Abstract

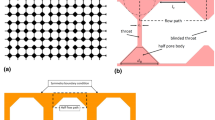

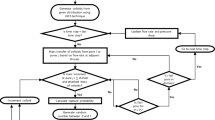

Geometric straining of particles in porous media is of critical importance in a broad range of natural and industrial settings, such as contaminant transport in aquifers and the permeability decline due to pore plugging in oil reservoirs. Pore network modeling is a computationally efficient approach to simulate transport problems in porous media that has been used to simulate particle deposition and size exclusion. However, existing network models are unable to simulate particle jamming due to the simplification of geometry and the lack of capability for simulating particle–particle interactions. Here, we develop a novel pore network model for particle jamming in porous media. The jamming in pore throats is predicted by the probability of jamming, which is a function of pore/particle size ratio, particle concentration, and coefficient of friction (COF). A unified probability model is developed based on Discrete Element Method (DEM) simulations of particle jamming in porous media consisting of a single layer of spherical grains. The geometry is based on two packing extremes, those with grains arranged in a triangle and a square. The model is then implemented into the pore network model to predict jamming in porous media. This framework combines the efficiency of network modeling and the accuracy of direct simulations on particle jamming. We verify the model against CFD-DEM simulations. The results of network simulations show that the probability of jamming increases with COF. At low particle concentrations (C = 5%), the probability of jamming for large pore throats is small. There is a critical particle concentration (C = 9%) when the grain/particle size ratio is 10, above which jamming is self-reinforcing and the inlet face of the porous medium will be completely blocked (C = 11%). The effect of velocity on the probability of jamming is insignificant compared with the effects of particle concentration and pore/particle size ratio.

Article Highlights

-

We propose a novel pore network model for particle jamming based on the probability.

-

The pore network model has a higher computational efficiency, compared with other numerical models, such as CFD-DEM model.

-

The pore network model can accurately predict the permeability changes of porous media during the jamming process.

Similar content being viewed by others

Data Availability

The authors confirm that the data supporting the findings of this study are available.

Code Availability

The authors confirm that the code supporting the findings of this study are available.

Abbreviations

- A :

-

Probability of a particle touching the solid boundary when it is passing through a hole

- C i :

-

Species concentration at pore i

- C :

-

Volumetric concentration of particles

- C st :

-

Model constant

- COR:

-

Coefficient of restitution

- d :

-

Particle diameter

- D :

-

Hole size

- E :

-

Young’s modulus

- f :

-

Coefficient of friction (COF)

- F n :

-

Normal repulsive force

- F t :

-

Tangential contact force

- g i,j :

-

Hydraulic conductivity of the throat connecting pore i and j

- g new :

-

New hydraulic conductivity of the pore throat

- gt :

-

Permeability of the trapped particle zone

- h 1 :

-

Effect of geometry on jamming

- h 2 :

-

Effect of concentration on jamming

- h 3 :

-

Effect of friction on jamming

- k :

-

Permeability

- k 0 :

-

Permeability before the injection

- k n :

-

Normal stiffness

- k t :

-

Tangential stiffness

- l :

-

Mesh width

- L :

-

Length of particle flow

- L t :

-

Length of trapped particle region

- m i :

-

Mass of particle i

- m j :

-

Mass of particle j

- n :

-

Average number of particles needed to form a “bridge”

- N :

-

The number of particles left on the top of the screen

- N e :

-

The total number of particles in the simulation

- N in :

-

Average number of particles arriving at each pore throat

- N out :

-

Average number of particles going through one pore throat

- N ptc :

-

The number of particles passing a pore throat

- p :

-

Fluid pressure

- P 0 :

-

Probability of jamming

- P 0, max :

-

Jamming plateau when the pore size is close to the particle size

- P i :

-

Pressure in pore i

- P j :

-

Pressures in pore j

- q i,j :

-

Flow rate between pore i and neighbors

- R and :

-

Random number uniformly distributed between 0 and 1

- R pf :

-

Momentum exchange between fluid and particles

- S r :

-

Effective pore radius/particle size ratio

- u f :

-

Fluid velocity

- V p i :

-

Volume of pore i

- V ptc :

-

Volume of a particle

- V t :

-

Volume of trapped particles

- α :

-

Flow characteristic parameter

- α f :

-

Volume fraction occupied by fluids in a mesh cell

- β :

-

Proportionality factor

- γ n :

-

Damping constant for normal contact

- γ t :

-

Damping constant for tangential contact

- µ :

-

Fluid viscosity

- ϕ t :

-

Porosity of the trapped particle zone

- ρ f :

-

Fluid density

- ρ p :

-

Particle density

- τ :

-

Stress tensor of the fluid

- ν :

-

Poisson’s ratio

- Δt :

-

Time step

- Δu p ,n :

-

Relative normal velocity between particles in contact

- Δu p ,t :

-

Relative tangential velocity between particles in contact

- Δx p ,n :

-

Normal overlap between particles

- Δx p ,t :

-

Tangential overlap between particles

References

Bedrikovetsky, P., Tran, T.K., Van den Broek, W.M.G.T., Marchesin, D., Rezende, E., Siqueira, A., Souza, A.L., Shecaira, F.: Damage characterization of deep bed filtration from pressure measurements. SPE Prod. Facil. 18, 119–128 (2003)

Boek, E.S., Hall, C., Tardy, P.M.J.: Deep bed filtration modelling of formation damage due to particulate invasion from drilling fluids. Transp. Porous Media 91, 479–508 (2011)

Bradford, S.A., Torkzaban, S.: Colloid transport and retention in unsaturated porous media: a review of interface-, collector-, and pore-scale processes and models. Vadose Zool. J. 7, 667 (2008)

Chand, R., Khaskheli, M.A., Qadir, A., Ge, B., Shi, Q.: Discrete particle simulation of radial segregation in horizontally rotating drum: Effects of drum-length and non-rotating end-plates. Phys. A 391(20), 4590–4596 (2012)

Cundall, P., Strack, O.: A discrete numerical model for granular assemblies. Geotechnique 29, 47–65 (1979)

Dallinger, N., Hübler, J.: Simulation of bottle conveyors—opportunities of the discrete element method (DEM). In: International Symposium Plastic-Slide-Chains and Tribology in Conveyor Systems. pp. 1–10 (2017)

Goniva, C., Kloss, C., Hager, A., Pirker, S.: An open source CFD-DEM perspective. In: Proceedings of the OpenFOAM Work, pp. 1–10 (2010)

Hwang, J., Lehardi, S., Sharma, M.M.: Filtration in Frac-Packs and its Impact on Injector Performance, pp. 26–28 (2014)

Ishibashi, I., Perry, C., Agarwal, T.K.: Experimental determinations of contact friction for spherical glass particles. Soils Found. 34, 79–84 (1994)

Khan, H., Mirabolghasemi, M., Yang, H., Prodanovic, M., DiCarlo, D., Balhoff, M., Gray, K.: Comparative study of formation damage due to straining and surface deposition in porous media. In: SPE International Conference & Exhibition on Formation Damage Control, Lafayette, Louisiana, USA (2016)

Khan, H.J., Mirabolghasemi, M.S., Yang, H., Prodanović, M., DiCarlo, D., a., Balhoff, M.T. : Study of formation damage caused by retention of bi-dispersed particles using combined pore-scale simulations and particle flooding experiments. J. Pet. Sci. Eng. 158, 293–308 (2017)

Kloss, C.: LIGGGHTS Users Manual. https://www.cfdem.com/media/DEM/docu/Manual.html

Kloss, C., Goniva, C., Hager, A., Amberger, S., Pirker, S.: Models: algorithms and validation for opensource DEM and CFD–DEM. Prog. Comput. Fluid Dyn. Int. J. 66, 140–52 (2012)

Lafond, P.G., Gilmer, M.W., Koh, C.A., Sloan, E.D., Wu, D.T., Sum, A.K.: Orifice jamming of fluid-driven granular flow. Phys. Rev. E Stat. Nonlinear Soft Matter Phys. 87, 66 (2013)

Liu, X., Civan, F.: Formation damage and filter cake buildup in laboratory core tests: modeling and model-assisted analysis. SPE Form. Eval. 66, 26–30 (1996)

Mirabolghasemi, M.: Micro-scale Modeling of Formation Damage (2017)

Mirabolghasemi, M., Prodanović, M., DiCarlo, D., Ji, H.: Prediction of empirical properties using direct pore-scale simulation of straining through 3D microtomography images of porous media. J. Hydrol. 529, 768–778 (2015)

Moghadasi, J., Müller-Steinhagen, H., Jamialahmadi, M., Sharif, A.: Theoretical and experimental study of particle movement and deposition in porous media during water injection. J. Pet. Sci. Eng. 43(3–4), 163–181 (2004)

Mondal, S., Wu, C.H., Sharma, M.M.: Coupled CFD-DEM simulation of hydrodynamic bridging at constrictions. Int. J. Multiph. Flow. 84, 245–263 (2016)

Otomo, R., Harada, S.: End effect on permeability of loose particulate bed having different internal structures. Part. Sci. Technol. 29, 2–13 (2011)

Pang, S., Sharma, M.M.: A model for predicting injectivity decline in water-injection wells. SPE Form. Eval. 12, 66 (1997)

Potyondy, D.O., Cundall, P.A.: A bonded-particle model for rock. Int. J. Rock Mech. Min. Sci. 41(8), 1329–1364 (2004)

Rege, S.D., Fogler, H.S.: Network model for straining dominated particle entrapment in porous media. Chem. Eng. Sci. 42, 1553–1564 (1987)

Rege, S.D., Fogler, H.S.: A network model for deep bed filtration of solid particles and emulsion drops. AIChE J. 34, 1761–1772 (1988)

Rhie, C.M., Chow, W.L.: Numerical study of the turbulent flow past an airfoil with trailing edge separation. AIAA J. 21(11), 1525–1532 (1983)

Roussel, N., Nguyen, T.L.H., Coussot, P.: General probabilistic approach to the filtration process. Phys. Rev. Lett. 98, 1–4 (2007)

Sangani, A.S., Behl, S.: The planar singular solutions of Stokes and Laplace equations and their application to transport processes near porous surfaces. Phys. Fluids A. 1, 21–37 (1989)

Sharma, M.M., Yortsos, Y.C.: A network model for deep bed filtration processes. AIChE J. 33, 1644–1653 (1987a)

Sharma, M.M., Yortsos, Y.C.: Transport of particulate suspensions in porous media: model formulation. AIChE J. 33, 1636–1643 (1987b)

Sun, Z., Espinoza, N., Balhoff, M.T.: Discrete element modeling of indentation tests to investigate mechanisms of CO2-related chemomechanical rock alteration. J. Geophys. Res. Solid Earth. 121, 2338–2360 (2016)

Sun, Z., Espinoza, D.N., Balhoff, M.T., Dewers, T.A.: Discrete element modeling of micro-scratch tests: investigation of mechanisms of CO2 alteration in reservoir rocks. Rock Mech. Rock Eng. 50, 3337–3348 (2017)

Sun, Z., Balhoff, M.T., Espinoza, D.N.: Fluid injection induced fracture initiation based on a resolved CFD-DEM approach. In: 52nd US Rock Mechanics/Geomechanics Symposium. American Rock Mechanics Association (2018)

Sun, Z., Li, Z., Espinoza, D.N., Balhoff, M.T.: Fluid-driven fractures in granular media: insights from numerical investigations. Phys. Rev. E 101(4), 042903 (2020)

Svarovsky, L.: Solid–Liquid Separation. Butterworth-Heinemann (2000)

Thane, C.: Geometry and Topology of Model Sediments and Their Influence on Sediment Properties (2006)

Thompson, K.E., Fogler, H.S.: Modeling flow in disordered packed beds from pore-scale fluid mechanics. AIChE J. 43, 1377–1389 (1997)

To, K.: Jamming transition in two-dimensional hoppers and silos. Phys. Rev. E Stat. Nonlinear Soft Matter Phys. 71, 1–4 (2005)

To, K., Lai, P.Y., Pak, H.K.: Jamming of granular flow in a two-dimensional hopper. Phys. Rev. Lett. 86, 71–74 (2001)

Tsuji, Y., Kawaguchi, T., Tanaka, T.: Discrete particle simulation of two-dimensional fluidized bed. Powder Technol. 77(1), 79–87 (1993)

Won, J., Lee, J., Burns, S.E.: Upscaling polydispersed particle transport in porous media using pore network model. Acta Geotechnol. 16(2), 421–432 (2021)

Wu, C., Sharma, M.: M: modeling proppant transport through perforations in a horizontal wellbore. SPE J. 24(04), 1777–1789 (2019)

Yang, H.: Pore-Scale Modeling of Particle Filtration in Porous Media. PhD Dissertation. University of Texas at Austin, Austin (2018)

Yang, H., Balhoff, M.T.: Pore-network modeling of particle retention in porous media. AIChE J. 6, 66 (2017)

Zhao, J., Shan, T.: Coupled CFD–DEM simulation of fluid–particle interaction in geomechanics. Powder Technol. 239, 248–258 (2013)

Zuriguel, I., Garcimartín, A., Maza, D., Pugnaloni, L.A., Pastor, J.M.: Jamming during the discharge of granular matter from a silo. Phys Rev E Stat Nonlinear Soft Matter Phys 71, 1–25 (2005)

Acknowledgements

This material is based upon work supported as part of the Center for Frontiers of Subsurface Energy Security, an Energy Frontier Research Center funded by the US Department of Energy, Office of Science, and Office of Basic Energy Sciences under Award Number DE-SC0001114.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix 1: Sensitivity analysis of particle properties

Mondal et al. (2016) found that Young’s modulus does not affect the simulation results of particle jamming. In this study, sensitivity analysis of particle properties, including Young’s modulus, Poisson’s ratio, and coefficient of restitution on jamming probability have been performed and the results are shown in Fig.

13. The triangle packing structure is used, and the grain/particle size ratio is 10. The particle concentration is 5%, and coefficient of friction is 0.5. Figure 13 shows that these three properties do not have a significant effect on jamming probability.

Appendix 2: Derivation of Eq. 6

Given the probability of jamming, P0, and the number of injected particles, Nin, the average number of particles goes through a pore throat is expected to be,

Assume the first term on the right-hand side is,

Multiply Eq. 16 by (1 − P0) we have

So

Substitute y back into Eq. 15, we have

Appendix 3: Derivation of Eq. 7

We performed sensitivity analysis on triangle packing structure (screen a) to understand the effect of particle concentration, grain/particle size ratio, and inflow velocity on the probability of jamming. Three velocities (10–4 cm/s, 5 × 10–4 cm/s, and 10–3 cm/s) are used for each case. Figure

14 shows the jamming probability as a function of concentration and Fig. 15 shows jamming probability as a function of grain/particle size ratio.

The suspensions with higher particle concentrations and larger particles more easily jam and have a bigger probability of jamming. The probability of jamming decreases significantly around D/d = 10. The effect of velocity on the probability of jamming is insignificant compared with that of particle concentration and grain/particle size ratio (Figs. 14, 15). Therefore, in the following discussion, jamming is assumed to be independent of velocity, but is a function of concentration, friction, and pore throat geometry. We also assume that the effects of concentration, friction, and geometry on jamming are independent; therefore, the probability can be represented as

where h1, h2, and h3 represent the effects of geometry, concentration, and friction on jamming, respectively. These effects will be studied individually.

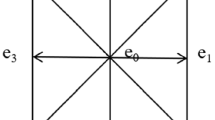

We first investigate the effects of grain/particle size ratio and pore throat geometry on jamming. Both triangle and square packing structures are used. The simulation results are given in Fig. 16. Figure 16 shows that the probability of jamming increases with decreasing grain size (relative to the particle size). A plateau is found when the pore size is close to the particle size, which is referred to as P0,max. More importantly, it shows that the same grain size with different pore geometry will result in different jamming probability. Jamming probability does not scale with grain/particle size ratio, since jamming always occurs at the constrictions (throats). The geometry and size of the throats would have a significant effect on jamming. Lafond et al. (2013) performed jamming experiments using a channel with a circular outlet. They found that the average number of particles discharged prior to jam can be scaled with the pore/particle size ratio, Sr. Pores in our case and in real porous media are often not circular. Here we defined an effective circle as the circle that has the same area as that of the constriction. Figure 17 shows the effective radius for triangle and square pores, respectively. This definition can also be used in more general cases where the pores are not a regular geometry.

From Eq. 20, we can get

As P0 is at its plateau value, the effect of Sr on jamming probability is small and the value of h1 is close to 1. Therefore,

The curve in Fig.

18 is h1, and it can be best fit by

Figure 19 shows the effect of the concentration on the jamming probability. As we assumed that each factor acts independently on jamming probability, h2 is only a function of concentration. Therefore, we only study triangle packing structure. Figure 19a shows the jamming probability as a function of concentration. Again, a plateau is observed as concentration increases. Similarly, by normalizing the values by the plateau value, all curves collapse to a single curve (Fig. 19b), which is exactly h2. Considering that jamming probability will be zero when particle concentration C is zero, we use the following equation to match the data in Fig. 19b,

We also performed sensitivity analysis on the effect of friction. Figure

20a shows the probability of jamming as a function of COF at three different particle concentrations: C = 0.04, 0.08, and 0.15. The grain/particle size ratio is 10 (Sr = 3.2). In agreement with To et al. (2001), the probability of jamming increases with the COF in all cases. There are two mechanisms that contribute to the increase of jamming. First, the friction between particles and grains slow down the movement of particles. Particles accumulate around the constriction and form a local dense cluster. Second, friction reduces the number of particles that is required to form a “bridge” (To et al. 2001). As COF increases, the probability of jamming approaches a constant. Figure 20b shows that all three curves collapse on each other when P0 is normalized by its peak value (at f = 1.5). We find that the effect of friction can be predicted well by an exponential function:

By combining Eqs. 23, 24, and 25, we can get a new model for the probability of jamming, which takes into account the effect of friction, concentration, pore size and geometry. When Sr < 1, size exclusion occurs so P0 is 1. The new model is given by

where Cst is model constant. It is found that Cst = 0.6 gives the best match between model and DEM simulations.

Appendix 4: The criteria for determining the REV

Three screens with different size (Fig. 21) are used to perform sensitivity analysis and determine the REV. We inject a layer of particles with the same size, thickness and concentration into the screens, which means that the number of injected particles is proportional to the screen area. After the simulation, we count the number of particles remaining on the screen (Table 3). The number of remained particles are also proportional to the screen size. We find that increasing the screen size beyond 3 × 4 grains does not increase the accuracy of the simulation and is, therefore, an REV. We also performed similar test for the screen in Fig. 2b and found that 4 × 4 grains is a valid REV.

Rights and permissions

About this article

Cite this article

Li, Z., Yang, H., Sun, Z. et al. A Probability-Based Pore Network Model of Particle Jamming in Porous Media. Transp Porous Med 139, 419–445 (2021). https://doi.org/10.1007/s11242-021-01673-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11242-021-01673-4