Abstract

The dynamic behaviour of a single PEM fuel cell (PEMFC) with a PtRu/C anode catalyst using CO containing H2 as anode feed was investigated at ambient temperature. The autonomous oscillations of the cell potential were observed during the galvanostatic operation with hydrogen anode feed containing CO up to 1000 ppm. The oscillations were ascribed to the coupling of the adsorption of CO (the poisoning step) and the subsequent electrochemical oxidation of CO (the regeneration step) on the anode catalyst. The oscillations were dependent on the CO concentration of the feed gas and the applied current density. Furthermore, it was found that with CO containing feed gas, the time average power output was remarkably higher under potential oscillatory conditions in the galvanostatic mode than during potentiostatic operation. Accompanying these self-sustained potential oscillations, oscillation patterns of the anode outlet CO concentration were also detected at low current density (<100 mA/cm2). The online measurements of the anode outlet CO concentrations revealed that CO in the anode CO/H2 feed was partially electrochemically removed during galvanostatic operation. More than 90% CO conversion was obtained at the current densities above 125 mA/cm2 with low feed flow rates (100–200 mL/min).

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The hydrogen gas produced by the steam reforming of light alkanes (e.g., methane) or alcohols is a suitable fuel for H2 polymer electrolyte membrane fuel cells (PEMFCs) [1–3]. However, even traces (ppm) of carbon monoxide (CO) in the hydrogen feed gas can cause serious performance degradation of PEMFCs [1–6]. In order to achieve higher power output with CO containing feed in fuel cells, the utilisation of bimetallic anode catalysts, PtM/C, have been largely investigated [1–3, 6–12]. The influence of Ru, Mo, Sn with Pt as anode catalyst is intensively studied. The enhanced CO-tolerance of PtRu/C is generally ascribed to the decrease in CO binding energy on Pt due to electronic substrate effects, and to the oxidation of chemisorbed CO being catalyzed at low potential by the activation of H2O. The CO poisoning and recovery processes on the anode are strongly influenced by the kinetics and thermodynamics of either direct or electrochemical oxidation of CO, as well as the physical and chemical adsorption/desorption processes. In addition, because of the strong poisoning of the anode catalyst with CO at lower temperatures, it is important to investigate the fuel cell performance at room temperature relating to the start-up conditions of the PEM fuel cell system [2, 4]. Potential oscillations have been previously reported by other groups [2, 4, 10–12], but our goal was to obtain further insight into the CO poisoning process and into the resulting dynamic characteristics of a cell using CO-containing H2 as anode feed. In fact, the transient recovery of the cell performance is likely related to the fast electrochemical oxidation of the adsorbed CO occurring above certain anode overpotential. Therefore, the removal of the trace amount of CO in the feed by electrochemical CO oxidation in a fuel cell type unit could provide an alternative for the conventional preferential oxidation technology with gaseous CO in the bulky and cost-intensive reactors [2].

He et al. [13] and Lakshmanan et al. [14] reported the pioneering investigations of the CO oxidative conversion in PEMFC-type configurations. Recently, the electrochemical preferential oxidation (EPrOx) of CO has been intensively studied by Zhang et al. [2, 15]. Their results demonstrated that CO in the anode feed was partly removed by the electrochemical oxidation of CO in the anodic electrode. Therefore, aside from the power generation by hydrogen oxidation, these results clearly indicate that CO is oxidised both on the anode in PEM fuel cells and under mild operation conditions. Huang et al. [3] presented an analogous concept for CO treatment, in which the CO-containing reformate hydrogen was conducted in an Adsorber/Electrolyzer/Humidifier reactor unit similar to a MEA structure before feeding it into PEMFCs. The results showed that the PEMFC performance was improved because of the removal of CO in the fuel feed, although the experimentally measured CO conversion was not reported. Ioroi et al. [1] observed a remarkable increase in the anode outlet CO concentrations in a PEMFC with PtRu/C anode catalyst due to the high utilisation degree of the hydrogen fuel in the feed gas. However, with the Pt–MoO x /C anode catalyst CO was also efficiently removed at 80 °C at a given current density. These observations demonstrate that it is crucial to understand the CO transient poisoning/recovery mechanism and CO electrochemical oxidation process occurring with the CO-containing H2 anodic feed.

To get deeper insight into the influence of CO on the poisoning of the anode catalyst and the resulting dynamic behaviour of the cell potential, we compared the steady-state polarization performance (potentiostatic V–i curves) to the galvanostatic operation with a single fuel cell using H2 containing different CO concentration (0–1000 ppm) as anode feed. The dynamic behaviour (the self-sustained potential oscillations) of the fuel cell voltage during galvanostatic operation is reported at various applied current densities. Furthermore, a quantitative on-line determination of the CO concentration in the anode outlet gas stream during the self-sustained potential oscillations is reported as well. Finally, we evaluate the feasibility of a PEM fuel cell with a bimetallic anode catalyst to work as a reactor unit for removing traces of CO in the H2 stream.

Experimental

The experiments were carried out in a single cell with an active electrode area of 26 cm2 equipped with membrane electrode assembly (MEA) prepared in-house. The catalyst layers (anode: carbon supported 30% PtRu (atomic ratio 1:1) with 0.75 mg/cm2 metal loading; cathode: unsupported Pt black with 5 mg/cm2 loading) were fixed on the commercial Nafion 117 membrane foil by airbrush technique as described in detail in a prior publication of our group [16]. The commercial catalysts were purchased from the Alfa Aesar® Johnson Matthey (Germany). The graphite bipolar plates had parallel flow-field channels illustrated photographically in [16]. The PEMFCs were completed by gold-plated copper plates as current collectors and stainless plates for bracing the whole sandwich structure.

The experimental setup consisted of calibrated rotameters to conduct the reactant gases (H2 containing ppm level of CO) to the anodic (f = 100–400 mL/min) and to the cathodic (pure O2, f = 300 mL/min) compartments as shown in Fig. 1 The CO concentration in the CO/H2 fuel was varied by diluting a premixed gas containing 1000 ppm of CO in H2 with pure H2. The anode and cathode feed streams were humidified by saturating them with moisture at room temperature in bubble bottles. All the experiments in this work were carried out under atmospheric pressure at room temperature without further thermostatic equipments.

An electrochemical workstation (IM6e, Zahner-Elektrik GmbH, Germany) equipped with an external booster (EL101, Zahner-Elektrik GmbH, Germany) was used for the potentiostatic or galvanostatic electrochemical analysis and for the exploration of the transient behavior of the system. An additional in-house constructed, multi-channel potential recorder (with a sampling interval of 1 s) was used to record the cell potential as a function of time.

The concentrations of CO in the anode inlet and outlet gases were analysed with an online infra red CO gas analyzer (URAS 14, ABB Automation GmbH, Germany) with a measurement range of 0–250 ppm CO. The moisture of the anode outlet gas was removed by conducting the exit gas first through a cooling trap (0 °C, ~33 mL) and subsequently through a silica-gel column (~10 mL, estimated void fraction of 0.5) before permitting it to enter the moisture-sensitive chamber in the IR analyzer.

Results and Discussion

Cell Performance with CO Containing H2 Anode Feed

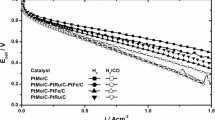

Figure 2a shows the cell voltage as a function of the current density obtained in the potentiostatic mode with various concentration levels (50–1000 ppm) of CO in H2 as anode feed. The polarization curve measured without CO in the H2 feed is also presented here for comparison. The open-circuit voltage (OCV) of the fuel cell with CO free H2 feed was ~1.03 V. The highest power density obtained was ~150 mW/cm2 at a current density of ~325 mA/cm2 (Fig. 2b), which demonstrates a good operating performance of the fuel cell with CO-free H2 feed at room temperature. However, as expected, the fuel cell performance decreased significantly when CO-containing gas was fed to the anode compartment. Remarkable voltage loss was observed immediately, as trace amounts of CO were included in the anode feed gas. The dependence of the measured cell voltage on the CO concentration in the anode gas and on the current density was strongly nonlinear as seen in Fig. 2a. For example, at a current density of 25 mA/cm2, the cell voltage was ~0.89 V with pure H2 as anode feed. The cell voltage decreased sharply in the current density range between 0 and 25 mA/cm2 and was ~0.47 and 0.40 V with anode fuel gas containing 200 and 1000 ppm CO in hydrogen, respectively. The obvious decrease in the fuel cell power output is due to the strong adsorption of CO which occupies the active sites of the anode catalysts in a potentiostatic controlled system, in this way hindering the electrochemical oxidation of hydrogen [1–3, 6].

Onset of the Autonomous Potential Oscillations

Figure 3 illustrates the cell voltage behaviour in the galvanostatic operation as a function of time as the anode feed was switched between CO free hydrogen and CO containing (200 ppm) hydrogen at a current density of 100 mA/cm2. As expected, the cell voltage remained unchanged, high level using CO free H2 feed (not shown here). However, the autonomous oscillations of the fuel cell potential were observed in the galvanostatic operation when CO-free H2 stream was replaced by CO/H2 stream with 200 ppm CO. This observation is in full accordance with the results previously reported by Zhang and Datta [2, 10]. When the CO containing H2 stream was replaced by the CO free H2 stream, the potential oscillations disappeared, the cell operation was gradually revived, and the cell voltage was recovered to the initial value obtained with the CO-free hydrogen. These results clearly indicate that the poisoning process is not completely irreversible, and that the investigated cell could be regenerated during 20 min by operating with CO-free hydrogen to the cell. The observed performance recovery is likely due to the gradual desorption of the adsorbed CO molecules from the PtRu/C active sites. The following mechanism has been suggested for the re-activation of the CO-poisoned sites [1–4]:

where S represents the adsorption active sites of the PtRu/C anode catalyst. Equation 1 describes the direct desorption processes, and Eq. 2 the direct oxidation of CO, Eq. 3 the electrochemical oxidation of CO, and Eq. 4 the water–gas-shift (WGS) reaction, respectively. Considering the operation conditions in this study (room temperature), the dynamic recovery is likely related to the electrochemical CO oxidation process. This would mean that—depending on the anode potential—the adsorbed CO reacts on the PtRu/C active sites according to Eq. 3.

The Influence of the Current Density on Potential Oscillations

In order to analyse the potential oscillations observed with CO containing feed gas, the dependence of the oscillations on the applied current density and on the feed flow rate was investigated in more detail. Figure 4 illustrates the oscillation patterns (time duration: 300 s) of the fuel cell using H2 with 200 ppm CO as anode feed at various current densities between 0 and 200 mA/cm2. The voltage remained expectedly stable at a value of 1.03 V during the initial conditions without current (open-circuit condition). The autonomous oscillations of the cell potential were observed when a current density of 25 mA/cm2 or higher was applied to the system. At the lower current range, <100 mA/cm2, the oscillations occurred with a constant frequency, and showed nearly constant amplitude over time at each measured current density. At higher current densities, >100 mA/cm2, the frequency remained constant at each measured current density, but the amplitude showed noticeable fluctuations. The frequency was clearly dependent on the current density, and was found to increase nearly linearly as a function of the applied current densities (as seen in Fig. 4). It should be pointed out here that the observed dependence of the oscillation frequency on the current density, which was obvious in our measurements, was not detected in the earlier investigations by Zhang and Datta [10]. The reason for the performance difference might be attributed to the different current density range or to the operation temperature. Our measurements were carried out at room temperature without the external thermostating at the current density range up to 200 mA/cm2. In comparison to our experimental conditions, Zhang and Datta [10] investigated the influence of the current density at the cell temperature of 55 °C with current densities from 300 up to 700 mA/cm2. Furthermore, the different behaviour observed here might be related to the cell size: 26 cm2 (this study) vs. 5 cm2 in [10], whereas the larger anode compartment in our system might cause more complex, non-ideal flow distribution [17–19]. However, more detailed experiments and multidimensional modelling will be carried out later to elucidate the influence of the different flow fields/electrode areas on the cell potential oscillations in detail.

As mentioned above, the potential oscillation patterns are likely related to the CO adsorption and the electro-oxidation processes in the anode PtRu/C catalyst surface. Initially, at low CO coverage, the cell generates the desired current at high cell voltage (i.e., low anodic overpotential). As the CO coverage increases, the current remains constant but the cell voltage rapidly decreases due to the continuously increasing anodic overpotential. The adsorbed CO is then electrochemically oxidised on the anode catalyst surface above a certain limiting overpotential. This in turn releases the active sites earlier occupied by CO [10, 20–23]. The simple dynamic modelling proposed by Zhang and Datta [10] was mainly based on this mechanism and was able to successfully describe most experimental observations.

Improved Cell Performance Under the Oscillatory-State Operation

Figure 5a depicts the amplitude of the potential oscillations as a function of applied current densities with 200 ppm CO/H2 feed stream. The time-averaged voltage was calculated for each applied current density (as illustrated also in Fig. 5a), and the polarization curve in the galvanostatic operating mode was determined on the basis on this time-averaged value. Figure 5b, c illustrate the polarization and the power density curves under the potentiostatic and galvanostatic operation modes (corresponding to the potential steady-state and potential oscillatory-state). For comparison, in Fig. 5b, c, the V–i curve and the power output for CO-free hydrogen under potentiostatic conditions is also shown. As can be seen in Fig. 5b, with CO containing feed gas the time-averaged voltage at the applied current density in the galvanostatic mode is clearly higher than the corresponding value in the potentiostatic mode.

Anode Outlet CO Concentrations/Electrochemical CO Removal

The anode outlet CO concentrations were experimentally determined by an IR CO gas analyzer as a function of the current density applied (0–200 mA/cm2). If the fuel cell was operated in the low current density range (<100 mA/cm2), the CO concentration in the reactor outlet was found to oscillate (as seen in Fig. 6a). Figure 6b illustrates the experimentally determined signal amplitudes of the CO concentration at various applied current densities. The frequency of the concentration oscillations was approximately equal to that of the cell potential oscillations. This observation makes it evident that aside from the hydrogen oxidation, the CO is also electrochemically oxidised on the anodic electrode.

As the measured CO concentration oscillations were found to be dependent on the current density, and as they were experimentally detectable only in the lower current density range (low frequency), we should briefly describe the analytical procedure applied here for the CO analysis. IR-spectroscopy is a very precise detection method even for small concentrations (ppm range) of CO. However, due to the limited absorbance of IR light by gas molecules, a certain light path (and the measurements chamber volume) is necessary in the IR equipment. Furthermore, due to the high sensitivity of the IR chamber windows (typically KBr) to humidity, the incoming gas has to be completely dehumidified before conducting it into the equipment. The water was removed in a cooling trap (0 °C) followed by a column filled with the silica gel. All three units (the cooling trap, the silica gel column and IR measurement chamber) possess certain volumes, which inevitably causes some back mixing of the gas stream. The back mixing would not be critical in steady-state measurements where the concentrations on the reactor outlet remain constant over time. However, during the signal oscillating conditions as measured here, the back mixing dramatically influences the measured signal amplitude. We might expect here that the measured signal amplitude \( \hat{x}_{CO}^{meas} \) is depressed due to the internal back mixing in each of the three units in the cascade, and therefore the measured signal amplitude is smaller than the actual reactor outlet amplitude \( \hat{x}_{CO}^{reactor} \). The ratio of the measured/actual amplitudes can be roughly estimated by a simple mathematical model. For this purpose the three units are treated as a cascade of ideally mixed tanks (volumes approximately 33, 5 and 22 mL). Ideal tubular flow behavior (no back mixing) is assumed in the tubular lines (i.d. 1 mm) between the tanks. Furthermore, the CO concentration signal is approximated by a harmonic oscillation. The signal amplitudes can then be related by the frequency response of the cascade (e.g., [24]):

In the above equation \( \omega \) is the angular frequency of the signal, \( \tau_{1} \)–\( \tau_{3} \) are the time constants of the three tanks (tank volume divided by volumetric flow rate) and \( \theta \) is the dead time of the tubular lines. The last parameter however has no influence on the modulus of the frequency response function and therefore does not influence the amplitude ratio of the cascade input and output signal.

Figure 6b shows the amplitude of the measured CO concentration oscillations, \( \hat{x}_{CO}^{meas} \). They were found to decrease with increasing current density. No oscillations were experimentally observed in the CO signal at current densities higher than 125 mA/cm2. As can be seen from Fig. 6c, the calculated signal amplitudes at the reactor outlet, \( \hat{x}_{CO}^{reactor} \), also decrease with increasing current density. As, the frequency of the oscillations is increasing as a function of the current density (see Fig. 4), the attenuation of the cascade is also increasing. This fact allows us to expect that the CO concentration in the reactor outlet likely oscillates at higher current densities as well. For current densities higher than 125 mA/cm2, the potential frequency was found to be higher than 0.1 Hz. This value lies considerably above the cut-off frequency of the cascade. It is therefore not possible to resolve the CO concentration oscillations at higher current densities with the present analysis system.

The average concentration of CO in the anode outlet (based on the maximum and minimum CO concentrations) was calculated for each experimental conditions. Figure 7a presents the measured average outlet CO concentrations when 200 ppm CO containing H2 was used as anode feed stream at various current densities of 25–200 mA/cm2. As expected, under open circuit conditions, the anode outlet CO concentration was equal to the inlet CO concentration. This agrees with the reported observation that CO does not react in the anode chamber under open circuit conditions. This was also observed by Ioroi et al. [1], as they reported that the anode outlet CO concentrations for PtRu/C catalyst were nearly equal to the inlet values, and the outlet CO concentrations were hardly affected by the species of the cathode feed (pure O2 or pure N2 stream) under the open-circuit conditions. However, under conditions where current was applied, we found that the CO concentration steadily decreased as a function of the current density from 25 to 200 mA/cm2 at a constant flow rate. For 200 ppm CO/H2 with a flow rate of 300 mL/min, the anode outlet CO concentrations were 150, 109, 79, 62 and 58 ppm, respectively, at the current densities of 25, 50, 100, 150 and 200 mA/cm2, respectively. At current densities >125 mA/cm2, only minor differences were observed in the CO conversion. Furthermore, the anode outlet CO concentrations were found to decrease with increasing residence time at a given current density. For example, for 200 ppm CO/H2 as anode feed, the anode outlet CO concentrations were 115, 79, 43 and 19 ppm corresponding to the flow rates of 400, 300, 200 and 100 mL/min at the current density of 100 mA/cm2. If we take into consideration the hydrogen fuel utilisation degree at the above flow rates (4.9, 6.59, 9.88, 19.8%) we observe a clear, non-linear dependence of the CO conversion from the hydrogen utilisation degree. CO conversion increases as the hydrogen utilisation degree increases, but due to the non-linear dependency, high CO conversion is possible only with very high utilisation degree. At current density 200 mA/cm2, the anode outlet CO concentration decreased from 75 to 12 ppm as the anode flow rate decreased from 400 to 100 mL/min. The observed low CO outlet concentration in the cell outlet stream clearly indicates that CO in the anode feed was partly converted to CO2 by the electrochemical oxidation of CO in the anode. Finally, the dependence of CO conversion on the hydrogen recovery degree (calculated as the ratio of unconsumed H2 to the feed of H2) is given in Fig. 7b. The ideal operating point for the system would be in the right upper corner in this graph, where the high CO conversion is achieved with simultaneous high hydrogen recovery. However, as seen in the illustration, the conversion of CO was found to decrease with the high recovery degree of H2. The optimum operating point (high H2 recovery degree, high CO conversion) with the investigated cell was achieved at the lowest investigated feed rate (100 mL/min) with moderate current density (50–75 mA/cm2), where the conversion of CO was approximately 75–85% and the H2 recovery degree 85 to 90%.

Conclusions

The PEMFC cell performance with the PtRu/C anode catalyst using various CO concentrations (0–1000 ppm) in the CO/H2 anodic feed was investigated at room temperature and atmospheric pressure. The self-sustained oscillations of the cell voltage were observed under the galvanostatic operation with CO-containing H2 anodic feed. The CO concentration oscillations in the anode outlet gases were also experimentally observed at low current densities (<100 mA/cm2) for the first time, which directly proves the occurrence of the electrochemical oxidation of CO in the anode field. The quantitative analysis of the anode outlet CO concentration demonstrated that CO in the anodic feed was removed by the electrochemical CO oxidation accompanied by the periodical potential oscillations. Therefore, we might suggest here that a low temperature fuel cell equipped with PtRu anode could possibly work as an electrochemical membrane reactor for the removal of traces of CO in the H2 streams.

References

Ioroi T, Akita T, Yamazaki SI, Siroma A, Fujiwara N, Yasuda K (2006) Electrochim Acta 52:491

Zhang JX, Datta R (2005) J Electrochem Soc 152:A1180

Huang CP, Jiang RC, Elbaccouch M, Muradov N, Fenton J (2006) J Power Sources 162:563

Jimenez S, Soler J, Valenzuela RX, Daza L (2004) J Power Sources 151:69

Litster S, McLean KG (2004) J Power Sources 130:61

Wee JH, Lee KY (2006) J Power Sources 157:128

Crabb EM, Marshall R, David T (2000) J Electrochem Soc 147:A4440

Papageorgopoulos DC, Keijzer M, de Bruijn FA (2002) Electrochim Acta 48:197

Bonakdarpour A, Lobel R, Atanasoski RT, Vernstrom GD, Schmoeckel AK, Debe MK, Dahn JR (2006) J Electrochem Soc 153:A1835

Zhang JX, Datta R (2002) J Electrochem Soc 149:A1423

Murthy M, Esayian M, Hobson A, MacKenzie S, Lee WK, Van Zee JW (2001) J Electrochem Soc 148:A1141

Zhang JX, Fehribach JD, Datta R (2004) J Electrochem Soc 151:A689

He CZ, Kunz HR, Fenton JM (2001) J Electrochem Soc 148:A1116

Lakshmanan B, Huang W, Weidner JW (2002) Electrochem Solid-State Lett 5:A267

Zhang JX, Datta R (2003) Electrochem Solid-State Lett 6:A5

Schultz T, Sundmacher K (2005) J Power Sources 145:435

Stumper J, Campbell SA, Wilkinson DP, Johnson MC, Davis M (1998) Electrochim Acta 43:3773

Kanezaki T, Li XG, Baschuk JJ (2006) J Power Sources 162:415

Brett DJL, Aguiar P, Brandon NP, Kucernak AR (2007) Int J Hydrogen Energy 32:863

Zhang JX (2004) PhD thesis, Worcester Polytechnic Institute, Worcester, pp 92–154, 179–205

Zhang JX, Datta R (2004) Electrochem Solid-State Lett 7:A37

Thomason AH, Lalk TR, Appleby AJ (2004) J Power Sources 135:204

Farrell CG, Gardner CL, Ternan M (2007) J Power Sources 171:282

Bequette BW (1998) Process dynamics: modeling, analysis, and simulation. Prentice Hall PTR, Upper Saddle River, NJ

Acknowledgements

Dr. Hui Lu is grateful for a Max Planck Scholarship from the Max-Planck-Gesellschaft (MPG). The financial support obtained from the co-operation project ProBio between the Max Planck Society and Fraunhofer Society is gratefully acknowledged.

Open Access

This article is distributed under the terms of the Creative Commons Attribution Noncommercial License which permits any noncommercial use, distribution, and reproduction in any medium, provided the original author(s) and source are credited.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This is an open access article distributed under the terms of the Creative Commons Attribution Noncommercial License (https://creativecommons.org/licenses/by-nc/2.0), which permits any noncommercial use, distribution, and reproduction in any medium, provided the original author(s) and source are credited.

About this article

Cite this article

Lu, H., Rihko-Struckmann, L., Hanke-Rauschenbach, R. et al. Dynamic Behavior of a PEM Fuel Cell During Electrochemical CO Oxidation on a PtRu Anode. Top Catal 51, 89–97 (2008). https://doi.org/10.1007/s11244-008-9117-9

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11244-008-9117-9