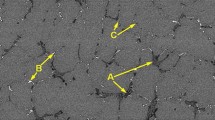

Reformer furnaces are an essential part of the petrochemical industry to produce hydrogen. Their most critical components are radiant tubes, where extreme temperature and pressure conditions require the high alloyed austenitic HP grade steels, owing to their excellent strength to creep rupture and corrosion resistance. Therefore, radiant tubes are the most critical components of reformer furnaces. Life assessment of cast 25Cr35Ni-Nb (HP-40Nb) reformer tube was performed. For this purpose, the nature of the damage and the experimental Larson–Miller diagram were used. The nature of damage of the tube in service was metallographically analyzed using optical and scanning electron microscopes. Samples from the serviced tube were cut and prepared for the stress rupture test at 900–1040°C under 20–30 MPa stress. Microstructure changes were observed with SEM. They included internal and external layer oxides, the network of carbides and isolated/ oriented cavities.

Similar content being viewed by others

References

A. Alvino, D. Lega, F. Giacobbe, et al., “Damage characterization in two reformer heater tubes after nearly 10 years of service at different operative and maintenance conditions,” Eng. Fail. Anal., 17, Nos. 7–8, 1526–1541 (2010).

I. Le May, T. L. da Silveria, and C. H. Vianna, “Criteria for the evaluation of damage and remaining life in reformer tubes,” Int. J. Pres. Ves. Pip., 66, Nos. 1–3, 233–241 (1996).

C. W. Thomas, K. J. Stevens, and M. J. Ryan, “Microstructure and properties of alloy HP50-Nb: comparison of as cast and service exposed materials,” Mater. Sci. Tech., 12, No. 6, 469–475 (1996).

H. M. Tawancy, A. Ul-Hamid, A. I. Mohammed, and N. M. Abbas, “Failure analysis of catalytic steam reformer tubes,” Anti-Corros. Method. M., 52, No. 6, 337–344 (2005).

E. Guglielmino, R. Pino, C. Servetto, and A. Sili, “Creep damage of high alloyed reformer tubes,” in: A. S. H. Makhlouf and M. Aliofkhazraei (Eds.), Handbook of Materials Failure Analysis with Case Studies from the Chemicals, Concrete and Power Industries, Chapter 4, Butterworth-Heinemann, Oxford (2016), pp. 69–91.

T. L. D. Silveria and I. L. May, “Reformer furnaces: materials, damage mechanisms, and assessment,” Arab. J. Sci. Eng., 31, No. 2C, 99–119 (2006).

R. J. Gommans, “Life assessment and inspection techniques in reformer furnaces,” in: Proc. of the 6th Schmidt+Clemens Group Symposium, Bali, Indonesia, August 2002.

X. Q. Wu, Y. S. Yang, Q. Than, and Z. Q. Hu, “Structure degradation of 25Cr35Ni heat-resistant tube associated with surface coking and internal carburization,” J. Mater. Eng. Perform., 7, 667–672 (1998).

R. Voicu, E. Andrieu, D. Poquillon, et al., “Microstructure evolution of HP40-Nb alloys during under air at 1000°C,” Mater. Charact., 60, No. 9, 1020–1027 (2009).

M. Naghi Khani and S. A. Jenabali Jahromi, “Creep life assessment of primary reformer HP40-Nb modified steel tube of an ammonia plant,” IJE Trans. B-Appl., 17, No. 2, 183–190 (2004).

IPS-M-ME-206. Material and Equipment Standard for Reformer Furnaces Including Tube and Outlet Manifolds, Original Edition, January 1996.

M. Abbasi, I. Park, Y. Ro, et al., “Microstructural evaluation of welded fresh-to-aged reformer tubes used in hydrogen production plants,” Eng. Fail. Anal., 92, 368–377 (2018).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Problemy Prochnosti, No. 2, pp. 170 – 181, March – April, 2021.

Rights and permissions

About this article

Cite this article

Kazempour-Liasi, H., Lalegani, Z. & Rayatpour, M. Life Assessment of HP-40Nb Reformer Furnace Tube of a Petrochemical Plant. Strength Mater 53, 364–375 (2021). https://doi.org/10.1007/s11223-021-00295-x

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11223-021-00295-x