Abstract

Understanding how hydrotreating oxygen-containing compounds together with nitrogen-containing compounds affects the reactivity and selectivity is relevant for processing renewable feedstocks. In this work, competitive hydrodeoxygenation (HDO) and hydrodenitrogenation (HDN) reactions were studied by co-hydrotreating palmitic acid (C16 acid) and tetradecylamine (C14 amine) over a Pt/ZrO2 catalyst in a batch reactor. HDO proceeded faster than HDN in the studied system, and the deoxygenation reactions were found to have an inhibitory effect on HDN. Co-hydrotreating the C16 acid and the C14 amine expanded the reaction network from the individual HDO and HDN networks and changed the prevailing reaction pathways, initially in favor of oxygen removal. The formation of heavy secondary amides and amines through condensation reactions became increasingly favored as the share of C16 acid in the feed increased. For a given conversion level, the condensation product selectivity was observed to increase as the reaction temperature was decreased, whereas increasing the reaction temperature promoted the formation of the desired paraffins. This work described the ease of HDO compared to HDN, the role of condensation reactions in the co-hydrotreating reaction network, and the inhibitory effect on HDN thereof.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Transport-related greenhouse gas emissions need to be reduced to mitigate global warming [1]. While electrification plays a key part in achieving zero-emission targets, high energy-density liquid fuels remain required to power existing fleet, heavy-duty transport sectors and the aviation industry [2]. Hydrotreatment is commercially used to produce paraffinic diesel out of renewable, biobased feedstock [3,4,5]. Major research efforts have been devoted towards hydrodeoxygenation (HDO) in the past years, as the main target in hydrotreating renewable feedstocks is to reduce their oxygen content [6,7,8,9]. Some biobased feedstocks, such as waste animal fats and algae biocrudes, additionally contain nitrogen in the form of e.g. alkyl amines, fatty amides and heterocyclic aromatics [10,11,12,13,14,15]. Since nitrogen-containing compounds influence the fuel stability and cause NOx emissions upon combustion, the nitrogen content of the feedstock must be reduced in parallel with the oxygen content [16].

Noble metal catalysts are an option to commercially used transition metal sulfide catalysts for the hydrotreatment of renewable, sulfur-free feedstocks [12, 17,18,19]. Noble metals, active in their reduced state, are known to display excellent hydrogenation and deoxygenation activities. While hydrogen dissociation and C-C bond scission are catalyzed by the noble metal, the catalytic selectivity can be influenced and the activity enhanced, by pairing the noble metal with a suitable support [17, 20, 21]. For example, Lewis acidic supports with oxygen vacancies catalyze the reduction of carboxylic acids and aldehydes, whereas supports with Brønsted acid sites introduce activity for reactions that involve dehydration steps [17, 20,21,22]. Platinum- and palladium-based catalysts have been studied extensively for the hydrotreatment of fatty acids [22,23,24,25]. Supported platinum catalysts display high activity towards Cn−1 paraffin formation through decarbonylation and decarboxylation, but can also catalyze the formation of Cn paraffins through HDO, i.e. a series of consecutive dehydration and hydrogenation reactions [22,23,24,25]. Mechanistic differences between the three HDO pathways have been discussed elsewhere [21, 26].

Metals of the platinum group are also known to be active for hydrodenitrogenation (HDN) [27, 28]. In the hydrotreatment of alkyl amines, reduced platinum is known to catalyze C-N bond hydrogenolysis and di-alkylamine, i.e. secondary amine, formation [27, 28]. In their review article on catalytic HDN of petroleum, Furimsky and Massoth [16] noted that significant secondary amine formation has been reported in alkylamine HDN studies over reduced metal catalysts. The formation of secondary amines as primary products was suggested to indicate that SN2 reactions with amines as bases may play a key part in the overall HDN mechanism [16]. Cattenot et al. [28] evaluated platinum catalysts supported on ZrO2, Al2O3 and SiO2-Al2O3 in the HDN of n-pentylamine, tert-pentylamine and neo-pentylamine, in the presence of H2S. They identified Pt/ZrO2 as the most active catalyst, yielding secondary amines and hydrocarbons [28]. In their methylamine HDN study, Meitzner et al. [27] similarly found Pt/SiO2 to produce both dimethylamine and methane, with a molar dimethylamine to methane ratio of 3, at conversion levels below 5%.

While HDO and HDN have been studied separately, information on how co-hydrotreating oxygen-containing and nitrogen-containing compounds affects the reaction network, is sparse. Based on separate HDN and HDO studies over noble metal catalysts, with the former reporting heavy secondary amine formation, and the latter describing excellent deoxygenation activity and high hydrocarbon selectivity, it can be hypothesized for HDO to proceed faster than HDN. The effect of oxygen-containing compounds on HDN, or nitrogen-containing compounds on HDO, has however not been described before. With previous work on competitive heteroatom removal centering around competitive hydrodesulfurization (HDS) and HDN, and competitive HDS and HDO, an information gap for competitive HDO and HDN remains [29,30,31,32,33,34,35].

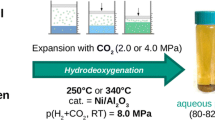

In this article, competitive HDO and HDN reactions were studied by co-hydrotreating palmitic acid (C16 acid, C16H32O2) and tetradecylamine (C14 amine, C14H31N) in a batch reactor, over a Pt/ZrO2 catalyst. The C16 acid was chosen as the oxygen-containing model compound due to the prevalence of triglycerides, and consequently fatty acids, in renewable feedstocks [18, 24, 36]. The C14 amine was selected as the nitrogen-containing compound, as amines also are found in nature and can be expected to be formed as intermediates in the hydrotreatment of other nitrogen-containing compounds [10, 12]. Different carbon chain lengths were chosen to enable following paraffin- and condensation product formation from each model compound more accurately.

The aim of the study was to describe how co-hydrotreating the C16 acid and C14 amine affects the heteroatom removal and to identify how the co-hydrotreatment reaction network differs from the individual HDO and HDN reaction networks. The purpose of the experiments was to study the relative reactivity of the compounds and to investigate the feed composition dependency of the reactivity, selectivity and prevailing heteroatom removal pathways. Furthermore, the effect of the reaction conditions on the reactivity and selectivity was studied. To our knowledge, this study describes the nature of competitive HDO and HDN reactions for the first time, for model compounds relevant to renewables refining.

2 Experimental

2.1 Materials

Monoclinic zirconia (ZrO2) from Saint-Gobain Norpro (SZ 31164) was used as the catalyst support, while platinum (IV) nitrate solution (15 wt% Pt) from Alfa Aesar was used as the metal precursor.

For the reactor experiments and product analytics, the following chemicals were used: tetradecylamine (> 95%, Sigma Aldrich), palmitic acid (> 98%, Riedel de Haën), n-pentadecane (> 99%, Aldrich), n-hexadecane (> 99%, Sigma Aldrich), hexadecanal (> 97%, Tokyo Chemical Industry), 1-hexadecanol (96%, Acros Organics), hexadecylamine (> 95%, Tokyo Chemical Industry), palmityl palmitate (> 99%, Sigma Aldrich), decalin (decahydronaphthalene, anhydrous, mixture of cis and trans, > 99%, Sigma Aldrich), n-dodecane (> 99%, Merck) and 2-propanol (> 99%, Riedel de Haën). All chemicals were used without further purification.

The hydrogen used for the reactor experiments was from Woikoski (99.999%). The nitrogen (99.999%) and helium (99.999%) used for physisorption measurements, and the 2 vol% H2/Ar (99.999%/99.999%) gas mixture used in the CO pulse titration measurement were obtained from Oy AGA Ab. The 10 vol% CO/He (99.999%/99.999%) gas mixture used for CO pulse titration was from Woikoski. The gases used for the product analytics; synthetic air (99.999%), He (99.999%), H2 (99.999%), Ar (99.999%) and O2 (99.999%), were obtained from AGA and Woikoski.

2.2 Catalyst Preparation

The Pt/ZrO2 catalyst was prepared with a vacuum impregnation method using a small excess of metal precursor solution. The ZrO2-support was crushed and sieved to a particle size of 0.25–0.42 mm, and calcined in ambient air at 600 °C in a static muffle furnace for 10 h prior to impregnation.

The impregnation was made as follows. Approximately 2.5 g of calcined ZrO2 was placed to a 100 ml round-bottom flask and dried at 60 °C under vacuum in a rotary evaporator for 90 min. The aqueous platinum precursor solution was prepared with type 1 ultrapure water, targeting a Pt loading of 1 wt%. The total volume of the impregnation solution corresponded to 4 times the support pore volume. The precursor solution was introduced dropwise to the support under vacuum at room temperature, while stirring at 120 rpm. The stirring was maintained for 2 h, allowing the excess liquid to slowly evaporate. The next day, the catalyst was dried under vacuum, first at 40 °C for 60 min and then at 60 °C for 30 min.

The catalyst was calcined in a flow through calcination oven under 100 ml/min synthetic air flow at 450 °C for 1 h, using a 2 °C/min heating ramp.

2.3 Catalyst Characterization

2.3.1 N2 Physisorption

A Surfer equipment by Thermo Scientific was used to carry out isothermal nitrogen physisorption at -196 °C for approximately 200 mg samples of the Pt/ZrO2 catalyst and the ZrO2 support, respectively. Liquid nitrogen was used as a coolant. Prior to analysis, the samples were degassed in vacuum at 350 °C for 180 min, using a 5 °C/min heating rate. A dead volume calibration was carried out with helium after the measurements. The specific surface area SBET (m2/g) was calculated from the adsorption isotherm with the Brunauer-Emmett-Teller (BET) method [37]. The Barrett-Joyner-Halenda (BJH) method was used for calculating the pore size distribution, mean pore diameter dpore (nm) and pore volume Vpore (cm3/g) from the desorption branch [38].

2.3.2 CO Pulse Titration

A CO pulse titration was carried out for a 100 mg sample of the Pt/ZrO2 catalyst, in order to estimate the dispersion D (%) and platinum particle size dPt, CO ads (nm). The measurement was carried out in an AMI-200R flow-through equipment (Altamira Instruments), connected to a Pfeiffer OmniStar mass spectrometer (MS). Prior to the titration, the sample was dried at 200 °C in helium for 120 min, reduced at 350 °C in 2 vol% H2/Ar for 60 min, cooled down to 50 °C and flushed for 60 min in helium. Next, 25 pulses of 5 vol% CO/He, 0.505 ml each, were introduced to the sample with 5-minute intervals, while monitoring the composition of the gas flow with the MS (m/z 44 for CO2, 28 for CO and 18 for H2O). The temperature of the equipment lines and pulse loop was 100 °C. The carrier gas flow was maintained at 50 ml/min (STP) throughout the measurement. The dispersion and platinum particle size were estimated from the CO uptake, assuming spherical platinum particles and an adsorption stoichiometry of 1, using the relations presented in the Handbook of Heterogeneous Catalysis [39].

2.3.3 Scanning Transmission Electron Microscopy

Scanning transmission electron microscopy (STEM) was used to estimate the particle size distribution and mean platinum particle size dPt, STEM (nm) of the catalyst. A JEOL JEM-220FS high resolution electron microscope with 200 kV acceleration voltage was used. The diameter of 200 particles was measured using the ImageJ software.

2.3.4 X-ray Fluorescence

A semi-quantitative estimation of the active metal loading was obtained with X-ray fluorescence (XRF). A wavelength dispersive PANalytical Axios mAx equipment was used for the measurement. For the analysis, a catalyst sample of approximately 200 mg was ground and placed to a sample cup with a 21 mm diameter, covered with 3.6 μm thick mylar film. The measurement was conducted in helium.

2.4 Catalytic Activity Tests

The catalytic activity tests were carried out in a 100 ml high-pressure Hastelloy batch reactor by Parr Instrument Co, equipped with a heated feed vessel. The experimental conditions were chosen based on preliminary experiments. The catalyst was first dried in-situ at 180 °C under 10 bar of N2 for 60 min, and reduced at 350 °C under 20 bar of H2 for 60 min. The catalyst weight varied from 14 to 80 mg depending on the feed composition, targeting a batch residence time of 0.39 gcath/greactants for the 60 min benchmark experiments. In this work, batch residence time, τ (gcath/greactants), is defined as the mass of catalyst multiplied by reaction time and divided by mass of reactants.

The feed mixtures were prepared by dissolving 37 mg of tetradecylamine and varying amounts of palmitic acid to 31 ml of decalin, targeting an initial nitrogen concentration of 80 ppm. The mixture was heated to approximately 100 °C under stirring to ensure complete dissolution of the reactants, and a 1 ml zero-sample was taken for analysis.

The feed mixture was released through the feed vessel to the reactor, which had been heated to the reaction temperature, most commonly 300 °C. The reactor was pressurized with H2, typically to 80 bar, and stirring at 600 rpm was initiated, which marked the onset of the reaction time. Once the reaction time had elapsed, heating and stirring was stopped and the reactor was cooled down with ice. The reaction time ranged from 15 to 300 min, with 60 min used for the benchmark experiments.

A set of control experiments was carried out for mixtures of tetradecylamine and palmitic acid with 80 ppm of nitrogen and 80 ppm of oxygen. These included a thermal test without catalyst, an experiment with the bare ZrO2 support, and experiments stirring at 200 rpm and 1000 rpm instead of 600 rpm, to ensure the absence of external diffusion limitations. An experiment with 80 ppm of nitrogen and 80 ppm of oxygen, using tetradecylamine and 1-hexadecanol as reactants was additionally done. The repeatability of the experiments was confirmed by conducting repetition experiments for the pure tetradecylamine mixture and some of the different feed ratios. The product distributions of the control experiments are presented in Fig. S1 of the Online Resource, whereas the product distributions of the repetition experiments are presented in Fig. S2 of the Online Resource. In this work, the product distribution is defined as presented in Eq. (1),

where ci is the molar share of compound i in the reaction products (mol %), ni is the amount of compound i in the reaction products (mol) and nreactants is the total amount of reactants in the feed (mol). The product distributions presented in this work also include the unreacted reactants.

2.5 Product Analytics

Prior analysis, the product and reaction mixture samples (1 ml) were finalized by the addition of 0.18 ml of a second solvent (2-propanol) and 60 µl of the internal standard (n-dodecane). The second solvent was needed to avoid precipitation of the reactants and some products.

2.5.1 Identification of Liquid Products

The products were identified with gas chromatography-mass spectrometry (GC-MS), using a Shimadzu QP2010SE device equipped with a HP1 column (60 m × 0.25 mm × 1 μm). Several programs were used.

2.5.2 Quantification of Liquid Products

Quantification of the liquid products was done with an Agilent 7890 gas chromatograph (GC), equipped with an Agilent J&W HP1-MS column (60 m × 0.25 mm × 0.25 μm). The column outlet was split to a flame ionization detector (FID) and a nitrogen phosphorus detector (NPD).

The inlet temperature and the temperature of both the FID and the NPD was 325 °C. An injection volume of 2 µl and a split ratio of 5:1 was used. The analysis program started at a 3 min hold at 80 °C, from where the temperature, with a ramp of 20 °C/min, first was elevated to 100 °C and then held for 3 min. The temperature was next elevated to 160 °C with a ramp of 10 °C/min, and from there to 325 °C with a ramp of 20 °C/min, where a final 20 min hold took place.

Weight-based FID response factors, relative to the internal standard n-dodecane, for n-pentadecane, n-hexadecane, tetradecylamine, hexadecylamine, 1-hexadecanol and palmitic acid were determined experimentally. The response factors for n-tetradecane, 1-tetradecanol, methyl palmitate, tetradecyl tetradecylamine, tetradecyl hexadecylamine, hexadecyl hexadecylamine, hexadecyl palmitate and tetradecyl hexadecanamide were estimated using their combustion enthalpy, following the procedure presented by de Saint Laumer et al. [40]. The carbon balances of all hydrotreating experiments are presented in Tables S1-S6 of the Online Resource. The carbon balance was calculated with Eq. (2),

where Bc is the carbon balance (%), nC, products is the amount of quantified carbon in the product mixture, including unreacted reactants (mol), and nC, reactants is the amount of quantified carbon in the feed mixture (mol).

2.5.3 Total Nitrogen Content Analysis

The total nitrogen content of the feed and reaction products was analyzed with an AntekPAC ElemeNtS analyser, calibrated with standard calibration solutions (AC Analytical Controls BV) for nitrogen contents between 0 and 1000 ppm. The nitrogen removal was calculated with Eq. (3),

where N-removal denotes the nitrogen removal (%), cN, products is the nitrogen content of the products (ppm) and cN, feed is the nitrogen content of the feed (ppm).

3 Results and Discussion

3.1 Catalyst Preparation and Characterization

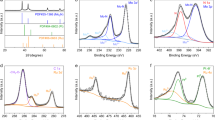

Table 1 displays characterization data for the Pt/ZrO2 catalyst and the ZrO2 support. A semi-quantitative platinum loading of 0.7 wt% was measured with XRF. The specific surface area, pore volume, mean pore diameter and pore size distribution of the catalyst were similar to those of the support, suggesting that impregnation of the active metal did not alter the porous properties of the support much. The physisorption isotherms and pore size distribution of the Pt/ZrO2 catalyst and the ZrO2 support are presented in Fig. S3 of the Online Resource. The CO pulse titration indicated that the catalyst adsorbed 30 µmol/gcat of CO, which corresponds to a mean platinum particle size of 1.9 nm and a dispersion of 59%.

Figure 1a displays the particle size distribution measured for the Pt/ZrO2 catalyst, whereas one of the STEM images taken of the catalyst is presented in Fig. 1b. Based on the STEM images, the size of most platinum particles ranged from 1.3 to 2.3 nm, and the mean platinum particle size was 1.9 nm. The STEM images displayed both regions rich and poor in platinum particles, implying a somewhat uneven distribution.

3.2 Hydrotreating Experiments

3.2.1 Individual Hydrodenitrogenation and Hydrodeoxygenation Experiments

Figure 2 displays the product distribution and nitrogen removal of the individual C14 amine HDN and C16 acid HDO experiments, as well as the C14 amine and C16 acid co-hydrotreating experiments. The carbon balance closure ranged between 91 and 97% (Table S1, Online Resource).

Product distribution of the C14 amine and C16 acid hydrotreating experiments, carried out at 300 °C, 80 bar H2 and batch residence time 0.39 gcath/greactants, ordered by increasing oxygen content in the feed. The nitrogen removal (%) is indicated with white circles. The C14 amine HDN products and reactant are indicated in green shades, the C16 acid HDO products and reactant are colored purple, and products specific to the co-hydrotreating experiments are colored blue

The products of the individual C14 amine HDN benchmark experiment, which was carried out with 80 ppm of nitrogen in the feed at 300 °C, 80 bar H2 and a batch residence time of 0.39 gcath/greactant, consisted of n-tetradecane (C14 paraffin) and n-tetradecyl tetradecylamine (C28 amine). The C14 paraffin yield was approximately 12 mol %, whereas the C28 amine accounted for 7 mol % of the product distribution (Fig. 2). The C14 amine conversion was 37% and a 17% nitrogen removal was measured. Isopropyl tetradecylamine (C17 amine) was additionally found in the product sample, but was not considered to be a true part of the reaction network. The compound was likely formed through the reaction between the C14 amine and an acetone impurity, yielding isopropyl tetradecyl imine, which was rapidly hydrogenated under the used reaction conditions and in the presence of the Pt/ZrO2 catalyst. The acetone residue likely originated from the reactor lines that were washed with acetone after each experiment.

The C16 acid HDO products included n-pentadecane (C15 paraffin), n-hexadecane (C16 paraffin), 1-hexadecanol (C16 alcohol), palmityl palmitate (C32 ester) and methyl palmitate (C17 ester). Hexadecanal (C16 aldehyde), i.e. the primary HDO product of the C16 acid, was not detected in the product sample, likely due to its reactivity in the presence of hydrogen and the Pt/ZrO2 catalyst [22, 41,42,43,44]. The 0.39 gcath/greactant benchmark HDO experiment with 720 ppm of oxygen in the feed, resulted in a conversion of 77% and a combined paraffin yield of 19% (Fig. 2). The C16 alcohol, with a yield of 42%, was the main product, whereas the C16 paraffin was present in a lower concentration than the C15 paraffin (4% vs. 15%).

3.2.2 Co-hydrotreating Experiments

Co-hydrotreating the C16 acid and the C14 amine was observed to expand the reaction network and change the prevailing reaction pathways from the individual HDN and HDO experiments markedly, which was reflected by changes in the conversion and product distribution of both reactants, as well as in the nitrogen removal (Fig. 2). The co-hydrotreating experiments gave all products observed in the individual C16 acid HDO and C14 amine HDN experiments, as well as products originating from reactions between the C14 amine, the C16 acid and the C16 acid-derived oxygenates.

Two condensation products, n-tetradecyl hexadecanamide (C30 amide) and n-tetradecyl hexadecylamine (C30 amine), emerged as important intermediates, together accounting for approximately 7 mol % of the products in the 0.39 gcath/greactant benchmark experiments, for a wide range of feed compositions. Additionally, 1-tetradecanol (C14 alcohol) and hexadecylamine (C16 amine) were found in the reaction products. These may have been formed through the decomposition of the C30 condensation products. Amination of the C16 alcohol might also explain the presence of the C16 amine [45]. Furthermore, traces of n-hexadecyl hexadecanamide (C32 amide) and n-hexadecyl hexadecylamine (C32 amine) were identified, originating from condensation reactions between the C16 amine and C16 oxygenates.

The ratio between C15 and C16 paraffins was found to vary in the experiments depending on the C16 acid conversion, the concentration of other intermediates, but also on the absolute amount of acid in the feed (Fig. 2). The ratio of C15 to C16 paraffins in the product samples increased with the initial C16 acid concentration in the feed. The higher the initial C16 acid concentration was, the more C16 alcohol, but less C16 paraffin was obtained. The C16 alcohol is an intermediate in the formation of the C16 paraffin from the C16 acid, whereas the C15 paraffin is formed directly from the C16 acid through decarboxylation, or through decarbonylation of the reactive C16 aldehyde [21, 26]. The relatively low C16 paraffin concentration, and thus elevated ratio of C15 to C16 paraffin, could potentially be explained by competitive adsorption phenomena between the C16 acid and the C16 alcohol [44].

The ZrO2 support test (Online Resource, Fig. S1), carried out for a C16 acid and C14 amine mixture with 80 ppm of oxygen and 80 ppm of nitrogen in the feed, gave C16 aldehyde and C30 amide. The products of the support test also included a compound that was not detected in the Pt/ZrO2 experiments, proposed to be n-tetradecyl hexadecyl imine (C30 imine), formed from the C16 aldehyde and the C14 amine. As with the C16 aldehyde, the C30 imine was presumably hydrogenated to C30 amine in the presence of Pt/ZrO2. No paraffins, C14 or C16 alcohol, C16 amine or secondary C28, C30 and C32 amines were detected from the ZrO2 support experiment. The C16 aldehyde formation is in line with literature, as oxygen vacancies of ZrO2 are known to be active in the reduction of carboxylic acids to aldehydes [46, 47].

3.2.3 Effect of the Feed Composition on the Reactivity and Product Selectivity

Figures 3a-d display the reactant conversions (a), the paraffin yields originating from the C16 acid and the C14 amine (b), the nitrogen removal relative to the C14 amine conversion (c) and amount of the C30 condensation products (d), as a function of the molar fraction of the C16 acid in the feed (xacid).

The reactant conversions (a), paraffin yields originating from the C16 acid and the C14 amine (b), the nitrogen removal relative to amine conversion (c), and the amount of C30 condensation products (d), as a function of the molar fraction of C16 acid in the reactive feed (C14 amine, C16 acid). The experiments were carried out at 300 °C, 80 bar H2, and at τ = 0.39 gcath/greactants

The C16 acid was more reactive than the C14 amine, with the C16 acid conversion exceeding the C14 amine conversion for any given feed composition, as displayed in Fig. 3a. The lowest C16 acid conversion was recorded in the individual C16 acid experiment, where no competitive adsorption with the C14 amine occurred. The C16 acid conversion systematically increased as its fraction in the feed decreased, reaching 93% in the experiment where the C16 acid accounted for 20 mol % of the feed.

The effect of the feed composition on the C14 amine conversion was more pronounced than for the C16 acid (Fig. 3a). Similarly to the C16 acid, the lowest C14 amine conversion, 37%, was recorded in the individual C14 amine HDN experiment. As the initial C16 acid concentration was increased, the C14 amine conversion started increasing, eventually reaching 73% at 80 mol % C16 acid. The differences in the reactivity were accompanied by a switch in selectivity, away from HDN and towards the formation of the C30 condensation products, enabled by the presence of the C16 acid and the acid-derived C16 alcohol intermediate.

Figure 3b displays the C14 amine-originating paraffin yield and the combined yield of C16 acid-originating paraffins as a function of the feed composition. The relative ease of HDO compared to HDN is further evident from the C16 acid-originating paraffin yield, which consistently exceeded the C14 amine-originating paraffin yield by approximately 10 percentage points. The yield of C15 and C16 paraffins followed the same trend as the C16 acid conversion and kept increasing as the fraction of C16 acid in the feed was decreased. The C14 paraffin yield remained stable, around 12%, throughout the studied feed composition range, despite a monotonically decreasing nitrogen removal (Fig. 2). This suggests that an increasing share of the C14 paraffin was formed through pathways that retained the nitrogen, in experiments with relatively high initial C16 acid concentrations. Such pathways could be related to the decomposition of the C30 condensation products.

Figure 3c displays the nitrogen removal relative to the C14 amine conversion as a function of the feed composition, thus expressing the fraction of the reacted C14 amine that underwent HDN. The metric linearly decreased as the C16 acid content of the feed increased, as a result of the simultaneously increasing C14 amine conversion and decreasing nitrogen removal. With 80 mol % C16 acid in the feed, a modest 3% of the reacting C14 amine underwent HDN, compared to 45% in the individual C14 amine experiment. The behavior reflects the C14 amine preferentially participating in condensation reactions instead of undergoing HDN, which further is evident from Fig. 3d, where the molar fraction of C30 condensation products is presented as a function of the feed composition.

The amount of condensation products remained stable for feed compositions that exceeded approximately 40 mol % of C16 acid (Fig. 3d), which indicates that relatively larger shares of the C14 amine kept being consumed for the formation of the C30 amide and the C30 amine. In other words, the higher the initial C16 acid concentration was, the more the C14 amine HDN was impeded by preferential condensation product formation. This finding may be of importance for some real feeds, where the nitrogen content is significantly lower than the oxygen content. The share of C30 condensation products for the experiment with 20 mol % C16 acid and 80 mol % C14 amine, was considerably lower compared to the opposite experiment with 80 mol % C16 acid and 20 mol % C14 amine, which hints that the selectivity of the reactions of the C16 acid were not affected by the C14 amine to quite the same extent as the other way around.

Another nitrogen-containing condensation product, the C28 amine, was formed through self-condensation of the C14 amine, even with no oxygenates in the system [16, 27, 28, 48]. The formation of the C14 alcohol however enabled another, although due to its low concentration likely a less significant, formation pathway for the C28 amine in the co-hydrotreating experiments. Multiple formation pathways were additionally identified for the C30 amine. Therefore, the most preferred secondary amine formation pathway could not be deduced by comparing the shares of C28 and C30 amines in the product distributions. Based on the co-hydrotreating product distributions (Fig. 2), it however seems that the C30 condensation products were formed with a higher selectivity than the C28 amine. In terms of heteroatom removal, the formation of the C28 amine from C14 amine self-condensation results in the loss of one molecule of ammonia, while a water molecule is cut in the formation of the C30 amide and amine, retaining the nitrogen. In other words, the formation of the C30 intermediates changed the prevailing oxygen- and nitrogen removal pathways, initially for the benefit of the oxygen removal. The C30 condensation products therefore played a key part in the reaction network, affecting both the HDN and HDO rates and distinguishing the reaction network from those of the individual compounds.

It should be noted that the initial C16 acid concentration on its own affected both the C16 acid conversion and the C16 acid-related product distribution, as explained by the law of mass action. For example, an individual C16 acid HDO experiment with 80 ppm of oxygen in the feed, presented in Fig. 4, gave a conversion 15 percentage points lower and a paraffin yield 5 percentage points lower than the individual C16 acid HDO experiment with 720 ppm of oxygen. The co-hydrotreating experiment with 80 ppm of oxygen and 80 ppm of nitrogen in the feed, resulted in a C16 acid conversion 13 percentage points higher and a paraffin yield 7 percentage points higher, than the individual acid HDO experiment with 720 ppm of oxygen in the feed. In other words, the effect of increasing the C16 acid concentration in individual C16 acid HDO experiments, was the opposite to the trend that emerged from the co-hydrotreating experiments, where the highest conversion and paraffin yields were recorded in the experiment where the initial C16 acid concentration was the lowest.

3.2.4 Effect of the Reaction time

The temporal evolution of the intermediates and the final product distribution was studied by carrying out experiments with different batch residence times. The experiments were conducted for the mixture with 80 ppm of both oxygen and nitrogen in the feed, which corresponds to 30 mol % C16 acid and 70 mol % C14 amine. Batch residence times ranging from 0.1 to 2.7 gcath/greactants were evaluated, with the 60 min benchmark experiment with 21 mg of catalyst corresponding to 0.39 gcath/greactants. Figure 5 displays the product distribution as a function of batch residence time. For clarity, compounds that contributed less than 2 mol % towards the product distribution throughout all batch residence time points were left out of the graph (C14 alcohol, C16 amine, C32 ester, C32 amine). The carbon balance closure ranged between 91 and 98% (Table S2, Online Resource).

The data presented in Fig. 5 has been broken up to smaller units in Figs. 6a-e. The panels highlight the differences in reactivity, account for the different molar amounts of reactant in the feed and emphasize the temporal evolution of key intermediates.

C16 acid-related product distribution (a), C14 amine-related product distribution (b), C14 amine and C16 acid conversions (c), C14 amine- and C16 acid-originating paraffin yields and nitrogen removal (d), and concentration of condensation products (e), obtained from hydrotreating the C14 amine and C16 acid mixture with 80 ppm of oxygen and 80 ppm of nitrogen for batch residence times between 0.1 and 2.7 gcath/greactants. The data is from the same experiments as in Fig. 5

Figures 6a and b display the product distributions of the HDO- and HDN-related intermediates, respectively. The C16 alcohol, mainly formed through hydrogenation of the reactive C16 aldehyde, reached its maximum concentration already by batch residence time point 0.20 gcath/greactants (Fig. 6a). The rapid rise of the C16 alcohol concentration suggests that the HDO of the C16 acid to the C16 aldehyde, at least to some extent catalyzed by the ZrO2 support (Fig. S1, Online Resource), was the initially dominating reaction in the co-hydrotreating system. After batch residence time point 0.20 gcath/greactants, the net consumption of the C16 alcohol towards the C16 paraffin and C30 amine exceeded its net formation. The formation of the C30 amine from the C16 alcohol and the C14 amine was confirmed from a co-hydrotreating experiment with C16 alcohol and C14 amine in the feed (Fig. S1, Online Resource), where the C30 amide and C30 imine pathways were unavailable due to the absence of the C16 acid and the C16 aldehyde. The pathway is also established in literature [48].

The C15 and C16 paraffins were initially formed at a similar rate (Fig. 6a). After batch residence time 0.20 gcath/greactants, the C16 paraffin concentration steeply increased, while the C15 paraffin formation first slowed down, and then stopped after batch residence time 1.2 gcath/greactants. The stabilization of the C15 paraffin yield coincides with the complete consumption of the C16 acid, implying the absence of other significant formation pathways than decarboxylation of the C16 acid and decarbonylation of the C16 aldehyde. The C16 paraffin, formed from the C16 alcohol and C30 condensation products, emerged as the dominant C16 acid-originating final product, with a C16 to C15 paraffin ratio of approximately 5 measured for the last time point. The HDO of the C16 alcohol to the C16 paraffin may have proceeded through dehydration to the C16 olefin and subsequent hydrogenation, or direct C-O bond hydrogenolysis [21, 41, 49]. The mechanism could not be deduced with certainty from the product distribution, as the absence of the C16 olefin was expected due to the used H2 pressure and hydrogenation activity of the Pt/ZrO2 catalyst [17, 18, 20].

The C32 ester was not a significant product for the feed composition the time series experiments were conducted for. This could be because there were not many batch residence time points, where both the C16 alcohol and C16 acid would have been present in high enough concentrations to promote the esterification reaction. The C32 ester was more prominent for feed compositions with a higher initial C16 acid concentration (Fig. 2). In said experiments, the reactions of the C16 acid proceeded slower (Fig. 3a), expanding the batch residence time-window where the C16 acid and the C16 alcohol were readily present simultaneously.

The initial importance of the condensation reactions in the co-hydrotreating experiments is highlighted in Fig. 6b. The combined concentration of nitrogen-containing condensation products (C28 amine, C30 amine, C30 amide) exceeded the C14 paraffin concentration until batch residence time point 0.39 gcath/greactants, after which the condensation product concentration first stabilized, and then started decreasing, while the C14 paraffin concentration steadily increased. The changes in the C14 amine concentration were rather small during the last batch residence time points, which partly can be explained by its consumption towards HDN being balanced out by its re-formation from the condensation products.

The differences in the C14 amine and C16 acid reactivity and accumulation of the final products are visualized in Figs. 6c and d, respectively. The C16 acid conversion remained higher than the C14 amine conversion throughout all batch residence time points (Fig. 6c). The difference between the C14 amine and the C16 acid conversion was the largest around batch residence time points 0.20 and 0.39 gcath/greactants, after of which the C14 amine conversion started catching up, as the C16 acid conversion approached 100%. The conversion differences during the first batch residence time points highlight the ease of the C16 aldehyde formation and removal of the first oxygen atom of the C16 acid. The C14 amine conversion hovered around 85% for the last time points.

The C16 acid- and C14 amine-originating paraffin yields, presented as a function of batch residence time in Fig. 6d, provide another means for comparing the progression of HDO and HDN. The nitrogen removal measured for each batch residence time point has additionally been indicated in the graph. The combined C15 and C16 paraffin yield systematically exceeded the C14 paraffin yield, even for the highest batch residence time points. It is worthwhile to note that both the C16 acid- and C14 amine-originating paraffin yields kept increasing throughout the studied batch residence times, despite the stabilization of the reactant conversions and the consumption of the intermediates, potentially pointing towards the presence and decomposition of heavy, nonvolatile compounds that could not be detected by GC-FID. Such compounds could be e.g. tertiary amines, formed from the secondary amines and alcohols in the system [45, 48, 50]. The nitrogen removal correlated well with the C14 paraffin yield, which highlights the role of the C14 paraffin as the true HDN product of the system. As noted earlier, this was not the case for all feed ratios, where the C30 condensation products were more significant (Fig. 3d-c).

A closer look on the nitrogen-containing condensation products of the system is provided in Fig. 6e. It should be noted that the relative concentrations of the nitrogen-containing condensation products depend on the feed composition, as presented in Fig. 3. The initial formation rate of the C30 amide appeared similar to that of the C28 and C30 amines, but slowed down rapidly, limited by the availability of the C16 acid. The maximum concentration of the C30 amide was reached by batch residence time point 0.39 gcath/greactants, and by batch residence time point 1.21 gcath/greactants, no C30 amide could be detected from the product mixtures anymore. The decomposition of the C30 amide was assumed to proceed through the C30 amine [51].

The overall shapes of the C28 and C30 amine product distribution curves were strikingly similar, despite different prevailing formation pathways (Fig. 6e). The net formation of both secondary amines exceeded their net decomposition until batch residence time point 0.78 gcath/greactants, which was followed by decomposition at similar rates. The C28 and C30 amines thus appeared equally reactive, as expected given their structural similarity. Decomposition may have occurred through hydrogenolysis [51].

The peak C28 and C30 amine concentrations coincided with the consumption of the C16 alcohol and the C30 amide, providing a clear explanation for the C30 amine formation coming to an end. Since plenty of C14 amine remained in the mixture, the reason for the C28 amine net decomposition exceeding the net formation after 0.78 gcath/greactants was not the lack of reactants, potentially pointing towards thermodynamic limitations. The water and ammonia that accumulated in the batch reactor may have shifted equilibrium away from the condensation products. Given the initial ease of C28 amine formation through C14 amine self-condensation, which in the literature has been reported to readily occur over reduced catalysts, it is possible that the prevailing C14 paraffin formation pathway in individual C14 amine HDN, involved the formation and decomposition of the C28 amine (Figs. 2 and 6) [16, 27, 28]. Equilibrium limitations for C28 amine formation could therefore provide an explanation for the stabilization of the C14 amine conversion. Alternatively, competitive adsorption of reaction products on the active sites of the catalyst could be responsible the phenomena. Such products could be water, ammonia or any undetected non-volatile compounds.

3.2.5 Reaction Network

The proposed reaction scheme for co-hydrotreating the C14 amine and the C16 acid, drawn based on the product distributions and findings of the activity tests, and supported by published literature, is presented in Scheme 1. To our knowledge, this is the most extensive reaction network for the co-hydrotreatment of fatty acids and amines proposed to date.

Reaction network for co-hydrotreatment of the C14 amine and C16 acid. The pathways available in the individual C16 acid and C14 amine networks have been indicated with purple and green, respectively, whereas reaction pathways specific for the co-hydrotreatment experiments have been colored blue. For simplicity, the decomposition pathway from the C30 amine to the C14 amine and C16 olefin has been omitted

As indicated in Scheme 1, the reaction pathways of the C16 acid and C14 amine co-hydrotreatment network can be divided to three groups, i.e. reactions that are included in the individual C16 acid HDO network, reactions included in the C14 amine HDN network, and reactions specific to co-hydrotreating the C16 acid and the C14 amine. No such distinctions can be made for the products, as co-hydrotreating the C14 amine and C16 acid introduced new pathways to products that also could be obtained from the individual HDN and HDO experiments.

The reactions related to the formation and decomposition of the secondary C30 amide and C30 amine distinguish the co-hydrotreating network from the individual C16 acid HDO and C14 amine HDN networks. To summarize, a total of four different pathways were identified for the formation of secondary amines: secondary amide HDO, amine self-condensation, condensation of an alcohol and an amine, and imine hydrogenation. Out of these, only the amine self-condensation pathway was available in the individual C14 amine HDN network. The secondary amines were observed to decompose as the reaction proceeded, eventually accounting for a significant share of the produced paraffins.

The secondary amides and amines of the co-hydrotreating network are unacceptable fuel components due to their carbon chain length and nitrogen content. Attention should therefore be paid to the development and use of catalysts capable of efficiently eliminating them. Alternatively, catalysts that suppress their formation could be sought after. In the light of C30 amide and imine formation even on the bare ZrO2 support and considering the trends illustrated in Fig. 3, the prospect of finding such materials should be considered uncertain. Particularly, as the sites of the support which catalyzed some of the condensation reactions, are needed for the desired hydrogenolysis reactions as well [17, 20].

3.2.6 Effect of the Reaction Conditions

The effect of the reaction temperature was studied by conducting activity tests for the mixture with 80 ppm of oxygen and 80 ppm of nitrogen at 270, 300 and 330 °C. The experiments were carried out at 0.39 gcath/greactants. Moreover, a longer 0.88 gcath/greactants experiment was done at 270 °C, and a shorter 0.13 gcath/greactants experiment at 330 °C, targeting similar conversion levels as achieved in the 0.39 gcath/greactants benchmark activity test at 300 °C. The product distributions are displayed in Fig. 7. The carbon balance closure was between 88 and 93% (Table S3, Online Resource).

As expected, increasing the temperature substantially increased the conversion and paraffin yield of both reactants, for a given batch residence time. For a given conversion level, subtle selectivity differences were additionally observed between the different reaction temperatures. The condensation product selectivity was higher at the lower reaction temperature, whereas a higher paraffin selectivity was achieved by increasing the reaction temperature. This can be observed from the product distribution, the nitrogen removal and the C14 amine conversion of the experiments carried out at 270, 300 and 330 °C for batch residence times 0.88, 0.39 and 0.13 gcath/greactants, respectively (Fig. 7). Out of the three experiments, the experiment at 270 °C had the highest C14 amine conversion and the most C28 and C30 condensation products, but the lowest C14 paraffin yield and lowest nitrogen removal. The experiment at 330 °C, which had the lowest C14 amine conversion and the least C28 and C30 condensation products, had the highest paraffin yield and nitrogen removal. Particularly the C30 amide appeared to be reactive at 330 °C, with none detected even at 0.13 gcath/greactants.

At 270 °C, the C16 acid conversion exceeded 80% at 0.39 gcath/greactants and was complete at 0.88 gcath/greactants. The formation of the C16 alcohol, likely through the C16 aldehyde, seemed to proceed readily at 270 °C. As discussed in Sect. 3.2.4, the C16 alcohol is eventually converted to the C16 paraffin, both directly and through the decomposition of the C30 condensation products. Therefore, a longer batch residence time increases the selectivity towards the C16 paraffin. Comparing the product distributions of the experiments with complete C16 acid conversion at 270 and 330 °C, revealed that a higher temperature favored the formation of the C15 paraffin through decarbonylation of the C16 aldehyde or decarboxylation of the C16 acid, leading to a higher ratio of C15 to C16 paraffins. The observed temperature-dependency of the distribution between C15 and C16 paraffins is in line with literature [21]. The HDN of the C14 amine and HDO of the C16 alcohol were affected by the temperature increase and decrease in a similar way.

HDO of vegetable oils and fatty acids has often been carried out at temperatures between 200 and 300 °C in literature [17,18,19]. Due to the increased condensation product selectivity, lowering the temperature from 300 °C did not emerge as an attractive option for the co-hydrotreatment of the C14 amine and the C16 acid.

The 80 bar H2 pressure used throughout this work was chosen to keep the solvent and products in the liquid phase, and to ensure the sufficient availability of hydrogen for all experiments, including those with the highest initial C16 acid concentrations. To confirm the suitability of the used H2 pressure, activity tests were carried out at 300 °C with 60 and 100 bar H2 for mixtures with 80 ppm of oxygen and 80 ppm of nitrogen, using the same 0.39 gcath/greactants benchmark time as for the feed-composition experiments. The experiments with 60 and 80 bar H2 resulted in product distributions that were the same within experimental variation, whereas the experiment with 100 bar H2 resulted in paraffin yields that were a maximum of 5 percentage points higher. The product distributions are displayed in Fig. S4 of the Online Resource.

4 Conclusion

In this work, competitive HDO and HDN reactions in the co-hydrotreatment of the C16 acid and the C14 amine were studied over a Pt/ZrO2 catalyst. The effect of the feed composition and reaction conditions on the reactivity, selectivity and heteroatom removal pathways were investigated, and a reaction network was formulated based on the findings. In general, oxygen removal was found to proceed faster than nitrogen removal in the studied system. Not only was the HDO of the C16 acid faster than the HDN of the C14 amine when the compounds were hydrotreated individually, but the presence of the C16 acid was found to have an inhibitory effect on HDN in the co-hydrotreating experiments. HDN was partly hindered due to the C16 acid simply being more reactive than the C14 amine, but most notably due to the formation of secondary amides and amines through condensation reactions, which preferentially occurred instead of HDN.

The feed composition was observed to affect both the reactivity and selectivity, with the formation of the condensation products introducing oxygen removal pathways specific to the co-hydrotreating experiments, while retaining the nitrogen in the middle of the molecule. The condensation products became increasingly prominent in systems where the initial oxygen content exceeded the nitrogen content, which was reflected in an increasing amine conversion and a lower nitrogen removal. Increasing the reaction temperature mitigated the condensation product formation and increased the paraffin selectivity.

Time-series experiments for co-hydrotreating the C14 amine and the C16 acid revealed that the nitrogen removal started proceeding readily once the C16 acid and the C16 alcohol intermediate had been mostly consumed, i.e. when the factors that inhibited HDN in the first place were eliminated. Still, even by the highest studied batch residence time, neither the C14 amine conversion nor the C14 paraffin yield had caught up with the C16 acid conversion or the combined C15 and C16 paraffin yield. No secondary amides or amines were detected at the highest studied batch residence time, indicating that they can be converted, provided that the residence time is long enough.

The results of this work provided insights into competitive HDO and HDN reactions in the co-hydrotreatment of fatty acids and alkyl amines, and can serve as a basis for further catalyst development. In particular, catalysts active in the HDN of secondary amides and amines, or catalysts capable of mitigating their formation, should be sought after.

References

UNFCC (2015) Paris Agreement. Paris Climate Change Conference – November 2015

Hari TK, Yaakob Z, Binitha NN (2015) Aviation biofuel from renewable resources: routes, opportunities and challenges. Renew Sustainable Energy Rev 42:1234–1244. https://doi.org/10.1016/j.rser.2014.10.095

Neste Corporation Neste My Renewable Diesel (2021) https://www.neste.us/neste-my-renewable-diesel. Accessed 22 Oct 2021

UPM UPM BioVerno fuel for all diesel engines (2021) https://www.upmbiofuels.com/traffic-fuels/upm-bioverno-diesel-for-fuels. Accessed 22 Oct 2021

Berenblyum AS, Danyushevsky VYa, Katsman EA, Podoplelova TA, Flid VR (2010) Production of engine fuels from inedible vegetable oils and fats. Pet Chem 50:305–311. https://doi.org/10.1134/S0965544110040080

Mortensen PM, Grunwaldt J-D, Jensen PA, Knudsen KG, Jensen AD (2011) A review of catalytic upgrading of bio-oil to engine fuels. Appl Catal A 407:1–19. https://doi.org/10.1016/j.apcata.2011.08.046

Šimáček P, Kubička D, Šebor G, Pospíšil M (2009) Hydroprocessed rapeseed oil as a source of hydrocarbon-based biodiesel. Fuel 88:456–460. https://doi.org/10.1016/j.fuel.2008.10.022

Huber GW, O’Connor P, Corma A (2007) Processing biomass in conventional oil refineries: production of high quality diesel by hydrotreating vegetable oils in heavy vacuum oil mixtures. Appl Catal A 329:120–129. https://doi.org/10.1016/j.apcata.2007.07.002

Bu Q, Lei H, Zacher AH, Wang L, Ren S, Liang J, Wei Y, Liu Y, Tang J, Zhang Q, Ruan R (2012) A review of catalytic hydrodeoxygenation of lignin-derived phenols from biomass pyrolysis. Bioresour Technol 124:470–477. https://doi.org/10.1016/j.biortech.2012.08.089

Biller P, Ross AB (2011) Potential yields and properties of oil from the hydrothermal liquefaction of microalgae with different biochemical content. Bioresour Technol 102:215–225. https://doi.org/10.1016/j.biortech.2010.06.028

Madl T, Mittelbach M (2005) Quantification of primary fatty acid amides in commercial tallow and tallow fatty acid methyl esters by HPLC-APCI-MS. Analyst 130:565–570. https://doi.org/10.1039/b415779f

Furimsky E (2013) Hydroprocessing challenges in biofuels production. Catal Today 217:13–56. https://doi.org/10.1016/j.cattod.2012.11.008

Palardy O, Behnke C, Laurens LML (2017) Fatty amide determination in neutral molecular fractions of green crude hydrothermal liquefaction oils from algal biomass. Energy Fuels 31:8275–8282. https://doi.org/10.1021/acs.energyfuels.7b01175

Yang C, Li R, Cui C, Liu S, Qiu Q, Ding Y, Wu Y, Zhang B (2016) Catalytic hydroprocessing of microalgae-derived biofuels: a review. Green Chem 18:3684–3699. https://doi.org/10.1039/C6GC01239F

Chen W-T, Tang L, Qian W, Scheppe K, Nair K, Wu Z, Gai C, Zhang P, Zhang Y (2016) Extract nitrogen-containing compounds in biocrude oil converted from wet biowaste via hydrothermal liquefaction. ACS Sustainable Chem Eng 4:2182–2190. https://doi.org/10.1021/acssuschemeng.5b01645

Furimsky E, Massoth FE (2005) Hydrodenitrogenation of petroleum. Catal Rev Sci Eng 47:297–489. https://doi.org/10.1081/CR-200057492

Marafi M, Furimsky E (2017) Hydroprocessing catalysts containing noble metals: deactivation, regeneration, metals reclamation, and anvironment and safety. Energy Fuels 31:5711–5750. https://doi.org/10.1021/acs.energyfuels.7b00471

Ding S, Parlett CMA, Fan X (2022) Recent developments in multifunctional catalysts for fatty acid hydrodeoxygenation as a route towards biofuels. Mol Catal 523:111492. https://doi.org/10.1016/j.mcat.2021.111492

Li X, Luo X, Jin Y, Li J, Zhang H, Zhang A, Xie J (2018) Heterogeneous sulfur-free hydrodeoxygenation catalysts for selectively upgrading the renewable bio-oils to second generation biofuels. Renew Sustainable Energy Rev 82:3762–3797. https://doi.org/10.1016/j.rser.2017.10.091

Robinson AM, Hensley JE, Medlin JW (2016) Bifunctional catalysts for upgrading of biomass-derived oxygenates: a review. ACS Catal 6:5026–5043. https://doi.org/10.1021/acscatal.6b00923

Rogers KA, Zheng Y (2016) Selective deoxygenation of biomass-derived bio-oils within hydrogen-modest environments: a review and new insights. Chemsuschem 9:1750–1772. https://doi.org/10.1002/cssc.201600144

Peng B, Zhao C, Kasakov S, Foraita S, Lercher J (2013) Manipulating catalytic pathways: Deoxygenation of palmitic acid on multifunctional catalysts. Chem Eur J 19:4732–4741. https://doi.org/10.1002/chem.201203110

Snåre M, Kubičková I, Mäki-Arvela P et al (2006) Heterogeneous catalytic deoxygenation of stearic acid for production of biodiesel. Ind Eng Chem Res 45:5708–5715. https://doi.org/10.1021/ie060334i

Cheah KW, Yusup S, Loy ACM, How BS, Skoulou V, Taylor MJ (2022) Recent advances in the catalytic deoxygenation of plant oils and prototypical fatty acid models compounds: Catalysis, process, and kinetics. Mol Catal 523:111469. https://doi.org/10.1016/j.mcat.2021.111469

Malins K (2021) Synthesis of renewable hydrocarbons from vegetable oil feedstock by hydrotreatment over selective sulfur-free SiO2-Al2O3 supported monometallic Pd, Pt, Ru, Ni, Mo and bimetallic NiMo catalysts. Fuel 285:119129. https://doi.org/10.1016/j.fuel.2020.119129

Kim SK, Han JY, Lee H, Yum T, Kim Y, Kim J (2014) Production of renewable diesel via catalytic deoxygenation of natural triglycerides: Comprehensive understanding of reaction intermediates and hydrocarbons. Appl Energy 116:199–205. https://doi.org/10.1016/j.apenergy.2013.11.062

Meitzner G (1986) Metal-catalyzed reactions of methylamine in the presence of hydrogen. J Catal 98:513–521. https://doi.org/10.1016/0021-9517(86)90339-8

Cattenot M, Peeters E, Geantet C, Devers E, Zotin JL (2005) Mechanism of carbon-nitrogen bond scission in the presence of H2S on Pt supported catalysts. Catal Lett 99:171–176. https://doi.org/10.1007/s10562-005-2110-z

Zepeda TA, Pawelec B, Obeso-Estrella R, Díaz de León JN, Fuentes S, Alonso-Núñez G, Fierro JLG (2016) Competitive HDS and HDN reactions over NiMoS/HMS-Al catalysts: diminishing of the inhibition of HDS reaction by support modification with P. Appl Catal B 180:569–579. https://doi.org/10.1016/j.apcatb.2015.07.013

Zepeda TA, Navarro RM, Huirache-Acuña R, Vazquez-Salas PJ, Alonso-Núñez G, Sánchez-López P, Pawelec B (2021) Positive phosphorous effect during co-processing of pyrolysis bio-oils and S-content model compounds over sulfide NiMo/P/HMS-Al catalysts. Fuel Process. Technol. 211:106599. https://doi.org/10.1016/j.fuproc.2020.106599

Egorova M, Prins R (2004) Competitive hydrodesulfurization of 4,6-dimethyldibenzothiophene, hydrodenitrogenation of 2-methylpyridine, and hydrogenation of naphthalene over sulfided NiMo/γ-Al2O3. J Catal 224:278–287. https://doi.org/10.1016/j.jcat.2004.03.005

Viljava T-R, Krause AOI (1997) Hydrotreating of compounds and mixtures of compounds having mercapto and hydroxyl groups. Stud Surf Sci Catal 106:343–352343. https://doi.org/10.1016/S0167-2991(97)80032-8

Viljava T-R, Krause AOI (1996) Hydrotreating of compounds containing both oxygen and sulfur: effect of para-hydroxyl substituent on the reactions of mercapto and methylmercapto groups. Appl Catal A 145:237–251. https://doi.org/10.1016/0926-860X(96)00139-1

Viljava T-R, Saari ERM, Krause AOI (2001) Simultaneous hydrodesulfurization and hydrodeoxygenation: interactions between mercapto and methoxy groups present in the same or in separate molecules. Appl Catal A 209:33–43. https://doi.org/10.1016/S0926-860X(00)00741-9

Toropainen P, Bredenberg JB (1989) Catalytic hydrogenolysis of heteroatom substituted benzenes. Appl Catal 52:57–68. https://doi.org/10.1016/S0166-9834(00)83372-2

Brännström H, Kumar H, Alén R (2018) Current and potential biofuel production from plant oils. Bioenerg Res 11:592–613. https://doi.org/10.1007/s12155-018-9923-2

Brunauer S, Emmett PH, Teller E (1938) Adsorption of gases in multimolecular layers. J Am Chem Soc 60:309–319. https://doi.org/10.1021/ja01269a023

Barrett EP, Joyner LG, Halenda PP (1951) The determination of pore volume and area distributions in porous substances. I. Computations from nitrogen isotherms. J Am Chem Soc 73:373–380. https://doi.org/10.1021/ja01145a126

Bergeret G, Gallezot P (2008) Particle size and dispersion measurements. Handbook of Heterogeneous Catalysis. John Wiley & Sons, pp 738–765

de Saint Laumer J-Y, Cicchetti E, Merle P, Egger J, Chaintreau A (2010) Quantification in gas chromatography: prediction of flame ionization detector response factors from combustion enthalpies and molecular structures. Anal Chem 82:6457–6462. https://doi.org/10.1021/ac1006574

Kumar P, Yenumala SR, Maity SK, Shee D (2014) Kinetics of hydrodeoxygenation of stearic acid using supported nickel catalysts: effects of supports. Appl Catal A 471:28–38. https://doi.org/10.1016/j.apcata.2013.11.021

Chen J, Xu Q (2016) Hydrodeoxygenation of biodiesel-related fatty acid methyl esters to diesel-range alkanes over zeolite-supported ruthenium catalysts. Catal Sci Technol 6:7239–7251. https://doi.org/10.1039/C6CY01242F

He Z, Wang X (2012) Hydrodeoxygenation of model compounds and catalytic systems for pyrolysis bio-oils upgrading. Catal Sustainable Energy 1:28–52. https://doi.org/10.2478/cse-2012-0004

Poissonnier J, Ranga C, Lødeng R, Thybaut JW (2022) Oxygen functionality and chain length effects in HDO: impact of competitive adsorption on reactivity. Fuel 308:121940. https://doi.org/10.1016/j.fuel.2021.121940

Ruiz D, Aho A, Mäki-Arvela P, Kumar N, Oliva H, Murzin DYu (2017) Direct amination of dodecanol over noble and transition metal supported silica catalysts. Ind Eng Chem Res 56:12878–12887. https://doi.org/10.1021/acs.iecr.7b03580

Foraita S, Fulton JL, Chase ZA, Vjunov A, Xu P, Baráth E, Camaioni DM, Zhao C, Lercher JA (2015) Impact of the oxygen defects and the hydrogen concentration on the surface of tetragonal and monoclinic ZrO2 on the reduction rates of stearic acid on Ni/ZrO2. Chem. Eur J 21:2423–2434. https://doi.org/10.1002/chem.201405312

Pestman R, van Duijne A, Pieterse JAZ, Ponec V (1995) The formation of ketones and aldehydes from carboxylic acids, structure-activity relationship for two competitive reactions. J Mol Catal A Chem 103:175–180. https://doi.org/10.1016/1381-1169(95)00138-7

Salvatore RN, Yoon CH, Jung KW (2001) Synthesis of secondary amines. Tetrahedron 57:7785–7811

Şenol O, Ryymin E-M, Viljava T-R, Krause AOI (2007) Reactions of methyl heptanoate hydrodeoxygenation on sulphided catalysts. J Mol Catal A Chem 268:1–8. https://doi.org/10.1016/j.molcata.2006.12.006

Hamid MHSA, Williams JMJ (2007) Ruthenium-catalysed synthesis of tertiary amines from alcohols. Tetrahedron Lett 48:8263–8265. https://doi.org/10.1016/j.tetlet.2007.09.134

Zhu C, Gutiérrez OY, Santosa DM, Flake M, Weindl R, Kutnyakov I, Shi H, Wang H (2022) Kinetics of nitrogen-, oxygen- and sulfur-containing compounds hydrotreating during co-processing of bio-crude with petroleum stream. Appl Catal B 307:121197. https://doi.org/10.1016/j.apcatb.2022.121197

Acknowledgements

This work used the Aalto University Bioeconomy research infrastructure, Raw materials research infrastructure and OtaNano Nanomicroscopy center research infrastructure. Dr. Hua Jiang is acknowledged for the STEM images.

Funding

This work was carried out for the Neste-Aalto HDN catalyst development project, funded by Neste Corporation.

Open Access funding provided by Aalto University.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Declarations

The authors declare no conflicts of interests.

Supplementary material

The Online Resource contains the product distributions of control experiments and repetition experiments, N2-physisorption isotherms and pore size distribution of the Pt/ZrO2 catalyst and the ZrO2 support, the effect of the H2 pressure in the co-hydrotreatment experiments, and carbon balances of the experiments.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic Supplementary Material

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Verkama, E., Auvinen, P., Albersberger, S. et al. Competitive Hydrodeoxygenation and Hydrodenitrogenation Reactions in the Hydrotreatment of Fatty Acid and Amine Mixtures. Top Catal 66, 1353–1368 (2023). https://doi.org/10.1007/s11244-023-01784-w

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11244-023-01784-w