Abstract

In the current research, we report on the synthesis of WO3/GQD system as a heterogeneous catalyst for the transesterification of waste cooking oil into biodiesel using methanol. The characterization of the prepared catalyst was done by X-ray diffraction (XRD), Raman spectroscopy, transmission electron microscope (TEM), energy-dispersive X-ray (EDX), Fourier transform-infrared spectroscopy (FT-IR) techniques, and Brunauer-Emmett-Teller surface area measurement. To study the effect of process variables such as methanol to oil ratio, reaction temperature, and time, we have employed response surface methodology (RSM) based on Box-Behnken design (BBD). The suitability of the predicted model was verified, and the average biodiesel yield of (96.8 ± 0.16%) was reported at optimal reaction condition of 1:6 oil to methanol ratio, 70 °C reaction temperature, 2 wt% catalyst loading, and 3.5 h reaction time. Biodiesel was characterized using proton nuclear magnetic resonance (1H NMR) and carbon nuclear magnetic resonance (13C NMR) techniques, and fatty acid methyl ester composition was determined using gas chromatography-mass spectrometry (GC-MS). Fuel properties of the biodiesel obtained comply with ASTMD6751 biodiesel standards. The kinetics of transesterification was studied and found to follow pseudo-first order. The results showed the rate constant ranging from 0.0028 to 0.007 min−1, activation energy (Ea) of 55.92 kJ mol−1, and frequency factor (A) of 1.72 × 106 min−1.

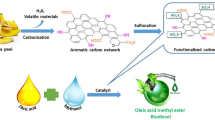

Graphical abstract

Similar content being viewed by others

References

Demirbas A (2009) Progress and recent trends in biodiesel fuels. Energy Convers Manag 50:14–34

Mardhiah HH, Ong HC, Masjuki HH, Lim S, Lee HV (2017) A review on latest developments and future prospects of heterogeneous catalyst in biodiesel production from non-edible oils. Renew Sust Energ Rev 67:1225–1236

Gui MM, Lee KT, Bhatia S (2008) Feasibility of edible oil vs. non-edible oil vs. waste edible oil as biodiesel feedstock. Energy 33:1646–1653

Helwani Z, Othman MR, Aziz N, Kim J, Fernando WJ (2009) Solid heterogeneous catalysts for transesterification of triglycerides with methanol: a review. Appl Catal A Gen 363:1–10

Endalew AK, Kiros Y, Zanzi R (2011) Heterogeneous catalysis for biodiesel production from Jatropha curcas oil (JCO). Energy 36:2693–2700

Lee JS, Saka S (2010) Biodiesel production by heterogeneous catalysts and supercritical technologies. Bioresour Technol 101:7191–7200

Xie W, Peng H, Chen L (2006) Calcined Mg–Al hydrotalcites as solid base catalysts for methanolysis of soybean oil. J Mol Catal A Chem 246:24–32

Arzamendi G, Campo I, Arguinarena E, Sánchez M, Montes M, Gandia LM (2007) Synthesis of biodiesel with heterogeneous NaOH/alumina catalysts: comparison with homogeneous NaOH. Chem Eng J 134:123–130

Vujicic D, Comic D, Zarubica A, Micic R, Boskovic G (2010) Kinetics of biodiesel synthesis from sunflower oil over CaO heterogeneous catalyst. Fuel 89:2054–2061

Tran TT, Kaiprommarat S, Kongparakul S, Reubroycharoen P, Guan G, Nguyen MH, Samart C (2016) Green biodiesel production from waste cooking oil using an environmentally benign acid catalyst. Waste Manag 52:367–374

Boz N, Degirmenbasi N, Kalyon DM (2009) Conversion of biomass to fuel: transesterification of vegetable oil to biodiesel using KF loaded nano-g-Al2O3 as catalyst. Appl Catal B Environ 89:590–596

Banerjee M, Dey B, Talukdar J, Kalita MC (2014) Production of biodiesel from sunflower oil using highly catalytic bimetallic gold-silver core-shell nanoparticle. Energy 30:1–5

Chen L, Yin P, Liu X, Yang L, Yu Z, Guo X, Xin X (2011) Biodiesel production over copper vanadium phosphate. Energy 36:175–180

Deng X, Fang Z, Liu YH, Yu CL (2011) Production of biodiesel from Jatropha oil catalyzed by nanosized solid basic catalyst. Energy 36:777–784

De Almeida RM, Noda Lucia K, Goncalves Norberto S, Meneghetti Simoni MP, Meneghetti Mario R (2008) Transesterification reaction of vegetable oils, using superacid sulfated TiO2–base catalysts. Appl Catal A Gen 347:100–105

Lee HV, Taufiq-Yap YH, Hussein MZ, Yunus R (2013) Transesterification of jatropha oil with methanol over Mg–Zn mixed metal oxide catalysts. Energy 49:12–18

Mazaheri H, Ong HC, Masjuki HH, Amini Z, Harrison MD, Wang CT, Kusumo F, Alwi A (2018) Rice bran oil-based biodiesel production using calcium oxide catalyst derived from Chicoreus brunneus shell. Energy 144:10–19

Seffati K, Honarvar B, Esmaeili H, Esfandiari N (2019) Enhanced biodiesel production from chicken fat using CaO/CuFe2O4 nanocatalyst and its combination with diesel to improve fuel properties. Fuel 235:1238–1244

Ambat I, Srivastava V, Sillanpaa M (2018) Recent advancement in biodiesel production methodologies using various feedstock: a review. Renew Sust Energ Rev 90:356–369

Borah MJ, Devi A, Saikia RA, Deka D (2018) Biodiesel production from waste cooking oil catalyzed by in-situ decorated TiO2 on reduced graphene oxide nanocomposite. Energy 158:881–889

Bankovic-Ilic IB, Miladinovic MR, Stamenkovic OS, Veljkovic VB (2017) Application of nano CaO–based catalysts in biodiesel synthesis. Renew Sust Energ Rev 72:746–760

Alaei S, Haghighi M, Toghiani J, Vahid BR (2018) Magnetic and reusable MgO/MgFe2O4 nanocatalyst for biodiesel production from sunflower oil: influence of fuel ratio in combustion synthesis on catalytic properties and performance. Ind Crop Prod 117:322–332

Ambat I, Srivastava V, Haapaniemi E, Sillanpaa M (2019) Nano-magnetic potassium impregnated ceria as catalyst for the biodiesel production. Renew Energy 139:1428–1436

Manzeli S, Ovchinnikov D, Pasquier D, Yazyev OV, Kis A (2017) 2D transition metal dichalcogenides. Nat Rev Mater 2:17033

Mas-Balleste R, Gomez-Navarro C, Gomez-Herrero J, Zamora F (2011) 2D materials: to graphene and beyond. Nanoscale 3:20–30

Xiao H, Liu S (2017) 2D nanomaterials as lubricant additive: a review. Mater Des 135:319–332

Das S, Robinson JA, Dubey M, Terrones H, Terrones M (2015) Beyond graphene: progress in novel two-dimensional materials and van der Waals solids. Annu Rev Mater Res 45:1–27

Ramasubramaniam A, Naveh D, Towe E (2011) Tunable band gaps in bilayer transition-metal dichalcogenides. Phys Rev B 84:205325

Fardindoost S, Hosseini ZS, Hatamie S (2016) Detecting hydrogen using graphene quantum dots/WO3 thin films. Mater Res Express 3:116407

Song B, Wang T, Sun H, Shao Q, Zhao J, Song K, Hao L, Wang L, Guo Z (2017) Two-step hydrothermally synthesized carbon nanodots/WO3 photocatalysts with enhanced photocatalytic performance. Dalton Trans 46:15769–15777

Kong M, Li Y, Chen X, Tian T, Fang P, Zheng F, Zhao X (2011) Tuning the relative concentration ratio of bulk defects to surface defects in TiO2 nanocrystals leads to high photocatalytic efficiency. J Am Chem Soc 133:16414–16417

Liu GB, Xiao D, Yao Y, Xu X, Yao W (2015) Electronic structures and theoretical modelling of two-dimensional group-VIB transition metal dichalcogenides. Chem Soc Rev 44:2643–2663

Razack SA, Duraiarasan S (2016) Response surface methodology assisted biodiesel production from waste cooking oil using encapsulated mixed enzyme. Waste Manag 47:98–104

Niju S, Anushya C, Balajii M (2019) Process optimization for biodiesel production from Moringa oleifera oil using conch shells as heterogeneous catalyst. Environ Prog Sustain Energy 38: e13015

Firouzjaee MH, Taghizadeh M (2017) Optimization of process variables for biodiesel production using the nanomagnetic catalyst CaO/NaY-Fe3O4. Chem Eng Technol 40:1140–1148

Coleman JN, Lotya M, O’Neill A, Bergin SD, King PJ, Khan U, Young K, Gaucher A, De S, Smith RJ, Shvets IV (2011) Two-dimensional nanosheets produced by liquid exfoliation of layered materials. Science 331:568–571

Azam A, Kim J, Park J, Novak TG, Tiwari AP, Song SH, Kim B, Jeon S (2018) Two-dimensional WO3 nanosheets chemically converted from layered WS2 for high-performance electrochromic devices. Nano Lett 18:5646–5651

Flood ME, Connolly MP, Comiskey MC, Hupp AM (2016) Evaluation of single and multi-feedstock biodiesel–diesel blends using GCMS and chemometric methods. Fuel 186:58–67

Mohamad M, Ngadi N, Wong SL, Jusoh M, Yahya NY (2017) Prediction of biodiesel yield during transesterification process using response surface methodology. Fuel 190:104–112

Aydın YA, Aksoy ND (2009) Adsorption of chromium on chitosan: optimization, kinetics and thermodynamics. Chem Eng J 151:188–194

Petříček V, Dušek M, Palatinus L (2014) Crystallographic computing system JANA 2006: general features. Zeitschrift für Kristallogr-Cryst Mat 229:345–352

Momma K, Izumi F (2011) VESTA 3 for three-dimensional visualization of crystal, volumetric and morphology data. J Appl Crystallogr 44:1272–1276

Yoon H, Mali MG, Kim MW, Al-Deyab SS, Yoon SS (2016) Electrostatic spray deposition of transparent tungsten oxide thin-film photoanodes for solar water splitting. Catal Today 260:89–94

Ferrari AC, Meyer JC, Scardaci V, Casiraghi C, Lazzeri M, Mauri F, Piscanec S, Jiang D, Novoselov KS, Roth S, Geim AK (2006) Raman spectrum of graphene and graphene layers. Phys Rev Lett 97:187401

Sarmah HJ, Deka A, Kulriya PK, Mohanta D (2019) Evidence of diamond-like carbon phase formation due to 80 keV Xe+ ion impact on pencil-lead graphitic systems with oblique angle incidence. EPL (Europhysics Letters) 125:36003

Vattikuti SP, Byon C, Chitturi V (2016) Selective hydrothermally synthesis of hexagonal WS2 platelets and their photocatalytic performance under visible light irradiation. Superlattice Microst 94:39–50

Kruk M, Jaroniec M (2001) Gas adsorption characterization of ordered organic− inorganic nanocomposite materials. Chem Mater 13:3169–3183

Betiku E, Ajala SO (2014) Modeling and optimization of Thevetia peruviana (yellow oleander) oil biodiesel synthesis via Musa paradisiacal (plantain) peels as heterogeneous base catalyst: a case of artificial neural network vs. response surface methodology. Ind Crop Prod 53:314–322

Dai JY, Li DY, Zhao YC, Xiu ZL (2014) Statistical optimization for biodiesel production from soybean oil in a microchannel reactor. Ind Eng Chem Res 53:9325–9330

Borah MJ, Das A, Das V, Bhuyan N, Deka D (2019) Transesterification of waste cooking oil for biodiesel production catalyzed by Zn substituted waste egg shell derived CaO nanocatalyst. Fuel 242:345–354

Foroutan R, Mohammadi R, Esmaeili H, Bektashi FM, Tamjidi S (2020) Transesterification of waste edible oils to biodiesel using calcium oxide@ magnesium oxide nanocatalyst. Waste Manag 105:373–383

Sharma A, Kodgire P, Kachhwaha SS (2019) Biodiesel production from waste cotton-seed cooking oil using microwave-assisted transesterification: optimization and kinetic modeling. Renew Sust Energ Rev 116:109394

Chowdhury S, Dhawane SH, Jha B, Pal S, Sagar R, Hossain A, Halder G (2019) Biodiesel synthesis from transesterified Madhuca indica oil by waste egg shell–derived heterogeneous catalyst: parametric optimization by Taguchi approach. Biomass Con Bioref 1: 11

Xie W, Huang X (2006) Synthesis of biodiesel from soybean oil using heterogeneous KF/ZnO catalyst. Catal Lett 107:53–59

Olutoye MA, Lee SC, Hameed BH (2011) Synthesis of fatty acid methyl ester from palm oil (Elaeis guineensis) with Ky(MgCa)2xO3 as heterogeneous catalyst. Bioresour Technol 102:10777–10783

Borah MJ, Devi A, Borah R, Deka D (2019) Synthesis and application of co doped ZnO as heterogeneous nanocatalyst for biodiesel production from non-edible oil. Renew Energy 133:512–519

Boro J, Thakur AJ, Deka D (2011) Solid oxide derived from waste shells of Turbonilla striatula as a renewable catalyst for biodiesel production. Fuel Process Technol 92:2061–2067

Gurunathan B, Ravi A (2015) Process optimization and kinetics of biodiesel production from neem oil using copper doped zinc oxide heterogeneous nanocatalyst. Bioresour Technol 190:424–428

Tariq M, Ali S, Ahmad F, Ahmad M, Zafar M, Khalid N et al (2011) Identification, FT-IR, NMR (1H and 13C) and GC/MS studies of fatty acid methyl esters in biodiesel from rocket seed oil. Fuel Process Technol 92:336–341

Nongbe MC, Ekou T, Ekou L, Yao KB, Le Grognec E, Felpin FX (2017) Biodiesel production from palm oil using sulfonated graphene catalyst. Renew Energy 106:135–141

Ambat I, Srivastava V, Haapaniemi E, Sillanpää M (2018) Application of potassium ion impregnated titanium dioxide as nanocatalyst for transesterification of linseed oil. Energy Fuel 32:11645–11655

Roschat W, Siritanon T, Yoosuk B, Sudyoadsuk T, Promarak V (2017) Rubber seed oil as potential non-edible feedstock for biodiesel production using heterogeneous catalyst in Thailand. Renew Energy 101:937–944

Roschat W, Siritanon T, Yoosuk B, Promarak V (2016) Biodiesel production from palm oil using hydrated lime-derived CaO as a low-cost basic heterogeneous catalyst. Energy Convers Manag 108:459–467

Ramezani K, Rowshanzamir S, Eikani MH (2010) Castor oil transesterification reaction: a kinetic study and optimization of parameters. Energy 35:4142–4148

Ma Y, Wang Q, Sun X, Wu C, Gao Z (2017) Kinetics studies of biodiesel production from waste cooking oil using FeCl3-modified resin as heterogeneous catalyst. Renew Energy 107:522–530

Acknowledgements

M. J. Borah thanks Tezpur University for financial support in the form of institutional fellowship to him. We acknowledge SAIC, Tezpur University for different instrumental facilities. We are also thankful to colleagues and friends for their help and useful suggestions.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

ESM 1

(DOCX 219 kb)

Rights and permissions

About this article

Cite this article

Borah, M.J., Sarmah, H.J., Bhuyan, N. et al. Application of Box-Behnken design in optimization of biodiesel yield using WO3/graphene quantum dot (GQD) system and its kinetics analysis. Biomass Conv. Bioref. 12, 221–232 (2022). https://doi.org/10.1007/s13399-020-00717-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-020-00717-x