Abstract

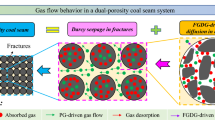

Diffusion is an important process in coalbed methane migration. In addition to diffusion coefficient, the size and shape of coal particles also have influences on methane adsorption and desorption. Thus, the matrix shape factor is a key parameter affecting the methane diffusion rate in coal matrix. The matrix shape factor of intact coal has been studied by many scholars, but that of the tectonic coal has not been established. In this paper, the theoretical expression of matrix shape factor of the tectonic coal is proposed for the first time, which is \(\alpha_{N} = 480Nb/\left( {(27 - 2N)a^{3} } \right)\). The experimental test of gas emission characteristics of the standard tectonic coal sample is conducted, and the numerical simulation of gas emission is also carried out under the same conditions as the experiment. By matching the numerically calculated gas volumes with the experimental values, the approximate matrix shape factor of the tectonic coal sample can be obtained, and the value is 1.83 × 106 m−2. The matrix scale and fracture aperture are further calculated, which are 0.518 mm and 3.702 μm, respectively. On this basis, the effects of the matrix scale and fracture aperture on coalbed methane migration are analyzed, and the stress relief measures to enhance the methane recovery of tectonic coal seam are proposed.

Article Highlights

-

(1)

Theoretical expression of matrix shape factor of tectonic coal is proposed for the first time.

-

(2)

Values of shape factor, matrix size and fracture aperture are determined.

-

(3)

Stress relief measures to enhance methane recovery in tectonic coal seam are proposed.

Similar content being viewed by others

References

Cheng, Y., Pan, Z.: Reservoir properties of Chinese tectonic coal: a review. Fuel 260, 116350 (2020)

Cheng, M., Fu, X., Kang, J., Chen, Z., Tian, Z.: Effect of water on methane diffusion in coal under temperature and pressure: a LF-NMR experimental study on successive depressurization desorption. Fuel 324, 124578 (2022)

Coats KH (1989) Implicit compositional simulation of single-porosity and dual-porosity reservoirs paper Spe

Dong, J., Cheng, Y., Jin, K., Zhang, H., Liu, Q., Jiang, J., Hu, B.: Effects of diffusion and suction negative pressure on coalbed methane extraction and a new measure to increase the methane utilization rate. Fuel 197, 70–81 (2017a)

Dong, J., Cheng, Y., Liu, Q., Zhang, H., Zhang, K., Hu, B.: Apparent and true diffusion coefficients of methane in coal and their relationships with methane desorption capacity. Energy Fuels 31, 2643–2651 (2017b)

Dong, J., Cheng, Y., Jiang, J., Guo, P.: Effects of tectonism on the pore characteristics and methane diffusion coefficient of coal. Arab. J. Geosci. 13, 1–10 (2020a)

Dong, J., Cheng, Y., Pan, Z.: Comparison of transient and pseudo-steady diffusion of methane in coal and implications for coalbed methane control. J. Petrol. Sci. Eng. 184, 106543 (2020b)

Dong, J., Cheng, Y., Wang, L., Guo, P.: Establishment of the equivalent structural model for the tectonic coal and some implications for the methane migration. RSC Adv. 10, 9791–9797 (2020c)

Fan, C., Elsworth, D., Li, S., Zhou, L., Yang, Z., Song, Y.: Thermo-hydro-mechanical-chemical couplings controlling CH4 production and CO2 sequestration in enhanced coalbed methane recovery. Energy 173, 1054–1077 (2019)

Gray, I.: Reservoir engineering in coal seams: part 1—the physical process of gas storage and movement in coal seams. SPE Reserv. Eng. 2, 28–34 (1987)

Guo, H., Yuan, L., Shen, B., Qu, Q., Xue, J.: Mining-induced strata stress changes, fractures and gas flow dynamics in multi-seam longwall mining. Int. J. Rock Mech. Min. Sci. 54, 129–139 (2012)

Kazemi, H., Merrill, L.S., Jr., Porterfield, K.L., Zeman, P.R.: Numerical simulation of water–oil flow in naturally fractured reservoirs. Soc. Petrol. Eng. J. 16, 317–326 (1976)

Liao, X., Wang, L., Zhu, J., Chu, P., Liu, Q., Yang, T.: Experimental study on the wettability of tectonic soft coal in Huaibei Mining Area, China. Energy Fuels 35, 6585–6599 (2021)

Lim, K.T., Aziz, K.: Matrix-fracture transfer shape factors for dual-porosity simulators. J. Petrol. Sci. Eng. 13, 169–178 (1995)

Lin, J., Cheng, Y., Ren, T., Liu, Q., Tu, Q.: New insights into failure behaviors of tectonic coal under triaxial conditions using reconstituted coal specimens. Rock Mech. Rock Eng. 55, 1361–1374 (2022)

Liu, Q., Cheng, Y., Wang, H., Zhou, H., Wang, L., Li, W., Liu, H.: Numerical assessment of the effect of equilibration time on coal permeability evolution characteristics. Fuel 140, 81–89 (2015)

Liu, T., Lin, B., Fu, X., Gao, Y., Kong, J., Zhao, Y., Song, H.: Experimental study on gas diffusion dynamics in fractured coal: a better understanding of gas migration in in-situ coal seam. Energy 195, 117005 (2020)

Liu, T., Lin, B., Fu, X., Zhao, Y., Yang, W.: Modeling coupled gas flow and geomechanics process in stimulated coal seam by hydraulic flushing. Int. J. Rock Mech. Min. Sci. 142, 104769 (2021)

Liu, P., Fan, L., Li, Q., Zhong, F.: Power ultrasound assisted coalbed methane enhancement recovery: field application and performance evaluation in underground coal mine. Fuel 324, 124575 (2022)

Lu, S., et al.: Gas time-dependent diffusion in pores of deformed coal particles: model development and analysis. Fuel 295, 120566 (2021)

Mora, C., Wattenbarger, R.: Analysis and verification of dual porosity and CBM shape factors. J. Can. Pet. Technol. 48, 17–21 (2009)

Palmer, I., Mansoori, J.: How permeability depends on stress and pore pressure in coalbeds: a new model. SPE Reserv. Eval. Eng. 1, 539–544 (1996)

Pan, Z., Connell, L.D., Camilleri, M., Connelly, L.: Effects of matrix moisture on gas diffusion and flow in coal. Fuel 89, 3207–3217 (2010)

Shi, J., Durucan, S.: A bidisperse pore diffusion model for methane displacement desorption in coal by CO2 injection. Fuel 82, 1219–1229 (2003)

Shi, J., Durucan, S.: Gas storage and flow in coalbed reservoirs: implementation of a bidisperse pore model for gas diffusion in a coal matrix. SPE Reserv. Eval. Eng. 8, 169–175 (2005)

Wang, L., et al.: Safe strategy for coal and gas outburst prevention in deep-and-thick coal seams using a soft rock protective layer mining. Saf. Sci. 129, 104800 (2020)

Wang, L., Wang, H., Zhu, J., Huang, W., Zhao, Y.: Experimental study on particle size distribution of impact crushed coal containing gas. Fuel 325, 124745 (2022)

Warren, J., Root, P.J.: The behavior of naturally fractured reservoirs. Soc. Petrol. Eng. J. 3, 245–255 (1963)

Xie, H.: Research on Safety, High Efficiency and Green Coal Mining Technology and Strategy. Science Press, Beijing (2014)

Yang R (1997) Gas separation by adsorption processes. Chem. Eng. Sci. 43

Yi, M., Wang, L., Hao, C., Liu, Q., Wang, Z.: Method for designing the optimal sealing depth in methane drainage boreholes to realize efficient drainage International Journal of. Coal Sci. Technol. 8, 1400–1410 (2021)

Yi, M., Wang, L., Cheng, Y., Wang, C., Hu, B.: Calculation of gas concentration-dependent diffusion coefficient in coal particles: Influencing mechanism of gas pressure and desorption time on diffusion behavior. Fuel 320, 123973 (2022)

Zhang, K., Cheng, Y., Wang, L., Dong, J., Hao, C., Jiang, J.: Pore morphology characterization and its effect on methane desorption in water-containing coal: an exploratory study on the mechanism of gas migration in water-injected coal seam. J. Nat. Gas Sci. Eng. 75, 103152 (2020)

Zhang, H., et al.: A novel in-seam borehole discontinuous hydraulic flushing technology in the driving face of soft coal seams: enhanced gas extraction mechanism and field application. Rock Mech. Rock Eng. 55, 885–907 (2022a)

Zhang, H., Yang, Y., Wei, J., Liu, Y., Hao, Y., Wei, L., Si, L.: Gas desorption law of granular coal in negative-pressure environment and calculation of gas loss during negative-pressure sampling. Fuel 328, 125368 (2022b)

Zhang, R., Wang, P., Cheng, Y.: A new technology to enhance gas drainage in the composite coal seam with tectonic coal sublayer. J. Nat. Gas Sci. Eng. 106, 104760 (2022c)

Zhao, W., Su, X., Xia, D., Hou, S., Wang, Q., Zhou, Y.: Enhanced coalbed methane recovery by the modification of coal reservoir under the supercritical CO2 extraction and anaerobic digestion. Energy 259, 124914 (2022)

Zimmerman, R.W., Chen, G., Hadgu, T., Bodvarsson, G.S.: A numerical dual-porosity model with semianalytical treatment of fracture/matrix flow. Water Resour. Res. 29, 2127–2137 (1993)

Acknowledgements

This research was supported by the National Natural Science Foundation of China (No. 52004132) and the Postgraduate Research & Practice Innovation Program of Jiangsu Province (No. SJCX23_0457).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix 1: Derivation of Matrix Shape Factors for Intact Coal

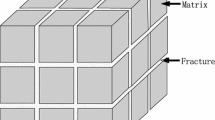

For the three-dimensional diffusion of intact coal, the amount of methane diffusing to six faces can be considered consistent, and one-sixth of them is taken as the research object (see Fig.

12a). The methane concentration at each point on the cross section perpendicular to the x-axis is set to be equal, and it can be expressed as the concentration at the center point of the cross section:

Suppose that the methane concentration \(c\) in the matrix follows a parabolic distribution during the diffusion process, and the following equation can be obtained:

where \(b_{1}\) and \(b_{2}\) are undetermined coefficients. Assuming that the gaseous methane concentration at the matrix boundary is equal to the methane concentration in the fractures, then,

The area of the cross section is \(4x^{2}\), and the volume of the research domain is \(a^{3} /6\). Then, the integral average value of methane concentration in the matrix can be obtained:

Combining Eqs. (22) and (23), we can obtain

Then,

According to Fick’s first law, the diffusion flux through the contact surface between the matrix and fractures is

Therefore, under the condition of three-dimensional diffusion, the diffused gas amount per volume of coal matrix in unit time can be obtained as follows:

Combined with Eq. (1), the matrix shape factor for the intact coal under three-dimensional diffusion condition is

For the two-dimensional diffusion, methane diffusion through four faces is consistent, and one-fourth of the matrix is taken as the research object (see Fig. 12b). Equations (20), (21) and (22) are still valid. The areas of the cross section is \(2ax\), and the volume of the research domain is \(a^{3} /4\). Then, the integral average value of methane concentration in the matrix can be obtained:

Combining Eqs. (22) and (29), we can obtain

Then,

Similar to Eq. (26), the diffusion flux through the contact surface between the matrix and fractures is

Then, the gas amount for two-dimensional diffusion can be obtained:

Thus, the matrix shape factor for two-dimensional diffusion of intact coal is

For the one-dimensional diffusion, methane diffusion through two faces is consistent, and a half of the matrix is taken as the research object (see Fig. 12c). Equations (20), (21) and (22) are still valid. The areas of the cross section is \(a^{2}\), and the volume of the research domain is \(a^{3} /2\). Then, the integral average value of methane concentration in the matrix can be obtained:

Combining Eqs. (22) and (35), we can obtain

Then,

Similar to Eq. (26), the diffusion flux through the contact surface between the matrix and fractures is

Then, the gas amount for one-dimensional diffusion can be obtained:

Thus, the matrix shape factor for one-dimensional diffusion of intact coal is

Appendix 2: Derivation of Matrix Shape Factors for Two- and One-Dimensional Diffusion of Tectonic Coal

For the two-dimensional diffusion, methane diffusion through eight edges is consistent, and one-eighth of the matrix is taken as the research object (see Fig. 2b). Equations (3), (4) and (5) are still valid. The areas of the two cross sections are \(2x(a/2 - x)\) and \((2x + a)(a/2 - x)/2\), and the volume of the research domain is \(a^{3} /8\). Then, the integral average value of methane concentration in the matrix can be obtained:

Combining Eqs. (5) and (41), we can obtain

Then,

Similar to Eq. (9), the diffusion flux through the contact surface between the matrix and fractures is

Then, the gas amount for two-dimensional diffusion can be obtained:

Thus, the matrix shape factor for two-dimensional diffusion of tectonic coal is

For the one-dimensional diffusion, methane diffusion through four edges is consistent, and one-fourth of the matrix is taken as the research object (see Fig. 2c). Equations (3), (4) and (5) are still valid. The area of each cross section is \(a(a/2 - x)\), and the volume of the research domain is \(a^{3} /4\). Then, the integral average value of methane concentration in the matrix can be obtained:

Combining Eqs. (5) and (47), we can obtain

Then,

The diffusion flux through the contact surface between the matrix and fractures is

Then, the gas amount for one-dimensional diffusion can be obtained:

Thus, the matrix shape factor for one-dimensional diffusion of tectonic coal is

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Dong, J., Zhao, Z., Wang, X. et al. Establishment and Determination of Matrix Shape Factor for Tectonic Coal: Theoretical, Experimental and Simulation Study. Transp Porous Med 150, 465–489 (2023). https://doi.org/10.1007/s11242-023-02022-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11242-023-02022-3