Abstract

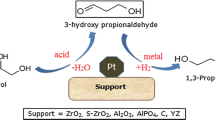

A systematic study of the comparative performances of supported Pt, Pd, Ru and conventional CoMo/Al2O3, NiMo/Al2O3, NiW/Al2O3 catalysts as well as the effects of solvent, H2 pressure and temperature on the hydroprocessing activity of a representative model bio-oil compound (e.g., p-cresol) is presented. With water as solvent, Pt/C catalyst shows the highest activity and selectivity towards hydrocarbons (toluene and methylcyclohexane), followed by Pt/Al2O3, Pd and Ru catalysts. Calculations indicate that the reactions in aqueous phase are hindered by mass-transfer limitations at the investigated conditions. In contrast, with supercritical n-heptane as solvent at identical pressure and temperature, the reactant and H2 are completely miscible and calculations indicate that mass-transfer limitations are eliminated. All the noble metal catalysts (Pt, Pd and Ru) show nearly total conversion but low selectivity to toluene in supercritical n-heptane. Further, conventional CoMo/Al2O3, NiMo/Al2O3 and NiW/Al2O3 catalysts do not show any hydrodeoxygenation activity in water, but in supercritical n-heptane, CoMo/Al2O3 shows the highest activity among the tested conventional catalysts with 97 % selectivity to toluene. Systematic parametric investigations with Pt/C and Pt/Al2O3 catalysts indicate that with water as the solvent, the reaction occurs in a liquid phase with low H2 availability (i.e., low H2 surface coverage) and toluene formation is favored. In supercritical n-heptane with high H2 availability (i.e., high H2 surface coverage), the ring hydrogenation pathway is favored leading to the high selectivity to 4-methylcyclohexanol. In addition to differences in H2 surface coverage, the starkly different selectivities between the two solvents may also be due to the influence of solvent polarity on p-cresol adsorption characteristics.

Similar content being viewed by others

Abbreviations

- \( a_{\text{b}} \) :

-

Gas–liquid interfacial area per unit volume of reactor, m2/m3

- \( a_{\text{p}} \) :

-

Liquid–solid interfacial area, m−1

- \( C_{\text{A}}^{ *} \) :

-

Saturation solubility of H2 in liquid phase, kmol/m3

- \( C_{\text{AS}} \) :

-

H2 concentration on the catalyst surface, kmol/m3

- \( D_{\text{e}} \) :

-

Effective diffusivity, m2/s

- \( d_{\text{i}} \) :

-

Impeller diameter, m

- \( D_{\text{M}} \) :

-

Molecular diffusivity, m2/s

- \( d_{\text{p}} \) :

-

Particle diameter, m

- \( d_{\text{t}} \) :

-

Reactor diameter, m

- \( H_{\text{e}} \) :

-

Henry’s law constant, kmol/m3/atm

- \( h_{\text{l}} \) :

-

Height of the first impeller from the bottom, m

- \( h_{2} \) :

-

Height of the liquid, m

- \( K_{\text{l}} \) :

-

Liquid film mass-transfer coefficient, m/s

- \( K_{\text{l}} a_{\text{b}} \) :

-

Overall gas–liquid mass-transfer coefficient, s−1

- \( K_{\text{s}} \) :

-

Liquid–solid mass-transfer coefficient, m/s

- \( m \) :

-

Order of reaction with respect to hydrogen

- \( M_{\text{w}} \) :

-

Molecular weight of solvent, g/mol

- \( n \) :

-

Moles of gas at constant pressure, kmol

- \( N \) :

-

Agitation speed, Hz

- \( N_{\text{p}} \) :

-

Power number

- \( P_{\text{H2}} \) :

-

Partial pressure of hydrogen, MPa

- \( R \) :

-

Universal gas constant, kJ/kmol/K

- \( R_{\text{H2}} \) :

-

Overall rate of hydrogenation, (kmol/m3) s−1

- \( r_{ \max }^{{}} \) :

-

Maximum rate of hydrogenation, (kmol/m3) s−1

- \( T \) :

-

Temperature, K

- \( V_{\text{g}} \) :

-

Volume of the gas in the reactor, m3

- \( V_{\text{l}} \) :

-

Volume of the liquid in the reactor, m3

- \( w \) :

-

Catalyst loading, kg/m3

- \( {{\upalpha}}_{ 1} \) :

-

Parameter defined by Eq. 1

- \( {{\upalpha}}_{ 2} \) :

-

Parameter defined by Eq. 3

- \( \phi_{ \exp } \) :

-

Parameter defined by Eq. 12

- \( \rho_{\text{l}} \) :

-

Density of liquid, kg/m3

- \( \mu_{\text{l}} \) :

-

Viscosity of liquid, centipoise

- \( \chi \) :

-

Association factor

- \( {{\upupsilon}}_{\text{M}} \) :

-

Molar volume of the solute, cm3/mol

- \( \rho_{\text{p}} \) :

-

Density of particle, kg/m3

- \( \in \) :

-

Porosity of the catalyst particle

- τ :

-

Tortuosity

References

Bridgwater AV, Peacocke GVC (2000) Renew Sustain Energy Rev 4:1

Demirbas A (2000) Energy Convers Managem 41:633

McKendry P (2002) Bioresour Technol 83:37

Yaman S (2004) Energy Convers Managem 45:651

Demirbas MF, Balat M (2006) Energy Convers Managem 47:2371

Meier D, Faix O (1999) Bioresour Technol 68:71

Islam MN, Beg MRA (2004) Bioresour Technol 92:181

Mohan D, Pittman CU, Steele PH (2006) Energy Fuels 20:848

Huber GW, Iborra S, Corma A (2006) Chem Rev 106:4044

Wright MM, Brown RC (2007) Biofuels Bioprod Bioref 1:49

Demirbas A (2001) Energy Convers Managem 42:1357

Bridgwater AV (1994) Appl Catal A Gen 116:5

Williams PT, Nugranad N (2000) Energy 25:493

Tang Y, Yu W, Mo L, Lou H, Zheng X (2008) Energy Fuels 22:3484

Miao S, Shanks BH (2009) Appl Catal A Gen 359:113

Tang Z, Lu Q, Zhang Y, Zhu X, Guo Q (2009) Ind Eng Chem Res 48:6923

Moens L, Black SK, Myers MD, Czernik S (2009) Energy Fuels 23:2695

Tang Z, Zhang Y, Guo Q (2010) Ind Eng Chem Res 49:2040

Putun E, Uzun BB, Putun AE (2009) Energy Fuels 23:2248

Wildschut J, Mahfud FH, Venderbosch RH, Heeres HJ (2009) Ind Eng Chem Res 48:10324

Vispute TP, Huber GW (2009) Green Chem 11:1433

Yang X, Chatterjee S, Zhang Z, Zhu X, Pittman CU Jr (2010) Ind Eng Chem Res 49:2003

Yakovlev VA, Khromova SA, Sherstyuk OV, Dundich VO, Ermakov DY, Novopashina VM, Lebedev MY, Bulavchenko O, Parmon VN (2009) Catal Today 144:362

Elliott DC (2007) Energy Fuels 21:1792

Elliott DC, Hart TR (2009) Energy Fuels 23:631

Elliott DC, Hart TR, Neuenschwander GG, Rotness LJ, Zacher AH (2009) Environ Progress Sustain Energy 28:441

Fisk CA, Morgan T, Ji Y, Crocker M, Crofcheck C, Lewis SA (2009) Appl Catal A Gen 358:150

Cortright RD, Davda RR, Dumesic JA (2002) Nature 418:964

Ford JW, Chaudhari RV, Subramaniam B (2010) Ind Eng Chem Res 49:10852

Czernik S, Bridgwater AV (2004) Energy Fuels 18:590

Ingram LL Jr, Mohan D, Bricka M, Steele P, Strobel DA, Crocker D, Mitchell BK, Mohammad J, Cantrell K, Pittman CU Jr (2008) Energy Fuels 22:614

Zhao C, Kou Y, Lemonidou AA, Li X, Lercher JA (2009) Angew Chem Int Ed 48:3987

Zhao C, Kou Y, Lemonidou AA, Li X, Lercher JA (2010) Chem Commun 46:412

Zhao C, He J, Lemonidou AA, Li X, Lercher JA (2011) J Catal 280:8

Sugii T, Kamiya Y, Okuhara T (2006) Appl Catal A Gen 312:45

Oasmaa A, Czernik S (1999) Energy Fuels 13:914

Fonts I, Kuoppala E, Oasmaa A (2009) Energy Fuels 23:4121

Yang X, Chatterjee S, Zhang Z, Zhu X, Pittman CU Jr (2010) Ind Eng Chem Res 49:2003

Graca I, Ribeiro FR, Cerqueira HS, Lam YL, de Almeida MBB (2009) Appl Catal B Environ 90:556

Alcala R, Mavrikakis M, Dumesic JA (2003) J Catal 218:178

Laurent E, Delmon B (1994) J Catal 146:281

Pray HA, Schweickert CE, Minnich BH (1952) Ind Eng Chem 44:1146

Ramachandran PA, Chaudhari RV (1983) Three phase catalytic reactors. Gordon & Breach, New York

Patil NG, Roy D, Chaudhari AS, Chaudhari RV (2007) Ind Eng Chem Res 46:3243

Faglioni F, Goddard WA III (2005) J Chem Phys 122:1

Eijsbouts S (1997) Appl Catal A Gen 158:53

Gainza AE, Ruette F, Rodriguez-Arias EN (1993) J Mol Catal 85:345

Xu H, Friend CM (1993) J Phys Chem 97:3584

Rufael TS, Huntley DR, Mullins DR, Gland JL (1994) J Phys Chem 98:13022

Centeno A, Laurent E, Delmon B (1995) J Catal 154:288

Tanksale A, Beltramini JN, Lu GQ (2006) Develop Chem Eng Min Process 14:9

Gholap RV, Chaudhari RV, Hofmann H (1987) Can J Chem Eng 65:744

Sano Y, Yamaguchi N, Adachi T (1974) J Chem Eng Jpn 1:255

Wilke CR, Chang P (1955) AIChE J 1:264

Calderbank PH (1958) Trans Inst Chem Eng 36:443

Acknowledgments

Funding for this work was provided by US Department of Agriculture (Grant 2011-10006-30362) and core funds from the Center for Environmentally Beneficial Catalysis (CEBC) at the University of Kansas. Helpful discussions with Drs Juan J. Bravo Suarez and Debdut Roy are gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Appendix: Criteria for Evaluating Significance of Mass-Transfer Limitations

Appendix: Criteria for Evaluating Significance of Mass-Transfer Limitations

(a) Gas–liquid mass-transfer resistance is considered insignificant if

where \( K_{\text{l}} a_{\text{b}} \) is the gas–liquid mass-transfer coefficient and is calculated according to the correlation proposed by Gholap and co-workers [52].

(b) Liquid–solid mass-transfer limitation is considered unimportant if

where \( a_{\text{p}} \), the external surface area of the catalyst per unit volume for spherical particles is given by

and \( K_{\text{s}} \) is the liquid–solid mass-transfer coefficient and is estimated by the correlation proposed by Sano and co-workers [53].

where \( F_{\text{c}} \) is the shape factor (assumed to be unity for spherical particles) and \( D_{\text{M}} \) is the molecular diffusivity calculated by using the correlation proposed by Wilke and Chang [54].

and e is the energy supplied calculated by using the correlation proposed by Calderbank [55].

where \( \psi \) is the correction factor for the presence of gas bubbles calculated by using the correlation proposed by Calderbank [55].

where \( Q_{\text{g}} \) is the volumetric flow rate (m3/s) of gas calculated by using the formula

where \( V_{\text{M}} \) is the molar gas volume (m3/kmol) calculated by using the formula

(c) Pore diffusion resistance can be considered to be insignificant if

where \( D_{\text{e}} \) is the effective diffusivity and is calculated by using the formula

If gas–liquid mass-transfer limitation is significant, \( C_{\text{A}}^{ *} \) is replaced by \( C_{\text{AS}} \) which is calculated by using the formula

Rights and permissions

About this article

Cite this article

Wan, H., Chaudhari, R.V. & Subramaniam, B. Catalytic Hydroprocessing of p-Cresol: Metal, Solvent and Mass-Transfer Effects. Top Catal 55, 129–139 (2012). https://doi.org/10.1007/s11244-012-9782-6

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11244-012-9782-6