Abstract

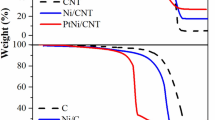

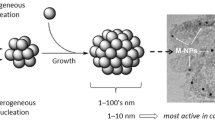

Fischer Tropsch Synthesis (FTS) using syngas, a mixture of carbon monoxide (CO) and hydrogen (H2), obtained from renewable sources in the presence of a catalyst, is an excellent route to long-chain hydrocarbons and fuels. In this study, cobalt-mesoporous silica catalysts for FTS were prepared by two procedures-Co@SiO2 at 200 °C, and high pressure in an autoclave (AC), Co@SiO2 (One Pot or OP) at room temperature and 1 atm; the effect of Al2O3 on Co-SiO2 as Co@SiO2Al2O3 (One Pot or OP) core–shell catalysts was investigated for FTS at 20 bar in 3D printed stainless steel (SS) microchannel microreactors. These catalysts were characterized by different techniques such as N2 physisorption, XRD, SEM, TEM, H2-TPR, TGA–DSC, and XPS. The N2 physisorption studies show that the BET surface area of Co@SiO2 (Autoclave) is much higher than that of Co@SiO2 (One Pot), and the surface area decreases upon the addition of Al2O3 to yield Co@SiO2Al2O3 (OP) catalyst. In TPR analysis, the Co@SiO2 (OP) based catalyst had much higher reduction temperature than the Co@SiO2 (AC) catalyst. The XRD analysis shows that the Co@SiO2 (Autoclave) based catalyst is more crystalline when compared to other catalysts. The TEM and SEM images revealed agglomerations in the case of Co@SiO2 (OP) and Co@SiO2Al2O3 (OP) based catalysts. The TGA analyses of as-synthesized catalysts, before calcination, showed good stability of the catalysts. The oxidation state and binding energy of all catalysts, evaluated by XPS analysis, show a significant shift based on the catalyst preparation. All F-T reactions were carried out in a 3D-printed SS microreactor at 20 bars in the temperature range of 200–370 °C with H2/CO molar ratio of 2:1. The highest CO conversion for Co@SiO2 AC, Co@SiO2Al2O3 OP, Co@SiO2 OP are 85%, 45%, and 27% respectively. The highest selectivity to C4+ % was observed for Co@SiO2 AC in SS Microreactors in the temperature range of 200–300 °C, and the % selectivity for the C4+ follows the order: Co@SiO2AC > Co@SiO2Al2O3 OP > Co@SiO2 OP.

Graphical Abstract

Similar content being viewed by others

References

Panda A, Kim E, Choi YN et al (2019) Phase controlled synthesis of Pt doped co nanoparticle composites using a metal-organic framework for Fischer–Tropsch catalysis. Catalysts 9:156. https://doi.org/10.3390/CATAL9020156

DE484337C—Process for the catalytic production of multi-membered paraffinic hydrocarbons from carbon oxides and hydrogen - Google Patents. https://patents.google.com/patent/DE484337C/en. Accessed 5 Aug 2022

Steynberg AP (2004) Chapter 1—introduction to Fischer-Tropsch technology. In: Steynberg A et al (eds) Fischer-Tropsch technology. Elsevier, pp 1–63

Jager B, Espinoza R (1995) Advances in low temperature Fischer-Tropsch synthesis. Catal Today 23:17–28. https://doi.org/10.1016/0920-5861(94)00136-P

Sie ST (1998) Process development and scale up: IV. Case history of the development of a fischer-tropsch synthesis process. Rev Chem Eng 14:109–157. https://doi.org/10.1515/REVCE.1998.14.2.109/MACHINEREADABLECITATION/RIS

Bepari S, Stevens-Boyd R, Mohammad N et al (2021) Composite mesoporous SiO2-Al2O3 supported Fe, FeCo and FeRu catalysts for Fischer-Tropsch studies in a 3-D printed stainless-steel microreactor. Mater Today Proc 35:221–228. https://doi.org/10.1016/J.MATPR.2020.04.582

Mohammad N, Abrokwah RY, Stevens-Boyd RG et al (2020) Fischer-Tropsch studies in a 3D-printed stainless steel microchannel microreactor coated with cobalt-based bimetallic-MCM-41 catalysts. Catal Today 358:303–315. https://doi.org/10.1016/J.CATTOD.2020.02.020

Bepari S, Li X, Abrokwah R et al (2020) Co-Ru catalysts with different composite oxide supports for Fischer-Tropsch studies in 3D-printed stainless steel microreactors. Appl Catal A Gen. https://doi.org/10.1016/j.apcata.2020.117838

Mohammad N, Kuila D, Aravamudhan S (2020) Catalyst and microreactor development for atmospheric and high-pressure Fischer-Tropsch synthesis. North Carolina Agricultural and Technical State University

Mohammad N, Basha OM, Bepari S et al (2021) Fischer-Tropsch synthesis in silicon and 3d printed stainless steel microchannel microreactors. Catal Clean Energy Environ Sustain. https://doi.org/10.1007/978-3-030-65021-6_14

Cybulski A, Edvinsson R, Irandoust S, Andersson B (1993) Liquid-phase methanol synthesis: modelling of a monolithic reactor. Chem Eng Sci 48:3463–3478. https://doi.org/10.1016/0009-2509(93)85002-7

Davis BH (2002) Overview of reactors for liquid phase Fischer-Tropsch synthesis. Catal Today 71:249–300. https://doi.org/10.1016/S0920-5861(01)00455-2

Mohammad N, Bepari S, Aravamudhan S, Kuila D (2019) Kinetics of Fischer-Tropsch synthesis in a 3-D printed stainless steel microreactor using different mesoporous silica supported Co-Ru catalysts. Catalysts 9:872. https://doi.org/10.3390/CATAL9100872

Das D, Samal DP, Mohammad N, Meikap BC (2017) Hydrodynamics of a multi-stage counter-current fluidized bed reactor with down-comer for amine impregnated activated carbon particle system. Adv Powder Technol 28:854–864. https://doi.org/10.1016/J.APT.2016.12.011

Jager B (1997) Developments in Fischer-Tropsch technology. Stud Surf Sci Catal 107:219–224. https://doi.org/10.1016/S0167-2991(97)80338-2

Mohammad N, Chukwudoro C, Bepari S et al (2022) Scale-up of high-pressure F-T synthesis in 3D printed stainless steel microchannel microreactors: Experiments and modeling. Catal Today 397–399:182–196. https://doi.org/10.1016/J.CATTOD.2021.09.038

Schulz H (1999) Short history and present trends of Fischer-Tropsch synthesis. Appl Catal A Gen 186:3–12. https://doi.org/10.1016/S0926-860X(99)00160-X

Singleton AH (1997) Advances make gas-to-liquids process competitive for remote locations. Oil Gas J 95

Eisenberg B, Fiato RA, Mauldin CH et al (1998) Exxons advanced gas-to-liquids technology. Elsevier

Davis BH (1997) Fischer-Tropsch conversion of gas to liquid. Appl Catal A Gen 155:N4–N7. https://doi.org/10.1016/S0926-860X(97)80024-5

Geng S, Mao ZS, Huang Q, Yang C (2021) Process intensification in pneumatically agitated slurry reactors. Engineering 7:304–325. https://doi.org/10.1016/J.ENG.2021.03.002

Deshmane VG, Abrokwah RY, Kuila D (2015) Synthesis of stable Cu-MCM-41 nanocatalysts for H2 production with high selectivity via steam reforming of methanol. Int J Hydrogen Energy 40:10439–10452. https://doi.org/10.1016/j.ijhydene.2015.06.084

Rouquerol F, Rouquerol J, Sing K et al (1999) Chapter 1—introduction. Adsorption by powders and porous solids. Elsevier, pp 1–26

García Blanco AA, Gabriela Amaya M, Eugenia Roca Jalil M et al (2011) Effect of the synthesis method on co-catalysts based on MCM-41 for the Fischer-Tropsch reaction. Top Catal. https://doi.org/10.1007/s11244-011-9638-5

Ni Z, Kang S, Bai J et al (2017) Uniformity dispersive, anti-coking core@double-shell-structured Co@SiO2@C: effect of graphitic carbon modified interior pore-walls on C5+ selectivity in Fischer-Tropsch synthesis. J Colloid Interface Sci 505:325–331. https://doi.org/10.1016/J.JCIS.2017.05.096

González O, Pérez H, Navarro P et al (2009) Use of different mesostructured materials based on silica as cobalt supports for the Fischer-Tropsch synthesis. Catal Today 148:140–147. https://doi.org/10.1016/J.CATTOD.2009.03.030

Xie R, Wang H, Gao P et al (2015) Core@shell Co3O4@C-m-SiO2 catalysts with inert C modified mesoporous channel for desired middle distillate. Appl Catal A Gen 492:93–99. https://doi.org/10.1016/J.APCATA.2014.12.023

Bartholomew CH (2001) Mechanisms of catalyst deactivation. Appl Catal A Gen 212:17–60. https://doi.org/10.1016/S0926-860X(00)00843-7

Dry ME (1991) (1990) Fischer-Tropsch synthesis over iron catalysts. Catal Lett 71(7):241–251. https://doi.org/10.1007/BF00764506

Bartholomewa CH, Stoker MV, Manskerb L, Datyeb A (1999) Effects of pretreatment, reaction, and promoter on microphase structure and Fischer-Tropsch activity of precipitated iron catalysts. Elsevier

Ernst B, Libs S, Chaumette P, Kiennemann A (1999) Preparation and characterization of Fischer-Tropsch active Co/SiO2 catalysts. Appl Catal A Gen 186:145–168. https://doi.org/10.1016/S0926-860X(99)00170-2

Saleh TA (2015) Nanocomposite of carbon nanotubes/silica nanoparticles and their use for adsorption of Pb(II): from surface properties to sorption mechanism. New Pub Balaban 57:10730–10744. https://doi.org/10.1080/19443994.2015.1036784

Monshi A, Foroughi MR, Monshi MR et al (2012) Modified Scherrer equation to estimate more accurately nano-crystallite size using XRD. World J Nano Sci Eng 2:154–160. https://doi.org/10.4236/WJNSE.2012.23020

Rotaru R, Savin M, Tudorachi N et al (2017) Ferromagnetic iron oxide-cellulose nanocomposites prepared by ultrasonication. Polym Chem. https://doi.org/10.1039/C7PY01587A

Chu W, Chernavskii PA, Gengembre L et al (2007) Cobalt species in promoted cobalt alumina-supported Fischer-Tropsch catalysts. J Catal 252:215–230. https://doi.org/10.1016/J.JCAT.2007.09.018

Saleh TA (2015) Isotherm, kinetic, and thermodynamic studies on Hg(II) adsorption from aqueous solution by silica- multiwall carbon nanotubes. Environ Sci Pollut Res 22:16721–16731. https://doi.org/10.1007/S11356-015-4866-Z/FIGURES/13

Saleh TA (2015) Mercury sorption by silica/carbon nanotubes and silica/activated carbon: a comparison study. J Water Supply Res Technol 64:892–903. https://doi.org/10.2166/AQUA.2015.050

Lv X, Yuan S, Zhang Y et al (2019) Preparation of cyclonic Co3O4/Au/mesoporous SiO2 catalysts with core–shell structure for solvent-free oxidation of benzyl alcohol. J Taiwan Inst Chem Eng 102:448–455. https://doi.org/10.1016/J.JTICE.2019.06.013

Li F, Wang M, Zhang J et al (2022) Sandwich-type Co core@shell nanocomposite (SiO2 @Co@CeO2): coke resistant catalyst toward CO2 reforming with ethanol. Appl Catal A Gen 638:118605. https://doi.org/10.1016/J.APCATA.2022.118605

Mirzaei F, Rezaei M, Meshkani F, Fattah Z (2015) Carbon dioxide reforming of methane for syngas production over Co–MgO mixed oxide nanocatalysts. J Ind Eng Chem 21:662–667. https://doi.org/10.1016/J.JIEC.2014.03.034

Cho JH, Park JH, Chang TS et al (2012) Reductive amination of 2-propanol to monoisopropylamine over Co/γ-Al2O3 catalysts. Appl Catal A Gen 417–418:313–319. https://doi.org/10.1016/J.APCATA.2012.01.011

Rosynek MP, Polansky CA (1991) Effect of cobalt source on the reduction properties of silica-supported cobalt catalysts. Appl Catal 73:97–112. https://doi.org/10.1016/0166-9834(91)85115-C

Li YP, Wang TJ, Wu CZ et al (2009) Effect of Ru addition to Co/SiO2/HZSM-5 catalysts on Fischer-Tropsch synthesis of gasoline-range hydrocarbons. Catal Commun 10:1868–1874. https://doi.org/10.1016/J.CATCOM.2009.06.021

Trépanier M, Dalai AK, Abatzoglou N (2010) Synthesis of CNT-supported cobalt nanoparticle catalysts using a microemulsion technique: role of nanoparticle size on reducibility, activity and selectivity in Fischer-Tropsch reactions. Appl Catal A Gen 374:79–86. https://doi.org/10.1016/J.APCATA.2009.11.029

Park JY, Lee YJ, Karandikar PR et al (2012) Fischer-Tropsch catalysts deposited with size-controlled Co3O4 nanocrystals: Effect of Co particle size on catalytic activity and stability. Appl Catal A Gen 411–412:15–23. https://doi.org/10.1016/J.APCATA.2011.10.010

Laboureur D, Glabeke G (2019) Gouriet JB (2019) Aluminum nanoparticles oxidation by TGA/DSC. J Therm Anal Calorim 1374(137):1199–1210. https://doi.org/10.1007/S10973-019-08058-2

Gill P, Moghadam TT, Ranjbar B (2010) Differential scanning calorimetry techniques: applications in biology and nanoscience. J Biomol Tech 21:167

Pejova B, Isahi A, Najdoski M, Grozdanov I (2001) Fabrication and characterization of nanocrystalline cobalt oxide thin films. Mater Res Bull 36:161–170. https://doi.org/10.1016/S0025-5408(00)00479-7

He T, Chen D, Jiao X (2004) Controlled synthesis of Co3O4 nanoparticles through oriented aggregation. Chem Mater 16:737–743. https://doi.org/10.1021/CM0303033/SUPPL_FILE/CM0303033_S.PDF

Meng Y, Chen D, Jiao X (2006) Fabrication and characterization of mesoporous Co3O4 core/mesoporous silica shell nanocomposites. J Phys Chem B 110:15212–15217. https://doi.org/10.1021/JP0626465/SUPPL_FILE/JP0626465SI20060618_045155.PDF

Ocana M, Gonzalez-Elipe AR (1999) Preparation and characterization of uniform spherical silica particles coated with Ni and Co compounds. Colloids Surfaces A Physicochem Eng Asp 157:315–324. https://doi.org/10.1016/S0927-7757(99)00088-6

Gao Z, Zhao D, Cheng Q et al (2021) Mesoporous SiO2-encapsulated nano-Co3O4 catalyst for efficient CO oxidation. ChemCatChem 13:4010–4018. https://doi.org/10.1002/CCTC.202100602

Wang D, Chen C, Wang J et al (2016) High thermal conductive core-shell structured Al2O3@Al composite supported cobalt catalyst for Fischer-Tropsch synthesis. Appl Catal A Gen 527:60–71. https://doi.org/10.1016/J.APCATA.2016.08.027

Toshima N (2000) Core/shell-structured bimetallic nanocluster catalysts for visible-light-induced electron transfer. Pure Appl Chem 72:317–325. https://doi.org/10.1351/PAC200072010317/MACHINEREADABLECITATION/RIS

Mohammad N, Aravamudhan S, Kuila D (2022) Atomic layer deposition of cobalt catalyst for Fischer-Tropsch synthesis in silicon microchannel microreactor. Nanomaterials 12:2425. https://doi.org/10.3390/NANO12142425/S1

Acknowledgements

The authors gratefully acknowledge the help from Dr. Kyle Nowlin for TEM studies at Joint School of Nanoscience and Nanoengineering, Dr. Shima Masoumi and Dr. Xin Li for SEM and XRD studies, Mr. Saif Hassan for TGA-DSC analyses, and Mr. Xiao Ma and Ms. Nourigheimasi Farnoush for XRD studies at Wake Forest University.

Funding

This work was performed at North Carolina A&T State University, the Department of Applied Science Technology, the Department of Chemistry, and the Joint School of Nanoscience and Nanoengineering, a member of Southeastern Nanotechnology Infrastructure Corridor (SENIC) supported by National Science Foundation, USA (Grant ECCS-1542174). This project was partially supported by funds provided by National Science Foundation-Center of Research Excellence in Science and Technology, USA ( HRD #1736173) and the University of North Carolina System-Research Opportunities Initiative(UNC-ROI 2017).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Arslan, M., Bepari, S., Abrokwah, R. et al. Effect of Al2O3 Support on Co-Based SiO2 Core–Shell Catalysts for Fischer–Tropsch Synthesis in 3D Printed SS Microchannel Microreactor. Top Catal 66, 477–497 (2023). https://doi.org/10.1007/s11244-022-01733-z

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11244-022-01733-z