Abstract

The aerobic oxidation of cinnamyl alcohol in toluene under autoxidation conditions has been studied using a range of 1 wt% Au–Pd/TiO2 catalysts. The catalysts have been studied to determine the effect of preparation method (impregnation and sol immobilisation) and metal ratio on the conversion of cinnamyl alcohol and the selectivity to cinnamaldehyde. The catalysts prepared by sol-immobilisation demonstrate higher selectivity to the desired aldehyde than the analogous impregnation materials. The most active catalyst was found to be 0.75 wt% Au–0.25 wt% Pd/TiO2 prepared by sol-immobilisation and this demonstrates the importance of metal ratio optimisation in this catalytic process. Furthermore, this metal ratio was found to be most stable under the reactions conditions with little change observed over multiple uses.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

One of the major challenges facing the chemical industry is to introduce efficient and benign methods for the production of fine chemicals. There is currently a large demand for carbonyl compounds that are obtained through the oxidation of alcohols. However, harmful and expensive oxidants such as chromates and permanganates are currently used for these purposes [1]. In recent years, heterogeneous catalysts have received great interest as an excellent green alternative for these processes largely due to their ability to utilise O2 as the oxidant. Au–Pd supported nanoparticles have proven to be extremely active and selective for various alcohol oxidation reactions [2,3,4,5]. Cinnamyl alcohol oxidation is a model reaction to underpin work on renewable and sustainable feedstocks such as lignocellulosic biomass [6,7,8,9]. The desired product of this reaction, cinnamaldehyde, finds many applications in pesticides, medicines and cosmetics [10,11,12]. The large majority of literature studies for cinnamyl alcohol oxidation focus on the use of mild conditions. However, these low temperatures do not necessarily lend themselves to an efficient industrial process due to the inability to recapture heat below the boiling point of water. This publication is an extension to our previous work on the oxidation of cinnamyl alcohol under more industrially relevant autoxidation conditions [13].

In the previous paper we studied the phenomenon of autoxidation of cinnamyl alcohol, the effect of reaction conditions and the impact of Au–Pd catalysts, obtained by two different preparation methods, on the reaction. It was found that a 1%Au–Pd/TiO2 catalyst prepared by the sol-immobilisation method prevented autoxidation and enabled the catalytic process to take place under conditions where a significant blank reaction is normally observed. During the reaction with the use of 1%Au–Pd/TiO2 catalyst prepared by impregnation, it was found that autoxidation and catalytic oxidation occurred at the same time. This resulted in large differences in selectivities between the two sets of catalysts with the sol immobilisation catalyst found to be extremely selective to the desired product, cinnamaldehyde. The difference in activity and selectivity between these sets of catalysts was largely attributed to the distinct difference in particle size. However, these particles would also vary heavily in terms of composition and structure of the Au–Pd nanoparticles. In order to further investigate these variables, a series of experiments were conducted focusing on optimisation of the Au–Pd metal ratio.

There are numerous studies which have investigated the effect of bimetallic ratio on both activity and selectivity for a number of reactions. The study of benzyl alcohol oxidation has demonstrated a large synergistic effect between Au and Pd and also a high sensitivity to metal ratio, with the optimum being 50:50 by weight [14]. This has also been contrasted with reactions for which addition of Au to Pd leads to an anti-synergistic effect such as CO oxidation and the water–gas shift reaction [15]. Prati et al. produced a series of studies on glycerol oxidation using carbon supported gold and palladium nanoparticles. It has been confirmed that also in this case bimetallic catalysts demonstrate higher activity than monometallics. It was noted that the nature of the support influences the observed nanoparticle behaviour [16]. The authors ascribed higher activity to the Au–Pd bifunctional sites and in general to a combination of electronic and geometric effects. It was noted that similar sites were determined at the edge of Au on Pd surface by Gleich et al. and suggested these to be responsible for CO adsorption [17]. Prati et al. observed less than 1% palladium leaching with gold being stable [16]. Despite the leaching of palladium, the catalyst was active for up to ten reuses. Researchers pointed to the fact that the Au–Pd ratio in the surface might be different from the nominal calculated value of components. This was justified by the observation that the Au–Pd pair potential is similar to the potential of monometallic components [18].

The highest activity has been obtained in case of homogeneously alloyed nanometals, however, the catalysts prepared by different methods leading to separated phases were also significantly more active than their monometallic counterparts. This implied that even the presence of Pd leads to overall enhancement of Au catalyst [19]. The researchers have found that the size of the metal nanoparticles (2–16 nm) affects the activity and selectivity of the catalyst. It was also noticed that the synergistic effect seemed to be lower in the case of larger nanoparticles [20]. Further characterisation using TEM and HRTEM of the same catalysts but prepared by various methods (resulting in a different degree of mixing of the phases) showed that the most active are single-phase bimetallic alloy catalysts. Monometallics and catalysts with segregated, mixed phase Au–Pd with incoherent structure were less active. Scientists have proven that nanoparticles of homogeneous, alloyed phase were of multiply twinned structure [21]. In the next stage, Au–Pd/carbon catalysts were tested with a different metal ratio in the 95:5–20:80 range. As a result, a typical volcano relationship was obtained with the most active catalyst being 90 Au:10 Pd. All bimetallic catalysts and monometallic Pd were found to be more active than monometallic Au [22]. Inspired by these observations, the researchers performed a detailed characterisation of the catalysts with different metal ratios. In general, the size of nanoparticles in all catalysts was similar. HRTEM analysis demonstrated that nanoparticles in the range of 9:1 to 6:4 are homogeneously alloyed with multiply twinned structure [21]. In contrast, Pd-rich 2:8 and Au-rich 9.5:0.5 catalysts have an irregular shape and a different structure than the ones previously mentioned. It was observed that the separated Pd phases forming inhomogeneity might be the cause of inferior catalytic performance for the oxidation of glycerol, as the synergistic effect between Au and Pd is weakened [18]. The researchers have shown that optimization of the metal ratio is extremely important in order to obtain the best possible results.

Prati et al. extended their studies by examining the influence of previously tested Au–Pd metal ratio on the oxidation of a few alcohols: benzyl, cinnamyl, 2-octen-1-ol and 1-octanol. The reactions were performed in water at 60 °C under 1.5 atm of oxygen pressure. These conditions were relatively mild and therefore no autoxidation was observed. The only products detected during cinnamyl alcohol oxidation were cinnamaldehyde and 3-phenyl-1-propanol. The researchers also tested the influence of base which in the case of benzyl and cinnamyl alcohol led to acid and ester formation. The synergistic effect was maximum for 80 Au: 20 Pd in case of benzyl and cinnamyl alcohols; the most effective metal ratio for aliphatic alcohols have been found to be 60 Au:40 Pd [23].

Dimitratos et al. studied oxidation of cinnamyl alcohol at 60 °C under oxygen [24]. Here, the researchers tested monometallic and bimetallic Au–Pd and Au–Pt systems supported over TiO2 by sol-immobilisation method, with products of cinnamaldehyde and 3-phenyl-1-propanol. The conversion and selectivity varied for mono- and bimetallic catalysts. The Au–Pd system was more active than Au–Pt for the oxidation of cinnamyl alcohol both in water and in toluene. A 0.73 wt% Au–0.27 wt% Pd catalyst was found to be superior to its monometallic counterparts (conversion was 72% after 2 h, selectivity to cinnamaldehyde was 85% and selectivity to 3-phenyl-1-propanol was 13%). Despite this metal ratio performing well, there was no further information given as to the full range of Au–Pd bimetallic catalysts.

Tiruvalam et al. studied the morphology of Au–Pd obtained by the sol-immobilisation method (homogeneous alloy and core–shell structures). The support influenced the morphology of nanoparticles as different structures were formed on C and on TiO2. All structures supported on TiO2 formed flat interfaces with the underlying TiO2 which suggested to the researchers that PVA did not hinder particle-support interaction (stronger adhesion of the particle to the support). The influence of temperature on the behaviour of TiO2 supported Au–Pd nanoclusters was also investigated. Drying at 120 °C did not heavily influence the structure, however calcination significantly affected the chemical ordering. At 200 °C core–shell structures were still visible however gold had diffused and was attached to the TiO2 while Pd component has moved slightly in the opposite direction. Calcination at 400 °C caused only a small increase in particles size (due to the strong wetting interaction). Particles that were formed as homogeneous alloys remained as random alloys, however no core structures were retained. In the latter case particles divided into two phases: Au-rich and Pd-rich. Pd transformed from Pd(0) to Pd(+ 2). Interestingly, Pd:Au surface ratio was not changed [5].

Xu et al. investigated the structure and redox properties of Au–Pd catalysts under operating conditions [25]. Nanoparticles undergo restructuring influenced by many various factors among other temperature and interestingly in the presence of gases (e.g. NO, CO and H2). This is in agreement with observations made by Carter et al. that the segregation of Au and Pd components of alloys under CO exposure leads to the migration of Pd to the surface of the nanocluster (driven by Pd high affinity to CO) [15, 26]. Xu reported that freshly prepared Au–Pd clusters were spherical, however immediately after immobilisation on TiO2 their shape became elongated what indicates strong metal-support interactions which is in line with the experimental reports by Prati et al. This proves that the support plays an enormous role in nanoparticle behaviour during chemical processes [16]. The researchers pointed to the fact that the cluster-support interaction might be weakened by the adsorption of H atoms. Subtle, but extremely important, differences regarding the oxidation state of a support have been explained in the paper. Electronic properties of the cluster have been subjected to discussions as important factor playing a role in the structural changes. Generally, the presence of adsorbed O or H atoms influences the charge state of the Au–Pd immobilized cluster [25].

In this work we investigate the influence of metal ratio in bimetallic catalysts prepared by wet impregnation (imp) and sol immobilisation (SIm) for the oxidation of cinnamyl alcohol under autoxidation conditions. It is clear from the previous literature that the activity of catalysts can be tuned by optimisation of Au–Pd metal ratio under relatively mild conditions. The data also has given some indication that the same way of optimisation may be possible under harsher, autoxidation conditions. The aim of this study is to investigate these catalysts under these harsher reaction conditions.

2 Experimental

2.1 Catalyst Preparation

Preparation methods have been described in detail previously [1, 13, 27].

2.2 Impregnation Method

TiO2 was slowly added to the mixture of solid PdCl2 dissolved in an aqueous solution of HAuCl4, followed by heating at 90 °C until the consistence of a smooth paste was obtained. The amounts of metals precursor were calculated to achieve desired metal ratio. The material was dried (16 h, 110 °C), ground in a pestle and mortar and calcined in static air (400 °C, 3 h).

2.3 Sol-Immobilisation Method

Aqueous solutions of PdCl2 (Alfa Aesar) and HAuCl4·H2O (Strem) were added to deionized water under vigorous stirring, followed by PVA (1 wt% aqueous solution, Aldrich, MW = 10,000) (PVA/(Au + Pd) (wt/wt) = 1) and a freshly prepared solution of NaBH4 (0.1 M, NaBH4/(Au + Pd) (mol/mol) = 5). The amounts of metal precursors, coating agent and reducing agent were calculated to achieve desired metal ratio. After 1 h, the formed nanoparticles were immobilised onto a TiO2 with the addition of sulphuric acid to obtain pH 1. The slurry was filtered, then solid was washed with distilled water followed by drying (16 h, 110 °C), and ground in pestle and mortar. The sol-immobilised catalysts were used without any additional calcination step.

2.4 Catalyst Testing

The oxidation of cinnamyl alcohol was carried out in Radley reactor (120 °C) under an oxygen atmosphere (3 bar). Cinnamyl alcohol in toluene (5 ml 0.5 M) was charged to the reactor, followed by addition of the catalyst (0.01 g). The glass reactor flasks were purged with oxygen three times before caps were sealed and placed on the hot plate. The stirring rate was set to 1000 rpm. The collected mixture of products was centrifuged to separate the catalyst. Samples were diluted with mesitylene as internal standard and analysed by gas chromatography (Agilent Technologies 7820 A) fitted with a CPwax 52 CB capillary column and a flame ionization detector. Conversion and selectivity values are reported within ± 3% error (calculated as a standard deviation).

Conversion of tested substrates was calculated with the use of following equation (C subA, C subB—represent the substrate concentrations [mol/dm3] at the beginning of the reaction and at the end of the reaction, respectively):

Selectivity was calculated according to following equation:

The influence of water on the oxidation of cinnamyl alcohol has been tested by the addition of water (2 mL) to the standard reaction mixture. Standard high stirring rate of 1000 rpm was sufficient for this experiment in order to create an emulsion as two phases were present. The catalyst resided in the aqueous phase in the absence of stirring, however, the post reaction aqueous phase has been analysed and only traced amounts of cinnamyl alcohol and cinnamaldehyde were detected.

2.5 Scanning Electron Microscopy (SEM)

Microscopy was performed on a Tescan Maia3 field emission gun scanning electron microscope (FEG-SEM) operating at 15 kV. Images were acquired using the backscattered electron detector. Samples were dispersed as a powder onto 300 mesh copper grids coated with holey carbon film.

2.6 X-ray Photoelectron Spectroscopy (XPS)

XPS analysis was performed on a ThermoFisher Scientific K-alpha + spectrometer. Samples were analysed as received by pressing gently in to wells of a copper powder holder as supplied with the spectrometer. Analysis of the samples was conducted using a micro-focused monochromatic Al X-ray source (72 W) over an elliptical area of approximately 400 × 200 µm. Data was recorded at pass energies of 150 eV for survey scans and 40 eV for high resolution scan with 1 eV and 0.1 eV step sizes respectively. Charge neutralisation of the sample was achieved using a combination of both low energy electrons and argon ions. Data analysis was performed in CasaXPS using a Shirley type background and Scofield cross sections, with an energy dependence of − 0.6.

3 Results and Discussion

Bimetallic Au–Pd catalysts have been well studied to date [28,29,30,31]. Indeed, catalytic performance is a result of numerous variables that one needs to consider including structure and composition of nanoparticles and their behaviour in relation to support, reactants, reaction conditions and many other factors. However, composition and metal ratio are significant factors that should be investigated and optimised to design the most effective catalyst [32,33,34].

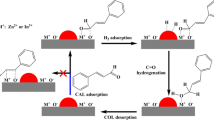

In our previous work we have examined the oxidation of cinnamyl alcohol in detail. As previously reported [13], the main products are (Fig. 1): cinnamaldehyde (CinnALD), benzaldehyde (benzALD), 3-phenyl-1-propanol (PP), methylstyrene (MS), styrene, benzoic acid (BenzACID). CO, CO2, and further unidentified organic substances were observed in trace amounts (typically < 5%).

Autoxidation was found to be dominant in the blank reaction and also in the reaction carried out with the use of a low activity Au–Pd catalyst prepared by impregnation method (1%AuPd/TiO2 imp). The major product being formed from the autoxidation pathway was benzaldehyde, which was undesirable. The catalyst prepared with the same metal ratio by sol-immobilisation method (1%AuPd/TiO2 SIm) was found to be extremely selective to the desired product, cinnamaldehyde. The reason for this different behaviour of catalysts has been attributed to the size of the nanoparticles. Presumably, small particles (3–5 nm) obtained by sol-immobilisation method were able to scavenge radical species responsible for autoxidation, thus increasing selectivity to cinnamaldehyde. Analysis of the product distribution in the reaction carried out with the use of less active 1%AuPd/TiO2 imp (particle size 20 nm) showed that the autoxidation and catalytic mechanisms took place simultaneously [13]. Figure 2 gives an overview of the differences in the product distribution for blank and catalysed reactions after 4 h.

Oxidation of cinnamyl alcohol carried out in the absence and presence of a catalyst. Reaction conditions: 0.5%Au 0.5%Pd/TiO2 (SIm), 0.5%Au 0.5%Pd/TiO2 (imp), 10 mg; oxygen pressure, 3 bar; temperature, 120 °C; time, 4 h; 0.5 M cinnamyl alcohol in toluene. Cinnamaldehyde

; benzaldehyde

; benzaldehyde

; benzoic acid

; benzoic acid

; 3-phenyl-1-propanol

; 3-phenyl-1-propanol

; methylstyrene

; methylstyrene

; conversion: filled square; carbon balance: filled circle

; conversion: filled square; carbon balance: filled circle

In addition to the large particle size effects observed in the previous study, many other morphological and electronic differences could potentially dictate activity and selectivity in cinnamyl alcohol oxidation. In this work, we decided to focus on optimisation of the Au–Pd metal ratio. Catalysts have been prepared by sol-immobilisation and impregnation methods. The following metal ratios of TiO2 supported Au–Pd nanoparticles have been studied: 1%Au/TiO2; 0.95%Au 0.05%Pd/TiO2; 0.75%Au 0.25%Pd/TiO2; 0.50%Au 0.50%Pd/TiO2; 0.25%Au 0.75%Pd/TiO2; 1%Pd/TiO2. Time-online experiments revealed that selectivity is constant over time (taking into account the experimental error of 3%) however initial rates vary heavily between each catalyst. Therefore, the catalysts have been compared after 1 h of reaction to elucidate any difference in activity.

Figure 3 demonstrates the results of the catalytic oxidation of cinnamyl alcohol with the use of a number of catalysts prepared by impregnation method. The amount of converted alcohol is a result of two different mechanisms taking part simultaneously: autoxidation and catalytic oxidation. We demonstrated recently that benzaldehyde is indicative of autoxidation [13], hence the analysis of the influence of Au–Pd metal ratio on the reaction should be focused not only on the conversion but also on the selectivity (Fig. 4). From Fig. 3 it is clear that Pd-rich catalysts are the most active ones. The catalysed reactions have been contrasted against the reaction carried out in the absence of a catalyst marked as a blue line on the graph. The blank reaction shows around 30% conversion after 1 h (blue line). Reactions catalysed with the use of Pd-rich catalysts (1%Pd/TiO2 imp, 0.25%Au 0.75%Pd/TiO2 imp) have comparable conversions to the blank reaction, however the selectivity profile differs (Figs. 2, 4). Pd-rich imp catalysts limited formation of benzaldehyde which suggests that the catalytic mechanism is dominant over autoxidation.

Oxidation of cinnamyl alcohol as a function of reaction time using catalysts prepared by the impregnation method. Reaction conditions: oxygen pressure, 3 bar; temperature, 120 °C; 0.5 M cinnamyl alcohol in toluene; catalyst, 10 mg: 1%Au/TiO2 (filled square); 0.95%Au 0.05%Pd/TiO2 (open circle); 0.75%Au 0.25%Pd/TiO2 (filled circle); 0.50%Au 0.50%Pd/TiO2 (filled triangle); 0.25%Au 0.75%Pd/TiO2 (open square); 1%Pd/TiO2 (filled diamond); blank reaction (blue line)

Oxidation of cinnamyl alcohol using catalysts prepared by impregnation method. Reaction conditions: oxygen pressure, 3 bar; temperature, 120 °C; 0.5 M cinnamyl alcohol in toluene; catalyst mass, 10 mg; time, 1 h. Cinnamaldehyde

; benzaldehyde

; benzaldehyde

; benzoic acid

; benzoic acid

; 3-phenyl-1-propanol

; 3-phenyl-1-propanol

; methylstyrene

; methylstyrene

; conversion: filled square

; conversion: filled square

1%Au/TiO2 imp catalyst limited the conversion significantly (Fig. 3). The product distribution, largely to benzaldehyde, suggests that the autoxidation was still present (Fig. 4). The catalyst acted as a scavenger to some extent, however was not active enough to perform catalytic dehydrogenation towards cinnamaldehyde. This can be explained by the larger size of gold nanoparticles, which are visible in SEM images (presented later). Miedziak et al. proved that even a small addition of palladium improves significantly the dispersion of gold, and hence activity [35, 36]. It is widely known that alloying Au with Pd leads to a better activity of nanoclusters, therefore the combination of those two effects, namely better dispersion and alloying, leads to an enhanced activity.

0.75%Au 0.25%Pd/TiO2 imp and 0.5%Au 0.5%Pd/TiO2 imp demonstrated a synergistic effect towards limiting autoxidation, as the conversions compared to the blank reaction are lower and the selectivity to cinnamaldehyde is higher in each case (Figs. 3, 4). Large amounts of benzaldehyde were still formed hence the ratio of Au and Pd is not ideal for effectively supressing autoxidation.

An emerging conclusion that needs to be emphasised is that it is possible to increase the selectivity of even poor activity catalysts by optimising the metal ratios.

Figure 5 plots catalytic activity and yield of cinnamaldehyde produced in relation to weight percent of gold. It can be seen that the conversion trend is reflected in the yield to cinnamaldehyde trend. Pd-rich catalysts are the most effective towards formation of cinnamaldehyde. Surprisingly, 0.5%Au 0.5%Pd/TiO2 imp catalyst demonstrated a lower activity compared to other metal ratios, which is particularly noticeable after longer reaction times (4 h).

As we have shown in the previous work, the 0.5%Au 0.5%Pd/TiO2 SIm has been found to be extremely active for the studied reaction. Moreover, the SIm catalyst was highly selective resulting in a small amount of undesired benzaldehyde, which is formed in large amounts as a by-product of non-selective oxidation.

Figure 6 demonstrates that the highest conversion (nearly 96% after 4 h, selectivity to cinnamaldehyde of 80%) was achieved using the 0.75%Au 0.25%Pd/TiO2 catalyst. This finding is in good agreement with Prati’s work reporting 0.73 wt% Au–0.27 wt% Pd SIm catalyst which was more active than monometallic catalysts. Interestingly, the correlation in metal ratio and activity again dipped at 50Au:50Pd as with the impregnation catalysts. Therefore, to confirm this trend and proposed optimum of 75Au:25Pd, an additional two catalysts have been prepared with following metal ratio: 0.60%Au 0.40%Pd/TiO2 SIm; 0.85%Au 0.15%Pd/TiO2 SIm (Figs. 6, 7). The data revealed that the tested catalysts were active, as expected, but still not as active as 0.75%Au 0.25%Pd/TiO2 SIm.

Oxidation of cinnamyl alcohol as a function of reaction time using catalysts prepared by sol-immobilisation method. Reaction conditions: oxygen pressure, 3 bar; temperature, 120 °C; 0.5 M cinnamyl alcohol in toluene; catalyst mass, 10 mg. 1%Au/TiO2(filled square); 0.95%Au 0.05%Pd/TiO2 (filled diamond); 0.75%Au 0.25%Pd/TiO2 (open square); 0.50%Au 0.50%Pd/TiO2 (filled triangle); 0.25%Au 0.75%Pd/TiO2 (filled circle); 1%Pd/TiO2 (open diamond); 0.60%Au 0.40%Pd/TiO2 (open circle); 0.85%Au 0.15%Pd/TiO2 (open triangle); blank reaction (blue line)

Oxidation of cinnamyl alcohol using catalysts prepared by sol-immobilisation method. Reaction conditions: oxygen pressure, 3 bar; temperature, 120 °C; 0.5 M cinnamyl alcohol in toluene; catalyst mass, 10 mg; time, 1 h. Cinnamaldehyde

; benzaldehyde

; benzaldehyde

; 3-phenyl-1-propanol

; 3-phenyl-1-propanol

; methylstyrene

; methylstyrene

; styrene

; styrene

; conversion: filled square

; conversion: filled square

Figure 7 displays the results obtained after 1 h reaction 1% Au/TiO2 catalyst has relatively low activity and selectivity as the amount of benzaldehyde formed is high (around 35%). The small addition of palladium (0.05% wt) clearly increased the selectivity to cinnamaldehyde of the gold catalyst by 20%, however the conversion was only slightly higher (from 9 to 16%). Further increasing of palladium content resulted in dramatic improvement of conversion maintaining at the same time high selectivity to cinnamaldehyde (around 80%) which indicates a strong synergistic effect.

Figure 8 presents trend of activity for the range of SIm catalysts with different gold content. It is clear that 0.75%Au 0.25%Pd/TiO2 SIm showed the highest activity in the oxidation of cinnamyl alcohol. Similar to previous observations for imp catalysts, 0.5%Au 0.5%Pd/TiO2 SIm catalyst showed unexpected drop in activity compared to other bimetallic catalysts. The presented results proved that not only the size of nanoparticles is important but also their morphology and composition. In theory, geometric and electronic effects might explain different activity of bimetallic catalysts which possibly can be dictated by different way of alloying, phases separation or presence of inhomogeneities [16].

3.1 SEM

We have shown that the preparation method influences the size and the nature of nanoparticles hence their effect on the oxidation of cinnamyl alcohol [13]. SEM have been used to investigate the size of the metal nanoparticles in case of fresh and used catalysts.

The size range of nanoparticles produced by impregnation method on 0.5%Au 0.5%Pd/TiO2 catalyst is broad, from 3 to 100 nm (Fig. 9). Large clusters (~ 100 nm) are especially visible and there is only a few small nanoparticles. Poor gold dispersion has been confirmed by XPS results. There is no massive change noticed in the particle size on the used catalyst.

Figure 10 shows a SEM image of the 0.5%Au 0.5%Pd/TiO2 SIm. The nanoparticles are very small, in range < 10 nm. Slighlty larger clusters have been observed after second and third use of 0.5%Au 0.5%Pd/TiO2 SIm, however not exceeding 13 nm (Fig. 11).

SEM analysis of fresh and spent 0.75%Au 0.25%Pd/TiO2 SIm presented in Fig. 11 revealed that the particle growth is negligible.

The difference in nanometals size explains well the difference in activity of the catalysts as smaller nanoparticles are more active. The particle growth in case of 0.5%Au 0.5%Pd/TiO2 SIm and lack of agglomeration in case of 0.75%Au 0.25%Pd/TiO2 SIm can explain the deactivation of the range of 1%AuPd/TiO2 SIm catalysts with the exception of 75Au:25Pd ratio presenting an extraordinary stability.

3.2 X-ray Photoelectron Spectroscopy (XPS)

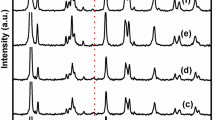

To investigate the chemical state and surface ratios of the Au/Pd species, XPS analysis of the catalysts was performed. For the catalysts prepared by impregnation, both Pd(II) and Pd(0) are found with respective binding energies of 336.4 and 335.3 eV respectively, furthermore, regardless of the amount of Au present, the Pd species are present in approximately a 1:1 ratio. Gold is found to have a binding energy of 83.2 eV, characteristic of metallic Au in a low coordinated state [37], whilst the relative intensities of the Au(4f) peaks as a function of increasing Au loading indicate the Au itself is poorly dispersed.

Contrastingly, the impregnation prepared catalysts, sol-based preparations reveal a more systematic influence of the Au. First, with increasing Pd content, there is a gradual downward shift in the Au(4f) peaks to a maximum of 0.4 eV; this shift is not observed in the core-levels of the support or that of the adventitious carbon, indicating this is a consequence of the dilution of the Au by the Pd resulting in a lower coordination for the Au species present. Throughout the compositional range, both Au(4f) and Pd(3d) peaks are observable, even in cases of low metal concentration (e.g. 0.95%Au, 0.05% Pd/TiO2), indicating a more dispersed system than that found for the wet impregnation samples.

Moreover, for compositions of 0.75%Au 0.25%Pd and lower in respect of Pd content, no Pd(II) is discernible in the Pd(3d) spectra, however we appreciate its concentration may be low and therefore accurate determination is difficult. Coincident with increasing the Pd content above 0.25% is the formation of Pd(II) species, similar to that observed for the 1% Pd sol. Notably, the Pd(II) concentration is lowest for the 0.5%Au 0.5%Pd/TiO2 catalysts, which may explain the observed selectivity.

The role of O2 in the oxidation of cinnamyl alcohol (and other allylic alcohols) is contentious [38]. Baiker et al. carried out detailed studies on the effect of oxygen on the process [38]. They reported that dehydrogenation of cinnamyl alcohol over Pd/Al2O3 catalysts took place in the absence of oxygen in the system. Increased selectivity to 3-phenyl-1-propanol and methylstyrene under inert gas indicated that cinnamyl alcohol acted as a hydrogen acceptor [38]. These observations led the researchers to the conclusion that oxygen might clean the catalyst surface and therefore takes a part in the process [38]. Lee et al. suggest that PdO is the active centre and oxygen plays a direct, important role in the catalytic process [39]. In our previous paper, the role of oxygen in cinnamyl alcohol oxidation has been investigated in terms of its influence on the products distribution. Little attention has been paid to the subtle matter of the influence of oxygen on the nanoparticles.

It is extremely difficult to indicate active centres of the catalysts even with the participation of modern technologies. Lee and Wilson delivered valuable publications on the active site in Pd supported catalysts in the oxidation of various alcohols in mild conditions (air as an oxidant, low temperatures ~ 60 °C) [40, 41]. The researchers investigated the structural changes in a Pd/C catalyst using in situ XAFS and XPS techniques. Their work confirmed Baiker’s report that cinnamyl alcohol rapidly reduces the surface palladium oxide [8]. The most important observation concerned the correlation of catalytic activity with the oxidation state of Pd. Designed experiment with cycles of oxidation and catalyst reduction has shown that palladium oxide surface layer was crucial for high catalytic performance [40]. In a later paper the scientists emphasize the importance of high Pd dispersion for enhanced catalytic activity [41]. Good Pd dispersion was observed up to 1 wt% bulk loading; higher Pd content (up to 8.55 wt%) resulted in worse dispersion and larger Pd clusters occurrence. The phenomenon of dispersion was directly linked with the palladium oxide presence as the researchers noticed the relation between increasing TOF in cinnamyl alcohol oxidation with increasing surface layer of PdO [%] [41]. Wilson et al. made efforts to improve Pd catalytic performance by changing support to mesoporous alumina and three-dimensional silicas (KIT-6, SBA-16). Indeed, suggested supports have been more suitable than SBA-15 or ɣ-Al2O3 which was explained by enhanced Pd nanoparticles stabilization hence high concentration of palladium oxide has been maintained [42, 43].

3.3 Reusability of the Catalyst

Reusability studies revealed that the catalysts show gradual mild deactivation. In case of the impregnation method (Fig. 12), Au-rich catalysts showed minimal loss of activity, whereas Pd-rich deactivated by 25% after first use. Also higher selectivity to benzaldehyde with every use suggests inferior catalytic performance. Catalysts prepared by sol-immobilisation method (Fig. 13) maintained high selectivity to cinnamaldehyde with every use, however conversion decreased. 0.75%Au 0.25%Pd/TiO2 SIm has been found to be stable up to 3 reuses.

Reusability studies of 1%Au–Pd/TiO2 catalysts prepared by impregnation method. Reaction conditions: oxygen pressure, 3 bar; temperature, 120 °C; 0.5 M cinnamyl alcohol in toluene; catalyst mass, 10 mg; time, 4 h. Conversion: filled square; carbon balance: open circle; cinnamaldehyde

; benzaldehyde

; benzaldehyde

; methylstyrenre

; methylstyrenre

3-phenyl-1-propanol

3-phenyl-1-propanol

; benzoic acid

; benzoic acid

Reusability studies of 1%Au–Pd/TiO2 catalysts prepared by sol-immobilisation method. Reaction conditions: oxygen pressure, 3 bar; temperature, 120 °C; 0.5 M cinnamyl alcohol in toluene; catalyst mass, 10 mg; time, 4 h. Conversion: filled square; carbon balance: open circle; cinnamaldehyde

; benzaldehyde

; benzaldehyde

; methylstyrene

; methylstyrene

; 3-phenyl-1-propanol

; 3-phenyl-1-propanol

; styrene

; styrene

Among various reasons of catalyst deactivation, the most common are: metal leaching, surface changes and poisoning [41].

Elemental analysis (ICP-MS) of the post reaction mixtures (imp & SIm catalysts) showed that leaching has been negligible (Au < 0.05%; Pd ~ 0.3%) in the oxidation of cinnamyl alcohol under autoxidation conditions.

The problem of surface changes is more complex. Computational chemistry develops extremely quickly and provides novelty approach to existing problems. Theory should be coupled with practical experiments to deliver edge-cutting discoveries. Mentioned before investigations carried out by Xu et al. about the structure and redox properties of Au–Pd catalysts under operating conditions allow to visualize the nanoalloys as a flowing/running system rather than a “stiff” structure [25]. 38-atom cluster, Au32Pd6 was chosen for the simulations what stands for nanocluster of roughly 1 nm diameter. Nanoparticles undergo restructuring influenced by e.g. temperature and gases (e.g. NO, CO and H2). It was suggested that Pd in Au–Pd cluster remains always positive due to an electronegativity difference. Adsorbed O and H influence the electronic properties of the cluster. It has been proved that cinnamyl alcohol reduces PdO to Pd. The nature and detailed mechanism of subtle structural changes is not clear, however the amount of PdO seems to play a significant role in catalytic activity. Nevertheless, presented results prove that the synergistic effect and hence the electronic effect between Au and Pd is extremely important factor to consider in alcohols oxidations. Zhu et al. have established magic compositions (compositions at which nanoclusters present exceptional stability) of Au and Pd by computational analysis [44]. Size effects in the chemical ordering and surface segregation were studied for Au–Pd nanoalloys consisted of 38, 55, 147, 201,309, and 405 atoms what is less or equal to 2 nm. The observations were compared to the structural behaviour of larger 6 nm clusters (6525 atoms). Au–Pd nanoalloys can be structured in icosahedra and truncated octahedra. Depending on the structure, different chemical arrangements of metals can be formed what is driven by the surface segregation of gold and the chemical ordering at the surface and in the core. Researchers suggested that the size of the nanoparticles and the ratio of metals building the cluster determine the alignment and structure of the whole cluster. Scientists have identified the possible structures in which a cluster can organize: vertex, edge, facets and core. Numerical simulations were used to analyse the chemical potential difference as a function of a gold concentration to determine magic compositions of Au and Pd towards formation of individual structures in clusters of various sizes. Gold and palladium are miscible hence Au–Pd bonds are favoured both in the core and at the surface. However, metal ratio optimization and the resultant effect of two factors: the difference in surface energy (cohesion energy) and the size difference between Au and Pd, make it possible to achieve core–shell structures. In larger clusters, the core–shell structure is not “pure” as small atoms are placed in the centre of the core to mitigate the internal stress. These hypotheses are extremely difficult to confirm experimentally due to limitations of characteristic techniques. Nevertheless, it can be assumed that Au–Pd form a kind of homogeneous nanoalloy.

Poisoning (third common reason of catalyst deactivation) is especially difficult obstacle in the oxidation of allylic alcohols. Studies carried out by Baiker et al. and Wilson et al. using Pd supported nanoparticles revealed that CO formed during decarbonylation is able to adsorb on Pd clusters hindering the process [45,46,47,48]. Small amount of CO is produced during cinnamyl alcohol oxidation, which can explain lower carbon balance in case of imp catalysts, however taking into consideration the particle growth observed in SEM images it is difficult to distinguish the contribution to the overall loss of activity.

Observations of such small structures are very difficult and require specialized techniques and a lot of work and combined strengths from specialists in the field of chemistry, engineering, and physics. One of the most important challenges is the improvement of technologies to observe nanostructures without interfering. Recent achievements in the field of computational chemistry provide valuable guidance and information to come closer to achieving success in the design of excellent catalysts.

4 Conclusions

The catalyst synthesis method and metal ratio have an enormous impact on the size and morphology of nanoparticles, which in turn determines the catalyst's activity. Sol-immobilisation method have been found to be more suitable to produce active and selective catalysts for oxidation of cinnamyl alcohol. 0.75 wt% Au–0.25 wt%Pd/TiO2 SIm catalyst is extremely selective toward cinnamaldehyde at high conversion and is reusable up to 3 cycles. Experimental work presented in this study proved that optimisation of Au–Pd metal ratio is a crucial step towards improving the overall efficiency of oxidation in the liquid phase under autoxidation conditions.

References

Miedziak PJ, He Q, Edwards JK et al (2011) Oxidation of benzyl alcohol using supported gold–palladium nanoparticles. Catal Today 163:47–54. https://doi.org/10.1016/j.cattod.2010.02.051

Evangelisti C, Schiavi E, Aronica LA et al (2012) Bimetallic gold–palladium vapour derived catalysts: the role of structural features on their catalytic activity. J Catal 286:224–236. https://doi.org/10.1016/j.jcat.2011.11.007

Cao E, Sankar M, Nowicka E et al (2013) Selective suppression of disproportionation reaction in solvent-less benzyl alcohol oxidation catalysed by supported Au–Pd nanoparticles. Catal Today 203:146–152

Caravati M, Meier DM, Grunwaldt JD, Baiker A (2006) Continuous catalytic oxidation of solid alcohols in supercritical CO2: a parametric and spectroscopic study of the transformation of cinnamyl alcohol over Pd/Al2O3. J Catal 240:126–136. https://doi.org/10.1016/j.jcat.2006.03.009

Tiruvalam RC, Pritchard JC, Dimitratos N et al (2011) Aberration corrected analytical electron microscopy studies of sol-immobilized Au + Pd, Au{Pd} and Pd{Au} catalysts used for benzyl alcohol oxidation and hydrogen peroxide production. Faraday Discuss 152:63–86. https://doi.org/10.1039/c1fd00020a

Costa JCS, Corio P, Rossi LM (2015) Catalytic oxidation of cinnamyl alcohol using Au–Ag nanotubes investigated by surface-enhanced Raman spectroscopy. Nanoscale 7:8536–8543. https://doi.org/10.1039/c5nr01064k

Grunwaldt JD, Keresszegi C, Mallat T, Baiker A (2003) In situ EXAFS study of Pd/Al2O3 during aerobic oxidation of cinnamyl alcohol in an organic solvent. J Catal 213:291–295. https://doi.org/10.1016/S0021-9517(02)00083-0

Mallat T, Bodnar Z, Hug P, Baiker A (1995) Selective oxidation of cinnamyl alcohol to cinnamaldehyde with air over Bi–Pt/alumina catalysts. J Catal 153:131–143. https://doi.org/10.1006/jcat.1995.1115

Abad A, Almela C, Corma A, García H (2006) Unique gold chemoselectivity for the aerobic oxidation of allylic alcohols. Chem Commun. https://doi.org/10.1039/b606257a

Williams AR, Hansen TVA, Krych L et al (2017) Dietary cinnamaldehyde enhances acquisition of specific antibodies following helminth infection in pigs. Vet Immunol Immunopathol 189:43–52. https://doi.org/10.1016/j.vetimm.2017.06.004

Jiménez-Salcedo M, Tena MT (2017) Determination of cinnamaldehyde, carvacrol and thymol in feedstuff additives by pressurized liquid extraction followed by gas chromatography–mass spectrometry. J Chromatogr A 1487:14–21. https://doi.org/10.1016/j.chroma.2017.01.042

Na YE, Il KS, Bang HS et al (2011) Fumigant toxicity of cassia and cinnamon oils and cinnamaldehyde and structurally related compounds to Dermanyssus gallinae (Acari: Dermanyssidae). Vet Parasitol 178:324–329. https://doi.org/10.1016/j.vetpar.2011.01.034

Rucinska E, Miedziak PJ, Pattisson S et al (2018) Cinnamyl alcohol oxidation using supported bimetallic Au–Pd nanoparticles: an investigation of autoxidation and catalysis. Catal Sci Technol 8:2987–2997. https://doi.org/10.1039/c8cy00155c

Enache DI, Barker D, Edwards JK et al (2007) Solvent-free oxidation of benzyl alcohol using titania-supported gold–palladium catalysts: effect of Au–Pd ratio on catalytic performance. Catal Today 122:407–411. https://doi.org/10.1016/j.cattod.2007.01.003

Carter JH, Althahban S, Nowicka E et al (2016) Synergy and anti-synergy between palladium and gold in nanoparticles dispersed on a reducible support. ACS Catal 6:6623–6633. https://doi.org/10.1021/acscatal.6b01275

Prati L, Villa A, Porta F et al (2007) Single-phase gold/palladium catalyst: the nature of synergistic effect. Catal Today 122:386–390. https://doi.org/10.1016/j.cattod.2006.11.003

Gleich B, Ruff M, Behm RJ (1997) Correlation between local substrate structure and local chemical properties: CO adsorption on well-defined bimetallic Au/Pd(111) surfaces. Surf Sci 386:48–55. https://doi.org/10.1016/S0039-6028(97)00302-6

Wang D, Villa A, Porta F et al (2008) Bimetallic gold/palladium catalysts: correlation between nanostructure and synergistic effects. J Phys Chem C 112:8617–8622. https://doi.org/10.1021/jp800805e

Bianchi CL, Canton P, Dimitratos N et al (2005) Selective oxidation of glycerol with oxygen using mono and bimetallic catalysts based on Au, Pd and Pt metals. Catal Today 102:203–212

Dimitratos N, Lopez-Sanchez JA, Lennon D et al (2006) Effect of particle size on monometallic and bimetallic (Au, Pd)/C on the liquid phase oxidation of glycerol. Catal Lett 108:147–153. https://doi.org/10.1007/s10562-006-0036-8

Prati L, Villa A, Su D et al (2006) Single-phase bimetallic system for the selective oxidation of glycerol to glycerate. Stud Surf Sci Catal 162:553–560

Villa A, Campione C, Prati L (2007) Bimetallic gold/palladium catalysts for the selective liquid phase oxidation of glycerol. Catal Lett 115:133–136. https://doi.org/10.1007/s10562-007-9077-x

Villa A, Janjic N, Spontoni P et al (2009) Au–Pd/AC as catalysts for alcohol oxidation: effect of reaction parameters on catalytic activity and selectivity. Appl Catal A Gen 364:221–228. https://doi.org/10.1016/j.apcata.2009.05.059

Dimitratos N, Villa A, Wang D et al (2006) Pd and Pt catalysts modified by alloying with Au in the selective oxidation of alcohols. J Catal 244:113–121. https://doi.org/10.1016/j.jcat.2006.08.019

Xu CQ, Lee MS, Wang YG et al (2017) Structural rearrangement of Au–Pd nanoparticles under reaction conditions: an ab initio molecular dynamics study. ACS Nano 11:1649–1658. https://doi.org/10.1021/acsnano.6b07409

Beck A, Horváth A, Schay Z et al (2007) Sol derived gold–palladium bimetallic nanoparticles on TiO2: structure and catalytic activity in CO oxidation. Top Catal 44:115–121. https://doi.org/10.1007/s11244-007-0284-x

Dimitratos N, Lopez-Sanchez JA, Morgan D et al (2007) Solvent free liquid phase oxidation of benzyl alcohol using Au supported catalysts prepared using a sol immobilization technique. Catal Today 122:317–324. https://doi.org/10.1016/j.cattod.2007.01.002

Sankar M, Dimitratos N, Miedziak PJ et al (2012) Designing bimetallic catalysts for a green and sustainable future. Chem Soc Rev 41:8099–8139

Qian K, Luo L, Jiang Z, Huang W (2017) Alloying Au surface with Pd reduces the intrinsic activity in catalyzing CO oxidation. Catal Today 280:253–258. https://doi.org/10.1016/j.cattod.2016.03.035

Lee AF, Hackett SFJ, Hutchings GJ et al (2009) In situ X-ray studies of crotyl alcohol selective oxidation over Au/Pd(1 1 1) surface alloys. Catal Today 145:251–257. https://doi.org/10.1016/j.cattod.2008.10.034

Nowicka E, Sankar M (2018) Designing Pd-based supported bimetallic catalysts for environmental applications. J Zhejiang Univ Sci A 19:5–20

Dimitratos N, Porta F, Prati L, Villa A (2005) Synergetic effect of platinum or palladium on gold catalyst in the selective oxidation of D-sorbitol. Catal Lett 99:181–185. https://doi.org/10.1007/s10562-005-2114-8

Hou W, Dehm NA, Scott RWJ (2008) Alcohol oxidations in aqueous solutions using Au, Pd, and bimetallic AuPd nanoparticle catalysts. J Catal 253:22–27. https://doi.org/10.1016/j.jcat.2007.10.025

Enache DI, Edwards JK, Landon P et al (2006) Solvent-free oxidation of primary alcohols to aldehydes using Au–Pd/TiO2 catalyst. Science 311:362–365. https://doi.org/10.1126/science.1120560

Kondrat SA, Shaw G, Freakley SJ et al (2012) Physical mixing of metal acetates: a simple, scalable method to produce active chloride free bimetallic catalysts. Chem Sci 3:2965–2971. https://doi.org/10.1039/c2sc20450a

Miedziak PJ, Kondrat SA, Sajjad N et al (2013) Physical mixing of metal acetates: optimisation of catalyst parameters to produce highly active bimetallic catalysts. Catal Sci Technol 3:2910–2917. https://doi.org/10.1039/c3cy00263b

Radnik J, Mohr C, Claus P (2003) On the origin of binding energy shifts of core levels of supported gold nanoparticles and dependence of pretreatment and material synthesis. Phys Chem Chem Phys 5:172–177. https://doi.org/10.1039/b207290d

Keresszegi C, Bürgi T, Mallat T, Baiker A (2002) On the role of oxygen in the liquid-phase aerobic oxidation of alcohols on palladium. J Catal 211:244–251. https://doi.org/10.1016/S0021-9517(02)93723-1

Parlett CMA, Durndell LJ, Wilson K et al (2014) Selective oxidation of allylic alcohols over highly ordered Pd/meso-Al2O3 catalysts. Catal Commun 44:40–45. https://doi.org/10.1016/j.catcom.2013.07.005

Lee AF, Wilson K (2004) Structure–reactivity correlations in the selective aerobic oxidation of cinnamyl alcohol: in situ XAFS. Green Chem 6:37–42. https://doi.org/10.1039/b310505a

Lee AF, Hackett SFJ, Hargreaves JSJ, Wilson K (2006) On the active site in heterogeneous palladium selox catalysts. Green Chem 8:549–555. https://doi.org/10.1039/b601984f

Parlett CMA, Bruce DW, Hondow NS et al (2011) Support-enhanced selective aerobic alcohol oxidation over Pd/mesoporous silicas. ACS Catal 1:636–640. https://doi.org/10.1021/cs200145n

Hackett SFJ, Brydson RM, Gass MH et al (2007) High-activity, single-site mesoporous Pd/Al2O3 catalysts for selective aerobic oxidation of allylic alcohols. Angew Chem Int Ed 46:8593–8596. https://doi.org/10.1002/anie.200702534

Zhu B, Front A, Guesmi H et al (2017) Magic compositions in Pd–Au nanoalloys. Comput Theor Chem 1107:49–56. https://doi.org/10.1016/j.comptc.2016.12.023

Lee AF, Ellis CV, Naughton JN et al (2011) Reaction-driven surface restructuring and selectivity control in allylic alcohol catalytic aerobic oxidation over Pd. J Am Chem Soc 133:5724–5727. https://doi.org/10.1021/ja200684f

Naughton J, Pratt A, Woffinden CW et al (2011) Metastable de-excitation spectroscopy and density functional theory study of the selective oxidation of crotyl alcohol over Pd(111). J Phys Chem C 115:25290–25297. https://doi.org/10.1021/jp205340z

Keresszegi C, Ferri D, Mallat T, Baiker A (2005) Unraveling the surface reactions during liquid-phase oxidation of benzyl alcohol on Pd/Al2O3: an in situ ATR-IR study. J Phys Chem B 109:958–967. https://doi.org/10.1021/jp0459864

Keresszegi C, Ferri D, Mallat T, Baiker A (2005) On the role of CO formation during the aerobic oxidation of alcohols on Pd/Al2O3: an in situ attenuated total reflection infrared study. J Catal 234:64–75. https://doi.org/10.1016/j.jcat.2005.05.019

Acknowledgements

The authors would like to thank Dr. Thomas Davies for supervision, training and advice regarding microscopy and the EM facility for providing instrumentation.

Author information

Authors and Affiliations

Contributions

Conceptualization: ER, SP, PJM and GJH; Methodology: ER and SP; Formal analysis and investigation: ER; Writing—original draft preparation: ER and SP; Writing—review and editing: ER, SP, PJM, GLB, DJM, MS and GJH; Funding acquisition: GJH; Resources: GJH; Supervision: SP, PJM, MS and GJH.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Rucinska, E., Pattisson, S., Miedziak, P.J. et al. Cinnamyl Alcohol Oxidation Using Supported Bimetallic Au–Pd Nanoparticles: An Optimization of Metal Ratio and Investigation of the Deactivation Mechanism Under Autoxidation Conditions. Top Catal 63, 99–112 (2020). https://doi.org/10.1007/s11244-020-01231-0

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11244-020-01231-0