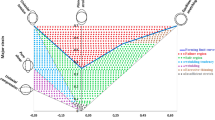

Known parametric methods and a modified base diagram method were used to analyze extrapolation results for creep rupture diagrams of heat-resistant steels. Two model alternatives are examined: viz when the hypothesis of the “unified” curve is valid and when its application leads to significant errors in prediction of creep strain processes. The efficiency of proposed procedures and their advantages over other approaches are demonstrated.

Similar content being viewed by others

References

Yu. N. Rabotnov, Creep of Structure Elements [in Russian], Nauka, Moscow (1966).

A. M. Lokoshchenko, Simulation of Creep and Creep Rupture Strength of Metals [in Russian], MGIU, Moscow (2007).

S. A. Shesterikov (Ed.), Creep and Creep Rupture Strength Relationships. Handbook [in Russian], Mashinostroenie, Moscow (1983).

V. T. Troshchenko (Ed.), Strength of Materials and Structures [in Russian], Vol. 5: V. V. Krivenyuk, Prediction of High-Temperature Creep and Creep Rupture Strength, Pisarenko Institute of Problems of Strength, National Academy of Sciences of Ukraine, Kiev (2012).

V. V. Krivenyuk, D. S. Avramenko, and R. P. Prikhod’ko, “Interpolation analysis of the features of long-term creep rupture in chrome-nickel and chrome-molybdenum steels,” Strength Mater., 45, No. 2, 187–191 (2013).

I. I. Trunin, “A mechanical equation of the condition of metal materials and prediction of high-temperature strength characteristics,” Strength Mater., 8, No. 9, 1013–1018 (1976).

F. R. Larson and J. Miller, “A time-temperature relationship for rupture and creep stresses,” Trans. ASME, 74, No. 5, 765–775 (1952).

R. L. Orr, O. D. Sherby, and J. E. Dorn, “Correlation of rupture data for metals at elevated temperatures,” Trans. ASM, 46, 113–128 (1954).

S. S. Manson and A. M. Haferd, A Linear Time-Temperature Relation for Extrapolation of Creep and Stress Rupture Data, NASA TN 2890 (1953).

V. I. Kovpak, Prediction of Heat Resistance of Metallic Materials [in Russian], Naukova Dumka, Kiev (1981).

N. K. Kucher and R. P. Prikhod’ko, “Prediction of high-temperature long-term strength of materials,” Strength Mater., 45, No. 5, 517–522 (2013).

P. K. Raut and W. R. Clough, “Computerized evaluations of the relative abilities of seven time-temperature parameters to correlate and exstrapolate nickel alloy stress-rupture date,” Trans. ASME, J. Basic Eng., 94, 7–12 (1972).

R. V. Romashov, “Evaluation of creep rupture characteristics from the test results of limited time span,” Usp. Sovrem. Estestvozn., No. 11, 69–71 (2006).

A. I. Orlov, Applied Statistics [in Russian], Ékzamen, Moscow (2004).

Data Sheets on the Elevated-Temperature Properties of 18Cr–12Ni–Nb Stainless Steel Tubes for Boilers and Heat Exchangers (SUS 347H TB), NRIM Creep Data Sheet, No. 28, 1–26 (2001).

Micrographs and Microstructural Characteristics of Crept Specimens of 18Cr–Ni Stainless Steel for Boiler and Heat Exchanger Seamless Tubes (SUS 304H TB), NRIM Creep Data Sheet, No. M-1, 1–76 (1999).

Data Sheets on the Elevated-Temperature Properties of 5Cr–0.5Mo Steel Tubes for Boilers and Heat Exchangers (SNBA 25), NRIM Creep Data Sheet, No. 42, 1–25 (1992).

Micrographs and Microstructural Characteristics of Crept Specimens of 2,25Cr–1Mo Steel Tube for Boiler and Heat Exchanger (JIS STBA24), Normalized and Tempered 2,25Cr–1Mo Steel Plate for Boiler and Pressure Vessels (JIS SCM V 4NT) and Quenched and Tempered 2,25Cr–1Mo Steel Plate for Pressure Vessels (ASTM A542), NIMS, No. M-4, 1–217 (2005).

Author information

Authors and Affiliations

Additional information

Translated from Problemy Prochnosti, No. 5, pp. 56 – 65, September – October, 2015.

Rights and permissions

About this article

Cite this article

Kucher, M.K., Prikhod’ko, R.P. Reliability of Time-Temperature Extrapolation of Creep Rupture Diagrams for Heat-Resistant Steels. Strength Mater 47, 697–704 (2015). https://doi.org/10.1007/s11223-015-9706-3

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11223-015-9706-3