the hydroxyl and water concentrations are maximal. The analysis indicates that only those hydrogen atoms getting close to the reaction front border may propagate the reaction. Of course, the used model has limitations, as we assume a hydrogen diffusion coefficient, which is independent of the oxygen coverage. This needs to be studied further. We come to the following overall picture: There are two important steps to explain the observed front movement. Those are the dissociative adsorption of hydrogen, and the reaction of hydrogen with oxygen to form hydroxyls. All following steps are faster and do not limit the reaction rates. An analysis of the effective rate of adsorption, i.e. how fast an active site can be refilled with hydrogen once desorption has taken place, which range between 10–15 m2/s for the bare metal surface and 10−23 m2/s for the confined and those are compared with the reaction constant for OH formation (10−16 m2/s), the limitation of the reaction under confinement by hydrogen becomes obvious. There is, however, another important aspect that needs further studies: The position of the bilayer silica film has, according to the theoretical studies, a strong influence on the last reaction step responsible for the addition of hydrogen to form water.

Results of the numerical calculations on concentration profiles of Hads, Oads, OHads, and H2Oads for the water formation reaction obtained from the numerical simulations on a bare Ru(0001), b in confinement under a constrained SiO2 crystalline bilayer, and c in confinement under an optimized SiO2 crystalline bilayer at 500 K [19]

5 Structure Determination

The question arising at this point is: Are there any direct experimental indications that the position of the bilayer depends on the oxygen coverage at the surface? Since those data had been missing so far, the question triggered a LEED I/V to explicitly determine the structure of the bilayer system [39]. Parallel to the measurements and its evaluation, calculations on the metal supported silica bilayer have been performed, in order to evaluate the energy differences between structures, where the silica film has been moved parallel to the metal surface, depending on the oxygen coverage on the Ru(0001) surface. As demonstrated in [39] there are directions across the surface of a 3ORu(0001) surface, where the activation energy to shift the film parallel to the surface is only of the order of 0.5 eV. This is another indication, that the assumption to be dealing with static structure is probably not appropriate. This becomes evident when we look at the results of the LEED I/V studies [39]. Note, that the quality of agreement between calculation of the diffraction intensities as a function of electron energy and the experimental observations is measured by the so-called Pendry-R-factor, varying between 1 (no correlation) and 0 (complete agreement). The LEED data were taken on a silica bilayer grown on a formally fully oxygen covered (3O) Ru(0001) surface, using a standard LEED system, as well as the numerical data analysis are collected in Fig. 14. Figure 14b compares the calculated intensities as a function of electron energy for various diffraction peaks with the experimental data. Figure 14a shows a collection of several results, where single structures and mixed structures are compared. The structure based on the most stable structure, where the bilayer silica film is placed on a 3O/Ru(0001) surface with oxygen atoms in hcp threefold hollow sites, an R-factor of 0.55 is found, which is far away from an acceptable value. It turns out, that it is only possible to reach an acceptable agreement between experiment and calculations, if a number of structures are combined. An acceptable value should be below 0.2. The optimal solution is shown in Fig. 15. The main component is still the most stable structure, but shifted components have to be included. The latter are connected with the most stable structure by shifting this structure along the low energy paths. This is in line with our preliminary conclusions derived from the kinetic studies of water formation in confined space, where the comparison of the experimental data with calculations indicated that the structure adapts to the oxygen coverage.

a Summary of calculated Pendry R-factors for a variety of structural models. b Comparison of measured LEED I/V curves in comparison to the calculated ones, for the best fit. The graphs have been reproduced with permission from [39]

Schematic representation of those structures contributing to the best LEED I/V simulation with a Pendry R-factor of 0.16. The models have been reproduced with permission from [39]

It should be clear that this is not a unique solution but a possible one. The pros and cons are discussed in [39], see also Refs. [40, 41]. Another example in the literature, where a similar situation has been accounted is given in Ref. [42].

Besides the importance for the structure determination, interfacial oxygen is relevant for reactions in the confined space between the silica film and the underlying substrate, as discussed above. While STM measurements are mostly sensitive to the top surface layer, literature also reports on sample systems of graphene, bi- and tri-layer insulating films where the underlying substrate contributes to the STM imaging contrast [43,44,45].

Also, sublayer oxide structures are revealed depending on the scan parameters and the sample temperature [46, 47]. Depending on these parameters, the interfacial oxygen may be accessible with STM. Therefore, STM can potentially contribute to reveal dynamics related to reactions in confined space. In recent work, we focused on capturing dynamics in these oxygen adlayers on Ru(0001). For this purpose, we increased the frame rate of our STM using a spiral scan approach.

Figure 16 shows the schematic raster scan pattern conventionally used in STM in comparison to our spiral approach to fast STM.

Comparison of raster and spiral scans on oxygen adlayers on Ru(0001). a, b Schematic of the raster and the spiral scan geometry, respectively. Yellow and red triangles represent data acquisition points and indicate the scan direction as a function of time (Adapted from Ref. [48]). c, d Atomically resolved STM images of O(2 × 2)/Ru(0001) (Adapted from Ref. [49]) (VS = 1 V, IT = 1.4 nA, T = 300 K, scan area = 5 nm × 5 nm). The raster image in c was acquired in 100 s while the spiral image in d was acquired in 50 ms. e, f STM images of O(2 × 1)/Ru(0001) (Adapted from Ref. [50]) (VS = 0.6 V, IT = 1.4 nA, T = 300 K, scan area = 9 nm × 9 nm). The raster image in e was acquired in 100 s while the spiral image in f was acquired in 33 ms

The atomically resolved O(2 × 2) structure and the O(2 × 1) structure are shown acquired in both conventional raster mode and in high-speed spiral mode. Spiral images are acquired in quasi-constant height mode. The data acquisition is approximately 3000 times faster than in conventional raster mode.

In Fig. 17, the silica bilayer is shown measured with conventional STM and spiral STM.

Resolved atomic network structure of the silica bilayer by raster and spiral STM. a, b Crystalline domain of the silica bilayer imaged by raster and spiral STM with the superimposed hexagonal network structure. b Is the average of ten consecutive frames, each acquired in 50 ms. c, d Vitreous domain of the silica bilayer imaged by raster and spiral STM with indicated domain orientations. d Is the average of 20 consecutive frames, each acquired in 50 ms (VS = 1.6 V, IT = 1 nA, T = 300 K, scan area = 5 nm × 5 nm)

The crystalline and the vitreous domains are imaged. In future studies, we will focus on dynamics related to the supported silica bilayer and verify whether dynamics in the interfacial region are accessible with STM.

6 Summary, Conclusion and Perspective

We have investigated water formation within the confined space between a bilayer silica film and an oxygen covered Ru(0001) surface, employing a XPEEM/LEEM system, to analyze the temperature dependence of the reaction front, in order to determine the apparent activation energy, in direct comparison to the same reaction without confinement. It turns out that the activation energy in confinement is only half of the one observed without confinement, which has also been discussed in the literature in connection with diffusion control [51, 52]. A kinetic study, based on theoretical calculations and modelling of the kinetic constants and the spatio-temporal dependences of surface concentrations, reveals, that it is the hydrogen diffusion between oxygen free areas at the surface, where the hydrogen dissociation reaction has taken place, and areas with high oxygen coverage, in order to propagate the reaction, which is the rate determining process, as opposed to the reaction on the open surface. On the latter, OH formation, as the elementary reaction step with the highest activation energy, is the rate determining transition step. In case of the confined system this step remains the one with the highest activation energy, but it does not control the overall kinetics. The theoretical calculations reveal, that during the reaction the bilayer silica film shifts parallel to the surface as the reaction proceeds, and the oxygen coverage varies. Those theoretical indications triggered an experimental LEED I/V study on the structure of the film to determine all structural parameters in detail. The outcome showed, that, indeed, the structure of the film cannot be described by a single fixed structure, but rather only by a superposition of several structures. Only by considering a superposition are we able to obtain a reasonable Pendry R-factor. Conceptually, this result is consistent with observations made earlier for layered compounds, where for a long time it had been assumed, that the layers are stacked in a fixed geometry. However, recently, it has become obvious that the stacking is statistical, i.e. the layers are slightly shifted with respect to each other statistically to the left and the right [53]. For graphene on nickel, the coexistence of two laterally shifted structures with almost identical energies have been reported based on a combination of high-resolution XPS and DFT calculations [42].

In conclusion we may state, that one may contribute substantially to unravel the factors influencing reactions in confined space, given that the samples are designed in such a way that surface science techniques may be applied. In perspective, future studies on the comparison between reaction in confinement with membranes of varying permeability, for example, comparing crystal and vitreous silica bilayers could provide even more new insights. The Altman group [54] established a new possibility to prepare the silica bilayers by atomic layer deposition, that may be removed from the substrate rather easily, and used to prepare free standing membranes, and also be used to prepare new stacked layered materials.

References

Ertl G (2008) Reactions at surfaces: from atoms to complexity (Nobel Lecture). Angew Chem Int Ed 47(19):3524–3535

Freund HJ (2010) Model studies in heterogeneous catalysis. Chem Eur J 16(31):9384–9397. https://doi.org/10.1002/chem.201001724

Pacchioni G, Freund H-J (2018) Controlling the charge state of supported nanoparticles in catalysis: lessons from model systems. Chem Soc Rev 47(22):8474–8502. https://doi.org/10.1039/C8CS00152A

Freund H-J, Heyde M, Kuhlenbeck H, Nilius N, Risse T, Schauermann S, Schmidt T, Shaikhutdinov S, Sterrer M (2020) Thin oxide films as model systems for heterogeneous catalysts. In: Rocca M, Rahman TS, Vattuone L (eds) Springer handbook of surface science. Springer International Publishing, Cham, pp 267–328. https://doi.org/10.1007/978-3-030-46906-1_10

Freund H-J (2017) Models for heterogeneous catalysts: studies at the atomic level. Rend Fis Acc 28(1):5–18. https://doi.org/10.1007/s12210-016-0560-4

Sauer J, Freund H-J (2015) Models in catalysis. Catal Lett 145(1):109–125. https://doi.org/10.1007/s10562-014-1387-1

Bäumer M, Freund H-J (1999) Metal deposits on well-ordered oxide films. Progr Surf Sci 61:127–198

Wu Z, Plucienik A, Liu Y, Naschitzki M, Wachsmann W, Gewinner S, Schöllkopf W, Kuhlenbeck H, Freund H-J (2018) Surface action spectroscopy with rare gas messenger atoms. Rev Sci Instrum 89(8):083107. https://doi.org/10.1063/1.5045324

Liu Y, Wu Z, Kuhlenbeck H, Freund H-J (2021) Surface action spectroscopy: a review and a perspective on a new technique to study vibrations at surfaces. Chem Rec 21(6):1270–1283. https://doi.org/10.1002/tcr.202000111

Cejka J, Corma A, Zones S (eds) (2010) Zeolites and catalysis: synthesis, reactions and applications, vol 1. Wiley-VCH Verlag GmbH & Co. KG, Weinheim

Deng H, Grunder S, Cordova KE, Valente C, Furukawa H, Hmadeh M, Gándara F, Whalley AC, Liu Z, Asahina S, Kazumori H, O’Keeffe M, Terasaki O, Stoddart JF, Yaghi OM (2012) Large-pore apertures in a series of metal-organic frameworks. Science 336(6084):1018–1023. https://doi.org/10.1126/science.1220131

Fu Q, Bao X (2017) Surface chemistry and catalysis confined under two-dimensional materials. Chem Soc Rev 46(7):1842–1874. https://doi.org/10.1039/C6CS00424E

Li H, Xiao J, Fu Q, Bao X (2017) Confined catalysis under two-dimensional materials. PNAS 114(23):5930–5934. https://doi.org/10.1073/pnas.1701280114

Miners SA, Rance GA, Khlobystov AN (2013) Regioselective control of aromatic halogenation reactions in carbon nanotube nanoreactors. Chem Commun 49(49):5586–5588. https://doi.org/10.1039/C3CC42414F

Pascua L, Stavale F, Nilius N, Freund H-J (2014) Autocatalytic growth of ZnO nanorods from flat Au(111)-supported ZnO films. Phys Chem Chem Phys 16(48):26741–26745. https://doi.org/10.1039/C4CP03730H

Loeffler D, Uhlrich JJ, Baron M, Yang B, Yu X, Lichtenstein L, Heinke L, Büchner C, Heyde M, Shaikhutdinov S, Freund HJ, Wlstrokodarczyk R, Sierka M, Sauer J (2010) Growth and structure of crystalline silica sheet on Ru(0001). Phys Rev Lett 105(14):146104

Zhang Y, Fu Q, Cui Y, Mu R, Jin L, Bao X (2013) Enhanced reactivity of graphene wrinkles and their function as nanosized gas inlets for reactions under graphene. Phys Chem Chem Phys 15(43):19042–19048. https://doi.org/10.1039/C3CP52115J

Prieto MJ, Klemm HW, Xiong F, Gottlob DM, Menzel D, Schmidt T, Freund H-J (2018) Water formation under silica thin films: real-time observation of a chemical reaction in a physically confined space. Angew Chem Int Ed 57(28):8749–8753. https://doi.org/10.1002/anie.201802000

Prieto MJ, Mullan T, Schlutow M, Gottlob DM, Tănase LC, Menzel D, Sauer J, Usvyat D, Schmidt T, Freund H-J (2021) Insights into reaction kinetics in confined space: real time observation of water formation under a silica cover. J Am Chem Soc 143(23):8780–8790. https://doi.org/10.1021/jacs.1c03197

Zhong J-Q, Freund H-J (2022) Two-dimensional ultrathin silica films. Chem Rev 122(13):11172–11246. https://doi.org/10.1021/acs.chemrev.1c00995

Yang B, Kaden WE, Yu X, Boscoboinik JA, Martynova Y, Lichtenstein L, Heyde M, Sterrer M, Włodarczyk R, Sierka M, Sauer J, Shaikhutdinov S, Freund H-J (2012) Thin silica films on Ru(0001): monolayer, bilayer and three-dimensional networks of [SiO4] tetrahedra. Phys Chem Chem Phys 14(32):11344–11351. https://doi.org/10.1039/C2CP41355H

Büchner C, Lichtenstein L, Yu X, Boscoboinik JA, Yang B, Kaden WE, Heyde M, Shaikhutdinov SK, Włodarczyk R, Sierka M, Sauer J, Freund H-J (2014) Ultrathin silica films: the atomic structure of two-dimensional crystals and glasses. Chem Eur J 20(30):9176–9183. https://doi.org/10.1002/chem.201402452

Lichtenstein L, Heyde M, Freund H-J (2012) Atomic arrangement in two-dimensional silica: from crystalline to vitreous structures. J Phys Chem C 116(38):20426–20432. https://doi.org/10.1021/jp3062866

Zachariasen WH (1932) The atomic arrangement in glass. J Am Chem Soc 54(10):3841–3851. https://doi.org/10.1021/ja01349a006

Lichtenstein L, Heyde M, Freund H-J (2012) Crystalline-vitreous interface in two dimensional silica. Phys Rev Lett 109(10):106101

Klemm HW, Prieto MJ, Xiong F, Hassine GB, Heyde M, Menzel D, Sierka M, Schmidt T, Freund H-J (2020) A silica bilayer supported on Ru(0001): following the crystalline-to vitreous transformation in real time with spectro-microscopy. Angew Chem Int Ed 59(26):10587–10593. https://doi.org/10.1002/anie.202002514

Stone AJ, Wales DJ (1986) Theoretical studies of icosahedral C60 and some related species. Chem Phys Lett 128(5):501–503. https://doi.org/10.1016/0009-2614(86)80661-3

Wichtendahl R, Fink R, Kuhlenbeck H, Preikszas D, Rose H, Spehr R, Hartel P, Engel W, Schlögl R, Freund H-J, Bradshaw AM, Lilienkamp G, Schmidt T, Bauer E, Benner G, Umbach E (1998) SMART: an aberration-corrected XPEEM/LEEM with energy filter. Surf Rev Lett 5(6):1249–1256

Schmidt T, Groh U, Fink R, Umbach E, Schaff O, Engel W, Richter B, Kuhlenbeck H, Schlögl R, Freund HJ, Bradshaw AM, Preikszas D, Hartel P, Spehr R, Rose H, Lilienkamp G, Bauer ED, Benner G (2002) XPEEM with energy-filtering: advantages and first results from the SMART project. Surf Rev Lett 9(1):223–232

Hacarlioglu P, Lee D, Gibbs GV, Oyama ST (2008) Activation energies for permeation of He and H2 through silica membranes: an ab initio calculation study. J Membr Sci 313(1):277–283. https://doi.org/10.1016/j.memsci.2008.01.018

Bauer E (2014) Surface microscopy with low energy electrons. Springer, New York, Heidelberg, Dordrecht, London. https://doi.org/10.1007/978-1-4939-0935-3

Bauer E (1994) Low energy electron microscopy. Rep Progr Phys 57(9):895–938. https://doi.org/10.1088/0034-4885/57/9/002

Flege JI, Krasovskii EE (2014) Intensity–voltage low-energy electron microscopy for functional materials characterization. Physica Status Solidi RRL 8(6):463–477. https://doi.org/10.1002/pssr.201409102

Krasovskii EE, Höcker J, Falta J, Flege JI (2015) Surface resonances in electron reflection from overlayers. J Phys Condens Matter 27(3):035501. https://doi.org/10.1088/0953-8984/27/3/035501

Koch MH, Jakob P, Menzel D (1996) The influence of steps on the water-formation reaction on Ru(001). Surf Sci 367(3):293–306. https://doi.org/10.1016/S0039-6028(96)00811-4

Gounder R, Iglesia E (2012) The roles of entropy and enthalpy in stabilizing ion-pairs at transition states in zeolite acid catalysis. Acc Chem Res 45(2):229–238. https://doi.org/10.1021/ar200138n

Jones AJ, Zones SI, Iglesia E (2014) Implications of transition state confinement within small voids for acid catalysis. J Phys Chem C 118(31):17787–17800. https://doi.org/10.1021/jp5050095

Gallego EM, Portilla MT, Paris C, León-Escamilla A, Boronat M, Moliner M, Corma A (2017) “Ab initio” synthesis of zeolites for preestablished catalytic reactions. Science 355(6329):1051–1054. https://doi.org/10.1126/science.aal0121

Soares E, Paier J, Gura L, Burson KM, Ryczek C, Yang Z, Stavale F, Heyde M, Freund H-J (2022) Structure and registry of the silica bilayer film on Ru(0001) as viewed by LEED and DFT. Phys Chem Chem Phys. https://doi.org/10.1039/D2CP04624E

Parreiras DE, Soares EA, Abreu GJP, Bueno TEP, Fernandes WP, de Carvalho VE, Carara SS, Chacham H, Paniago R (2014) Graphene/Ni(111) surface structure probed by low-energy electron diffraction, photoelectron diffraction, and first-principles calculations. Phys Rev B 90(15):155454. https://doi.org/10.1103/PhysRevB.90.155454

Soares EA, Van Hove MA, Walters CF, McCarty KF (2002) Structure of the α−Al2O3(0001) surface from low-energy electron diffraction: Al termination and evidence for anomalously large thermal vibrations. Phys Rev B 65(19):195405. https://doi.org/10.1103/PhysRevB.65.195405

Zhao W, Kozlov SM, Höfert O, Gotterbarm K, Lorenz MPA, Viñes F, Papp C, Görling A, Steinrück H-P (2011) Graphene on Ni(111): coexistence of different surface structures. J Phys Chem Lett 2(7):759–764. https://doi.org/10.1021/jz200043p

Nie S, Bartelt NC, Wofford JM, Dubon OD, McCarty KF, Thürmer K (2012) Scanning tunneling microscopy study of graphene on Au(111): growth mechanisms and substrate interactions. Phys Rev B 85(20):205406. https://doi.org/10.1103/PhysRevB.85.205406

Rossel F, Pivetta M, Patthey F, Ćavar E, Seitsonen AP, Schneider W-D (2011) Growth and characterization of fullerene nanocrystals on NaCl/Au(111). Phys Rev B 84(7):075426. https://doi.org/10.1103/PhysRevB.84.075426

Lauwaet K, Schouteden K, Janssens E, Van Haesendonck C, Lievens P, Trioni MI, Giordano L, Pacchioni G (2012) Resolving all atoms of an alkali halide via nanomodulation of the thin NaCl film surface using the Au(111) reconstruction. Phys Rev B 85(24):245440. https://doi.org/10.1103/PhysRevB.85.245440

Kresse G, Schmid M, Napetschnig E, Shishkin M, Köhler L, Varga P (2005) Structure of the ultrathin aluminum oxide film on NiAl(110). Science 308:1440–1442

Schmid M, Shishkin M, Kresse G, Napetschnig E, Varga P, Kulawik M, Nilius N, Rust HP, Freund HJ (2006) Oxygen-deficient line defects in an ultrathin aluminum oxide film. Phys Rev Lett. https://doi.org/10.1103/PhysRevLett.97.046101

Gura L, Yang Z, Brinker M, Kalaß F, Kirstaedter W, Marschalik P, Junkes H, Heyde M, Freund H-J (2021) Spiral high-speed scanning tunneling microscopy: tracking atomic diffusion on the millisecond timescale. Appl Phys Lett 119(25):251601. https://doi.org/10.1063/5.0071340

Gura L, Yang Z, Paier J, Kalaß F, Brinker M, Junkes H, Heyde M, Freund H-J (2022) Resolving atomic diffusion in Ru(0001)−O(2×2) with spiral high-speed scanning tunneling microscopy. Phys Rev B 105(3):035411. https://doi.org/10.1103/PhysRevB.105.035411

Gura L, Yang Z, Paier J, Kalaß F, Brinker M, Junkes H, Heyde M, Freund H-J (2022) Dynamics in the O(2 × 1) adlayer on Ru(0001): bridging timescales from milliseconds to minutes by scanning tunneling microscopy. Phys Chem Chem Phys 24(25):15265–15270. https://doi.org/10.1039/D2CP02363F

Levenspiel O (ed) (1999) Chemical reaction engineering, 3rd edn. Wiley, New York

Fogler HS (ed) (1999) Elements of chemical reaction engineering, 3rd edn. Prentice-Hall of India, New Jersey

Zhang Y, Položij M, Heine T (2022) Statistical representation of stacking disorder in layered covalent organic frameworks. Chem Mater 34(5):2376–2381. https://doi.org/10.1021/acs.chemmater.1c04365

Hutchings GS, Shen X, Zhou C, Dementyev P, Naberezhnyi D, Ennen I, Hütten A, Doudin N, Hsu JH, Fishman ZS, Schwarz UD, Hu S, Altman EI (2022) Scalable production of single 2D van der Waals layers through atomic layer deposition: bilayer silica on metal foils and films. 2D Materials 9(2):021003. https://doi.org/10.1088/2053-1583/ac5005

Acknowledgements

We acknowledge Shamil Shaikhutdinov, Markus Heyde, Thomas Schmidt and Mauricio J. Prieto as well as other members of the former Chemical Physics Department of the Fritz-Haber-Institute for their valuable contributions to the research discussed in the present work. HJF acknowledges support through an Emeritus Group by the Max-Planck Society.

Funding

Open Access funding enabled and organized by Projekt DEAL.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Gura, L., Soares, E.A., Paier, J. et al. Models for Reactions in Confined Space: Can Surface Science Contribute? A Review and Perspective. Top Catal 66, 1073–1086 (2023). https://doi.org/10.1007/s11244-023-01787-7

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11244-023-01787-7