Abstract

We report the design and development of simple and economical Arduino-based four-channel data acquisition system with digital temperature control that is suitable for sensor parameter optimization involved in the search of appropriate chemiresistive gas sensing material for a particular gas. The developed system is capable of simultaneously capturing the data as well as controlling the desired operating temperature (up to 300 °C) of four sensing elements. This is achieved by employing sixteen analog and digital channels of the Arduino nano microcontroller. The sensing circuit is capable of recording the resistance changes from 20 kΩ to 5 MΩ at a rate of 15 kHz. The developed system has been tested rigorously, validated and demonstrated for its effectiveness towards investigating the gas sensing properties of chemiresistive NO2 sensors realized using ZnO nanowires. The present simple and low-cost alternative finds its application for developing the target specific chemiresistive sensors in particular for investigating the gas sensing properties of metal oxide semiconductors.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Rapid industrialization and urbanization have resulted in the increase of environmental pollution due to toxic gases such as NO2, NO, CO, CO2, NH3, H2S, and volatile organic compounds (VOC). This has caused hazardous health diseases, acid rain, depletion of ozone layer, and global warming [1]. Due to concerns about health safety, food safety, public security, and air quality monitoring, a miniature, highly sensitive portable gas sensor for real-time monitoring is needed. The market for gas sensors is envisaged to reach ∼ 2.3 billion USD by 2027 [2]. The good-quality gas sensor is required to follow the Ramgir ‘4S’ criteria, which means it should be highly sensitive, selective, stable and suitable. Nanotechnology has played a vital role in the development of small and portable gas sensors. The nanomaterials have the potential to compensate for all ‘4S’ parameters required for a good sensor [3]. This has been attributed to the high surface area-to-volume ratio along with dimensions comparable to Debye length. For example, 1-D ZnO nanowires have demonstrated excellent sensing properties with quick reaction kinetics at lower temperatures [4]. It is important to note that use of single nanowires could possibly help to detect different gas molecules, simultaneously. Further, the control over growth position, location, aspect ratio could lead to the integration of several devices in a miniaturized size. However, their use is restricted owing to non-availability of the miniaturized multiplex data acquisition systems (DAS) and the complexity involved when using large number of sensors. Such smaller systems are envisaged to play the important role in concepts like Smart-cities, Smart sensors, point of care devices. For example; internet of things (IOT)-enabled miniaturized sensors possibly as electronic nose (e-nose) for monitoring human health or indoor as well as outdoor air quality [5].

Basically, the DAS system comprises of a sensor, signal conditioning circuit, analog to digital converter, and a recording unit [6,7,8]. The sensor converts the physical parameter into the output value in the form of electrical signal. The noise in the electrical signal is resolved with the help of signal conditioning. Herein, the filter and amplification circuits are used to separate noise from the real signal and sometimes to strengthen the weak signals. The microchip is then used to convert a physical analog signal into a digital signal i.e., data that can be recorded. Data sampling refers to the process of sampling data at a rate in terms of frequency (F). The collected data can be recorded using the serial plotter software and saved as a file on the computer system. The microcontroller and computer system can be connected to different types of systems to acquire and transfer data, including USB ports, and Ethernet ports [7]. There are different configurations of the DAS systems such as simple embedded system-based DAS [8], web-based DAS [9], image-based DAS [10], and inexpensive Arduino-based DAS [11, 12].

Arduino-based single-board microcontrollers, which are commercially available, have gained tremendous popularity in the scientific community owing to their user friendliness and simplistic performance [11]. In general, Arduino is an open-source software and hardware company that designs and manufactures microcontroller-based kits for various digital devices. In particular, the Arduino board comprises of numerous microprocessors and controllers and is equipped with sets of digital and/or analog input or output pins along with a serial communication interface, namely the universal serial bus (USB), that can be used to load programs. Some of the commonly used programs and the corresponding software integrated development environment (IDE) are freely available and are being used by the researchers for their studies [13, 14]. Accordingly, in the present work, using Arduino board and ZnO nanowires as sensing elements, a simple data acquisition and testing setup has been designed, tested, validated and demonstrated for its effectiveness towards chemiresistive NO2 sensing, as a case study. The developed device could easily be used to tune the sensor operating temperature to the desired pre-set value (digitally) and record the responses (resistances) from the four sensing elements, simultaneously. The serial plotter software has been used for recording data and analyzing data from Arduino. We envisaged that these types of indigenous and inexpensive DAS will be useful for future applications in medical health monitoring, environmental monitoring, industrial automation and control, security, and defense equipment.

2 Design and Development of Complete Gas Sensing Setup

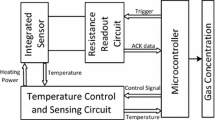

2.1 Control and Sensing Circuit

Figure 1, shows the circuit diagram of the four-channel gas sensing unit. Figure 2 shows the corresponding photograph of the fabricated PCB used for four-channel gas sensing and data acquisition.

Table 1 illustrates the specifications of the different components used to fabricate the unit. The developed unit can provide and maintain the desired temperature for the active gas sensing material from RT to 300 °C. The change in resistance of the sensing material can be recorded over time. The circuit consists of an AC-to-DC converter that provides a continuous 24 V supply to the heater, which is connected to a switch. The heater has been constructed from two PT-100’s linked in parallel and converted into PT-50. The pulse width of the switches (M1, M2, M3, and M4) has been controlled by the microcontroller as per the desired temperature value. The temperature of the heater is measured specifically through a PT-100, which is called a reader. The switches (M5, M6, M7, and M8) have been turned on periodically to sense voltages across the reader PT-100, which is calibrated in terms of temperature (PT-100 resistance). Periodic temperature detection via the reader overcomes the heater self-heating issue due to continuous current flow. The resistance (R1, R2, R3, R4) series with PT-100 is used to limit the large current flow through PT-100. Because ADC resistance is significantly greater than PT-100 resistance, the voltage drop across PT-100 is sensed directly through ADC. But the sensing material resistance varies largely, which needs an accurate voltage sensing circuit.

The constant 5 V is applied across the sensing material through the resistances (R5, R6, R7 and R8). The series resistance helps to hold the voltage across the sensing material below the ADC voltage limit. As the ADC resistance is smaller than the sensing resistance, an operational amplifier-based voltage follower circuit is used to sense the sensing material resistance. The sensing circuit is designed to sense resistance ranging from 20 kΩ to 5 MΩ with an error of ± 2%. The ATMEL-ATMEGA328p microcontroller is used to perform the control and sensing operations. It has a 16 MHz clock frequency with a 10-bit ADC. The program is burned into a microcontroller through an Arduino interface. Serial communication software is used to read and record the data [15]. Figure 3 shows the experimental setup of the developed DAS. In the plot on the laptop screen, Y-axis represents resistance in kΩ order, and the X-axis represents time in seconds (2 points per second).

2.2 Test Chamber

Figure 3 shows a photograph of the complete set-up, which is a static-type gas sensing set-up along with laptop. Table 2 indicates the specifications of the gas sensing unit which is in accordance to the table top static gas sensing unit, as reported elsewhere [16]. It consists of seven Teflon heads fixed to a stainless steel (SS 304) disc, as shown in Fig. 3 inset. The Teflon heads are provided with 6 pins (phosphor bronze) for electrical connections. Out of these 6 pins, two are used for the sensing element; two for the connection of the heater, and the rest are used for the reader, as shown in Fig. 3. These wires are connected to the Arduino-based sensing data acquisition circuit. The heater is realized by connecting two Pt-100s in parallel. The heater and reader Pt-100’s is physically connected adjacent to each other so as to form a platform (size ∼ 6 × 8 mm2) on which the sensing element can easily be rested. The heater and reader wires are connected to the phosphor bronze pins in such a way that direct contact with the Teflon base is avoided. Figure 1 shows the photograph of the actual circuit depicting the Arduino nano used for the present study, and Fig. 3 inset shows the sensor heads for the individual sensing element. The volume of the test chamber is ∼ 250 sccm. The program is written in Arduino IDE and software serial plot is used for computer communication [15]. The screen of the laptop shows the screen shot of the actual reading recorded during measurement.

2.3 Synthesis Process

For the testing of the DAS system, ZnO nanowires grown using hydrothermal method have been used as a sensing material. These nanowires have been grown using hydrothermal method as reported earlier [17]. The nanowires surface has been modified with thin layer (∼ 10 nm) of aluminum (Al) using vacuum based physical evaporation method to achieve sensitive sensor towards NO2 [18].

2.4 Gas Sensing Studies

The contact electrodes on the sensor films were realized using a 120 nm Au layer deposited using the thermal evaporation method. The sensor film was then mounted on a testing unit as shown in Fig. 3 inset, and final contacts to the individual sensing element were realized using silver paste and Pt wire (0.1 mm, OD). The response curves were measured by injecting the known concentration of test gas (NO2) in the test chamber. Figure 3 shows a screenshot of the program window while recording the temperature change. It clearly indicates the change in temperature (in Ω) and the resistance (in kΩ) of the sensor films with time. The developed unit could record data points simultaneously from the 4 channels. Further, it is observed that the heater takes approximately 10 s to reach the set operating temperature. The required concentration of the test gas in the chamber was achieved by injecting a known quantity of test gas in the chamber (250 ml) using an airtight syringe. From the response curve, sensor response values were measured using the relation;

where, Rg and Ra are the resistance in test gas and air, respectively. Response and recovery times were calculated as the time required by the sensor films to reach 90 and 10% of their saturation and original values, respectively [19, 20].

3 Testing and Validation of the System

To test and validate the developed system two sensors namely pure ZnO and Al modified ZnO nanowires have been used. The response curves were recorded by exposing the sensor to different concentration of gas at desired operating temperatures. As shown in Fig. 3, the sensor exhibited a typical response curve upon exposure to gas and ambient. From this curves, three parameters namely Sensor response, response and recovery times, were calculated. Figure 4 (a) shows the variation of sensor response (SR) with operating temperature towards 4 ppm of NO2 gas. The temperature was systematically varied from 160 to 240 ℃. The maximum response for both pure and Al-ZnO NW was found at 200 ℃ as shown in Fig. 4 (a). The comparative response curves for pure and Al-ZnO NW are shown in Fig. 4 (b). The SR, response time, and recovery time have been calculated for a 4-ppm gas concentration at 200 ℃. The SR, response, and recovery time’s values for Al modified ZnO NW were found to be 3.9, 65 s, and 170 s, respectively. For as-grown ZnO NW they were 1.4, 95 s, and 180 s, respectively.

The real-time response curves recorded using the unit for the ZnO NW n-type metal oxide sensors upon exposure to oxidizing (NO2) to optimize different parameters (a) operating temperature v/s SR, (b) resistance v/s time, (c) different concentration optimization, and (d) gas concentration/SR, respectively

In Fig. 4 (c), sensor response towards different concentrations (2, 4, 6, 8 ppm) of NO2 gas is shown which is used to determine the lower limit for the NO2 detection. It is evident that both as grown and Al modified samples exhibit a continuous increment in gas concentration, as shown in Fig. 4(d). From the measured response curves, it is evident that the developed system could easily be used to record the response curves from four sensing elements, simultaneously wherein the operating temperature for all these elements is preset to the desired value using the simple modifications in the freely available Arduino IDE program. Thus, the present result clearly demonstrates the complete working of the developed system for investigating the gas sensing properties of the chemiresistive gas sensors. This work is an important step towards achieving the desired miniaturization of the application specific DAS systems to be used for realizing chemiresistive sensors-based e-nose for toxic gas detection. Further, the developed system could easily be extended to increase the number of channels to achieve more data crucial for improving the performance of e-nose and is underway.

4 Conclusion

A unique, indigenous, compact, affordable and miniaturized multichannel (four) Arduino based gas sensing unit comprising data acquisition system with programmable temperature has been successfully designed, developed, tested, validated and demonstrated for its effectiveness for gas sensing application. The developed system can record response curves from the 4 sensing elements simultaneously. Further, the operating temperature of the individual sensing element can be tuned to the desired value between RT and 300 ℃. The unit can measure and record the three-order change in resistance from 20 KΩ to 5 MΩ. Importantly, the product demonstrated its utility in speeding up the parameter optimization method to achieve required sensing characteristics. The response curves were successfully recorded using the developed system and sensor based on pure and Al modified ZnO nanowires, respectively.

Data Availability

No datasets were generated or analysed during the current study.

References

Manisalidis, I., Stavropoulou, E., Stavropoulos, A., & Bezirtzoglou, E. (2020). Environmental and health impacts of air pollution: A review. Frontiers in Public Health. https://doi.org/10.3389/fpubh.2020.00014.

Gardner, E. L., Gardner, J. W., & Udrea, F. (2023). Micromachined Thermal Gas Sensors—A Review Sensors. https://doi.org/10.3390/s23020681.

Das, S., Mojumder, S., Saha, D., & Pal, M. (2022). Influence of major parameters on the sensing mechanism of semiconductor metal oxide based chemiresistive gas sensors: A review focused on personalized healthcare. Sensors and Actuators B: Chemical. https://doi.org/10.1016/j.snb.2021.131066.

Ramgir, N., Bhusari, R., Rawat, N. S., Patil, S. J., Debnath, A. K., & Gadkari, S. C. (2020). Muthe, TiO2/ZnO heterostructure nanowire based NO2 sensor. Materials Science in Semiconductor Processing. https://doi.org/10.1016/j.mssp.2019.104770.

Sinju, K. R., Bhangare, B., Pathak, A., Patil, S. J., Ramgir, N. S., Debnath, A. K., & Aswal, D. K. (2022). ZnO nanowires-based e-nose for the detection of H2S and NO2 toxic gases. Materials Science in Semiconductor Processing. https://doi.org/10.1016/j.mssp.2021.106235.

Sarma, P., Singh, H. K., & Bezboruah, T. (2018). A real-time data acquisition system for monitoring sensor data. International Journal of Computational Science and Engineering, 6(6), 539–542.

Emilio, M. D. P. (2013). Data Acquisition systems: Hardware. Data Acquisition systems. Springer. https://doi.org/10.1007/978-1-4614-4214-1_2.

Sumithra, G. R., & Poornima, S. (2018). Embedded based temperature monitoring system. Int J Eng Sci Invent, 7, 86–90.

Greitans, M., Grunde, U., Jakovics, A., & Gendelis, S. (2013). Web-based real-time data acquisition system as tool for energy efficiency monitoring. In 2013 21st Telecommunications Forum Telfor (TELFOR). IEEE. https://doi.org/10.1109/TELFOR.2013.6716289.

Nasution, I. S., & Gusriyan, K. (2019). Nutmeg grading system using computer vision techniques. In IOP Conference Series: Earth and Environmental Science p. 012003. https://doi.org/10.1088/1755-1315/365/1/012003.

Nasution, I. S., Sundari, S., & Rifky, N. (2020). Data acquisition of multiple sensors in greenhouse using Arduino platform. In IOP Conference Series: Earth and Environmental Science p. 012011 https://doi.org/10.1088/1755-1315/515/1/012011.

Barański, R., Galewski, M., & Nitkiewicz, S. (2019). The study of Arduino Uno feasibility for DAQ purposes. Diagnostyka. https://doi.org/10.29354/diag/109174.

Nichols, D. (2017). Arduino-based data acquisition into Excel, LabVIEW, and MATLAB. The Physics Teacher. https://doi.org/10.1119/1.4978720.

Jena, S. P, Aman, S., & Das, R. (2015). Computerized green house data acquisition system using arduino with LabVIEW. International Journal of Advanced Research in Electrical Electronics and Instrumentation Engineering, 4(4), 2350–2357. ISSN (Online): 2278–8875.

https://hackaday.io/project/5334-serialplot-realtime-plotting-software.

Ramgir, N. S., Datta, R., Avhad, K., Bhusari, R., Vedpathak, M. M., Meera, M., Katke, V. V., Ravisankar, E., Debnath, A. K., Saha, T. K., & Muthe, K. P. (2017). A table top static gas sensing unit: Model no. TPD-BARC-16CH. BARC Newsletter 14–18.

Goyal, C. P., Goyal, D., Ramgir, N. S., Navaneethan, M., Hayakawa, Y., Muthamizhchelvan, C., Ikeda, H., & Ponnusamy, S. (2021). Surface modification of ZnO nanowires with CuO: A tool to realize highly-sensitive H2S sensor. Physics of the Solid State. https://doi.org/10.1134/S1063783421030070.

Ramgir, N. S., Goyal, C. P., Goyal, D., Patil, S. J., Ikeda, H., Ponnusamy, S., & Muthe, K. P. (2021). Debnath, NO2 sensor based on Al modified ZnO nanowires. Materials Science in Semiconductor Processing. https://doi.org/10.1016/j.mssp.2021.106027.

Krishna, K. G., Parne, S., Pothukanuri, N., Kathirvelu, V., Gandi, S., & Joshi, D. (2022). Nanostructured metal oxide semiconductor-based gas sensors: A comprehensive review. Sensors and Actuators a: Physical. https://doi.org/10.1016/j.sna.2022.113578.

Zhang, J., Qin, Z., Zeng, D., & Xie, C. (2017). Metal-oxide-semiconductor based gas sensors: Screening, preparation, and integration. Physical Chemistry Chemical Physics. https://doi.org/10.1039/C6CP07799D.

Acknowledgements

Deepak Goyal thanks the Department of Science and Technology (DST), Government of India, for providing the Inspire fellowship (INSPIRE Reg. No. IFA22-ENG341). S. Patra thanks Dr. Ajay Singh for his support.

Funding

Open access funding provided by Department of Atomic Energy.

Author information

Authors and Affiliations

Contributions

DG and SP wrote the original draft, the acquisition, analysis, or interpretation of data; AS prepared sensing figures; MK funding, supervision, NSR: conception or design of the work; guidance, supervision.

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Goyal, D., Patra, S., Sapre, A. et al. Design and Development of Arduino-Based Four-Channel Data Acquisition System with Digital Temperature Control for Chemiresistive Sensors. Sens Imaging 25, 30 (2024). https://doi.org/10.1007/s11220-024-00477-2

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11220-024-00477-2