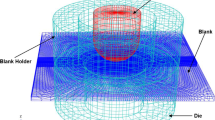

The formability of two types of tailor-welded blanks was analyzed with the concentration on the effects of planar anisotropy on eras forming of deep-drawn parts. The first tailor-welded blank consisted of bake-hardened BH220 steel with different rolling directions, which is applied to the surface car body parts. The second one consisted of dual-phase DP600 steel with different rolling directions, which is applied to supporting parts of automobiles. Stress-strain characteristics of experimental steel sheets were measured using the tensile tests and used in the respective simulations. Simulations via the Dynaform software were compared to the experimental values measured during the deep-drawing process of rectangular boxes.

Similar content being viewed by others

References

M. Merklein, M. Johannes, M. Lechner, and A. Kuppert, “A review on tailored blanks – Production, applications and evaluation,” J. Mater. Process. Tech., 214, 151–164 (2014).

E. Evin and M. Tomas, “Comparison of deformation properties of steel sheets for car body parts,” Procedia Engineer., 48, 115–122 (2012).

P. Baùon, A. Úwiàtoniowski, and J. Szostak, “Improved method of springback compensation in metal forming analysis,” Strength Mater., 48, No. 4, 540–550 (2016).

B. Kinsey and X. Wu, Tailor Welded Blanks for Advanced Manufacturing, Woodhead Publishing, Cambridge (2011).

J. Bílik, J. Ertel, J. Bárta, et al., “The analysis of properties and forming of laser welded superduplex steel SAF 2507,” Hutnik-WH, 82, No. 9, 627-631 (2015).

A. K. Sinha, D. Y. Kim, and D. Ceglarek, “Correlation analysis of the variation of weld seam and tensile strength in laser welding galvanized steel,” Opt. Laser Eng., 51, 1143–1152 (2013).

W. Fratz, F. Stachowitz, T. Trzepiecinski, and T. Pieja, “Forming limit of the heat resistant AMS 5599 sheet metal,” Hutnik-WH, 81, No. 7, 442–445 (2014).

Z. Q. Zhang, X. F. Jia, Y. J. Wang, and P. Gao, “Optimization analysis of initial sheet metal contour line for high-strength boron steel in hot stamping,” Strength Mater., 48, No. 1, 77–81 (2016).

A. Khan, V. V. N. Satya Suresh, and S. P. Regalla, “Effect of thickness ratio on weld line displacement in deep drawing of aluminium steel tailor welded blanks,” Proc. Mat. Sci., 6, 401–408 (2014).

J. Slota, M. Jurèiðin, and E. Spiðák, “Experimental and numerical analysis of local mechanical properties of drawn part,” Key Eng. Mater., 586, 245–248 (2014).

Y. Morishita, T. Kado, S. Abe, et al., “Role of counterpunch for square-cup drawing of tailored blank composed of thick/thin sheets,” J. Mater. Process. Tech., 212, 2102–2108 (2012).

J. Moravec, “Magnetic field application in area sheet metal forming,” in: Proc. of the 25th Anniversary Int. Conf on Metallurgy and Materials (METAL 2016, May 25–27, 2016, Brno), TANGER Ltd., Ostrava (2016), pp. 303–309.

V. V. N. Satya Suresh, S. P. Regalla, A. K. Gupta, and G. Padmanabham, “Weld line shift in the case of tailor welded blanks subjected to differential strengths with respect to TIG and laser welding,” Mater. Today - Proc., 2, 3501–3510 (2015).

Acknowledgments

This work was supported by the Slovak Research and Development Agency under the contract No. APVV-0281-12.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Problemy Prochnosti, No. 4, pp. 77 – 81, July – August, 2017.

Rights and permissions

About this article

Cite this article

Schrek, A., Švec, P. & Brusilová, A. Formability of Tailor-Welded Blanks From Dual-Phase and Bake-Hardened Steels with a Planar Anisotropy Influence. Strength Mater 49, 550–554 (2017). https://doi.org/10.1007/s11223-017-9898-9

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11223-017-9898-9