Abstract

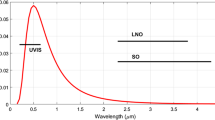

The Atmospheric Chemistry Suite (ACS) package is an element of the Russian contribution to the ESA-Roscosmos ExoMars 2016 Trace Gas Orbiter (TGO) mission. ACS consists of three separate infrared spectrometers, sharing common mechanical, electrical, and thermal interfaces. This ensemble of spectrometers has been designed and developed in response to the Trace Gas Orbiter mission objectives that specifically address the requirement of high sensitivity instruments to enable the unambiguous detection of trace gases of potential geophysical or biological interest. For this reason, ACS embarks a set of instruments achieving simultaneously very high accuracy (ppt level), very high resolving power (>10,000) and large spectral coverage (0.7 to 17 μm—the visible to thermal infrared range). The near-infrared (NIR) channel is a versatile spectrometer covering the 0.7–1.6 μm spectral range with a resolving power of ∼20,000. NIR employs the combination of an echelle grating with an AOTF (Acousto-Optical Tunable Filter) as diffraction order selector. This channel will be mainly operated in solar occultation and nadir, and can also perform limb observations. The scientific goals of NIR are the measurements of water vapor, aerosols, and dayside or night side airglows. The mid-infrared (MIR) channel is a cross-dispersion echelle instrument dedicated to solar occultation measurements in the 2.2–4.4 μm range. MIR achieves a resolving power of >50,000. It has been designed to accomplish the most sensitive measurements ever of the trace gases present in the Martian atmosphere. The thermal-infrared channel (TIRVIM) is a 2-inch double pendulum Fourier-transform spectrometer encompassing the spectral range of 1.7–17 μm with apodized resolution varying from 0.2 to 1.3 cm−1. TIRVIM is primarily dedicated to profiling temperature from the surface up to ∼60 km and to monitor aerosol abundance in nadir. TIRVIM also has a limb and solar occultation capability. The technical concept of the instrument, its accommodation on the spacecraft, the optical designs as well as some of the calibrations, and the expected performances for its three channels are described.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The detailed studies of the Martian atmosphere and climate were identified as the primary scientific goal of the ExoMars Trace Gas Orbiter (TGO) as reported in Zurek et al. (2011). TGO is a project initiated by the European Space Agency (ESA): it was conceived to carry a powerful set of atmospheric instruments to establish a detailed inventory of the trace gases existing in the Martian atmosphere as a response to the putative presence of methane, initially reported by the FKM group (Formisano et al. 2004; Krasnopolsky et al. 2004; and Mumma et al. 2009). The final configuration of the TGO project is based on a ESA-Roscosmos cooperation that started in 2011. On the Russian side, a suite of spectroscopic instruments for the studies of the Mars atmosphere in the infrared spectral range, the Atmospheric Chemistry Suite (ACS) was proposed. Selected by the Solar System Panel of the Space Council of Russian Academy of Science this instrument was introduced by Roscosmos as one of the two Russian contributions to TGO. The set of TGO instruments was discussed and later approved by the European Space Agency and Russian Federal Space Agency, Roscosmos, in 2012; the final ExoMars cooperation agreement was signed in March 2013. The TGO payload includes three other instruments: the Nadir and Occultation for Mars Discovery (NOMAD), the Fine Resolution Neutron Detector (FREND), and the Colour and Stereo Surface Imaging System (CASSIS, a high-resolution color stereo camera).

ACS is a set of three spectrometers (-NIR, -MIR, and -TIRVIM, see below and Figs. 1, 2) intended to observe Mars atmosphere in solar occultations, nadir and limb geometry. It was built by Space Research Institute (IKI) in Moscow (Russia) within a very constrained timeframe (only three years separate the approval of the mission and the delivery of the proto-flight model, PFM). ACS design leverages on previous developments thus providing high technology readiness levels at the onset of the project: two of the three channels were initially conceived and built for the unsuccessful Phobos-Grunt project (Korablev et al. 2012, 2013), while one instrument flew onboard the International Space Station from 2009 to 2012 (Korablev et al. 2011). Some components/subsystems were contributed by LATMOS (CNRS) in France. This paper is intended to give a comprehensive overview of the scientific objectives of the instrument as they have been implemented: the concept of the instrument is described, with details on the optical scheme retained for each channel. A preliminary set of instrument testing was conducted on the ground and verified during the cruise, whose principal outcomes are discussed in the following section. The expected performances, updated with the latest information collected to date during the flight, are presented and compared to our current knowledge of the various species targeted. The observations planned during the Science Phase of the TGO mission are then discussed.

ACS-NIR follows the lineage of the SPICAM-IR instrument operating in orbit around Mars since 2004 (Korablev et al. 2006), a copy of this instrument having been later associated to SPICAV onboard the Venus Express mission. The SPICAM-IR instrument family concept relies on a simple and light-weight pencil-beam AOTF spectrometer (800 grams total mass) covering the spectral range of 1 to 1.7 μm with a spectral resolution of \({\sim}3.5~\mbox{cm}^{-1}\) with a resolving power of ∼2,000. This small instrument has continuously delivered high-quality data for the last 14 years to help us characterize the Martian climatic processes and aeronomy phenomena (Montmessin et al. 2017). ACS-NIR with its ten-fold better spectral resolution will significantly enhance the fidelity of atmospheric measurements.

In the previous ExoMars cooperation, TGO was planned to carry a solar occultation Fourier-transform spectrometer MATMOS (Wennberg et al. 2011) as a core instrument for sensitive trace gases measurements with \(\lambda/\Delta \lambda \approx 72,000\) in the characteristic C–H range. NOMAD (Vandaele et al. this issue) covers the most important 3-μm range with spectral resolution of ∼20,000, but the accessible spectral intervals are narrow. Acquisition of a wider wavelength domain at once provides a strategic advantage by maximizing the number of gaseous species simultaneously mapped. A way to achieve high spectral resolution while pushing off the boundaries of the spectral range covered is an echelle cross-dispersion concept. Employing this principle ACS-MIR is intended to recover some of MATMOS capabilities. ACS-MIR has no direct prototype. Some solutions regarding its optics were verified in TIMM-2 for Phobos-Grunt (Korablev et al. 2013), but the instrument as a whole is completely new. It is a solar occultation only cross-dispersion spectrometer that covers the 2.2–4 μm range with a spectral resolving power of 50,000 and a signal-to-noise ratio (SNR) of >5000 per pixel per 1s-acquisition.

ACS-TIRVIM is a Fourier-spectrometer built around a 2-inch double-pendulum interferometer with cryogenically-cooled HgCdTe detector, allowing operation in nadir and in solar occultation. The primary goal of TIRVIM is the long-term monitoring of atmospheric temperature profiles and aerosol state in nadir as demonstrated by MGS/TES (Smith 2004). On TGO TIRVIM fills the niche of the limb radiometer MCS (Schofield et al. 2011). The instrument covers the spectral range from 1.7 to 17 μm and capitalizes on previously developed Fourier-spectrometers for Mars 96, Mars Express and Phobos-Grunt missions (Moroz et al. 1990; Formisano et al. 1997 2005; Korablev et al. 2012). The TIRVIM abbreviation honors Prof Vassilii Ivanovich Moroz, the IR astronomer and the leader of planetary school in IKI during 1968–2004, who introduced the Fourier-transform spectrometers and pursued their development in this institution.

2 Science Objectives

The ACS scientific objectives reflect the overall TGO mission philosophy and address the specific investigations defined in Zurek et al. (2011). These scientific objectives have driven the ACS development through the flow down of measurement requirements to their implementation in the instrument concept definition and later throughout its fabrication (see Table 1).

The scientific objectives of ACS can be broadly separated into three main categories: (1) first and foremost, the instrument is intended to provide “Breakthrough” science by contributing to the establishment of the most precise detection or upper limit values for a list of trace gases that could be potentially found in the Martian atmosphere, (2) ACS shall also contribute in a unique way to a so-called “Novel” science since it will be able to deliver a self-consistent dataset enabling the study of the quasi-complete atmospheric chemistry cycle controlled by the HO x radicals as well as the study of H2O and its isotope HDO in their gaseous phase, addressing here the crucial topic of the fate on geological timescales of water on Mars, then (3) comes the “Climatological” science focus of ACS with the continuous delivery of key climatic parameters to constrain the environmental background in which the species targeted by the “Breakthrough” and “Novel” science objectives are observed.

2.1 “Breakthrough” ACS Science

The TGO mission concept was in large part promoted by the three nearly simultaneous (in the first half of the 2000’s) pioneering works that reported for the first time the detection of methane in the Martian atmosphere (the FKM group: Formisano et al. 2004; Krasnopolsky et al. 2004; as well as Mumma et al. 2009; note that the latter observations were reported first in Mumma et al. 2004, but profound refinement of their inversion technique was implemented before the reference publication of 2009).

The discovery of methane revived hopes of Mars still being an active planet from a geological or biological perspective. However, the tenuous nature of the reported detections and the issues related to the observation methods made it clear that new measurements would have to be done, this time with an accuracy avoiding any confusion caused by instrumental artefacts. The TGO concept was born on this basis and also on acknowledging the fact that existing instrumental set ups could fulfill the requirements of ultra-high accuracy for a trace gas like methane. With ACS, these requirements have been overachieved, providing sensitivity levels about 100 times better than existing platforms orbiting Mars and around 10 times better than performances achieved on the ground by the Mars Science Laboratory rover (Webster et al. 2015). The latter set recently reported the observation of sporadic (day-to-week lifetime) methane plumes associated with 6 to 7 ppbv pulses of CH4. The same intriguing feature of transience was also reported by Mumma et al. (2009), suggesting a dominant seasonal signature in complete contradiction with theory. Indeed, even the most advanced photochemical models (Lefèvre and Forget 2009) predict a 300-year lifetime for CH4, and this short-scale variability defies our current understanding of the main mechanisms controlling chemistry and physics of the Martian atmosphere (see the “Novel” science subs-section thereafter).

While CH4 constitutes a central target for the “Breakthrough” science, ACS instrument will be used for the search and the quantification thereof of the abundance of a suite of companion trace gases: 13CH4, C2H2, C2H4, C2H6, CH2O, H2S, OCS, N2O, HCl, HCN. ACS was designed to improve detection capabilities over previous investigations by at least one and up to several orders of magnitude (Table 1). Many of these gases may be indicators of subsurface activity (Fig. 3).

HCl is known to be outgassed by volcanoes on Earth and thus would point to the existence of seepages. Detection of C2H6 above 1 ppbv would be indicative of active geochemical processes, as its production from biology and CH4 oxidation is expected to be several orders of magnitude smaller.

Both volcanism and biology produce H2S, but its presence would be indicative of an active surface or subsurface. N2O should have no significant abiotic source on Mars and thus its detection would rather point to a biogenic origin. Isotopologues are powerful probes of the origin and chemistry of trace gases. On Earth, the correlation between the ratio of CH4 over higher order alkanes and the isotopic composition of CH4 allows the discrimination between a biogenic and abiogenic source. ACS can detect as little as 25 pptv of \({}^{13}\mathrm{CH}_{4}\), equivalent to 2% precision on the \({}^{12}\mathrm{CH}_{4}/{}^{13}\mathrm{CH}_{4}\) for a 45 ppbv abundance, which can potentially put constraints to help establishing the origin of Martian methane.

ACS will allow identification and quantification of a large majority of the targetable species (listed previously) simultaneously. Such capability of observing most gases during the same acquisition is a critical feature, which enables the estimation of the oxidation rate and the lifetime of chemical species controlled by both homogeneous and heterogeneous processes. Regions of active release, if present, will be localized using the observed concentration patterns that will be further refined by the application of the three-dimensional (3-D) models developed in our team (Forget et al. 1999; Lefèvre et al. 2004; Hartogh et al. 2005). Depending on the gases observed, or through ratios with isotopologues, fundamental information on the nature of the source (biogenic vs. abiotic) will be deduced.

2.2 “Novel” ACS Science

HDO and H2O Cycles

On Mars, the mean D/H ratio in water vapor is enriched by a factor of \(5\pm 2\) compared to the terrestrial ratio (SMOW). This strongly suggests that water escaped from the planet over ages, leading to an enrichment of the heavier isotope. Quantifying the amount of escaped water requires refinement of the present D/H ratio and the differential escapes of D and H. By measuring simultaneously the H2O and HDO columns, ACS will establish a reference value for the present Martian D/H ratio. Over the course of the mission, ACS shall provide a globally and seasonally averaged unbiased value at a precision level better than 1%. The difference in mass, vertical distribution, and chemistry determines the differential escape of D and H. ACS will simultaneously measure the H2O and HDO vertical profiles from the surface up to 60 km. These measurements become increasingly powerful when coupled with the measurements of D and H performed by the MAVEN IUVS instrument at higher altitudes (see Clarke et al. 2017).

By measuring jointly HDO and H2O ACS will uniquely constrain the physics of the HDO cycle. Isotopic fractionation at condensation induces a strong distillation process depleting water vapor in deuterium (Fouchet and Lellouch 2000; Montmessin et al. 2005; Villanueva et al. 2015). The ACS observations of the HDO cycle over a full Martian year will validate our current understanding of the driving processes and potentially identify new ones. Such an understanding is a prerequisite to determine whether the perennial caps exhibit a different D/H ratio from the atmosphere. With the secular variations of the obliquity, isotopic fractionation at condensation may have archived the Martian climate history via D/H stratification in the polar caps. An in situ analysis of the isotopic composition of the polar caps is a must, yet such measurements are unlikely within the next decades. ACS can partially satisfy this kind of investigation by observing the deuterated content of the air masses flowing off the northern summer cap during the sublimation season, thereby opening the path for future measurements.

Oxidation State of the Martian Atmosphere

On this topic, “Novel” science would emerge from a quantitative understanding of the chemistry that oxidizes trace and main gases in the Martian atmosphere. Such quantitative understanding of the Martian atmospheric chemistry requires knowledge of how the abundances of trace gases vary in space and time, and how they correlate with relevant environmental parameters including dust, water ice and temperature (the “Climatological” science part of ACS). Previous satellite experiments have demonstrated the importance of global mapping at all seasons to pinpoint the sources, sinks, and processes controlling the distribution of water vapor, dust (Smith 2004) or O3 (Perrier et al. 2006).

Similarly, ACS will acquire 2-D (Lat, Lon) maps reconstructed from profiling the key species needed to quantify the oxidizing capacity of Mars atmosphere (CO, H2O, HO2, NO2) and the OH production rate. This information is required for characterizing the lifetime of trace species released in the atmosphere from the surface at different locations and seasons. The vertical profile of these trace gases will be established from 10 km up to 60 km at a vertical resolution of half a scale height (∼5 km).

Such understanding is a required step to determine the lifetime of trace gases and hence to understand their distribution. Oxidation of trace gases is believed to result from gas-phase chemical cycles catalyzed by hydrogen radicals. However, some relevant species have never been measured (Fig. 3). Heterogeneous electrochemical processes triggered by clouds or dust storms could also be important in regulating the amount of oxidants (Delory et al. 2006; Atreya et al. 2006). The simultaneous tracking of multiple tracers by ACS is intended to provide the needed information to help quantify the oxidation rate of trace gases on Mars, both by homogeneous and heterogeneous processes. In doing so, ACS will test our quantitative understanding of the gas-phase chemistry: hydrogen radicals (HO x : H, OH, HO2) are produced in the Martian atmosphere by the photolysis of H2O and then initiate catalytic cycles that recycle CO2 from its photolysis product CO. The concurrent mapping of CO and H2O will be a key measurement to determine the global oxidation rate of CO by OH. ACS will also provide a renewed characterization of the HO x abundance and variability. Detection of HO2 will give a direct access to a member of the HO x family (Fig. 3).

Concurrent measurement of HO2 and its source molecule H2O will be a major step forward to validate, improve, and understand quantitatively the processes responsible for the oxidation of trace gases in the Mars atmosphere. New information on the production of HOx will also be provided by the measurement of OH airglow, reported by Clancy et al. (2013). ACS will also observe O3 through the O2 (\(\mathrm{a}^{1} \Delta _{{g}}\)) dayglow, which are very sensitive to the local abundance of HO x . As on Earth, N and Cl compounds might also produce oxidants and play an important role in Mars photochemistry. With upper limits on NO2 and HCl improved by two orders of magnitude (in solar occultation), ACS will provide observations needed to quantify the role of the N and Cl species in the chemical equilibrium of the Martian atmosphere.

ACS will also be used to test the hypothesis of electrochemical activity and heterogeneous chemistry. Model simulations (performed by the ACS science team members) have shown that current observations of CH4 imply the existence of an unknown sink that is >300 times more efficient than the loss predicted by conventional chemistry (Lefèvre and Forget 2009). Delory et al. (2006), Farrell et al. (2006) proposed that CH4 could be destroyed by electrochemical processes triggered by the strong electric fields within dust storms. If true, these mechanisms should produce detectable increases in HO2 (>200 ppbv) and CO (>15,000 ppmv) from the electrochemical dissociation of H2O and CO2, respectively (Fig. 3, and Delory et al. 2006). Through its ability to observe the spatial distribution of CH4, HO2, CO, and aerosol dust simultaneously, ACS will provide a definitive answer on electrochemistry in dust storms as a cause for the apparently reduced lifetime of CH4 on Mars. Heterogeneous reactions on ice cloud particles have also been proposed to explain discrepancies between O3 measurements and model calculations (Lefèvre et al. 2008). Concurrent observations of HO2, O2 (a\(^{1} \Delta _{{g}}\)), and water ice by ACS will help us test this kind of hypothesis.

In addition, ACS will put us in the position of testing the CH4 gas-phase loss mechanisms. Independent of possible heterogeneous loss processes, CH4 is in theory oxidized by reactions with OH and O(1D). ACS observations of H2O, HO2, and the OH emission will be used to constrain the OH chemistry, whereas the O2 (a\(^{1} \Delta _{{g}}\)) airglow will constrain the O(1D) abundance. ACS will also have the ability to detect the main intermediate product of CH4 oxidation, CH2O. Simultaneous detection of CH4 and CH2O will provide new information for a quantitative understanding of what is thought to be the conventional loss mechanism of CH4. ACS will also determine the role of Cl in the chemistry of CH4. As in the Earth’s stratosphere, Cl could contribute up to 30% of the loss of Martian CH4. By performing the most sensitive search for HCl to date, ACS will provide the required information to evaluate how much CH4 can be destroyed by Cl in the atmosphere of Mars.

2.3 “Climatological” ACS Science

The nadir mapping capability of ACS NIR and TIRVIM channels will provide a global view of the spatial and temporal variability of trace gases, with sensitivity all the way down to the surface level, even under conditions of high dust loading. Concurrent mapping and vertical profiling of standard climatic variables (dust, clouds, temperature) will relate the trace species to their environmental context, providing a continued long-term monitoring of the present climatic conditions.

In addition, the unique characteristics of the TGO orbit will allow a detailed sampling of the diurnal cycle of the main climatic properties of the Martian atmosphere. As designed, the TGO orbit during the Science Phase will produce a complete daily cycle every two months, yielding a representative atmospheric state every hour of the day. No other spacecraft in the past was able to perform this kind of survey and TGO will thus open a new era of investigations, constraining Martian climate variability from diurnal through seasonal up to interannual timescales. This kind of information has long remained the unique feature of landed missions. With TGO and ACS, a detailed study of atmospheric wave amplitude and propagation thanks to temperature profiling will be carried out in an unprecedented way. Diurnal variations of the surface temperature will also place the most detailed constraints to date for retrieving the thermal inertia properties of the surface and may actually reveal departures from simple surface representations indicative of a more complex behavior of the thermal wave propagation inside the Martian regolith.

Correlating trace species variability with environmental variations (temperature measurements) is important as it controls gas-phase reaction rates and hence the lifetime of trace species. Knowledge of the water-ice and dust particles distribution is also essential to test the hypothesis of heterogeneous reactions on ice clouds, electrochemical processes in dust storms, or the presence of airborne CH4 clathrate particles. The correlation of the spatial distribution and temporal variation of trace gases with the environmental parameters is known to be critical for a comprehensive understanding of the dominant climatic mechanisms.

ACS will map the water vapor, the dust and water ice column densities for a full Martian year. Together with the previous surveys by MGS/TES, Odyssey/THEMIS, MEX/SPICAM, and MRO/CRISM, ACS will add to the long-term perspective necessary to determine if there are any inter-annual climate trends and further help to identifying the driving mechanisms. In particular, ACS-NIR will extend the over 15 Martian years of 1.38 μm water band monitoring initiated by Viking/MAWD, and also pursued by SPICAM-IR. Ultimately, such multi-annual surveys are crucial to test the models that are used to simulate the ancient climates under different orbital and solar forcing conditions.

In solar occultation, ACS will measure routinely the vertical temperature profile from near-surface up to 160 km. Solar occultation profiles will also yield the dust and water ice number density and particle size distribution. These environmental observations will allow estimation of the available surface area for heterogeneous reactions, sedimentation rates, and feedback mechanisms between the dust and water cycles (scavenging and super-saturation). With its nadir mapping capability, ACS will provide a global view of the spatial distribution of temperature dust and water ice cloud opacities. These measurements are a prerequisite for correlating aerosols and condensates with observed variations in the trace gas maps, and hence for identifying the role of heterogeneous chemistry and electrochemistry in the atmosphere.

3 ACS Design

3.1 ACS Architecture

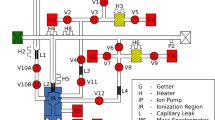

ACS includes three separate spectrometers. On the TGO spacecraft the instrument occupies the slot at the upper deck (Fig. 2). ACS has several optical openings allowing observations in nadir (\(\overrightarrow{-Y},\ \overrightarrow{-X}\) spacecraft coordinates, Fig. 2). The accuracy of spacecraft attitude control is ±1 mrad. The main opening of NIR is pointed to the nadir direction. The scanner mirror rotates within full \(360^{\circ}\) with minimal step \(0.1^{\circ}\), allowing to point in nadir, to the internal blackbody, and to the open space, which is necessary for absolute calibration of TIRVIM. TIRVIM is also equipped with a separate solar port.

The ACS block diagram is shown in Fig. 4, and its concept design—in Fig. 5. The instrument consists of four blocks bolted together and sharing the mechanical and thermal interfaces to the spacecraft. Roughly two thirds of its mass allocation of 33.5 kg is dedicated to larger channels, MIR and TIRVIM. The remaining mass is shared between the smaller NIR channel, the main electronics (Block of Electronics, BE), and the mechanical structure, thermal insulation, fixation brackets, etc. The BE is the only electrical interface of the ACS with TGO in terms of power, commands and data. The science channels can be operated together or standalone, or in any combination. The BE, MIR and NIR channels have two fully redundant sets of electronics. Either set of electronics in a science channel can be used with either set in the BE. The redundant set of the TIRVIM electronics could not be accommodated because of limited mass allocation. The ACS-BE turns on the scientific channels powering redundant 24-V lines. These internal power lines are conditioned and isolated from the spacecraft 28-V power line.

General measurement and interface parameters of ACS are summarized in Table 2.

Following the TGO requirements, the ACS suite regulates its thermal characteristics, minimizing the thermal flux to the spacecraft. Low-conductive titanium brackets are used for the mechanical fixation at the TGO honeycomb deck. The whole instrument is covered by MLI thermal blanket manufactured and tailored by NIIKAM (Russia). The MLI has a good conductivity, and can resist temperature loads during TGO aerobreaking. The thermal control is provided by several radiators placed at the upper plane of TIRVIM and MIR channels (+X axis of the spacecraft, see Fig. 1), and by means of several independent operational and survival thermal control systems. The radiators are covered by EKOM-1 enamel by Kompozit (Russia), and are solar-blind.

During the cruise and aerobraking phases the BE is OFF, and the temperature in the scientific channels is maintained at acceptable level by dedicated survival heaters subsystems (Fig. 4). These systems include thermosensors and heaters and are powered via dedicated power line (20–40 V) directly from the spacecraft, bypassing the BE.

TIRVIM is thermally insulated from other ACS constructions by means of plastic brackets and MLI patches. Some parts of TIRVIM could not be covered by MLI, and in order to diminish the thermal emission they were gold-coated by EKOMET (Russia). One of the two TIRVIM radiators drains the heat from the Stirling cooler, and the other regulates the overall instrument’s temperature. For maintaining a stable thermal environment it is planned that TIRVIM will be permanently ON when in TGO science orbit around Mars. It will predominantly perform nadir measurements, and will occasionally measure while the spacecraft is in solar occultation attitude.

3.2 NIR Channel

Concept

The ACS NIR channel employs the same optical layout as the SPICAV/SOIR (Solar Occultation Infrared) instrument on the ESA Venus Express mission, that is a combination of an echelle spectrometer and an acousto-optic tunable filter (AOTF) for the selection of diffraction orders. In space research this scheme was proposed and prototyped for the measurements of the terrestrial atmosphere (Korablev et al. 2002) and first implemented in space for Venus Express (Nevejans et al. 2006). NOMAD on TGO (Vandaele et al., this issue) employs the same principle and includes two similar SOIR-type spectrometers. The echelle-AOTF combination allows one to reach high spectral resolution in a compact and robust design. Several diffraction orders can be sequentially acquired during one measurement and they can be located anywhere within the entire spectral range thanks to the AOTF tuning versatility. Within the NIR range, atmospheric spectra are generally featureless, dominated by dust particle continuum properties, yet a number of spectral intervals can be used to cover interesting species. The main disadvantage of this design is the narrowness of the selected spectral intervals. In addition, sidelobes of the sinc function representative of the AOTF spectral bandpass imply that adjacent diffraction orders superimpose on top of each other. Also, the echelle grating efficiency quickly decreases away from the blaze angle (center of the detector) and, combined with a similar effect of the AOTF bandpass curve, induces a significant reduction of signal near the edges of the detector.

The closest analogue of NIR is the RUSALKA instrument (Russian acronym for Manual Spectral Analyzer of the Atmosphere Constituents), flown on the International Space Station (ISS) in 2009–2012 (Korablev et al. 2011). RUSALKA covered the spectral range of 0.7–1.65 μm with a resolving power of \(\lambda/\Delta \lambda \approx 20{,}000\), and demonstrated its capability to measure terrestrial CO2 and CH4 lines in a nadir viewing. Still, cosmonauts operated RUSALKA in the habitable compartment of the ISS, and the instrument was built according to requirements far less stringent than those imposed for a deep space mission such as TGO. ACS NIR is an adaptation of the RUSALKA design with several modifications aimed to improve the sensitivity and the optical quality of the instrument.

ACS NIR can perform nadir and occultation observations using two optical ports. A part of the nadir aperture of the instrument (Ø20 mm) is blocked by a periscope mirror, forming the solar port.

Optical Scheme

The optical scheme of the instrument consists of two main parts (see Fig. 6). The entry part, illuminating the slit of the echelle spectrometer includes the foreoptics, the telescope, and the AOTF with a number of auxiliary elements such as polarizers, diaphragms, etc. The entrance lens doublet has a focal length of 120 mm. A red filter cancels out all wavelengths shorter than 0.7 μm.

(a) A simplified optical scheme of the NIR channel. 1—solar periscope; 2—blocking filter; 3—entry telescope; 4, 8—folding mirrors; 5, 7—polarizers; 6—AOTF crystal; 9—slit; 10—collimating mirror; 11—diffraction grating; 12—detector array. (b) Qualification model of ACS-NIR with open cover, showing the main elements of the optical scheme

The AOTF is an optical filter based on the principle of acousto-optic diffraction in an anisotropic medium. The central wavelength of the filter spectral response function (SRF) is determined by the frequency of the ultrasonic wave in a birefringent crystal excited by an acoustic transducer. A non-collinear TeO2 AOTF is employed (Chang 1974). The acoustic wave modifies the refractive index, and diffraction at the resulting distributed structure separates the incident ray into two diffracted beams and a zero-order beam. The acousto-optic interaction length is 27 mm. The diffracted and non-diffracted rays are polarized athwart, permitting the use of polarizers to suppress the unwanted zero order. Besides, the non-diffracted light is separated angularly from the main throughput.

In contrast to previous AOTF-echelle based designs, this AOTF is placed in a converging beam. Therefore, the AOTF unit is a part of the foreoptics: it includes the polarizers and some folding mirrors (Figs. 6a, 7a). The FOV of the instrument is determined by the slit dimensions. The entrance optics, including the AOTF crystal preserves the image of the observed scene with a good quality over the full spectral range. This allows the use of NIR as a hyperspectral imager both with good spectral and spatial resolution. Undesired stray light in the entry part of the optical scheme is suppressed inside a long baffle that also holds the foreoptics elements.

The beam filtered in by the AOTF passes through the slit into the echelle-spectrometer. The slit has a size of \(4~\mbox{mm}\times 40~\upmu \mbox{m}\), forming a FOV of approximately \(2^{\circ}\times 0.02^{\circ}\) (\(35\times0.35\) mrad). The slit is inclined at \(5.5^{\circ}\) around the optical axis to compensate for the tilt of the slit image on the detector. The echelle-spectrometer employs a Littrow auto-collimation scheme, with a single off-axis parabolic mirror. The separation of the incident and the dispersed light is made in the plane perpendicular to the dispersion (along the slit height). A custom-size echelle grating from Spectra Physics Corp., Richardson Grating Laboratories (USA) on a Zerodur® substrate has a blaze angle of \(70^{\circ}\) (R3), 24.35 grooves/mm, and a useful area of \(46\times 102~\mbox{mm}^{2}\). The parabolic collimator mirror is fabricated by diamond turning from aluminum alloy (it has a focal length of 200 mm, \(10^{\circ}\) off-axis, size \(58\times53~\mbox{mm}^{2}\)). Its surface is additionally polished and coated with copper (Fig. 7b).

Compared with the heritage design of RUSALKA, NIR features a higher slit in combination with a 2D array detector (instead of a linear detector on RUSALKA), which captures the dispersed light along the full dimension of the slit. We adapted for space the infrared camera module XSW-640 from Xenics (Belgium) based on a thermo-electrically cooled (Peltier element) InGaAs array of \(640\times512\) pixels (Fig. 7c). This detector features a pixel size of \(20\times 20~\upmu \mbox{m}^{2}\), and a spectral range defined by the InGaAs sensitivity domain between 0.4 and 1.7 μm. The slit is imaged onto the detector with a ratio of 1:1, so only a part of the detector’s height (4 mm or ∼200 out of 512 pixel lines) is illuminated.

The main specification of the RUSALKA-SOIR design is that the AOTF spectral response function (SRF) width must be aligned with the free spectral range of the echelle spectrometer. Expressed in wavenumbers, the free spectral range is independent to wavelength:

where \(1/a\) is the number of grooves per cm, and \(\theta \) is the blaze angle (in autocollimation). If one ignores the dispersion of the TeO2, the width of the SRF is approximately constant in wavenumbers as well. By design, the half-width of the AOTF SRF is 70 cm−1.

The spectral range of the instrument (0.73–1.6 μm) corresponds to the echelle diffraction orders from 48 through 105. The spectral resolution is limited by the slit width and aberrations of the off-axis parabolic collimator. Following the sampling theorem (2 pixels per resolution element) the resolving power of an aberration-free spectrometer reaches \(R \approx 27{,}500\). The resolving power is variable over the detector and also depends on the diffraction order, but remains always ≥20,000 (see Sect. 4.1 below).

Electronics and Software

The NIR electronics consists of a power board with DC/DC converters and power switch, a processor module board, the XSW-640 detector module and the AOTF control electronics. These three modules of ACS NIR instrument are functionally independent devices and combined only with power lines and digital communication interfaces. Power board and processor module board are fully redundant. Thermal regulation systems are physically and logically separated from the electronics itself. Survival heaters are powered via fully independent line and they are always ON when the rest of the electronics is OFF.

The NIR control electronics is built around the TCM-BF537 processor module. Parallel Port Interface (PPI) of the processor module is used to input video data from the detector. Switchable line serial ports UART0 and UART1 are used to control the detector and AOM, as well as for communication with ACS BE. Serial Clock frequency is 129.17 MHz, supporting 8 Mb/s interface speed with BE and 115.2 kb/s with AOTF and the detector.

An AOTF module includes a microprocessor control system, a digitally controlled frequency synthesizer and a RF power amplifier. It is powered throughout the session, but the RF power to the crystal is sent only by the external command from the NIR control electronics. The same command also sets the frequency and the power of the RF signal. The frequency is set within a range of 64–156 MHz with a 50 kHz step. A limit of 100 ms for the duration of a single turn ON is used to protect crystal from overheating.

The detector module is working in the Integrate Then Read (ITR) mode, exposure starts with an external signal. A built-in Peltier cooling system of the detector can operate in the temperature stabilization mode and the temperature can be set with an accuracy of 3 K.

Operations

Each NIR observation session starts with a dedicated telecommand. A 64-byte command contains all the necessary parameters, including timing (overall time of observation, pauses, exposition time etc.), AOTF and detector settings, and also frame processing customization.

The instrument can be programmed to register sequentially up to ten diffraction orders (10 different AOTF tunings, i.e. acoustic frequencies and therefore 10 relatively small portions of the whole 0.73–1.6 μm range).

Depending on the telecommand, the NIR electronics commands the AOTF module to set the required frequency and triggers a detector exposure. After the integration time a single frame is read out within 9 ms (the ITR mode). At each frequency the instrument always performs two integrations, one with the AOTF ON and another with the AOTF OFF to allow dark subtraction subsequently. Either both frames are transmitted or only their difference.

The exposure time can be tuned from 0.45 ms to 100 ms depending on the observation regime. Furthermore, an on-board image averaging up to 96 single frames can be programmed in flight. The full frames are accumulated and averaged onboard by the NIR electronics for each frequency. In this case the control electronics continues to measure pairs of frames, stacking them in the internal memory. The resulting frame is scaled to fit each pixel value into 16 bits and then can be cut into up to five bands of programmable position and height (5 different areas on the detector). Each band contains a 640-pixel spectrum, corresponding to a certain portion of the slit height. Further co-adding along the height of each band into a line is also possible to reduce the data downlink volume.

Measurements for all given frequencies continue in a loop with a programmed duty factor, which will be used to regulate the data rate during nadir measurements.

3.3 MIR Channel

Concept

The MIR channel is a cross-dispersion spectrometer working in the 2.3–4.2 μm spectral range and acquiring simultaneously up to 0.3 μm per measurement. The echelle orders are dispersed along the \(x\)-axis and separated along the \(y\)-axis of the focal plane by a secondary dispersion element, making full use of the 2-D detector array. This concept is used in astronomy and has been employed in planetary missions with VIRTIS-H (Visible and InfraRed Thermal Imaging Spectrometer with High resolution) instrument flown on Rosetta and Venus Express (Coradini et al. 2007). VIRTIS-H acquires the spectral range of 2–5 μm instantaneously using an echelle grating and a prism. With a number of diffraction orders of ∼10, the resolving power of VIRTIS-H is \(\lambda / \Delta \lambda \approx 2000\). Targeting much higher resolving power, ACS-MIR features an echelle-spectrometer with a higher dispersion, and a steerable secondary dispersion element (reflecting grating). Working at high diffraction orders the instrument captures from 10 to 30 adjacent diffraction orders at once, covering approximately 15% of the spectral range in a single integration. Steering the secondary disperser allows one to switch from one group of diffraction orders to another, alternating between desired positions during one measurement sequence.

By analogy with MATMOS, several photometric channels for the wavelengths from 200 to 900 nm were studied for inclusion in MIR (Korablev et al. 2014). Their implementation would have supported aerosols characterization, and allow for measurements of UV-absorbing species. However, this unit did not fit into the initial allocated mass budget of ACS. Instead, aerosol studies will be carried out by combining the measurements made by all ACS channels (and potentially with NOMAD UV-visible spectra).

The Optical Scheme

The optical scheme of MIR may be separated into three main parts, the entry optics, the echelle spectrometer, and the secondary disperser (see Fig. 8). All the refractive elements are made in ZnSe and CaF2, transparent in the visible. Reflective elements are fabricated of aluminum alloy by diamond turning.

(a) A simplified optical scheme of the MIR channel. Foreoptics: 1, 3, 5—folding mirrors; 2—blocking filter; 4—entry telescope. Spectrometer: 6—slit; 7—primary collimator mirror, 8—secondary collimator mirror, 9—echelle diffraction grating, 10—folding convex mirror; 11—collimator of the secondary grating; 12—steerable secondary grating. Detector and the proximity optics: 13–14 detector’s focusing lenses; 15—cold filter; 16—detector array. (b) Proto-flight model of ACS-MIR with open cover, showing the main elements of the optical scheme

Radiation from the sun, passing through the Martian atmosphere, is directed inside the instrument by a periscope, which is imposed by mechanical constraints. A longpass entry filter is made of AR-coated Si 5-mm slab. The telescope forms the image of the solar disk on the slit (\(400~\upmu \mbox{m} \times 30~\upmu \mbox{m}\)). The FOV of \(0.3 \times 4.1~\mbox{mrad}\) is determined by the slit dimensions.

Similar to the ACS-NIR the echelle-spectrometer of MIR employs the autocollimation Littrow scheme. Two conditions are needed to achieve a high spectral resolution: firstly, the echelle grating must be large enough and have a high linear dispersion. The diffraction-limited resolving power is given by

where \(D\) is the collimator diameter and \(\theta \) is the blaze angle. For the worst case of 4.3 μm and \(\tan \theta = 2\) the ACS requirement of \(R \geq 50{,}000\) implies \(D \geq 54~\mbox{mm}\) that stays within allocations. The linear dispersion determines a slit-limited resolving power

where \(f_{ \mathit{col} }\) is the collimator focal length, and \(\delta _{\mathit{sl}}\) is the slit width. IR arrays with a pitch of less than 15 μm are not available, and to satisfy minimal sampling the slit should be \(2\times 15~\upmu \mbox{m}\) wide. Then the requirement of \(R \geq 50{,}000\) results in \(f_{ \mathit{col} } \geq 500~\mbox{mm}\). This value is the principal design driver: it determines the size of the grating and the dimensions of the MIR channel in general. The large focal length in a reasonable volume is achieved using a two-mirror collimator designed and fabricated by NIIKI (Sosnovy Bor, Russia; see Fig. 9a). Both mirrors are aspherical. The aperture of the collimator is chosen as a compromise between the desired etendue of the instrument and the suitable size of the grating given \(f_{ \mathit{col} } \approx 550~\mbox{mm}\).

We use a large custom-made echelle grating from AMOS (Liège, Belgium) with a ruled area of \(107 \times 240~\mbox{mm}\). The grating is blazed at \(63.43^{\circ}\) (R2), and has 3.03 grooves per mm (untypically low number for most grating providers). The grating is ruled on an aluminum substrate using diamond turning. Following Eq. (1) the free spectral range for one diffraction order is \(\mbox{FSR} \approx 16~\mbox{cm}^{-1}\) (or 17.7 nm at 3.3 μm). The full spectral range is covered with 107 diffraction orders, from 142 to 258.

The quality of the imaging system is close to the diffraction limit: the spot diagram yields a root mean square (RMS) of 6.5 μm in the center of the diffraction orders with a typical degradation toward the edges. Therefore, the resolving power of the spectrometer is aberration and slit-limited. With a 30-μm slit a resolving power of \(\lambda/\Delta \lambda \geq 50{,}000\) at 3.3 μm is achieved. The optical design of the MIR channel, folded in 3-D, is sensitive to the thermal regime and the mechanical strains. Although verified during the integration and the alignment procedures, the resolving power will have to be confirmed during the science phase of the mission after the thermal and mechanical state of the instrument will be fully settled. Despite a number of Sun observations completed in flight (see Sect. 4), it is not yet possible to characterize completely the spectral resolution. This characterization is planned after completion of the first solar occultation sequence at Mars. In Fig. 9b we present the LSF for the MIR echelle-spectrometer simulated by ray tracing.

Two secondary cross-dispersion diffraction gratings from Richardson Grating Laboratories, USA (plain, custom size, 361 and 180 grooves per mm) are mounted back-to-back on a stepper motor axis. The design of the grating positioner designed and fabricated by Astron Electronics (Orel, Russia) capitalizes on MSASI/Bepi Colombo scanner development (Yoshikawa et al. 2010). Though the two-face grating assembly is much heavier than the MSASI scanning mirror, the mechanism moves with a characteristic time of ∼0.1 s. Changing the position of the secondary grating in calibrated angular steps of \({\sim}1.8^{\circ}\), from 7 to 17 echelle orders can be made during the same acquisition, the final number being wavelength dependent (see Table 3). As a result, for each position of the secondary grating (see Fig. 10) the detector area is covered with a number of stripes, each corresponding to a single echelle diffraction order (see below Sect. 4.2). To switch between the two gratings, the positioner supports fast \(180^{\circ}\) overturn.

The detector is a space-grade version of the standard Scorpio MW K508 Sofradir (France) product, with optimized spectral range. Adaptations with respect to this standard detector are: (i) the replacement of the cold filter (bandpass 3.7–4.8 μm) by a custom filter; (ii) customized AR coating of the entry window; and (iii) adaptation of the cryocooler K508 RICOR (Israel) for operation in space. This detector includes a \(640 \times 512\) MWIR retina made of MCT (Mercury Cadmium Telluride, HgCdTe) hybridized onto a silicon ROIC (read-out integrated circuit) by indium bumps. The pixel area is \(15\times 15~\upmu \mbox{m}^{2}\).

In order to decrease the thermal background, a number of reflecting diaphragms are located in critical areas near the detector, around the slit, and throughout the instrument, so as beyond its useful area the detector images mostly the reflection from the internal cold baffle.

Electronics

The MIR electronics can be separated into five functional modules: power board, control electronics, rotational unit, Scorpio detector, Stirling cryocooler and its own driving system. As stated previously, survival heaters are powered independently.

Similarly with NIR, the MIR control electronics is built around the TCM-BF537 processor module. For fast handling of the Scorpio detector frames it includes a Complex Programmable Logic Device (CPLD) XC2C256. The main function of the CPLD is to synchronize the Scorpio detector, the ADC video processor interface and the PPI. In addition, the CPLD provides a UART interface line switch. CPLD is controlled by register from processor module via the serial interface, running at a speed of 10 Mbit/s. As in NIR, the UART ports of the processor are used to control communication with ACS BE (8 Mb/s interface speed) and with the rotational unit (129.17 MHz interface speed).

Stirling cryocooler motor is controlled by the processor via a dedicated driver. Cooling power is set by a Pulse Width Modulation (PWM) signal (40 kHz). The maximum value of the speed control—about 190 pulses/s, the minimum acceptable value—50 pulses/s. The detector has two in-built temperature sensors. Its temperature is PID-stabilized by the processor software with an accuracy of ≤0.1 K.

The Sofradir detector has four video outputs, fed to four parallel ADCs. Data is transmitted to the PPI interface with an overall speed of \(4\times 8~\mbox{MHz} = 32~\mbox{MHz}\). The dynamic range of the detector is 13 bits. The ADC has a 16 bits resolution, but only 13 most significant are used. After stacking of frames each pixel is described by a 16-bits word, and they are transmitted to the ground.

The Rotational unit is commanded by its own FPGA-based electronics, which enables closed-loop PID regulator using the signal from Hall’s sensors and drives the VSS 33.200.0,6-HV vacuum-grade Phytron (USA) motor.

MIR’s power board, control electronics and the rotational unit electronics are fully redundant (including the main ADCs). Cross-redundancy is possible for the Stirling cryocooler driver, and with the rotational unit electronics; either set can be used with either set of the control electronics.

Measurement Sequence

Each MIR observation session starts with a dedicated telecommand from the TGO spacecraft. A 64-byte command contains all necessary timing parameters (overall time of observation, pauses, exposure time, etc.), the grating positioner commands (defining the spectral range), detector settings, and frame processing customization. After the detector precooling time of ∼8 min, and rotational unit self-calibration procedure of ∼40 s, the MIR channel is ready to record spectra.

Rotational unit receives a command to turn one of the two secondary gratings into the required position, and returns confirmation upon readiness. This triggers the measurement series. In order to increase the effective measurement time, thus improving the signal to noise ratio, the instrument is designed to minimize gaps between frames measurements. The detector is run in an Integrate While Read regime (IWR). While measuring a new frame, the previous one is being simultaneously transmitted to the MIR control electronics, which stacks all frames measured for the current secondary grating position. The readout of the full frame (\(640 \times 512\) pixels) using four detector’s outputs requires 10.25 ms. The exposure time can be set in the range 0.125–32 ms with a 0.125 ms accuracy. The real exposures when observing the Sun are within 3–6 ms, depending on the spectral range. The video signal of each pixel is digitized with resolution of 13 bits. The MIR processor can measure and sum up to 200 consecutive single frames. The result is accumulated in 32-bit words.

If an occultation session includes measurements with several secondary grating positions, the Rotational unit mechanism allows the spectral range to be shifted with a characteristic time of ∼0.1 s for adjacent positions, ∼0.12 s for positions separated by a step, etc. Up to five positions can be commanded and be measured during an acquisition, though we plan to use only one or two positions during a real occultation. The switch between the two gratings is only possible before a series of measurements, so during a single occultation only one grating can be used.

A single data frame will be accumulated as a result of stacking a number of shorter exposures. Accumulated frames are transmitted to ACS BE. The full frame requires ∼0.9 s to transfer. Each transmitted frame is accompanied by two housekeeping frames with board time, temperatures and setup parameters. If more than one grating position is measured the MIR control electronics transmits data from the previous position to BE while measuring the new position. In order to reduce the downlink volume and/or to increase the number of measured frames per second, lossless compression, and windowing of the frames can be used. Up to 5 bands of programmable position, height and length can be selected to isolate the most interesting spectra. Given the complexity of the diffraction pattern, no line co-adding is foreseen on-board, although the embedded software provides such possibility. Normally full or partial detector frames will be transmitted to the ground with lossless compression.

3.4 TIRVIM Channel

Concept

TIRVIM is a 2-inch double pendulum Fourier-transform spectrometer (FTS) operating in the 1.7–17 μm spectral range. The primary scientific goal of TIRVIM relates to the Climatological goal of ACS through the monitoring of key climatic parameters, like atmospheric temperature and aerosol abundance from nadir viewing. The instrument leverages from previous developments of IKI in Fourier-spectrometers (Moroz et al. 1990; Formisano et al. 1997; Korablev et al. 2009). One may note its resemblance to 2.5-inch PFS/Mars Express (Formisano et al. 2005), however the mass allocation for TIRVIM on TGO was 12 kg against 31.4 kg of PFS, and so simple copy of the dual channel PFS design was excluded.

By concept a FTS measures an interferogram that is then converted into a spectrum, which covers the spectral range limited by the detector and the transparency of the optics. In TIRVIM the whole spectral range is covered by one double-pendulum interferometer with KBr beamsplitter (KBr is transparent from 0.25 to 25 μm). The principal improvements in comparison to PFS are: (i) the possibility to observe in solar occultations, (ii) one-side maximal optical path difference (MOPD) increased to as much as 5 cm, allowing to reach apodized spectral resolution of 0.13 cm−1 (compared to \({\approx}1.3~\mbox{cm}^{-1}\) for PFS), and (iii) a PV-MCT detector cooled by a Stirling machine, thus increasing the sensitivity of the instrument by a factor of 10–20. The detector is sensitive from 1.7 to 17 μm and is employed both for nadir and during solar occultation observations.

While observing Mars in nadir TIRVIM operates as a spectro-radiometer, providing absolute radiometric calibration by periodically measuring the temperature of the internal Black-Body and of the space. While observing during a solar occultation TIRVIM operates as a spectrometer, self-calibrating the relative transmission of the atmosphere by observing the Sun outside the atmosphere.

Initially the instrument design included a short-wave optimization in the 3-μm range for the mapping of putative hydrocarbons in nadir (Korablev et al. 2014). This feature had to be de-scoped because of lack of mass (its implementation involved an additional mechanism, and significant electronics). For the same reason the redundant pyroelectric detector for solar occultation had to be cancelled as well. Eventually, main science requirement was put on nadir observations.

Optical Scheme

A simplified optical scheme of TIRVIM is presented in Fig. 11. It consists of the following main parts: a sun periscope, a scanner, a blackbody simulator, the interferometer with a reference channel, and the detector with its proximity optics.

A simplified optical scheme of the TIRVIM channel. Foreoptics: 1—scanning flat mirror (rotates around TGO Z axis); 2—calibration blackbody; 3—fixed flat mirror; 4—inlet window. Solar entry: 5—blocking filter and field stop (Ge); 6, 7—folding mirrors. Interferometer: 8—compensator (KBr); 9—beam-splitter (KBr); 10, 11—corner-cube hollow retro-reflectors. Detector assembly: 12—fixed flat mirror; 13—aspheric plano-convex ZnSe lens, 14—MCT detectors inlet window (Ge), 15—MCT detector sensitive area. Red lines trace solar channel rays, blue lines trace Mars channel rays. The reference channel is not shown on this scheme

The scanning device of TIRVIM (see Fig. 12) allows it to point its optical axis to nadir, to the limb, and also to the internal blackbody and to the open space to obtain absolute radiometric calibration. It is rigorously not a scanner but a one-dimensional positioner. The main element is the flat mirror (\(85\times 60~\mbox{mm}^{2}\)), which can be rotated within \(360^{\circ}\) with a step of \(0.1^{\circ}\). It can be pointed to three principal directions: nadir, open space, and the black body, but also to any intermediate position, including the direction to the Sun.

The second optical port of the instrument is the solar periscope. Its direction is fixed and co-aligned with solar ports of NIR and MIR channels, i.e. pointed to the direction of \(67^{\circ}\) with \(\overrightarrow{-Y}\) spacecraft axis (see Fig. 2). The solar periscope includes a blocking filter and two elements folding the solar radiation into the interferometer. The aperture of the solar port is ∼10 mm wide which constitutes ∼4% of the useful interferometer aperture.

The Black Body was fabricated in IKI, its emitting surface is painted with space-qualified EKOM-2 enamel by Kompozit (Russia). Its temperature is regulated by either the survival heaters, or the operational thermal control systems of TIRVIM.

The interferometer is the core unit of TIRVIM (see Fig. 13). Most of principal design solutions are inherited from AOST/Phobos-Grunt, but the TIRVIM interferometer is larger (2″ against 1″). The length of the double-pendulum arm (from the rotation center to the center of the corner-cubes) is 130 mm. The interferometer pendulum full swing results in MOPD of 5 cm, so the spectral resolution, if defined as 1/MOPD is 0.2 cm−1. The spectral resolution defined at FWHM of the instrument function is better (0.603/MOPD), \({\approx}0.13~\mbox{cm}^{-1}\) (see Table 2). For nadir observations the OPD is reduced to 0.8–1 cm (the spectral resolution is of 1.3–1 cm−1 or ≈0.8 at FWHM). The double pendulum is mounted pending on a Flexural Pivot by Riverhawk Company (USA) and propelled by a momentum motor built in IKI. The hollow retro-reflectors are from PLX Inc. (USA), modified in IKI so they can withstand mechanical loads during the launch. Their useful diameter is Ø50.8 mm. The beamsplitter and the compensator are made of KBr, Ø88 mm and are 12 mm thick.

The reference channel allows for a precise synchronization of the interferogram sampling, and the wavelength link of the retrieved spectrum. The reference signal is generated from the interference of radiation of a monomode laser diode within the main interferometer of TIRVIM. The fraction of the aperture used for the reference channel is small. A distributed-feedback laser diode for the wavelength of 760 nm was supplied by Eagleyard Photonics (Germany). The channel includes also a Si photodiode detector and a number of optical elements necessary to introduce the laser beam into the interferometer. In all the operation modes the digitalization of the two-side interferogram is performed at each one out of two zero crossings of the reference signal. Therefore the sampling theorem is satisfied for all wavelengths longer than 1.52 μm. The germanium inlet window blocks all the radiation below 1.7 μm, removing aliasing.

Radiation is focused onto the detector sensitive element with an aspheric plano-convex ZnSe lens. The photovoltaic MCT detector unit is custom-built in Russia. It is sensitive in the range of 1.7–17 μm; a germanium inlet window determines its short-wavelength cut-off. The diameter of the sensitive element is 1.5 mm, and the specific detectivity peaking at 14.5 μm is D∗ of \(1\times 10^{1 1}~\mbox{cm}\,\mbox{Hz}^{1/2}\mbox{W}^{-1}\). The sensitive element is mounted in a Dewar and cooled down to 65 K with a rotary Stirling cooler from RICOR (Israel), similar to that of MIR channel. The beamsplitter, AR-coated Ge windows, objective aspheric ZnSe lens and aluminum mirrors with gold coating are supplied by Spectral Systems LLC (USA).

The FOV is determined by the diameter of the sensitive element of the detector size, and the focal length of the detector’s proximity ZnSe lens. When observing in nadir the full FOV diameter of \(2^{\circ}\) is used. From the TGO orbit (∼400 km) the track width on the surface of Mars is 14 km. When pointed to the Sun the instrument’s FOV is limited by the diameter of the solar disk diameter (\({\sim}0.35^{\circ}\)).

Electronics

The electronics of the TIRVIM channel is organized around the Central processor. It interacts with BE through the LVDS interface, interprets its telecommands, acquires interferograms and housekeeping data, processes them, packs and sends them back to BE. It controls, directly or via two auxiliary processors, all TIRVIM subsystems, the thermal regime, the scanner, and other mechanisms.

The scanner operation is controlled using its encoder or backup Hall sensors. There are two multi-usable arresters; one is immobilizing the double pendulum, and the other the entire interferometer unit (Fig. 13) mounted on vibration dumpers. The operation thermal stabilization system controls, by means of the central processor, the thermal regime of all critical optical parts. It includes six collocated heater-sensor pairs placed at the blackbody, at the fixed mirror, at the “front wall”, in two locations within the interferometer unit, and near the body-fixed optical elements. The maximum dissipated power is 16 W.

The Interferometer processor provides closed-loop PID stabilization of the interferometer OPD alternation speed, controls temperature and current of the diode laser, and other interferometer functions. The temperature and the current of the diode laser are set by telecommand in the ranges of \(14^{\circ}\)–\(35\ {}^{\circ}\mbox{C}\) and 43–75 mA respectively. The embedded software allows for searching of optimal PID coefficients values in flight. The position of the interferometer pendulum arms is registered by a Hall sensor. It triggers at zero OPD, and the interferometer processor moves the pendulum with respect to this point. In fact, the Hall triggers not exactly at \(\mbox{OPD}=0\) but the shift, in units of the reference channel period, is known.

The Stirling processor provides PID-stabilization of the cryogenic detector temperature. It gets information about temperature in the cryogenic zone from a dedicated thermo-sensor. The nominal temperature in the cold zone is 68 K.

The reference channel detector (Si photodiode) registers the interference of the monochromatic laser light. If the OPD alternates evenly, the signal is a sine function, allowing one to close the loop of interferometer mirrors motion. The reference signal is transferred to the square wave, which serves to govern the pendulum motor and triggers the conversion of the main ADC.

The signal from the cooled MCT detector after a preamplifier goes to variable-gain amplifier (eight gain levels \(1, 2, 4, \ldots, 128\) set by telecommand) and bandpass shaper, which gets the signal ready for the AD-conversion. The main ADC provides the interferogram sampling in 18 bits, 16 of them being effectively used. The central processor governs the amplification coefficient and the frequency bandpass, gets data from the ADC and processes them.

The Stirling is powered directly from 24-V regulated voltage provided by the ACS-BE. A dedicated power PCB creates all other needed voltages (−9, \(+3.3\), \(+5\), \(+6.5\), \(+12\) V).

The survival heaters are powered when the main TIRVIM electronics is OFF. This system includes three pairs of heaters-sensors (optical plate, interferometer and Black Body) and is powered directly from the spacecraft. The threshold values are set at \(+30\ {}^{\circ}\mbox{C}\), except for the Black Body (\(+60\ {}^{\circ}\mbox{C}\).) Higher temperature of the Black Body allows warming the rear side of the scanner mirror to avoid its contamination during spacecraft outgassing. The consumption is 8 W regardless of the voltage value (20–40 V).

Measurement Modes

The Fourier spectrometer subsystems allow for numerous settings and parameters, however few optimal combinations were selected and verified during calibrations. This parameter set is implemented in the embedded software of TIRVIM.

The interferometer pendulum can swing within its full range, resulting in a \(\mbox{MOPD}=5~\mbox{cm}\). Alternatively, a reduced swing with \(\mbox{MOPD}=0.8\mbox{--}1~\mbox{cm}\) can be employed for measuring weaker signals. The full swing is devoted to Sun observations, and the reduced one is devoted to nadir observations. Also, the interferometer mirrors can move with a slower or faster motion. The slow mode results in a reference channel frequency of ∼10 kHz, and the fast one in ∼80 kHz. With the change of the interferometer speed, the bandpass of the main tract is modified accordingly. The full swing is always implemented with the fast mode, and the reduced swing can use both speeds, resulting in three main interferometer modes.

To remove possible parasite signals (due to a variety of vibrations) the speed setting can be slightly modified: the slow mode may become 10% quicker, and the fast mode may become 10% slower. The 10% variation is enough to move the parasite signals along the wavenumber axis so they don’t distort the critical portions of the spectrum. So, in all, six interferometer modes (aliased as #0…#5) are possible.

TIRVIM interferograms are always two-sided. The interferograms recorded in the small-swing mode are much shorter, and the central processor can perform their on-board centering and stacking, increasing the SNR and decreasing the data downlink. The interferograms are averaged separately for forward and retrograde motion of the interferometer mirrors. It is possible to average \(2+2\) interferograms (2 “forward” and 2 “retrograde”), \(4+4\) or \(8+8\).

The central processor adds to every interferogram a header containing its parameters, onboard time, housekeeping and other data.

The TIRVIM parameters and observing modes are summarized in Table 4.

3.5 Main Electronics

The main electronics (BE) serves as a single electrical interface of the ACS to the spacecraft. The spacecraft harness including power, commands, data lines and auxiliary interfaces is wired to the BE. The main electronics is fully redundant (see Fig. 14).

The BE consists of two PCBs, located in a separate unit. The Processor PCB (visible in Fig. 14b) includes two redundant sets of FPGA, 32 GB of flash-memory, auxiliary controller, interface controller, etc. The Power PCB carries two redundant sets of filters, DC/DC converters, and power switches. As one may note in Fig. 14b, the electronics occupies a smaller volume than the one available in the BE box. In fact, the volume allocation had to be decided before the final definition of the electronics, and some margins had to be added.

The power interface includes the main power switch, power conditioning, and specific switches for each scientific channel. All power switches and relays are controlled by High Voltage High Power Command (HV-HPC) spacecraft lines. A Bi-level Switch Monitor (BSM) interface is used for the TGO system to acquire a signal from the instrument switch loads. The final power distribution to the channels is done using regulated voltage lines from BE. Redundant sets of MIR and NIR internal electronics can be used with either set of the BE electronics. The choice of nominal or redundant set of MIR or NIR electronics to be turned ON is defined by a telecommand. Upon request, BE is generating HV-HPC for the dedicated channel. BE is able control any science channel in any combination; in particular both MIR and NIR can be operated at the same time, regardless of which set of electronics controls them.

The survival heaters in the scientific channels are powered by a dedicated TGO power line, bypassing the ACS BE. There is no survival heater in the BE; its thermal regime in cruise is maintained by thermal conduction from surrounding MIR and NIR channels (see Fig. 5).

The command and data interfaces to TGO are MIL1553 and SpaceWire, respectively.

After powered on, the BE receives 64-byte telecommands (TC) from TGO. MIR and NIR TCs include a small header interpreted by the BE to generate appropriate HV-HPC for the science channel and overall time of observation. TIRVIM will be permanently ON during the nominal science operations, and it periodically receives TC blocks, programming a mid-term operation sequence. The BE itself nominally doesn’t require any TC during routine science operation.

The data/command interfaces between the BE and the scientific channels are LVDS with a maximum speed of 8 Mbit/s. The data from the science channels can be acquired simultaneously. They are stored in blocks with certain system headers, specific for each channel, and are transferred via SpaceWire to the TGO (21 Mbit/s). The BE internal memory will be used only in case of the temporary unavailability of the TGO memory. The mass memory was also included to validate the design solution for the ExoMars 2020 Surface platform where a similar main electronics will be serving several instruments on the landing platform (Rodionov et al. 2017).

4 Ground and Flight Calibration Results

4.1 Calibration Plan

Laboratory Calibrations

As mentioned above, the development time of the ACS instrumentation was short. The experiment was decided in 2012, and the team received Roscosmos funding in January 2013. The proto-flight model (PFM) of ACS has been assembled in March 2015, and on the 4th of June 2015 the PFM was sent to Thales Alenia Space facility in Cannes for an immediate integration with TGO. The short time slot in April–May 2015 was occupied mostly with the PFM test campaign, which involved moving the instrument from IKI to distant facilities. Some characterizations were done before the final integration of the relevant channels, but the calibrations of the completed instrument were therefore performed in a very constrained time in between the qualification tests. Because of that the three scientific channels were calibrated separately, and not all planned calibrations could be completed. Nevertheless, the ACS channels were thoroughly verified on the ground, and all three were pointed to the Sun.

Laboratory measurements with NIR included: standalone calibrations of the AOTF, measurements of different line spectrum sources (lasers, Pen-Ray® low pressure emission lamps), observations of the Sun, simulation of the nadir observation, and also the detector’s flat field and field of view measurements. Absolute radiometric calibrations were not completed and they will be done in flight using coordinated measurements with SPICAM-IR/MEX and CRISM/MRO.

Laboratory measurements with MIR included measurements of a laser emission line, observations of the Sun, detector’s flat field and dark current, and field of view measurements. Only the direction of the FOV was controlled. The latter procedure involved complicated cross-alignment against the TGO axes and the NOMAD FOV.

Laboratory measurements with TIRVIM were mostly dedicated to radiometric calibrations in the thermo-vacuum chamber. Also observations of the Sun, measurements of a laser emission line, and measurements of transmission of a gas cell filled with nitrogen-methane mixture were exercised. Finally, the angular diameter of the field of view was characterized.

In-Flight Calibrations

After successful launch of TGO on 14 March 2016 and en route to Mars, ACS was turned ON several times during Near-Earth Commissioning (NEC) in April 2016, and Mid-Cruise Check-up (MCC, June 2016) campaigns. The instrument’s main electronics was verified; functional checks, and several observations pointing to the Sun with all three ACS channels were carried out. Scanning over the solar disk was performed to characterize mutual alignment of different FOVs. Simultaneous observation by ACS channels in solar occultations are fully supported, corresponding pointing will be used on all available orbits. Unfortunately, the angle between the FOV of ACS MIR and NOMAD SO measured in-flight is 22 arc min, more than angular size of the Sun thus making joint observations by these channels impossible.

After the Mars orbit insertion on 19 October 2016 the Mars Capture Orbit (MCO) campaign of observations was carried out in November 2016. On the top of the checks done during the MCC, this campaign allowed for first Mars observations from near the pericenter of two highly elliptical orbits (\(380\times 66{,}000~\mbox{km}\)). The first orbit involved nadir pointing, which viewed the near-equatorial region from 4 to 21 hours of local time. On the second one, inertial pointing of Mars was performed. The second MCO-2 campaign is planned for March 2017. The intermediate TGO orbit does not permit solar occultation before May 2017. Their observation during the aerobraking phase is not confirmed.

For a number of reasons (changing temperature environment and associated mechanical strain, availability of the out-of-atmosphere solar flux, etc.) the focus of the ACS calibration analysis is on the in-flight calibrations. Some specific calibrations, in turn can be only performed in the laboratory. The in-flight calibration of ACS is in progress and will be ultimately completed during the commissioning on the science orbit. In the following sections we present some selected results of this on-going activity.

4.2 NIR Channel

AOTF Characterization

The AOTF used for the selection of spectral orders in the echelle-AOTF spectrometer is a critical component in terms of the laboratory characterization, because this kind of calibration in flight proved difficult (Vandaele et al. 2013). The side lobes of the AOTF cause spectral leakage from the adjacent and more distant diffraction orders. To model the measured spectrum it might be necessary to sum the signal from up to seven diffraction orders (the main one and the three leaking orders on each side). The temperature dependence of the AOTF passband function complicates the problem even further. Even though the NIR temperature is stabilized at \({\sim}25\ {}^{\circ}\mbox{C}\), during the operation the AOTF crystal is warming up by dissipation of the RF power.

The laboratory calibrations included the determination of the AOTF dispersion curve and its temperature dependence, characterization of the AOTF passband function including distant side lobes in the entire spectral range, and verification of its homogeneity within the spatial extent covered by the AOTF (along the echelle-spectrometer slit).

To characterize the AOTF passband and to obtain its dispersion curve over a spectral range as wide as possible, we used argon and krypton low-pressure lamps. Some results are demonstrated in Fig. 15. The measured passband FWHM is 65 cm−1. The spectral homogeneity of the AOTF within its imaging range was verified at several wavelengths. The shift of the passband maximum within the FOV of NIR is always <0.1 MHz, or 0.1%. The shift is smaller for shorter wavelengths. Such a small modification of the passband is evidence of good homogeneity of the acoustic field within the crystal. For practical reasons it may be neglected. For comparison, the AOTF of SOIR/Venus Express revealed a 1% shift of ∼0.2 MHz for frequencies of 13–25 MHz which had to be taken into account (Mahieux et al. 2008).

The modification of the AOTF characteristics with temperature was calibrated in a climatic chamber in the temperature range of \(+5\ {}^{\circ}\mbox{C}\ldots +35\ {}^{\circ}\mbox{C}\) using argon Pen Ray® lamp as a source. Five different temperatures were recorded. This calibration was mostly intended to determine the shift of the passband function with temperature, but will also serve to verify the modification of the passband shape. With the temperature difference of 30 K the shift amounts to 15 cm−1 at \(\lambda=800~\mbox{nm}\), and 8 cm−1 at \(\lambda=1500~\mbox{nm}\). This is well within the passband FWHM, but has to be taken into account.

Imaging capabilities of NIR were also studied during adjustments and tests. For instance, a 1-mm illuminated pattern was imaged through the AOTF onto the spectrometer’s slit from 5 meters to form a 20-μm image. This image quality is conserved in the echelle-spectrometer up to the detector. The corresponding instantaneous spatial resolution for nadir observation is 80 meters on the surface and 300 meters on the limb for occultation. It must be noted that during occultation sessions NIR slit is oriented nearly parallel to the surface, which gives an opportunity to use the spatial resolution to constrain the local atmospheric variability.

Echelle-Spectrometer Characterization

One of the most regarded characteristics for an echelle spectrometer is spectral resolution, which is defined by the Point Spread Function (PSF) Full-Width at Half Maximum (FWHM). This characteristic was measured experimentally on a fully assembled NIR with only the grating not fixed. As mentioned above, the spectrometer is almost in a Littrow configuration, with a slight rotation of the grating to obtain the most effective coverage of diffraction orders over the spectral range. To study the resolving power over the detector we adjusted the grating to project a narrow line of the low-pressure Ar lamp onto multiple positions along the detector. The recorded PSF were analyzed and the resolving power for individual line on the detector was calculated (Fig. 16). For nadir mode we plan to average all lines inside the slit to increase the SNR, and to decrease the downlink. It would decrease the resolving power by 20% (in case of averaging of all lines).