Abstract

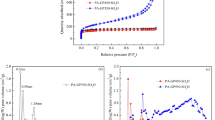

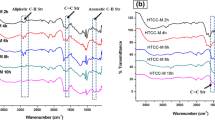

Carbon precursor derived from biomass waste gained significant interest as a component of heterogeneous catalysts that can be functionalized with active groups and provides the advantage of separating the catalyst from reactant and products, unlike common homogeneous catalyst. In this study, palm kernel shell (PKS) based char was developed by pyrolysis and hydrothermal carbonization methods and subsequently utilized for synthesizing bifunctional carbon catalyst. The wet impregnation method by loading K2CO3 and CuO provided bi-functional characteristics to the produced chars for conversion into efficient catalysts, which were suitable for concurrent esterification and transesterification processes. The prepared catalysts were characterized by BET, XRD, FESEM, FTIR, TGA, and CO2/NH3 TPD analysis. The report showed that the sample of hydrothermal-assisted carbonization (HTC) treatment possessed higher surface area (4056 m2/g) due to the steady degradation of lignocellulosic composition, thus improving the porous quality of carbon structure compared to normal pyrolytic carbon (2658 m2/g). Additionally, the PKSHAC@K2CO3-CuO catalyst sample embraced more potent acid-basic properties than PKSAC@K2CO3-CuO, yielding 98.4% and 96.7% of FAME respectively, at optimized reaction conditions, the temperature of 65 °C for 3 h, with 15:1 molar ratio of methanol to WCO with 3 wt% of catalysts loading.The reusability test showed that PKSHAC@K2CO3-CuO could catalyse up to 80.1% of FAME, while PKSAC@K2CO3-CuO recorded a yield of 60.1%. The biodiesel from waste cooking oil was analyzed to meet the ASTM D6751 standard for diesel fuel. The synthesized heterogeneous catalysts using different chars might be widely suitable for low-cost oil feedstocks used for biodiesel production.

Graphical Abstract

Similar content being viewed by others

References

Saini MK, Sharma P, Prasad J, Kothari SL, Gour VS (2019) Quality assessment of oil and biodiesel derived from Balanites aegyptiaca collected from different regions of Rajasthan. Biocatal Agric Biotechnol 22:101374. https://doi.org/10.1016/j.bcab.2019.101374

Syazwani ON, Ibrahim ML, Kanda H, Goto M, Taufiq-yap YH (2017) Esterification of high free fatty acids in supercritical methanol using sulfated angel wing shells as catalyst. J Supercrit Fluids 124:1–9. https://doi.org/10.1016/j.supflu.2017.01.002

Javidialesaadi A, Raeissi S (2013) Biodiesel production from high free fatty acid-content oils: experimental investigation of the pretreatment step. APCBEE Proc 5:474–478. https://doi.org/10.1016/j.apcbee.2013.05.080

Lokman MI, Rashid U, Taufiq-Yap YH (2015) Production of biodiesel from palm fatty acid distillate using sulfonated-glucose solid acid catalyst: characterization and optimization. Chin J Chem Eng 23:1857–1864. https://doi.org/10.1016/j.cjche.2015.07.028

Nayab R, Imran M, Ramzan M, Tariq M, Taj MB, Akhtar MN, Iqbal HMN (2022) Sustainable biodiesel production via catalytic and non-catalytic transesterification of feedstock materials: a review. Fuel 328:125254. https://doi.org/10.1016/j.fuel.2022.125254

Lokman IM, Rashid U, Yunus R, Taufiq-Yap YH (2014) Carbohydrate-derived solid acid catalysts for biodiesel production from low-cost feedstocks: a review. Catal Rev Sci Eng 56:187–219. https://doi.org/10.1080/01614940.2014.891842

Shuit SH, Ng EP, Tan SH (2015) A facile and acid-free approach towards the preparation of sulphonated multi-walled carbon nanotubes as a strong protonic acid catalyst for biodiesel production. J Taiwan Inst Chem Eng 52:100–108. https://doi.org/10.1016/j.jtice.2015.02.018

Vyas AP, Subrahmanyam N, Patel PA (2009) Production of biodiesel through transesterification of Jatropha oil using KNO3/Al2O3 solid catalyst. Fuel 88:625–628. https://doi.org/10.1016/j.fuel.2008.10.033

Ghani N, Iqbal J, Sadaf S, Nawaz Bhatti H, Asgher M (2020) Comparison of photo-esterification capability of bismuth vanadate with reduced graphene oxide bismuth vanadate (RGO/BiVO4) composite for biodiesel production from high free fatty acid containing non-edible oil. ChemistrySelect 5:9245–9253. https://doi.org/10.1002/slct.202001913

Degfie TA, Mamo TT, Mekonnen YS (2019) Optimized biodiesel production from waste cooking oil (WCO) using calcium oxide (CaO) nano-catalyst. Sci Rep 9:1–8. https://doi.org/10.1038/s41598-019-55403-4

Mekhilef S, Siga S, Saidur R (2011) A review on palm oil biodiesel as a source of renewable fuel. Renew Sustain Energy Rev 15:1937–1949. https://doi.org/10.1016/J.RSER.2010.12.012

Farabi MSA, Ibrahim ML, Rashid U, Taufiq-Yap YH (2019) Esterification of palm fatty acid distillate using sulfonated carbon-based catalyst derived from palm kernel shell and bamboo. Energy Convers Manag 181:562–570. https://doi.org/10.1016/j.enconman.2018.12.033

Mohammad Razi MA, Al-Gheethi A, Al-Qaini M, Yousef A (2018) Efficiency of activated carbon from palm kernel shell for treatment of greywater. Arab J Basic Appl Sci 25:103–110. https://doi.org/10.1080/25765299.2018.1514142

Lucian M, Fiori L (2017) Hydrothermal carbonization of waste biomass : cost analysis. Energies. https://doi.org/10.3390/en10020211

Jain A, Balasubramanian R, Srinivasan MP (2016) Hydrothermal conversion of biomass waste to activated carbon with high porosity: a review. Chem Eng J 283:789–805

Nasir S, Hussein MZ, Zainal Z, Yusof NA, Zobir SAM (2018) Electrochemical energy storage potentials of waste biomass: oil palm leaf- And palm kernel shell-derived activated carbons. Energies 11:3410. https://doi.org/10.3390/en11123410

Purnomo CW, Castello D, Fiori L (2018) Granular activated carbon from grape seeds hydrothermal char. Appl Sci 8:1–16. https://doi.org/10.3390/app8030331

MacDermid-Watts K, Pradhan R, Dutta A (2021) Catalytic hydrothermal carbonization treatment of biomass for enhanced activated carbon: a review. Waste Biomass Valoriz 12:2171–2186. https://doi.org/10.1007/s12649-020-01134-x

Visa M, Andronic L, Duta A (2015) Fly ash-TiO2 nanocomposite material for multi-pollutants wastewater treatment. J Environ Manag 150:336–343. https://doi.org/10.1016/j.jenvman.2014.10.026

Chen N, Zhang G, Zhang P, Tao X, Wu Y, Wang S, Nabi M (2019) Rice husk-based solid acid for efficient hydrolysis and saccharification of corncob. Bioresour Technol 292:121915. https://doi.org/10.1016/J.BIORTECH.2019.121915

González-Arias J, Gómez X, González-Castaño M, Sánchez ME, Rosas JG, Cara-Jiménez J (2022) Insights into the product quality and energy requirements for solid biofuel production: a comparison of hydrothermal carbonization, pyrolysis and torrefaction of olive tree pruning. Energy 238:122022. https://doi.org/10.1016/j.energy.2021.122022

Ren J, Cao J-P, Zhao X-Y, Yang F-L, Wei X-Y (2019) Recent advances in syngas production from biomass catalytic gasification: a critical review on reactors, catalysts, catalytic mechanisms and mathematical models. Renew Sustain Energy Rev 116:109426. https://doi.org/10.1016/J.RSER.2019.109426

Rao BVSK, Mouli KC, Rambabu N, Dalai AK, Prasad RBN (2015) Carbon-based solid acid catalyst from de-oiled canola meal for biodiesel production. CATCOM 14:20–26. https://doi.org/10.1016/j.catcom.2011.07.011

Liew RK, Chong MY, Osazuwa OU, Nam WL, Phang XY, Su MH, Cheng CK, Chong CT, Lam SS (2018) Production of activated carbon as catalyst support by microwave pyrolysis of palm kernel shell: a comparative study of chemical versus physical activation. Res Chem Intermed 44:3849–3865. https://doi.org/10.1007/s11164-018-3388-y

Ahmad R, Mohd Ishak MA, Kasim NN, Ismail K (2019) Properties and thermal analysis of upgraded palm kernel shell and Mukah Balingian coal. Energy 167:538–547. https://doi.org/10.1016/j.energy.2018.11.018

Ntenga R, Mfoumou E, Béakou A, Tango M, Kamga J, Ahmed A (2018) Insight on the ultrastructure, physicochemical, thermal characteristics and applications of palm kernel shells. Mater Sci Appl 09:790–811. https://doi.org/10.4236/msa.2018.910057

Azzaz AA, Matei Ghimbeu C, Jellai S, El-Bassi L, Jeguirim M (2022) Olive mill by-products thermochemical conversion via hydrothermal carbonization and slow pyrolysis: detailed comparison between the generated hydrochars and biochars characteristics. Processes 10:231. https://doi.org/10.3390/pr10020231

Kiliç M, Apaydin-Varol E, Pütün AE (2012) Preparation and surface characterization of activated carbons from Euphorbia rigida by chemical activation with ZnCl2, K2CO3, NaOH and H3PO4. Appl Surf Sci 261:247–254. https://doi.org/10.1016/j.apsusc.2012.07.155

Fadzilah R, Rashid U, Lokman M, Hazmi B, Alharthi A, Arbi I (2021) Bifunctional nano-catalyst produced from palm kernel shell via hydrothermal-assisted carbonization for biodiesel production from waste cooking oil. Renew Sustain Energy Rev 137:110638. https://doi.org/10.1016/j.rser.2020.110638

Allwar A (2020) Preparation and characterizations of activated carbon from banana fruit bunch with chemical treatments using hydrothermal processes. AIP Conf Proc 2229:1–9. https://doi.org/10.1063/5.0002794

Wong WY, Lim S, Pang YL, Shuit SH, Chen WH, Lee KT (2020) Synthesis of renewable heterogeneous acid catalyst from oil palm empty fruit bunch for glycerol-free biodiesel production. Sci Total Environ 727:138534. https://doi.org/10.1016/j.scitotenv.2020.138534

Ibrahim SF, Asikin-Mijan N, Ibrahim ML, Abdulkareem-Alsultan G, Izham SM, Taufiq-Yap YH (2020) Sulfonated functionalization of carbon derived corncob residue via hydrothermal synthesis route for esterification of palm fatty acid distillate. Energy Convers Manag 210:112698. https://doi.org/10.1016/j.enconman.2020.112698

Mukarakate C, Mittal A, Ciesielski PN, Budhi S, Thompson L, Iisa K, Nimlos MR, Donohoe BS (2016) Influence of crystal allomorph and crystallinity on the products and behavior of cellulose during fast pyrolysis. ACS Sustain Chem Eng 4:4662–4674. https://doi.org/10.1021/acssuschemeng.6b00812

Pari G, Darmawan S, Prihandoko B (2014) Porous carbon spheres from hydrothermal carbonization and KOH activation on cassava and tapioca flour raw material. Procedia Environ Sci 20:342–351. https://doi.org/10.1016/j.proenv.2014.03.043

Abdullah RF, Rashid U, Hazmi B, Ibrahim ML, Toshiki T, Alharthi FA (2021) Potential heterogeneous nano-catalyst via integrating hydrothermal carbonization for biodiesel production using waste cooking oil. Chemosphere 286:131913. https://doi.org/10.1016/j.chemosphere.2021.131913

Zhang B, Heidari M, Regmi B, Salaudeen S, Arku P, Thimmannagari M, Dutta A (2018) Hydrothermal carbonization of fruit wastes: a promising technique for generating hydrochar. Energies 11:1–14. https://doi.org/10.3390/en11082022

Sayğili H, Güzel F (2016) High surface area mesoporous activated carbon from tomato processing solid waste by zinc chloride activation: process optimization, characterization and dyes adsorption. J Clean Prod 113:995–1004. https://doi.org/10.1016/j.jclepro.2015.12.055

Santana Costa JA, Paranhos CM (2018) Systematic evaluation of amorphous silica production from rice husk ashes. J Clean Prod 192:688–697. https://doi.org/10.1016/j.jclepro.2018.05.028

Kang S, Li X, Fan J, Chang J (2012) Characterization of hydrochars produced by hydrothermal carbonization of lignin, cellulose, d-xylose, and wood meal. Proc Ind Eng Chem Res 51:9023–9031

Mestre AS, Hesse F, Freire C, Ania CO, Carvalho AP (2019) Chemically activated high grade nanoporous carbons from low density renewable biomass (Agave sisalana) for the removal of pharmaceuticals. J Colloid Interface Sci 536:681–693. https://doi.org/10.1016/j.jcis.2018.10.081

González JF, Ramiro A, González-García CM, Gańán J, Encinar JM, Sabio E, Rubiales J (2005) Pyrolysis of almond shells. Energy applications of fractions. Ind Eng Chem Res 44:3003–3012. https://doi.org/10.1021/ie0490942

Ogino I, Suzuki Y, Mukai SR (2018) Esterification of levulinic acid with ethanol catalyzed by sulfonated carbon catalysts: promotional effects of additional functional groups. Catal Today 314:62–69. https://doi.org/10.1016/j.cattod.2017.10.001

Naeem A, Wali Khan I, Farooq M, Mahmood T, Ud Din I, Ali Ghazi Z, Saeed T (2021) Kinetic and optimization study of sustainable biodiesel production from waste cooking oil using novel heterogeneous solid base catalyst. Bioresour Technol 328:124831. https://doi.org/10.1016/j.biortech.2021.124831

Hazmi B, Rashid U, Taufiq-yap YH, Ibrahim ML (2020) Supermagnetic nano-bifunctional catalyst from rice husk: synthesis, characterization and application for conversion of used cooking oil to biodiesel. Catalysts. https://doi.org/10.3390/catal10020225

Shan R, Han J, Gu J, Yuan H, Luo B, Chen Y (2020) A review of recent developments in catalytic applications of biochar-based materials. Resour Conserv Recycl 162:105036. https://doi.org/10.1016/j.resconrec.2020.105036

Teo SH, Rashid U, Thomas Choong SY, Taufiq-Yap YH (2017) Heterogeneous calcium-based bimetallic oxide catalyzed transesterification of Elaeis guineensis derived triglycerides for biodiesel production. Energy Convers Manag 141:20–27. https://doi.org/10.1016/j.enconman.2016.03.042

Murray R, King G, Wyse-Mason R (2019) Micro-emulsification vs. transesterification: an investigation of the efficacy of methanol use in improving vegetable oil engine performance. Biofuels 12:1–10. https://doi.org/10.1080/17597269.2019.1598316

Badnore AU, Jadhav NL, Pinjari DV, Pandit AB (2018) Efficacy of newly developed nano-crystalline calcium oxide catalyst for biodiesel production. Chem Eng Process Process Intensif 133:312–319. https://doi.org/10.1016/j.cep.2018.09.007

Jawad AH, Ismail K, Ishak MAM, Wilson LD (2019) Conversion of Malaysian low-rank coal to mesoporous activated carbon: structure characterization and adsorption properties. Chin J Chem Eng 27:1716–1727. https://doi.org/10.1016/j.cjche.2018.12.006

Hassan HMA, Alhumaimess MS, Alsohaimi IH, Essawy AA, Hussein MF, Alshammari HM, Aldosari OF (2020) Biogenic-mediated synthesis of the Cs2O-MgO/MPC nanocomposite for biodiesel production from olive oil. ACS Omega 5:27811–27822. https://doi.org/10.1021/acsomega.0c02814

Ashok A, Ratnaji T, John Kennedy L, Judith Vijaya J, Gnana Pragash R (2021) Magnetically recoverable Mg substituted zinc ferrite nanocatalyst for biodiesel production: process optimization, kinetic and thermodynamic analysis. Renew Energy 163:480–494. https://doi.org/10.1016/j.renene.2020.08.081

Zhou Q, Zhang H, Chang F, Li H, Pan H, Xue W, Hu DY, Yang S (2015) Nano La2O3 as a heterogeneous catalyst for biodiesel synthesis by transesterification of Jatropha curcas L. oil. J Ind Eng Chem 31:385–392. https://doi.org/10.1016/j.jiec.2015.07.013

Borah MJ, Sarmah HJ, Bhuyan N, Mohanta D, Deka D (2022) Application of Box-Behnken design in optimization of biodiesel yield using WO3/graphene quantum dot (GQD) system and its kinetics analysis. Biomass Convers Bioref 12:221–232. https://doi.org/10.1007/s13399-020-00717-x

Karmakar B, Samanta S, Halder G (2020) Delonix regia heterogeneous catalyzed two-step biodiesel production from Pongamia pinnata oil using methanol and 2-propanol. J Clean Prod 255:120313. https://doi.org/10.1016/j.jclepro.2020.120313

AbuKhadra MR, Basyouny MG, El-Sherbeeny AM, El-Meligy MA, Abd Elgawad AEE (2020) Transesterification of commercial waste cooking oil into biodiesel over innovative alkali trapped zeolite nanocomposite as green and environmental catalysts. Sustain Chem Pharm 17:100289. https://doi.org/10.1016/j.scp.2020.100289

Yadav M, Sharma YC (2019) Transesterification of used vegetable oil using BaAl2O4 spinel as heterogeneous base catalyst. Energy Convers Manag 198:111795. https://doi.org/10.1016/j.enconman.2019.111795

García-Martín JF, Alés-Álvarez FJ, López-Barrera MC, Martín-Domínguez I, Álvarez-Mateos P (2019) Cetane number prediction of waste cooking oil-derived biodiesel prior to transesterification reaction using near infrared spectroscopy. Fuel 240:10–15. https://doi.org/10.1016/j.fuel.2018.11.142

Bora AP, Dhawane SH, Anupam K, Halder G (2018) Biodiesel synthesis from Mesua ferrea oil using waste shell derived carbon catalyst. Renew Energy 121:195–204. https://doi.org/10.1016/j.renene.2018.01.036

Jamil F, Al-Muhatseb AH, Myint MTZ, Al-Hinai M, Al-Haj L, Baawain M, Al-Abri M, Kumar G, Atabani AE (2018) Biodiesel production by valorizing waste Phoenix dactylifera L. Kernel oil in the presence of synthesized heterogeneous metallic oxide catalyst (Mn@MgO-ZrO2). Energy Convers Manag 155:128–137. https://doi.org/10.1016/j.enconman.2017.10.064

Khan HM, Iqbal T, Ali CH, Yasin S, Jamil F (2020) Waste quail beaks as renewable source for synthesizing novel catalysts for biodiesel production. Renew Energy 154:1035–1043. https://doi.org/10.1016/j.renene.2020.03.079

Kataria J, Mohapatra SK, Kundu K (2019) Biodiesel production from waste cooking oil using heterogeneous catalysts and its operational characteristics on variable compression ratio CI engine. J Energy Inst 92:275–287. https://doi.org/10.1016/j.joei.2018.01.008

Fatima U, Ahmad F, Ramzan M, Aziz S, Tariq M, Iqbal HMN, Imran M (2021) Catalytic transformation of Brassica nigra oil into biodiesel using in-house engineered green catalyst: development and characterization. Clean Technol Environ Policy. https://doi.org/10.1007/s10098-021-02170-4

Lee CL, Chin KL, H’ng PS, Rashid U, Maminski M, Khoo PS (2021) Effect of pretreatment conditions on the chemical–structural characteristics of coconut and palm kernel shell: a potentially valuable precursor for eco-efficient activated carbon production. Environ Technol Innov 21:10309. https://doi.org/10.1016/j.eti.2020.101309

Misnon II, Zain NKM, Jose R (2019) Conversion of oil palm kernel shell biomass to activated carbon for supercapacitor electrode application. Waste Biomass Valoriz 10:1731–1740. https://doi.org/10.1007/s12649-018-0196-y

Liu Z, Zhang FS, Wu J (2010) Characterization and application of chars produced from pinewood pyrolysis and hydrothermal treatment. Fuel 89:510–514. https://doi.org/10.1016/j.fuel.2009.08.042

Adilah S, Nur S, Nurhayati A (2014) Slow pyrolysis of oil palm empty fruit bunches for biochar production and characterisation. J Phys Sci 25:97–112

Acknowledgements

Authors extend their thanks to Researchers Supporting Project (Ref: RSP-2021/78), King Saud University (Riyadh, Saudi Arabia).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Rashid, U., Hazmi, B., Abdullah, R.F. et al. Physicochemical Properties of Waste Palm-Based Catalysts Synthesized from Pyrolyzed and Hydrothermalized Chars for Biodiesel Production. Top Catal 66, 723–739 (2023). https://doi.org/10.1007/s11244-022-01736-w

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11244-022-01736-w