Abstract

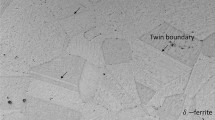

The paper addresses the influence of plastic prestraining in tension and combined tension at 150 and 350°C on the rupture stress in 15Kh2MFA steel upon heat treatment that simulates irradiation embrittlement of materials in a WWER-440 type reactor towards the end of its lifetime. The dependence of rupture stress on the dislocation density in the material upon plastic prestraining is studied. It is found out that as the plastic prestraining in tension and combined tension grows, the dislocation density within small-angle boundaries increases and thus results in a larger rupture stress. An increase in rupture stress in the case of prestraining at 350°C is more intensive than that at 150°C. We analyze the microcrack nucleation and growth micromechanisms in 15Kh2MFA steel during tensile plastic deformation and discuss the effect of the material substructure on the microcrack arrest.

Similar content being viewed by others

References

V. T. Troshchenko, V. V. Pokrovskii, and V. G. Kaplunenko, “Prediction of crack resistance for heat-resistant steels taking into account specimen size effect. Communication I. Results of experimental investigations,” Strength Mater., 29, No. 1, 1–15 (1997).

G. P. Karzov, B. Z. Margolin, and V. A. Shvetsova, Physical-Mechanical Modeling of Fracture Processes [in Russian], Politekhnika, St. Petersburg (1993).

V. B. Gutsailyuk and P. V. Yasnii, “The influence of elastoplastic strain cycling on the fracture mechanism and cleavage stress in heat-resistant steel,” Visn. Zhitomir. Inzh.-Tekhn. Inst., No. 16, 8–17 (2001).

V. B. Glad’o, V. B. Gutsailyuk, and P. V. Yasnii, “Micromechanisms of fatigue damage in 15Kh2MFA steel,” Visn. Zhitomir. Inzh.-Tekhn. Inst., 24, No. 1, 49–55 (2003).

V. B. Gutsailyuk, I. B. Okipnyi, and P. V. Yasnii, “The effect of combined tensile prestraining on cleavage stress,” Visn. Ternopol. Derzh. Tekhn. Univ., 8, No. 4, 5–12 (2004).

A. M. Glauert (Ed.), Practical Methods in Electron Microscopy [Russian translation], Mashinostroenie, Leningrad (1980).

I. I. Novikov, Crystalline Defects in Metals [in Russian], Metallurgia, Moscow (1983).

R. K. Melekhov and V. I. Pokhmurskii, Structural Materials for Power Equipment. Properties and Degradation [in Ukrainian], Naukova Dumka, Kiev (2003).

L. M. Utevskii, Diffraction Electron Microscopy in Metal Research. Introduction [in Russian], Metallurgia, Moscow (1973).

V. I. Vladimirov, Physical Nature of Fracture in Metals [in Russian], Metallurgia, Moscow (1984).

V. V. Panasyuk (Ed.), Fracture Mechanics and Strength of Materials [in Russian], Handbook in 4 volumes, Naukova Dumka, Kiev (1990).

Author information

Authors and Affiliations

Additional information

__________

Translated from Problemy Prochnosti, No. 4, pp. 19–30, July–August, 2007.

Rights and permissions

About this article

Cite this article

Yasnii, P.V., Glad’o, V.B. & Okipnyi, I.B. Relationship between rupture stress and microstructure parameters of plastically deformed heat-resistant steel. Strength Mater 39, 349–357 (2007). https://doi.org/10.1007/s11223-007-0039-8

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11223-007-0039-8