Abstract

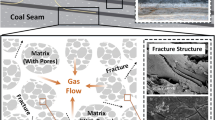

In the process of coalbed methane (CBM) exploitation, permeability is a key controlling parameter for gas transport in the CBM reservoirs. The CBM reservoir contains a large number of micropores and microfractures with complex structures. In order to accurately predict the gas permeability of the micropores and microfractures in CBM reservoirs, a fractal permeability model was developed in this work. This model considers the comprehensive effects of real gas, stress dependence, multiple gas flow mechanisms (e.g., slip flow, Knudsen diffusion and surface diffusion) and fractal characteristics (e.g., pore size distribution and flow path tortuosity) of micropores and microfractures on the gas permeability. Then, this fractal permeability model was verified by the reliable experimental data and other theoretical models. Finally, the sensitivity analysis is conducted to identify key factors to the permeability of CBM reservoir. The results showed that the fractal characteristics of the micropores and microfractures have significant effects on the permeability of CBM reservoir. Higher fractal dimension of micropores diameter and microfractures aperture represents the larger number of micropores and microfractures, resulting in a higher permeability. Higher tortuosity fractal dimension of micropores and microfractures means higher gas flow resistance, leading to the lower permeability. The multiple gas transport mechanisms coexist in micropores and microfractures of CBM reservoir. The permeability of slip flow and Knudsen diffusion both increases with the decrease in pore pressure. Surface diffusion is an important gas transport mechanisms in micropores, but it can be ignored in the microfractures. Knudsen diffusion plays a more obvious role in the lower pore pressure, which controls the gas transport in microfractures. And microfractures are beneficial to improve gas transport capacity of coalbed methane reservoir.

Similar content being viewed by others

References

Adler, P.M.: Transport processes in fractals II: stokes flow in fractal capillary networks. Int. J. Multiph. Flow 11(2), 213–239 (1985). https://doi.org/10.1016/0301-9322(85)90047-3

Adler, P.M.: Fractal porous media III: transversal stokes flow through random and Sierpinski Carpets. Transp. Porous Media 3, 185–198 (1988). https://doi.org/10.1007/BF00820345

Adler, P.M.: Transports in fractal porous media. J. Hydrol. 187, 195–213 (1996). https://doi.org/10.1016/S0022-1694(96)03096-X

Adler, P.M., Thovert, J.F.: Fractal porous media. Transp. Porous Media 13, 41–78 (1993). https://doi.org/10.1007/BF00613270

Beskok, A., Karniadakis, G.E.: Report: a model for flows in channels, pipes, and ducts at micro and nanoscales. Microsc. Thermophys. Ical Eng. 3, 43–77 (1999). https://doi.org/10.1080/108939599199864

Cai, J.C., Lin, D.L., Singh, H., Wei, W., Zhou, S.W.: Shale gas transport model in 3D fractal porous media with variable pore sizes. Mar. Pet. Geol. 98, 437–447 (2018). https://doi.org/10.1016/j.marpetgeo.2018.08.040

Chen, Z.W., Liu, J.S., Pan, Z.J., Connell, L.D., Elsworth, D.: Influence of the effective stress coefficient and sorption-induced strain on the evolution of coal permeability: model development and analysis. Int. J. Greenh. Gas Control 8, 101–110 (2012). https://doi.org/10.1016/j.ijggc.2012.01.015

Chen, Z.W., Pan, Z.J., Liu, J.S., Connell, L.D., Elsworth, D.: Effect of the effective stress coefficient and sorption-induced strain on the evolution of coal permeability: experimental observations. Int. J. Greenh. Gas Control 5, 1284–1293 (2011). https://doi.org/10.1016/j.ijggc.2011.07.005

Civan, F., Devegowda, D., Sigal, R.F.: Critical evaluation and improvement of methods for determination of matrix permeability of shale. SPE Annual Technical Conference and Exhibition (2013). https://doi.org/10.2118/166473-MS

Darabi, H., Ettehad, A., Javadpour, F., Sepehrnoori, K.: Gas flow in ultra-tight shale strata. J. Fluid Mech. 710, 641–658 (2012). https://doi.org/10.1017/jfm.2012.424

Dong, J.J., Hsu, J.Y., Wu, W.J., Shimamoto, T., Hung, J.H., Yeh, E.C., Wu, Y.H., Sone, H.: Stress-dependence of the permeability and porosity of sandstone and shale from TCDP Hole-A. Int. J. Rock Mech. Min. Sci. 47(7), 1141–1157 (2010). https://doi.org/10.1016/j.ijrmms.2010.06.019

Gao, Q., Han, S.C., Cheng, Y.F., Li, Y., Yan, C.L., Han, Z.Y.: Apparent permeability model for gas transport through micropores and microfractures in shale reservoirs. Fuel 285, 119086 (2021). https://doi.org/10.1016/j.fuel.2020.119086

Jarrahiana, A., Heidaryan, E.: A simple correlation to estimate natural gas viscosity. J. Nat. Gas Sci. Eng. 20, 50–57 (2014). https://doi.org/10.1016/j.jngse.2014.06.004

Javadpour, F.: Nanopores and apparent permeability of gas flow in mudrocks (Shales and Siltstone). J. Can. Pet. Technol. 48, 16–21 (2009). https://doi.org/10.2118/09-08-16-DA

Li, B., Liu, R.C., Jiang, Y.J.: A multiple fractal model for estimating permeability of dual-porosity media. J. Hydrol. 540, 659–669 (2016). https://doi.org/10.1016/j.jhydrol.2016.06.059

Li, Y., Yang, J.H., Pan, Z.J., Tong, W.S.: Nanoscale pore structure and mechanical property analysis of coal: an insight combining AFM and SEM images. Fuel 260, 116352 (2020). https://doi.org/10.1016/j.fuel.2019.116352

Li, Y.D., Kalantari-Dahaghi, A., Zolfaghari, A., Dong, P.C., Negahban, S.H., Zhou, D.W.: Fractal-based real gas flow model in shales: an interplay of nano-pore and nano-fracture networks. Int. J. Heat Mass Transf. 127, 1188–1202 (2018). https://doi.org/10.1016/j.ijheatmasstransfer.2018.08.077

Liu, H.H., Rutqvist, J., Berryman, J.G.: On the relationship between stress and elastic strain for porous and fractured rock. Int. J. Rock Mech. Min. Sci. 46, 289–296 (2009). https://doi.org/10.1016/j.ijrmms.2008.04.005

Liu, R.C., Li, B., Jiang, Y.J.: A fractal model based on a new governing equation of fluid flow in fractures for characterizing hydraulic properties of rock fracture networks. Comput. Geotech. 75, 57–68 (2016). https://doi.org/10.1016/j.compgeo.2016.01.025

Loebenstein, W.V.: Calculations and comparisons of nonideal gas corrections for use in gas adsorption. J. Colloid Interface Sci. 36(3), 397–400 (1971). https://doi.org/10.1016/0021-9797(71)90011-7

Miao, T.J., Yang, S.S., Long, Z.C., Yu, B.M.: Fractal analysis of permeability of dual-porosity media embedded with random fractures. Int. J. Heat Mass Transf. 88, 814–821 (2015a). https://doi.org/10.1016/j.ijheatmasstransfer.2015.05.004

Miao, T.J., Yu, B.M., Duan, Y.G., Fang, Q.T.: A fractal analysis of permeability for fractured rocks. Int. J. Heat Mass Transf. 81, 75–80 (2015b). https://doi.org/10.1016/j.ijheatmasstransfer.2014.10.010

Palmer, I., Mansoori, J.: How permeability depends on stress and pore pressure in coalbeds: a new model. SPE Reserv. Eval. Eng. 1998, 539–544 (1998). https://doi.org/10.2118/52607-PA

Pan, Z.J., Connell, L.D.: Modelling of anisotropic coal swelling and its impact on permeability behaviour for primary and enhanced coalbed methane recovery. Int. J. Coal Geol. 85(3–4), 257–267 (2011). https://doi.org/10.1016/j.coal.2010.12.003

Qi, L.L., Xu, T., Wang, Z.F., Peng, X.S.: Pore characterization of different types of coal from coal and gas outburst disaster sites using low temperature nitrogen adsorption approach. Int. J. Min. Sci. Technol. 27, 371–377 (2017). https://doi.org/10.1016/j.ijmst.2017.01.005

Robertson, E.P., Christiansen, R.L.: Modeling laboratory permeability in coal using sorption-induced strain data. SPE Reserv. Eval. Eng. 10, 260–269 (2007). https://doi.org/10.2118/97068-PA

Shi, J.Q., Durucan, S.: Drawdown induced changes in permeability of coalbeds: a new interpretation of the reservoir response to primary recovery. Transp. Porous Media 56, 1–16 (2004). https://doi.org/10.1023/B:TIPM.0000018398.19928.5a

Si, L.L., Wei, J.P., Xi, Y.J., Wang, H.Y., Wen, Z.H., Li, B., Zhang, H.T.: The influence of long-time water intrusion on the mineral and pore structure of coal. Fuel 290, 119848 (2021). https://doi.org/10.1016/j.fuel.2020.119848

Sun, H., Yao, J., Fan, D.Y., Wang, C.C., Sun, Z.X.: Gas transport mode criteria in ultra-tight porous media. Int. J. Heat Mass Transf. 83, 192–199 (2015). https://doi.org/10.1016/j.ijheatmasstransfer.2014.11.075

Tan, Y.L., Pan, Z.J., Liu, J.S., Zhou, F.B., Connell, L.D., Sun, W.J., Haque, A.: Experimental study of impact of anisotropy and heterogeneity on gas flow in coal. Part II: permeability. Fuel 230, 397–409 (2018). https://doi.org/10.1016/j.fuel.2018.05.033

Tang, J., Zhu, J., Shao, T.S., Wang, J.G., Jiang, Y.D.: A coal permeability model with variable fracture compressibility considering triaxial strain condition. Nat. Resour. Res. 30(2), 1577–1595 (2021). https://doi.org/10.1007/s11053-020-09793-2

Wang, F.Y., Liu, Z.C., Jiao, L., Wang, C.L., Guo, H.: A fractal permeability model coupling boundary-layer effect for tight oil reservoirs. Fractals 25(5), 1750042 (2017). https://doi.org/10.1142/S0218348X17500426

Wang, H.J., Ma, F., Tong, X.G., Liu, Z.D., Zhang, X.S., Wu, Z.Z., Li, D.H., Wang, B., Xie, Y.F., Yang, L.Y.: Assessment of global unconventional oil and gas resources. Pet. Explor. Dev 43(6), 925–940 (2016). https://doi.org/10.11698/PED.2016.06.02

Wang, J.G., Hu, B.W., Wu, D., Dou, F.K., Wang, X.L.: A multiscale fractal transport model with multilayer sorption and effective porosity effects. Transp. Porous Media 129, 25–51 (2019). https://doi.org/10.1007/s11242-019-01276-0

Wang, J.G., Wang, H.M.: Sealing efficiency analysis for shallow-layer caprocks in CO2 geological storage. Environ. Earth Sci. 77, 738 (2018). https://doi.org/10.1007/s12665-018-7924-2

Wu, H., Yao, Y.B., Liu, D.M., Cui, C.: An analytical model for coalbed methane transport through nanopores coupling multiple flow regimes. J. Nat. Gas Sci. Eng. 82, 103500 (2020). https://doi.org/10.1016/j.jngse.2020.103500

Wu, J.S., Yu, B.M.: A fractal resistance model for flow through porous media. Int. J. Heat Mass Transf. 50, 3925–3932 (2007). https://doi.org/10.1007/s11242-007-9129-0

Wu, K.L., Chen, Z.X., Li, X.F.: Real gas transport through nanopores of varying cross-section type and shape in shale gas reservoirs. Chem. Eng. J. 281, 813–825 (2015). https://doi.org/10.1016/j.cej.2015.07.012

Wu, K.L., Chen, Z.X., Li, X.F., Guo, C.H., Wei, M.Z.: A model for multiple transport mechanisms through nanopores of shale gas reservoirs with real gas effect–adsorption-mechanic coupling. Int. J. Heat Mass Transf. 93, 408–426 (2016). https://doi.org/10.1016/j.ijheatmasstransfer.2015.10.003

Wu, Y.T., Pan, Z.J., Zhang, D.Y., Lu, Z.H., Connell, L.D.: Evaluation of gas production from multiple coal seams: A simulation study and economics. Int. J. Min. Sci. Technol. 28, 359–371 (2018). https://doi.org/10.1016/j.ijmst.2018.03.008

Xin, F.D., Xu, H., Tang, D.Z., Yang, J.S., Chen, Y.P., Cao, L.K., Qu, H.X.: Pore structure evolution of low-rank coal in China. Int. J. Coal Geol. 205, 126–139 (2019). https://doi.org/10.1016/j.coal.2019.02.013

Xiong, X., Devegowda, D., Michel, V., Sigal, R.F., Civan, F.: A fully-coupled free and adsorptive phase transport model for shale gas reservoirs including non-Darcy flow effects. SPE Ann. Tech. Conf. Exhib. (2012). https://doi.org/10.2118/159758-MS

Xu, J.Z., Wu, K.L., Li, Z.D., Pan, Y., Li, R., Li, J., Chen, Z.X.: A model for gas transport in dual-porosity shale rocks with fractal structures. Ind. Eng. Chem. Res. 57(18), 6530–6537 (2018). https://doi.org/10.1021/acs.iecr.8b00021

Yao, Y.B., Liu, D.M., Liu, J.G., Xie, S.B.: Assessing the water migration and permeability of large intact bituminous and anthracite coals using NMR relaxation spectrometry. Transp. Porous Media 107(2), 527–542 (2015). https://doi.org/10.1007/s11242-014-0452-y

Yin, T.T., Liu, D.M., Cai, Y.D., Zhou, Y.F., Yao, Y.B.: Size distribution and fractal characteristics of coal pores through nuclear magnetic resonance cryoporometry. Energy Fuels 31, 7746–7757 (2017). https://doi.org/10.1021/acs.energyfuels.7b00389

Yu, B.M.: Analysis of flow in fractal porous media. Appl. Mech. Rev. 61(5), 050801 (2008). https://doi.org/10.1115/1.2955849

Yu, B.M., Cheng, P.: A fractal permeability model for bi-dispersed porous media. Int. J. Heat Mass Transf. 45(14), 2983–2993 (2002). https://doi.org/10.1016/S0017-9310(02)00014-5

Zeng, F.H., Peng, F., Guo, J.C., Rui, Z.H., Xiang, J.H.: Gas mass transport model for microfractures considering the dynamic variation of width in shale reservoirs. SPE Reserv. Eval. Eng. 22(04), 1265–1281 (2019). https://doi.org/10.2118/194494-PA

Zheng, Q., Yu, B.M., Duan, Y.G., Fang, Q.T.: A fractal model for gas slippage factor in porous media in the slip flow regime. Chem. Eng. Sci. 87, 209–215 (2013). https://doi.org/10.1016/j.ces.2012.10.019

Zhou, S.D., Liu, D.M., Karpyn, Z.T., Cai, Y.D., Yao, Y.B.: Dual compressibility characteristics of lignite, subbituminous, and high-volatile bituminous coals: A new insight into permeability. Transp. Porous Media 136, 295–317 (2021). https://doi.org/10.1007/s11242-020-01512-y

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Grant No.: 51974109), the Program for Leading Talents in Scientific and Technological Innovation of Henan Province (Grant No.: 204200510032) and the Scientific and Technological Projects of Henan Province (Grant No.: 202102310220).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix A. Real Gas Effect

Under the high gas pressure condition in the CBM reservoir, the real gas effect significantly affects gas transport in micropores and microfractures. The effects of real gas on gas transport are characterized by gas compressibility factor and gas viscosity. The gas compressibility factor will change with the gas pressure and reservoir temperature, and it can be expressed as the function of the reduced gas pressure and reduced temperature (Loebenstein 1971):

where \(Z\) is the real gas compressibility factor; \(p_{r} = {p \mathord{\left/ {\vphantom {p {p_{c} }}} \right. \kern-\nulldelimiterspace} {p_{c} }}\) is the reduced gas pressure; \(T_{r} = {T \mathord{\left/ {\vphantom {T {T_{c} }}} \right. \kern-\nulldelimiterspace} {T_{c} }}\) is the reduced temperature; \(p\) is the gas pressure, MPa; \(T\) is the temperature, K; \(p_{c}\) is the critical pressure MPa; and \(T_{c}\) is the critical temperature, K.

Similarly, gas viscosity can also be expressed as a function of the reduced gas pressure and reduced temperature (Jarrahiana and Heidaryan 2014):

where \(\mu\) is the gas viscosity under p = 1.01325 × 105 Pa and T = 423 K; \(\mu_{i}\) is the real gas viscosity, Pa s; and \(A_{1}\), \(A_{2}\) and \(A_{3}\) are the three fitting constants, respectively.

Appendix B. Dynamic Diameter of Micropores

With the gas pressure decrease during the development of CBM, the effective stress will increase. The increase in effective stress will reduce the permeability, porosity, pore diameter and fracture aperture of CBM reservoir.

For the micropores, a power law relationship can describe the effect of effective stress on permeability and porosity (Dong et al. 2010):

where \(k\) is the permeability of micropores under the effective stress, m2; \(k_{0}\) is the initial permeability of micropores, m2; \(p_{0}\) is the atmospheric pressure, m2; \(p_{e} = p^{\prime} - p\) is the effective stress, MPa; \(p^{\prime}\) is the total stress, MPa; and \(s\) is the permeability coefficient.

The relationship among the permeability, porosity, pore diameter and tortuosity can be expressed as (Civan et al. 2013):

where \(\tau\) is the tortuosity of micropores. Thus, the ratio of permeability to the initial permeability can be expressed as:

where \(\phi_{p0}\) and \(d_{p0}\) are the initial porosity and diameter of micropores. Besides, the porosity is positively proportional to the third power of micropore diameter. Thus, the following equation can be obtained:

When considering the stress dependence effect, the dynamic diameter of micropores can be expressed as:

Appendix C. Dynamic Aperture of Microfractures

For the microfractures network, the microfractures consist of the hard part and soft part, which follow different Hooke’s law (Liu et al. 2009; Chen et al. 2012). The hard part obeys the engineering strain based on Hooke’s law, and the soft part follows the natural strain based on Hook’s law. Thus, the stress–strain relationship of the hard part in microfractures can be expressed as:

where \(\sigma\) is the stress of the microfractures, MPa; \(K_{h}\) is the bulk modulus of the hard part, MPa; and \(\varepsilon_{h}\) is the engineering strain of hard part, defined as:

where \(h_{h}\) is the fracture aperture of the hard part under the stress condition, m; \(h_{0,h}\) is the initial aperture of the hard part, m.

For the soft part of the microfractures, the stress–strain relationship can be expressed as:

where \(K_{s}\) is the bulk modulus of the soft part; \(\varepsilon_{s}\) is the natural strain of soft part, defined as:

where \(h_{s}\) is the fracture aperture of the soft part.

Using the initial condition that \(h_{h} = h_{0,h}\) and \(h_{s} = h_{0,s}\) for \(\sigma = 0\), the engineering strain of the hard part and the natural strain of the soft part can be integrated into:

The total aperture of the microfractures can be obtained as:

\(K_{h}\) is generally much larger than \(K_{s}\), and the initial aperture of microfractures \(h_{0} = h_{0,h} + h_{0,s}\). Thus, Eq. (C7) can be simplified into:

Rights and permissions

About this article

Cite this article

Ren, Y., Wei, J., Zhang, L. et al. A Fractal Permeability Model for Gas Transport in the Dual-Porosity Media of the Coalbed Methane Reservoir. Transp Porous Med 140, 511–534 (2021). https://doi.org/10.1007/s11242-021-01696-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11242-021-01696-x