Abstract

A concise formal synthesis of racemic allocolchicine has been developed, centred on three principal transformations: a retro-Brook alkylation reaction to generate an arylsilane, a gold-catalysed arylative cyclisation to generate the B-ring via biaryl linkage, and a palladium-catalysed carbonylation of an aryl chloride to generate an ester. 1H NMR monitoring of the key gold-catalysed cyclisation step reveals that a powerful catalyst deactivation process progressively attenuates the rate of catalyst turnover. The origins of the catalyst deactivation have been investigated, with an uncatalysed side-reaction, involving the substrate and the iodine(III) oxidant, identified as the source of a potent catalyst poison. The side reaction generates 1–4% of a diaryliodonium salt, and whilst this moiety is shown not to be an innate catalyst deactivator, when it is tethered to the arylsilane reactant, the inhibition becomes powerful. Kinetic modelling of processes run at two different catalyst concentrations allows extraction of the partitioning of the gold catalyst between the substrate and its diaryliodonium salt, with a rate of diaryliodonium salt generation consistent with that independently determined in the absence of catalyst. The high partition ratio between substrate and diaryliodonium salt (5/1) results in very efficient, and ultimately complete, diversion of the catalyst off-cycle.

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Novel catalytic C–C and C–X bond-forming reactions offer numerous opportunities for potential application in the pharmaceutical, agrochemical, and fine chemical industries. Such reactions are of particular utility when they are orthogonal to existing reactions, providing new avenues for chemical diversification. In the context of the development of new catalytic reactions, their application to relatively more-complex molecules can provide extremely valuable insight in addition to simply the challenge of the synthesis of the target. Indeed, they can highlight unforeseen problems with catalyst chemo-, regio- (and perhaps stereo-) selectivity, as well as other critical aspects relating to catalyst stability, efficiency, activity and functional group compatibility. Thus, beyond the simple substrates that are frequently employed for initial reaction discovery, complex molecule synthesis might be viewed as an essential component in testing for catalyst robustness.

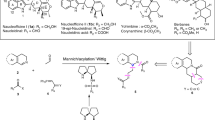

In 2012 we reported a new C–C bond-forming reaction involving the coupling of arylsilanes with arenes, using a gold(III) catalyst in the presence of a stoichiometric ArIX2 oxidant, Scheme 1 [1]. The methodology was initially established as an intermolecular process, and the mechanism shown to involve sequential auration of the silane then arene, followed by reductive elimination from a diaryl gold intermediate [2]. Itami and Sagewa subsequently reported that Au-complexation by a pyridylidene ligand facilitates arylation of isoxazoles, indoles and benzothiophenes [3], and Jeon applied the gold-catalysed process to functionalize ortho-silyl aryl triflates generated via Rh/Ir-catalyzed traceless ortho-CH silation [4]. We have also expanded the process to include the intermolecular arylation of a broad range of heteroarenes at room temperature [5], and developed intramolecular arylations to generate 5–9 membered rings [6]. Of the more than 140 examples of the Au-arylation reaction studied to date [1–6], the majority proceed efficiently with low catalyst loadings (typically 1–2 mol% Au) under mild conditions, and quite frequently at ambient (20–25 °C) temperature.

Reaction conditions for inter- and intramolecular direct arylation reactions. RSO3 = camphorsulfonate. HCIB is hydroxy(camphorsulfonyloxy)iodobenzene (1) and PIFA is ([bis(trifluoroacetoxy)iodo]benzene (2). A mixture of iodobenzene diacetate and camphorsulfonic acid can be used where HCIB is formed in-situ

The intramolecular process [6] allows the use of a much larger scope of arene substrates, and facilitates the study of mechanistic details [2] that cannot be elucidated in the intermolecular reaction. In the case of electron-rich arene substrates, replacing the “HCIB” oxidant (1), with “PIFA” (2) substantially reduced the rate of competing diaryliodonium salt formation [7], leading to greater yields of the desired C–C coupled cyclisation product. In the case of the cyclization of 3 to 4, where both the substrate and product bear a highly electron-rich trimethoxy benzene ring (Scheme 2), use of PIFA was essential.

Herein, we present further advancement of this gold-catalysed ring-forming process by way of a formal synthesis of (±)-allocolchicine (±)-5 [8–11], utilising the orthogonality of the process to palladium catalysis to install the requisite ester via carbonylation [12]. The synthesis has revealed a potent mechanism of catalyst deactivation, with substantial implications from this for the requirement of a change in the nature of the oxidant in further developments of the methodology.

2 (±)-Allocolchicine

The gold-catalysed synthesis of (±)-allocolchicine begins with commercially available ketone 6 Footnote 1. After conversion to a silyl enol ether, 7 [13], this is engaged in a retro-Brook rearrangement [14] and the resulting lithium enolate alkylated by trimethoxy benzylbromide 8 to afford ortho-silyl arylketone 9 [15]. Reduction to alcohol 10, then O-alkylation with MOMBr leads to the pre-cyclisation scaffold 11. Under the conditions employed for 3 (Scheme 2) this undergoes gold-catalysed cyclisation to give 12 in 56% yield (with 24% recovered starting material 11). Palladium-catalysed carbonylation of 12 gives 13 in 70% yield. Ester 13 connects with the synthetic pathway of Fagnou and Leblanc [9]Footnote 2, thus completing a 10-step formal synthesis of (±)-allocolchicine (±)-5.

Our initial strategy involved cyclisation of ketone 9 or alcohol 10, to give 14 or 15, which on carbonylation (Scheme 3) would give ketone 16 or alcohol 17, both of which are on the synthetic route developed by Wulff et al. [8]. This would provide a more concise and protecting-group free strategy. However, in contrast to MOM-protected 11, neither the ketone 9 nor alcohol 10 underwent gold-catalysed cyclisation.

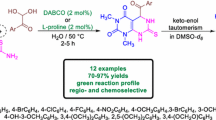

To further explore the impact of the ‘R’ group (Scheme 4) on the cyclisation process, several derivatives of the non-chlorinated analogue 3 were prepared (Scheme 5). Only azide 18d and methyl ether 18e underwent successful cyclisation. It is clear from these observations that the identity of the ‘R’ group, and possibly its propensity to coordinate to gold, has a major impact on the success of the reaction.

Attempted formal synthesis using ketone 9 or alcohol 10 to access compounds 17 and 18 on the synthetic route developed by Wulff [8]

3 Catalyst Deactivation

Although the formal synthesis of (±)-allocolchicine (5) was achieved, the 56% yield of 12 obtained from the cyclisation of 11 is low, especially considering that 5 mol% Au is employed. To gain a better understanding of the implications of using these more complex substrates in the direct arylation reaction, the kinetics of cyclisation of 3 and 11 using 2 mol% Au were monitored by 1H NMR (Figs. 1, 2). The temporal concentration profiles are indicative of severe catalyst deactivation: after initial rapid turnover, both reactions stall, with significant amounts of starting material remaining. Notably, the reaction of chloroarene 11 stalls significantly earlier than that of 3, after only ca.20% conversion to 12.

Temporal concentration profile for the cyclisation of 20–21. The initial (non-productive) burst of consumption of 20 arises from the catalyst activation process in which two gold-derived bromonium ions are trapped by the substrate [2]

In order to assess whether the catalyst deactivation is innate to the use of PIFA, the kinetics of cyclisation of the ‘defunctionalised’ substrate 20 were monitored under the same conditions. Even though the cyclisation of 20 is very slow compared to the initial rate of turnover using 3 and 11, the kinetic profile, which is approximately pseudo-zero order [6], indicates that there is no significant progressive catalyst deactivation, even after 100 h, as compared to 3 and 11 where catalyst deactivation is extensive within 2 h.

The difference in substrate structure between 3/11 and 20, is the absence of both the MOM ether and a highly electron-rich arene in 20, suggesting that the cause of deactivation is due to the presence of one or both of these functional groups. We thus considered a variety of generic catalyst deactivation mechanisms, including that shown in Scheme 6. Here, a side reaction, involving the side-chain (‘Z’) functionality, converts substrate (3 or 11) into an inhibitor (22), which then undergoes competitive transmetalation with the gold to generate an off-cycle complex 23. If this species is unable to cyclise to 24, or to reductively eliminate the biaryl product, and thus unable to release gold back on-cycle, then progressive catalyst inhibition will occur. The impact of the inhibition process will depend on the relative rate of reaction of substrate (3/11) versus the inhibitor (22) with the Au(III).

Reactivity of 18a–e in gold-catalysed direct arylation reaction. Yield determined by 1H NMR [16]

Our attention initially focussed on the MOM ether in 3 and 11, as this protecting group functionality is, by design, acid-labile, and the reaction medium contains, or generates, CF3CO2H from the PIFA (2). Partial in situ cleavage of the MOM group (Scheme 6), to liberate alcohols 10 and 18b, might then be a route to inhibitor species.

As noted above neither 10 nor 18b undergo cyclisation (see Schemes 4, 5). Moreover, inclusion of a catalytic amount of alcohol 18b in the reaction of 3 resulted in an even earlier onset of catalyst inhibition (Fig. 3).

Conditions A: cyclisation of 3–4 under standard conditions (as Fig. 1) ; Conditions B: same a conditions A, but with 10 mol% 18b added at the start of the reaction

Whilst this confirms that alcohol 18b can act as a catalyst poison, possibly by competition with 3 for the catalyst, and then strong off-cycle Au-chelation (25, Scheme 8), we were unable to isolate 18b from the reaction, or detect any formation in situ. Consequently, the kinetics of cyclisation of the acid-stable methyl ether 18e were monitored, with the expectation that no catalyst deactivation would occur if liberation of the hydroxyl group (3 →18a) is required for inhibition. However, 18e was found to undergo the same potent inhibition; indeed the initial rate and overall conversion (Fig. 4) was even lower than with the MOM ether substrate, 3.

Temporal concentration profile (in situ 1H NMR analysis, see SI for full details) for cyclisation of acid-stable methyl ether 18e, showing potent catalyst deactivation still occurs without the need for an acid-labile MOM protecting group (as in 3 and 11, Scheme 7)

In further experiments, we confirmed that product inhibition of the catalyst was not the source of reaction stalling: addition of 100 mol% cyclised product 4 had with no detectable impact on the rate of catalyst turnover. Efforts were thus made to identify side-products in the reaction mixture of 3, 11 and 18e that might behave as inhibitors. Whilst the reactions afforded satisfactory material balance, small quantities of side-products (22a-c) were detected by NMR. The rate of formation of 22a–c was largely independent of the substrate (Fig. 5), and indeed catalyst loading. Highly electron-rich arenes are known to react with iodine(III) oxidants, such as PIFA, to form diaryliodonium salts, π-complexes or radical cations [17]. Careful in situ analysis of the reactions of 3, 11 and 18e by 1H NMR indicated that 22a–c are diaryliodonium salts; this was subsequently confirmed by mass spectrometry. The arylated trimethoxybenzene rings in the cyclisation products (4, 12 and 19e) are more hindered and less electron-rich than the non-arylated starting materials (3, 11 and 18e), and, within the limits of the in situ 1H NMR analysis, do not detectably get converted to the corresponding diaryliodonium species.

Evidence for the impact of substrate-derived diaryliodonium salt (22) generation was obtained by exposing substrate 3 to PIFA prior to addition of catalyst, allowing the build-up of the proposed inhibitor 22a, and then initiating turnover by addition of the Au-precatalyst, Fig. 6. Significantly greater catalyst deactivation was observed in this case, indicative of a link between a reaction of the starting material with PIFA and the catalyst deactivation processFootnote 3.

Conditions A: cyclisation of 3 to 4 under standard conditions (as Fig. 1); Conditions B: same a conditions A, but after pre-incubation of 3 with PIFA before initiating reaction

On the basis of steric hindrance and reduced electron density on the arene ring, diaryliodonium (22) generation would be expected to deactivate the trimethoxy-arene ring in aurated intermediates 23a–c to aromatic electrophilic substitution, [7] and thus prevent either the cyclisation to 24a–c, or reductive elimination of 24a–c, and thus prevent release of gold (Scheme 9). In other words, it would not be the diaryliodonium salt generation per se that is poisoning the catalyst, but the result of tethering this salt to an arylsilane that can still undergo reaction with the gold catalyst (22a–c → 23a–c).

To further probe this aspect, trimethoxytoluene (26) was allowed to react with PIFA to form the diaryliodonium salt 27 (Scheme 10). Addition of 9 mol% 27 to the reaction of 3 resulted in no significant change in rate of turnover or inhibition, further reinforcing the concept that tethering of the diaryliodonium salt to the arylsilane is crucial in the proposed deactivation mechanism (Scheme 11).

This deactivation mechanism is consistent with the experimental observation that the absolute rate of cyclisation is an important factor in determining the final conversion. As shown in Fig. 5, the initial rate of inhibitor formation is independent of the identity of the substrate, as would be expected if there is no significant influence of the aryl silane at the end of the tether on the rate of reaction of the trimethoxybenzene ring with the oxidant. The impact of this is that the cyclisation that proceeds with the fastest absolute rate will have the lowest percentage of inhibitor at a given time, and therefore will suffer least inhibition and attain greatest conversion before stalling (Fig. 7).

The difference in turnover rate between MOM-protected 3, methyl ether 18e, and alcohol 18a, can be tentatively attributed to the coordinating ability of the oxygen ortho- to the silane. If the oxygen can coordinate to the catalyst after the transmetalation (Fig. 8), this could serve to slow π-complexation of the arene to the gold, and thus the rate of cyclisation.

Using 1H NMR to monitor the formation of the proposed inhibitors (22a–c), kinetic modelling [18] can be used to deduce the partitioning between the productive cycle and the deactivation pathway (k 1 / k 2 , Scheme 10). Using this model, a good fit for the deactivation of 18e can be obtained for runs conducted with 1 and 2 mol% catalyst (Fig. 9)Footnote 4. The model indicates that the in situ generated diaryliodonium salt (22c) is a powerful inhibitor, as k 2 ≈ 5 × k 1 . It initially appears surprising that a distal diaryliodonium salt would have the effect of accelerating the rate of transmetalation at the silane. Our previous work suggests that the Au-catalyst intermediates are loosely-solvated, ionic species [2]. Accelerated transmetallation of the catalyst-inhibiting silane-tethered diaryliodonium salts may possibly involve salt metathesis, or localisation of a counter-anion for C-Si cleavage. Efforts to understand this process are on-going.

Kinetics of gold-catalysed cyclisation of 18e. Conditions A: 1 mol%; Conditions B: 2 mol%. Black lines are simulated data based on the deactivation model shown in Scheme 10. The simulation correlates satisfactorily with experimental data for 18e, 19e and 22c when: k 1 :k 2 = 1:5 (where k 1 , k 2 > > k 3 ), k 3 = 0.014 s−1 (TLS) and k 5 = 1.63 × 10−4 dm3 mol−1 s−1. For simplicity, k 4 was set to an arbitrary value of > 1000 dm3 mol−1 s−1. See SI for full details

Although the oxidant change from HCIB (1) to PIFA (2) has allowed for the construction of new molecular structures by substantially attenuating diaryliodonium formation, the small amount (1–4%) of inhibitor that is still formed (Fig. 5) has been found to be significantly detrimental to the reaction (Fig. 9). We have also considered strategies to reduce the rate of the undesired diaryliodonium salt (22) generation by reducing the solution phase concentrations of the substrate or the oxidant, e.g. by slow addition techniques, or limiting rates of solid–liquid mass transfer. However, slow addition of oxidant or substrate both afforded poorer results, e.g. syringe-pump addition of a 0.1 M solution of 3 at a rate of 1 mol% per minute resulted in just 16% conversion to 4, as compared to 70% conversion under the normal conditions (Fig. 6). This arises because of the onset of different catalyst deactivation pathways: the Au(I) to Au(III) redox that completes the catalytic cycle [2] requires both oxidant and arylsilane present to avoid Au-disproportionation, leading to catalytically inactive species.

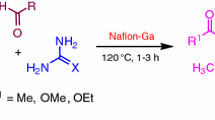

It is thus clear from this study that moving away from hypervalent iodine oxidants to other species will be essential in expanding the generality and utility of the Au-catalysed arylation reaction [1–5]. Despite this, the methodology in its current state provides a number of advantages over other processes, e.g. those catalysed by Pd where high temperatures are often required [19, 20]. Moreover, the synthesis of allocolchicine (Scheme 1) clearly demonstrates how the orthogonality of the Au-catalysed arylation to Pd-catalysed cross-coupling [4] and functionalisation can aid in the synthesis of complex molecules.

4 Conclusion

In conclusion, we have developed a synthetic route to a number of allocolchinoid analogues, including a formal synthesis of (±)-allocolchicine (±)-5 using a gold-catalysed direct arylation [1–6] in the key bond-forming step. The reaction is vulnerable to severe catalyst deactivation, with the likely cause identified as in situ inhibitor generation, involving a direct (uncatalysed) reaction of the substrate with the iodine(III) oxidant. The application of the process to complex molecule synthesis has led to new insights into Au(III) catalysis and has demonstrated both its strengths and weaknesses. We have shown that these complex highly electron rich molecules can be synthesised with operational simplicity and high turnover rates. However, the formation of side products can be seriously detrimental to the efficiency of the process by partial or complete progressive inhibition of the catalyst. The results reinforce the conclusion that finding alternatives to the use of hypervalent iodine oxidants will allow for significant improvements in the gold catalysed direct arylation methodology.

Change history

24 February 2020

The original version of this article unfortunately missed to include the link to the��Supplementary material. The authors would like to correct the error with this erratum.

Notes

CAS: 935-99-9.

18c and 18d were assigned tentatively, 19d was assigned in situ based on literature values (see ref. 7b)

See SI for full details.

Fits for the deactivation of 11 can be obtained with similar k 1 :k 2 partitioning, a poor fit was obtained for the cyclisation of 3.

References

Ball LT, Lloyd-Jones GC, Russell CA (2012) Gold-catalyzed direct arylation. Science 337:1644–1648

Ball LT, Lloyd-Jones GC, Russell CA (2014) Gold-catalyzed oxidative coupling of arylsilanes and arenes: origin of selectivity and improved precatalyst. J Am Chem Soc 136:254–264

Hata K, Ito H, Segawa Y, Itami K (2015) Pyridylidene ligand facilitates gold-catalyzed oxidative C–H arylation of heterocycles. Beilstein J Org Chem 11:2737–2746

Hua Y, Asgari P, Avullala T, Jeon J (2016) Catalytic reductive ortho-C–H silylation of phenols with traceless, versatile acetal directing groups and synthetic applications of dioxasilines. J Am Chem Soc 138:7982–7991

Lloyd-Jones GC, Cresswell A (2016) Room temperature gold-catalysed arylation of heteroarenes: complementarity to palladium catalysis. Chem-A Eur J 22:12641–12645. doi:10.1002/chem.201602893

Corrie TJ, Ball LT, Russell CA, Lloyd-Jones GC (2016) Au-catalyzed biaryl coupling to generate 5-to 9-membered rings: turnover-limiting reductive elimination versus π-complexation. J Am Chem Soc. doi:10.1021/jacs.6b10018

Merritt E, Olofsson B (2009) Diaryliodonium salts: a journey from obscurity to fame. Angew Chem Int Ed 48:9052–9070.

Vorogushin AV, Predeus AV, Wulff WD, Hansen HJ (2003) Diels-Alder reaction-aromatization approach toward functionalized ring C allocolchicinoids. Enantioselective total synthesis of (-)-7S-allocolchicine. J Org Chem 68:5826–5831

Leblanc M, Fagnou K (2005) Allocolchicinoid synthesis via direct arylation. Org Lett 7:2849–2852

Djurdjevic S, Yang F, Green JR (2010) Intramolecular Nicholas reactions in the synthesis of dibenzocycloheptanes. Synthesis of allocolchicine NSC 51046 and analogues and the formal synthesis of (-)-allocolchicine. J Org Chem 75:8241–8251

Besong G, Jarowicki K, Kocienski PJ, Sliwinski E, Boyle FT (2006) Synthesis of (S)-(-)-N-acetylcolchinol using intramolecular biaryl oxidative coupling. Org Biomol Chem 4:2193–2207

Watson DA, Fan X, Buchwald SL (2008) Carbonylation of aryl chlorides with oxygen nucleophiles at atmospheric pressure. Preparation of phenyl esters as acyl transfer agents and the direct preparation of alkyl esters and carboxylic acids. J Org Chem 73:7096–7101

Cazeau P, Duboudin F, Moulines F, Babot O, Dunogues J (1987) A new practical synthesis of silyl enol ethers. Tetrahedron 43:2075–2088

Comanita BM, Woo S, Fallis AG (1999) A versatile tandem retro-[1,4]-Brook rearrangement-condensation reaction of o-bromoacetophenone silyl enol ethers. Tetrahedron Lett 40:5283–5286

Díez-Barra E, Merino S, Sánchez-Verdú P, Torres J (1997) On the π-π interaction in the benzylation of ketones. Tetrahedron 53:11437–11448

18c and 18d were assigned tentatively, 19d was assigned in situ based on literature values (see ref. 9)

Kita Y, Tohma H, Hatanaka K, Takada T, Fujita S, Mitoh S, Sakurai H, Oka S (1994) Hypervalent iodine-induced nucleophilic substitution of para-substituted phenol ethers. Generation of cation radicals as reactive intermediates. J Am Chem Soc 116:3684–3691

DynoChem2011 Software, available from Scale-up Systems Ltd, Dublin, Ireland

Ackermann L (2011) Carboxylate-assisted transition-metal-catalyzed C-H bond functionalizations: Mechanism and scope. Chem Rev 111:1315–1345

Campeau LC, Fagnou K (2006) Palladium-catalyzed direct arylation of simple arenes in synthesis of biaryl molecules. Chem Commun 12:1253–1264.

Acknowledgements

Open access funding provided by University of Edinburgh. The research leading to these results has received funding from the European Research Council under the European Union’s Seventh Framework Programme (FP7/2007–2013) / ERC grant agreement n° [340163].

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Corrie, T.J.A., Lloyd-Jones, G.C. Formal Synthesis of (±)-Allocolchicine Via Gold-Catalysed Direct Arylation: Implication of Aryl Iodine(III) Oxidant in Catalyst Deactivation Pathways. Top Catal 60, 570–579 (2017). https://doi.org/10.1007/s11244-017-0742-z

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11244-017-0742-z