Abstract

A principal goal of the Mars Science Laboratory (MSL) rover Curiosity is to identify and characterize past habitable environments on Mars. Determination of the mineralogical and chemical composition of Martian rocks and soils constrains their formation and alteration pathways, providing information on climate and habitability through time. The CheMin X-ray diffraction (XRD) and X-ray fluorescence (XRF) instrument on MSL will return accurate mineralogical identifications and quantitative phase abundances for scooped soil samples and drilled rock powders collected at Gale Crater during Curiosity’s 1-Mars-year nominal mission. The instrument has a Co X-ray source and a cooled charge-coupled device (CCD) detector arranged in transmission geometry with the sample. CheMin’s angular range of 5∘ to 50∘ 2θ with <0.35∘ 2θ resolution is sufficient to identify and quantify virtually all minerals. CheMin’s XRF requirement was descoped for technical and budgetary reasons. However, X-ray energy discrimination is still required to separate Co Kα from Co Kβ and Fe Kα photons. The X-ray energy-dispersive histograms (EDH) returned along with XRD for instrument evaluation should be useful in identifying elements Z>13 that are contained in the sample. The CheMin XRD is equipped with internal chemical and mineralogical standards and 27 reusable sample cells with either Mylar® or Kapton® windows to accommodate acidic-to-basic environmental conditions. The CheMin flight model (FM) instrument will be calibrated utilizing analyses of common samples against a demonstration-model (DM) instrument and CheMin-like laboratory instruments. The samples include phyllosilicate and sulfate minerals that are expected at Gale crater on the basis of remote sensing observations.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

1.1 The Mars Science Laboratory Mission

The overall science objective of the Mars Exploration Program for the Mars Science Laboratory (MSL) mission is “To explore and quantitatively assess a local region on the Mars surface as a potential habitat for life, past or present.” Specific science objectives are: (1), to assess the biological potential of at least one target environment identified prior to MSL or discovered by MSL; (2), to characterize the geology and geochemistry of the landed region at all appropriate spatial scales (i.e., ranging from micrometers to meters); (3), to investigate planetary processes of relevance to past habitability including the role of water; and (4), to characterize the broad spectrum of surface radiation, including galactic cosmic radiation, solar proton events, and secondary neutrons.

1.2 Science Goals of the CheMin Mineralogical Instrument

The CheMin (Chemistry and Mineralogy) instrument directly addresses the Mars Exploration Program objectives by seeking to identify and characterize past or present habitable environments as recorded in the chemical and mineralogical composition of sediments and rocks. CheMin will principally address science objective 2 above, but it will also support goals 1, 3 and 4. To meet these objectives, CheMin will utilize X-ray diffraction (XRD) to perform mineralogical analyses of rocks, sediments, dusts and soils to assess the involvement of water in their formation, deposition or alteration, and to search for potential mineral biosignatures, energy sources for life, or indicators of past habitable environments.

1.3 The Importance of Mineralogy to MSL Science Goals

Minerals are natural crystalline materials of uniform inter-atomic structure and limited ranges of chemical composition. The century-old technique of X-ray diffraction (the operating principle of CheMin) is exquisitely sensitive to that structure and secondarily sensitive to chemical composition. Specific minerals can form and persist only through limited ranges of temperature, pressure, and ambient chemical conditions (i.e., humidity, water activity, Eh, pH, etc.). A material of a given chemical composition (like a basalt) may be transformed to a wide range of mineral assemblages depending on the physical and chemical conditions that it experienced (Spear 1993). Thus, knowledge of the minerals present in a sample provides insight into the physical and chemical conditions under which it was formed or altered.

Tables 1 and 2 show the elemental composition (measured by Alpha Particle X-ray Spectroscopy (APXS); Gellert et al. 2006) and iron mineralogy (measured by Mössbauer spectroscopy; Morris et al. 2006) of basaltic rocks of the Watchtower class, investigated by the MER-A rover Spirit at Gusev Crater. These rocks have nearly identical chemical compositions (Table 1), but have wildly differing amounts of particular iron-bearing minerals reflective of changes of oxidation state (Table 2). The observed mineralogical changes are inferred to represent progressive alteration and oxidation, something that is not evident from compositional data alone. The Mössbauer instruments on the MER rovers are very sensitive to iron-containing minerals but indifferent to others. On MSL, the CheMin instrument will be able to identify iron-containing as well as iron-free minerals. With a knowledge of the full suite of minerals present, a more complete story can be made of alteration and the history of rock-water interactions on Mars.

1.4 Integration of CheMin with Other MSL Instruments

CheMin is one of ten instruments on the MSL rover. The other instrument housed with CheMin in the analytical laboratory within the rover’s body is SAM (“Sample Analysis at Mars”), a gas chromatography (GC)-mass spectrometry (MS)-tunable laser spectrometry (TLS) instrument. Integration of CheMin and SAM analyses of splits of the same samples will maximize the information obtained by combining specific mineralogy with results from gas chromatography, mass spectrometry, evolved gas analysis, and tunable laser spectrometry. In addition, complementary quantitative chemical composition for elements Na and heavier (via XRF-equivalent APXS analysis) will be collected on the raw or brushed surfaces of samples, including those spots drilled to collect powder for CheMin and SAM. These analyses will be supplemented by hand-lens resolution investigation of sample spots with MAHLI (Mars Hand Lens Imager, with up to 14 μm resolution) before and after brushing. Remote chemical analyses by the ChemCam instrument using laser induced breakdown spectroscopy (LIBS) will provide guidance to appropriate sampling spots as well as data on elements that will not be measured by either APXS or CheMin (e.g., H, C, N). All analyses will be supported by high-magnification Remote Micro-imager (RMI) images co-located with the ChemCam remote spot analyses, by mast-mounted camera surveys, and by engineering camera data. CheMin data, comprising XRD patterns suitable for quantitative analysis and elemental energy-dispersive histograms (EDH) suitable for identification of elements present in the sample 13<Z<42, are particularly synergistic with the APXS and ChemCam analyses and the SAM GC-MS-TLS data. The challenge in integration of these datasets will be in identifying and accommodating sample selection differences between instruments, which are:

-

(1)

CheMin will analyze only the <150 μm size fraction of drilled or scooped samples.

-

(2)

SAM can analyze splits of the same <150 μm material as CheMin, but it can also accommodate splits <1 mm.

-

(3)

APXS will analyze 1.7 cm diameter areas on rock or soil, either unmodified or brushed.

-

(4)

ChemCam will obtain rapid compositional data on spots up to ∼7 m distant and ∼200 to 400 μm in diameter, with the ability to raster across the sample surface, produce linescans, or to excavate several hundred micrometers into a sample.

Because each MSL instrument has a distinct analytical area, volume and dataset, meaningful integration of the whole MSL dataset will require an understanding of these sampling issues. Dust cover and surficial alteration that might not be penetrated by either ChemCam or APXS is likely to have minimal influence on the deeper drill samples that will be delivered to SAM and CheMin. Grain-size heterogeneity may result in differences between <1 mm splits passed to SAM and <150 μm splits analyzed by CheMin. Viewing a sample at such different scales can be a powerful method for improving understanding, but multiple types and scales of analysis can be confusing. In order to address the sampling issue, the MSL rover is equipped with an Observation Tray where splits of the sieved samples delivered to SAM and CheMin can be analyzed by APXS and MAHLI. This permits chemical analysis of both pre-drilled and drilled material, as well as allowing high-magnification imaging of the sample to examine grain properties (UV fluorescence, angularity, size range, color, and “hand lens” mineral identification). In addition, samples on the Observation Tray can be examined by day or by night (with either visible or UV illumination) to determine sample stability over a range of temperatures.

1.5 CheMin Instrument Overview

CheMin is part of the Analytical Laboratory of the MSL rover Curiosity, located inside the main body of the rover. CheMin will analyze powdered rock and soil samples delivered to it by the Sample Analysis/Sample Processing and Handling (SA/SPaH) and Collection and Handling for In-Situ Martian Rock Analysis (CHIMRA) systems. CheMin is capable of analyzing up to 27 pristine samples and as many as 74 samples with reuse of sample cells. The total number of analyses will be determined by “drive” vs. “analyze” decisions made by the MSL Science Operations Working Group (SOWG) as Curiosity progresses towards Gale Crater’s central mound. Each CheMin analysis can take up to 10 hours of analysis time over two or more Martian nights, although some samples may require only one night for analysis. CheMin measures the mineralogy of crushed or powdered rock samples and/or soil through X-ray diffraction. The geometry of CheMin is shown in Fig. 1.

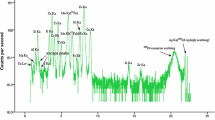

Geometry of the CheMin instrument. (Left) overall geometry of CheMin; (above right) XRD 2θ plot obtained by summing diffracted photons from the characteristic Kα line of the X-ray source (Co Kα is colored magenta in Fig. 1 (left); (below right) X-ray energy-dispersive histogram (EDH) obtained by summing all of the X-ray photons detected by the CCD (fluoresced photons from the sample shown schematically in green and red in Fig. 1 (left)

During an analysis, a collimated X-ray beam from an X-ray tube source is directed through powdered or crushed sample material. An X-ray sensitive CCD imager is positioned on the opposite side of the sample from the source and directly detects X-rays diffracted or fluoresced by the sample (Fig. 1, left). The CCD detector is operated in single-photon counting mode (the detector is read out sufficiently often that most pixels contain either no charge or charge derived from a single photon). When operated in this manner, the CCD can be used to measure the amount of charge generated by each photon (and hence its energy). Diffracted primary beam characteristic X-rays strike the detector and are identified by their energy (for CheMin, with a Co X-ray tube, Co Kα X-rays having an energy of 6.929 keV are selected), producing a two-dimensional image of Co Kα X-rays that constitutes the X-ray diffraction pattern. At incremental radii this pattern is summed circumferentially about the central nondiffracted beam to yield a one-dimensional plot of 2θ versus intensity comparable to conventional diffractometer data (Fig. 1, upper right).

From this diffraction pattern, one can (in theory) determine the minerals present in a sample and their relative abundances. Each mineral has a unique diffraction pattern, and the pattern of an unknown mineral or mineral mixture can be identified by comparison with standard patterns compiled for wide ranges of natural and synthetic materials. Two such compilations are from the International Centre for Diffraction Data (ICDD, Newtown Square, PA) and the Crystal Structure Database (Downs and Hall-Wallace 2003). Abundances of minerals can be retrieved by several methods that seek to model both diffraction peak positions and intensities. Among these methods are Rietveld refinement (Bish and Post 1993), the Reference Intensity Ratio (RIR) method (Chung 1974) and full-pattern fitting methods like FULLPAT (Chipera and Bish 2002). The last is particularly useful because it is well adapted for the processing of CheMin data products to quantify abundances of both crystalline and amorphous materials, a challenging task in remote XRD analysis. The CheMin team includes several clay mineralogists familiar with these and other methods for quantifying difficult phases such as poorly-crystalline clay minerals and X-ray amorphous materials. The diffraction data, including as-received and processed diffraction files, will be archived in NASA’s Planetary Data System for public access, where researchers around the world will be able to download, reprocess and reanalyze the data. The legacy of CheMin operations for MSL will be many years of improving mineral analysis as new researchers and new methods revisit the CheMin data archive.

Some of the X-rays that impinge on the sample are absorbed, and portions of their energies are re-emitted (i.e., fluoresced) as characteristic X-rays of elements in the sample (e.g. Ca Kα x-radiation). These fluoresced X-rays provide information about the elemental composition of the sample. These data are compiled into a histogram of the number of CCD-detected X-rays versus X-ray energy (Fig. 1, lower right). This energy-dispersive histogram (EDH) is used by to monitor CheMin’s performance (see Sect. 1.9) and to select the energy window for diffracted Co Kα photons from the CCD, minimizing background from fluoresced X-rays. Raw histograms of the intensities of fluoresced X-rays are used to evaluate CCD performance and to aid in mineral identification by observations of the presence or absence of elements expected to be in the mineral(s). However, because the sensitivity of the CCD detector changes as a function of time, temperature and radiation damage during the mission, these data cannot be accurately quantified.

1.6 The CheMin Instrument

1.6.1 The X-Ray Source

CheMin has a microfocus X-ray tube with a Co anode and a beam-defining final aperture placed at some distance from the tube, which together produce a collimated X-ray beam. The source produces continuum and characteristic X-radiation from a 50 μm diameter spot on the Co anode. The tube has a nominal operating voltage of 28 keV with a filament current of 1.5 A and cathode output of 100 μA. The photons emanate from the X-ray tube in a cone of radiation that exits the tube through a beryllium window. At a specific distance from the tube, the pinhole aperture intersects the beam, creating a nearly parallel, collimated ∼70 μm diameter beam of X-radiation directed at the center of the sample cell. After passing through the sample, the direct beam is stopped by a beam trap mounted on the edge of CCD detector.

The X-ray power supply is enclosed in a housing pressurized with a mixture of sulfur hexafluoride and nitrogen gas, mixed so that the condensation temperature of the gas is below the minimum expected temperature in the body of the rover (to ensure that the gas never liquefies).

1.6.2 The CheMin Sample Handling System

The CheMin sample handling system consists of a funnel, a sample wheel (which carries 27 reusable sample cells and 5 permanent reference standards), and a sample sump where material is dumped after analysis (Fig. 2). CheMin receives sieved and portioned drill powders and scoop samples from the SA/SPaH system (Jandura 2010) through the CHIMRA drill, scoop, and sorting assembly (Sunshine 2010). A maximum of 76 mm3 of sample material is delivered to the piezoelectrically vibrated funnel system that penetrates through the rover deck. When CheMin is not receiving samples, the CheMin inlet is protected by a cover. The material received through the funnel passes into a sample cell that consists of a 10 mm3 active cell volume and a ∼400 mm3 reservoir above the cell. Excess material, should it be delivered, will remain in the reservoir during analysis. The funnel contains a 1 mm mesh screen to keep larger grains from entering the CheMin sample handling system. Grains that cannot pass through the screen will remain there for the duration of the mission, although no material is expected because the sample is pre-sieved to <150 μm in the CHIMRA sorting chamber to prevent clogging of the CheMin funnel screen. Any grains smaller than 1.0 mm but larger than 150 μm will pass into the upper reservoir portion of the sample cell, where they will remain until the cell is inverted and they are dumped into the sump. For the lifetime of the mission, nominally one Mars year, CheMin is required to accept and analyze material delivered from SA/SPaH with no more than 5 % internal contamination between samples. Self-generated contamination may originate from material that has remained in the funnel from previously delivered samples (and delivered along with subsequent samples), or from material that has remained in previously used analysis cells (CheMin will be capable of reusing each cell two to three times to accommodate 74 or more analyses during an extended mission). Cells are emptied after an analysis by rotating the sample wheel 180∘ (to invert the cell) and vibrating the cell so that the sample material is emptied into a sump at the bottom of the instrument. If contamination is suspected either from the funnel or from a previously used cell, CheMin can reduce sample-to-sample contamination by dilution. Aliquots of sample material can either be dumped into the funnel and delivered directly to the sump through a shunt in the wheel without entering a sample cell (to entrain and remove funnel contamination), or a previously used sample cell can be filled, shaken and emptied to the sump prior to receiving a second aliquot of sample for analysis (to entrain and remove sample cell contamination). These processes will require coordination with SA/SPaH to deliver more than one aliquot of a given sample.

Schematic diagram of the CheMin sample wheel. Individual sample cells can hold as much as 400 mm3, but only ∼10 mm3 is required to fill the active analytical volume of a cell. Twenty-seven reusable cells are available for analysis of drilled or scooped samples sieved to <150 μm. Sample cells are filled at the top and dumped at the bottom. Cells in red hold standard materials that are accessible during the mission for calibration purposes

The collimated ∼70 μm diameter X-ray beam illuminates the center of a sample cell having 6 μm thick Mylar® or 10 μm Kapton® windows. The sample introduced into the funnel consists of ≤76 mm3 of powdered material with a grain size of <150 μm. Only about 10 mm3 of material is required to fill the active volume of the sample cell, which is a disc-shaped volume with an 8 mm diameter and 175 μm thickness. The remaining sample material occupies the reservoir above the cell (see Fig. 3). During filling, analysis and sample dumping, the sample cell is shaken by piezoelectric actuators (“piezos”). The modes in which the piezos will be driven are still under test and may vary from sample to sample, depending on sample-dependent characteristics such as grain cohesion (e.g., clay-rich samples versus samples that lack fine particles). In CheMin testbeds and prototype instruments, the frequency of the piezo-actuator is varied so that during a part of the cycle the sample holder is at resonance, at which time the sample exhibits bulk convective movement similar to a liquid, delivering sample grains in random orientation into the volume exposed to the beam. In the CheMin Flight Model (FM) and the equivalent Demonstration Model (DM) a nominal resonant frequency of 2150 Hz is maintained during analysis, and shaking amplitude is varied to adjust the intensity of grain motion.

During the moderate shaking that produces granular convection, it is possible that phase separation will occur as a result of size, density or shape differences between individual mineral grains. To mitigate this problem CheMin at intervals uses episodically larger shaking amplitudes (i.e., “chaos mode”) to re-homogenize the material in the sample chamber.

The CheMin sample cells are paired in dual-cell “tuning-fork” assemblies with a single horizontally driven piezoelectric actuator in each assembly (Fig. 3). Sixteen of the dual-cell assemblies are mounted around the circumference of the sample wheel (Figs. 2 and 4). Five of the cells will be devoted to carrying standards; the other 27 cells are available for sample analysis and can be reused by emptying samples into the sump after analysis. Cells are filled and analyzed at the top of the wheel. A cover assembly sits directly above the sample cell during analysis to keep material in the sample reservoir from being ejected during vibration. Inlets to the cells holding standards are sealed with HEPA filters to prevent the material from falling out as the wheel is moved, while allowing for pressure equalization within the cells.

Both Mylar®- and Kapton®-windowed cells are mounted on the wheel. The rationale for using two types of cell windows is based on our experience with CheMin prototype instruments. Mylar® windows exhibit a very flat diffraction background across the full range of 2θ. However MylarTM is less durable than Kapton® under severe vibration and is susceptible to destruction if highly acidic samples (e.g., copiapite; a hydrated iron sulfate) are encountered. What is known about mineralogy on Mars suggests that acidic conditions are not unlikely (e.g., determination of jarosite occurrences at both MER landing sites). Kapton® windows are more durable and are not susceptible to acid attack, but they have a small diffraction contribution at ∼6–7∘ 2θ that could interfere with the 001 diffraction peak from some clay minerals. For security and to assure that CheMin can handle a wide range of sample types on Mars, both Kapton® windows (in 13 cells) and Mylar® windows (in 14 cells) are used in the reusable cells. None of the remaining 5 cells, loaded with standards, have any concern related to clay-mineral diffraction so Kapton® is the norm for standard cells, but one of the standards (amphibole), useful for both XRD and EDH analysis, is loaded into a Mylar®-windowed cell to provide access to at least one standard with this window design throughout the duration of the mission.

Once data from an observation are sent to ground and accepted, the analyzed material is emptied from the cell and that cell is ready to be reused. CheMin does not have the capability to store previously analyzed samples for later re-analysis once the wheel has been moved to receive another sample or to analyze one of the standards.

1.6.3 The CCD Detector

CheMin uses a 600×1182 pixel E2V CCD-224 frame transfer imager operated with a 600×582 pixel data collection area (Fig. 5). Once the 600×582 pixel active area is exposed to X-ray photons for a brief period (5–30 seconds), it can be rapidly transferred into a 600×600 pixel shielded area (the “transfer frame”). This allows data collection to take place continuously without the use of an X-ray shutter or electronic beam blanking. The pixels in the active portion of the array are 40×40 micrometers square, and the active region of deep depleted silicon is 50 μm thick. The front surface passivation layer is thinned over a substantial fraction of the active pixel area. This imager is a modern version of the E2V CCD-22 that was specially built for an X-ray astronomy application (Kraft et al. 1994). The large size of the individual pixels (relative to those present in conventional CCD imagers) causes a greater percentage of X-ray photons to deposit their charge inside a single pixel rather than splitting the charge between pixels. The enhanced deep depletion zone results in improved charge collection efficiency for high energy X-rays. The thin passivation layer makes the CCD sensitive to relatively low-energy X-rays (down to Si and in some samples, down to Al). The frame transfer region of the CCD (the portion of the CCD in Fig. 5 that is covered by a metal bar) has much smaller pixels than the active region because they are only meant to hold the charge associated with an X-ray photon, not to absorb it. An individual pixel in the array can hold hundreds of thousands of electrons, many more than the few thousand electrons deposited by a single X-ray photon. The active portion of the CD has larger pixels because the charge cloud of electrons that is deposited from an absorbed photon can be tens of microns in size.

The CheMin CCD. The active 600×582 pixel region of the CCD is the exposed portion in the center. The frame transfer region of the CCD is the shielded portion to the right of the active area. The beam stop can be seen in the center of the upper edge of the active area (held with two screws). The CCD is cooled with an active cryocooler that is attached to the back of the CCD by a thermal strap. The CCD support/attachment hexapod structure (seen below the CCD assembly) supports but thermally isolates the CCD assembly from its attachment plate

In order to keep the CCD from being exposed to photons in the visible energy range (from X-ray induced optical fluorescence from the sample) during analysis, a 150 nm Al film supported on a 200 nm polyimide film is suspended on a frame placed in front of the detector. The detector itself is cooled by a cryocooler to approximately 48 ∘C below the temperature of the Rover Avionics Mounting Platform (RAMP) that is used as a heat sink by the cryocooler. The RAMP is expected to be between 0 ∘C and +26 ∘C during the mission, yielding CCD temperatures of −48 ∘C to −22 ∘C. By cooling, dark current in the CCD is reduced.

A number of interactions occur between the sample and the X-ray beam to produce photon fluxes detected by the CCD. The two interactions of importance to the CheMin experiment are elastic interactions in which primary beam photons are absorbed and re-emitted by sample atoms (i.e., diffraction events), and inelastic interactions in which sample atom inner shell electrons are ejected from the nucleus, resulting in the emission of a characteristic photon from the sample (i.e., fluorescence events). In X-ray diffraction, elastic interactions of primary beam photons with sample atoms constructively or destructively interfere, resulting in maxima in discrete angular directions (“Laue cones” or “Debye rings”) representative of the crystal structure of the sample. In fluorescence, sample-generated photons are emitted uniformly in all directions and the energies of individual photons can be used to identify the elements present in the sample.

1.7 Refinement of CheMin Instrument Performance

1.7.1 Analysis of Grain Motion in Vibrated Sample Cells

X-ray diffraction analysis consists of the measurement of the directions and intensities at which crystalline matter diffracts X-rays. Placing an individual crystal in fixed orientation in a monochromatic X-ray beam will at most lead to a single diffracted beam, and most likely no diffraction at all. To accurately identify a crystalline phase, it must be exposed to the X-ray beam in all orientations to record all possible diffracted beams within the angular range covered. Powder XRD achieves this condition by using powdered materials—or solid polycrystalline materials—to create a sample that offers all possible crystalline orientations within the analytical volume. In laboratory powder-XRD instruments, fine-grained samples (ideally <10 μm grainsize) offer a very large number of crystallites in random orientations in the analytical volume. Miniaturized XRD instruments have even more stringent grain-size constraints because their analytical volume is scaled down. In an instrument like CheMin, an ideal sample would have a submicron grain size, difficult to achieve by grinding. When coarser than ideal powders must be analyzed, a means of increasing crystalline orientation statistics is necessary. A common method used in laboratories is to spin the sample in a thin glass capillary. For CheMin, a new approach was developed based on granular convection of the sample in vibrated cells. The analytical volume represents a small fraction of the sample cell volume (∼1/6000) but the internal flow of material through granular convection ensures that the entire sample is analyzed in random orientation over time (Fig. 6). Granular convection is obtained by vibrating the sample holder to fluidize the powder. Gravity combined with the interaction of the powder with the oscillating cell walls leads to convective flow. In addition to allowing quality XRD to be obtained with large grain sizes (up to 150 μm), the vibrations facilitate sample insertion and removal. Conventional methods of XRD sample handling would have required CheMin to be fitted with a grinder, a cell filling mechanism and possibly a cell spinner, increasing mechanical complexity, cost and risk. The benefits of the convective cells in producing XRD data suitable for quantitative analysis have been demonstrated in a number of CheMin precursor and laboratory analog instruments.

Left: Schematic diagram of a vibrating sample holder for granular convection. Right: Cu Kα diffraction pattern of the 75–150 μm size fraction of a crushed quartz crystal sample in a laboratory instrument with convective sample holder. Upper: sample with vibration (ICDD database intensity reference values shown by red triangles); Lower: same sample without vibration

A convective sample holder must ensure an intense vibration in the cell, thousands of m s−2 (hundreds of g) being typically required to obtain reliable convection. This is achieved by using a balanced mechanical resonator similar to a tuning fork. A sample cell is integral to each arm of the tuning fork, and both cells are vibrated at the same time. The balanced design ensures minimal transmission of the vibration to the structure of the instrument; the energy is kept in the resonator. The vibration is induced by a piezoelectric actuator placed at the base of the tuning fork and driven at the resonance frequency of the assembly. The intensity of vibration is pulsed at about 1 Hz. A short period of intense shaking ensures that convection is initiated and a period of lower intensity maintains the motion while preventing the bed of powder from expanding and losing bulk density which would be detrimental to the XRD measurement.

Granular convection is a well-known phenomenon that finds few practical applications. It has been studied principally with reference to large beds of mm-sized particles, but little was known about the physics of granular convection in the micrometer range of the CheMin samples, or in the thin bed geometry of the CheMin sample cell. Granular flow in CheMin cells was modeled by Dr. C. Campbell (USC) using discrete particle computer simulations, and studied empirically by Particle Image Velocimetry (PIV). In PIV, contrast features (not necessarily individual grains—in fact the grains can be below the resolution of the observations) are identified and tracked from frame to frame in a sequence of captured video frames of particle motion. Vectors are drawn between the features to calculate granular flow velocities and bulk powder movement.

Both PIV and discrete particle computer simulations were carried out to better understand granular flow phenomena and predict the operation of the system at Mars surface conditions (lower gravity and lower pressure). The study of XRD data quality versus convection speed demonstrated that the velocity of convection has no real influence on quality of diffraction as long as the bed of powder is kept moving constantly. A pause in the motion will cause large grains to stay in a diffraction condition for an extended period of time, resulting in bright diffraction spots on the detector that anomalously increase the relative intensity of the corresponding XRD peaks. The main requirement for granular convection therefore, is that is must be robust.

Using PIV measurements, the velocity of granular flow was evaluated as a function of shaking conditions. It was found that above a specific vibration amplitude threshold, granular velocities are linear with amplitude for a given frequency (Fig. 7-left). The onset threshold for granular convection is reduced at higher frequencies (Fig. 7-right).

The granular flow model was used to evaluate the effect of Mars gravity. Simulations run under Earth (E) and Mars (M) gravity (Fig. 8) show that at slightly higher velocities, flow patterns at Mars gravity are equivalent to those at Earth gravity. This is at odds with what is known about conventional granular convection in large beds of particles, for which the vibration required for a given velocity scales linearly with gravity. This difference in behavior is due to the predominance of grain-wall interactions in the thin cells of the CheMin instrument, as opposed to the predominance of inertial effects in thick beds.

The effect of gravity was also studied experimentally by making PIV measurements of granular convection in a vibrated cell aboard a Piper Cherokee aircraft while performing a series of mini parabolic flights over the Pacific Ocean. Periods of 3–4 s at Mars gravity could be obtained. Slightly faster convection was observed under Mars gravity conditions. It was shown that only a small reduction of the vibration amplitude is required to maintain the same convection velocity from Earth to Mars gravity. For example a 30 μm peak-to-peak vibration at Earth gravity is equivalent to 25–28 μm at Mars gravity. Practically speaking, therefore, granular convection in Earth gravity is roughly equivalent to granular convection in Mars gravity.

The effect of the reduced atmospheric pressure on Mars was studied with the model and tested in a chamber at Mars pressure under dry conditions. No substantial effect could be associated with reduced pressure, although the transition from non-dry Earth conditions to low-pressure Mars conditions substantially slowed the convection. The transient state is due to water adsorbed on grains that increases the grain-grain cohesion when the pressure in reduced. Once the adsorbed water is removed, dry samples showed convection similar to that observed at ambient conditions.

The effect of electrostatic charging on granular flow under dry Mars conditions was also evaluated. A dedicated study was conducted by both modeling and experimental measurement of granular convection in a vibrated cell placed in a Mars atmospheric chamber. PIV measurements were made and charge accumulation on the windows measured. It was observed that granular flow initially creates a voltage on the windows by tribocharging, but this charge does not accumulate or persist. Most likely the charge is transported away by grain flow. PIV measurements showed no influence of this charge on granular convection. Based on this research, convective flow in vibrated sample cells on Mars should be similar to that observed on Earth.

Vibration is known to cause grain segregation when grains vary in size, density, shape or some other feature. Grain segregation in the CheMin vibrated cells is a concern because the analysis is performed in a very small volume in the middle of the cell. Preferential settling of a phase in any region of the cell would affect the measurement of mineral composition. Segregation in vibrated beds has been observed in particular when vibration amplitude is reduced to the point the convection no longer happens or happens very slowly, finer or denser particles are allowed to settle in lower regions of the cell. With higher vibration levels, the convective flow mixes the materials inside the cell at higher speed than segregation occurs, resulting in a cancellation of the effects of segregation in most cases. Segregation is still observed in the presence of convection in some extreme cases such as prepared mixtures of coarse grained materials with substantially different density (example: quartz + corundum). In order to limit this bias, the vibration profile includes a periodical shaking at very high amplitude for periods of a few seconds. This intense shaking is referred to as “Chaos mode” for the fast unstructured motion resulting in the cell, and has the effect of mixing and homogenizing the material. A case of apparent segregation in a beryl-quartz calibration sample data set from the flight instrument is presented in Sect. 4.2.1, thought to be due to the lack of chaos mode pulses during this particular measurement.

Another possible bias in the measurement of mineral composition is agglomeration of particles in the cell. This is observed at the edges of the cell in particular when the sample contains fines. The agglomerates are wedged between the polymer windows where they can least flex. These agglomerates grow over time as additional particles are jammed into them. As an example, crushed sandstone is likely to show a preferential agglomeration of the fine-grained cement matrix phases at the edge of the window, resulting in an apparent enrichment of the coarse sand particles (quartz) in the middle of the cell where the analysis is performed. The chaos mode also proves effective at limiting this agglomeration as long as the intense shaking pulses are applied frequently to break agglomerates in an early state of formation. If agglomerates are allowed to grow and compact over tens of minutes or hours, their compactness and resulting cohesion can make them difficult to break up and disperse with the chaos mode.

While segregation and agglomeration are of concern, methods have been found to mitigate or cancel them, and such methods have been validated by accurate quantitative analyses obtained with CheMin derived XRD instruments used at NASA Ames Research Center, NASA Johnson Space Center, Jet Propulsion Laboratory, Los Alamos National Laboratory, and Indiana University (see for example, Bish et al. 2008; Blake et al. 2009; Treiman et al. 2010; Achilles et al. 2011; Taylor et al. 2012). A good metric to evaluate the presence or absence of either segregation or agglomeration is to monitor the measured composition as a function of time during an analysis. Selective segregation or agglomeration progressively increases the proportion of one or more specific phases during an analysis. In such cases, more accurate compositional data are obtained at the beginning of the analysis, assuming the cell has not been shaken for an extended period between loading and start of the analysis.

1.7.2 Optimization of the CheMin Geometry for X-Ray Flux and 2θ Resolution

The first optimization of the CheMin X-ray geometry from an XRD performance standpoint was performed using a dedicated ray-tracing program called CheminRay that can simulate diffraction geometry based on the following components:

-

(1)

A microfocused X-ray tube with adjustable spot size. The spectral characteristics of this source include Kα 1, Kα 2 and Kβ lines with their specific peak width, shape and relative intensity, and bremsstrahlung radiation.

-

(2)

An elliptical (or circular ) pinhole with an adjustable radius and thickness or a slit collimator with adjustable size (x–y) and distance to the X-ray source.

-

(3)

A flat sample of a perfect randomly oriented powder in transmission with adjustable angle to the X-ray beam, distance to the collimator, thickness, compactness and composition (mineral or mixture of minerals). The interaction with the powder is calculated as a “reflectivity” (probability of diffraction) for each photon, as it depends on its energy and direction. When a photon is diffracted its path through the sample is modeled and an absorption probability is calculated. Any photon may be diffracted, transmitted or absorbed.

-

(4)

A CCD of adjustable dimensions, pixel size, angular orientation to the direct beam, and x, y position relative to the direct beam. An energy range can be selected taking into account the energy resolution capability of the CCD (allowing simulation of Kα data, for example).

All parameters can be set manually to simulate a specific geometry. Up to 3 parameters can be set as variables, scanned within a grid to study a range of configurations, and any set of parameters can be used as variables for optimization with a genetic algorithm approach. The data products of CheminRay include a 2-D image representing the distribution of diffracted photons on the CCD and a 1-D diffractogram resulting from the circumferential integration of intensity around the diffraction rings. An automatic line fitting tool imbedded in the application produces XRD peak intensities, peak shapes and peak positions which can be used for the optimization.

CheminRay is a virtual prototyping and testing tool. The advantage of ray tracing over other modeling approaches is that numerous parameters can be taken into account, yielding a numerical simulation with high fidelity to the real-world experiment. A drawback however, is that such simulations are time-consuming because as with real experiments the signal to noise ratio depends on the number of photons used in the model, hence the amount of computation time.

The starting point of the geometry optimization was the CheMin III instrument (a precursor to CheMin IV, the principal testbed of the CheMin flight instrument) available in the laboratory. The accuracy of CheminRay was first verified by comparing experimental data from CheMin III to simulated data of the CheMin III geometry as shown in Fig. 9. The CheMin III collimator design was then optimized using both a genetic algorithm and a grid scanning approach. Genetic algorithms apply techniques inspired by evolutionary biology to optimize a result by evolution from generation to generation of a population of potential solutions. In each generation, the fitness of the whole population is evaluated and individuals are selected and combined with a fitness-dependent probability to form a next generation of parameters. The formulation of “fitness factors” and “evolutionary rules” is critical in achieving an actual parameter optimization. The objective of the optimization of CheMin was to achieve the best resolution with the highest flux intensity. A number of fitness factor definitions were tested based on a mathematical combination of resolution and intensity, but all definitions proved to be too restrictive, leading to a particular throughput / resolution compromise. The genetic algorithm was modified to maximize the throughput of classes of XRD resolution as defined as the maximum FWHM observed in the XRD pattern. Computed populations of configurations were then reported in throughput versus resolution. After selecting a target resolution, the optimum configuration (in this case, a refinement of pinhole diameter and distance to the source) was obtained from the best configurations in the corresponding resolution class. Studies utilizing a grid scan led to similar results. The optimized geometry, which results in a resolution of 0.3∘ 2θ was chosen for implementation in the CheMin IV instrument. A 20× increase in the XRD throughput (X-ray flux) was calculated compared to the CheMin III geometry, with a uniform 2θ resolution along the full range of 2θ (e.g., see Fig. 10).

Comparison of performance of CheMin III (blue) and optimized CheMin IV geometry (red) using CheminRay simulations. Left: computed XRD pattern of Jarosite showing a 20× increase in integral intensity for the CheminRay optimization. Right: Resolution curve for the optimized geometry. While CheMin III offers higher resolution at low 2θ angles, for minerals, such high resolution at low 2θ is not required. The chosen optimization is based on high photon throughput with a flat resolution curve across 2θ

Similar optimization approaches with more parameters were taken to explore the potential of different instrument parameters for the flight instrument. In particular, optimized geometries were proposed based on a dual X-ray tube layout as specified in the early stage of the flight instrument development. After the second X-ray source was descoped, an instrument geometry was proposed based on a slight evolution of the CheMin IV design, having a single X-ray tube, and sample and CCD detector both perpendicular to the beam. CheminRay was used to study the effect of parameters such as pinhole diameter or sample thickness on resolution, intensity, peak asymmetry and peak shift. Ray tracing results were backed by experimental verification of selected geometries using a dedicated breadboard instrument based on commercial grade components.

Once the geometry of the system was established, a second model was developed based on a mathematical description of the diffracted intensity at the CCD taking into account all critical parameters of the geometry. Unlike the ray tracing model which could virtually explore all possible configurations but required extensive computation time, this model limits its scope to the chosen geometry through a number of approximations, but requires far less computation time. The output of the mathematical model was verified with ray tracing results as well as experimental data from breadboard instruments. This model was a critical engineering tool for the design of the flight instrument, allowing detailed investigation of the effect of small variations of design parameters on the resulting patterns. The model was used primarily to link engineering requirements to MSL level II science objectives. Small but significant adjustments were made to the geometry using this tool.

1.7.3 Fundamental-Parameters Modeling of Profiles Produced by CheMin

Line profile fitting is the basic approach to obtain phase contents and structure information from X-ray powder diffraction data. Typically, two methods are used for line profile fitting: Constrained or unconstrained analytical profile fitting, and the fundamental parameters method.

In the first method, empirical instrument profile functions (mathematical functions) are used to simulate the observed diffraction pattern. In some cases, these mathematical functions are convolved with other empirical descriptions of instrument- and sample-related contributions to generate a simulated diffraction pattern. The disadvantage of this method is that refinable variables relating to the instrument profile functions have no clear physical meaning; they are simply empirical mathematical functions. Profile parameters resulting from a refinement are generally not sensible, even though refinements converge well, giving acceptable residual factors. In such cases, it is often common to apply mathematical constraints to the refinement to obtain reasonable results.

In the case of fundamental parameter descriptions of profiles, all of the geometrical parameters of the entire instrument are mathematically described and are convolved together. In this case, results of refinement have definite physical meanings. By convolving the individual instrument parameter functions together, an instrument profile can be generated, and if these functions accurately describe the instrument, the simulated instrument profile can be very accurate (as determined through the use of profile standards such as NIST SRM 660a LaB6). This instrument profile can then be convolved with sample-related profiles to simulate the experimental diffraction pattern. Generally the individual instrument contributions to the observed profile are well known, for example, the diffraction geometry, slits, radius, etc., employed in a Bragg-Brentano powder diffractometer. Some instrument-related parameters are not precisely known, and refinement of these within a limited range can ultimately provide instrument functions that have physical meaning, in contrast to the analytical profile functions used in the empirical line profile fitting method. As a result, structure and phase information resulting from a refinement are more realistic and accurate.

The geometry of the CheMin instrument is shown schematically in Fig. 1. X-rays are generated by a Co radiation source, they are shaped by a collimator, and they are ultimately diffracted by the sample. The instrument profile for this configuration can be simulated by convolving the radiation source spectrum of Co with a function for the beam size aberration, a function for the collimator, and a function accounting for sample thickness. The source emission profile is generated by convolving seven Co Kα lines and six Co Kβ lines with a Lorentzian function (Hölzer et al. 1997). The Kβ lines in the diffraction pattern originate from radiation leakage (e.g., Kβ photons that have lost charge (“split events”) and fall into the Kα energy window), and the intensities are thus allowed to be refinable, maintaining their relative intensities. The finite X-ray beam size effect is approximated by a Gaussian function rather than an impulse function (Young 1993), and the collimator is described by a circular function.

Absorption Correction for the Normal-Beam-Transmission Diffraction Experiment

The diffraction geometry for the CheMin instrument is a normal-beam-transmission geometry. As shown below, diffraction intensities vary systematically with diffraction angle 2θ for this instrument geometry resulting from sample absorption (which is not the case in Bragg-Brentano geometry). Thus an absorption correction must be applied to obtain accurate diffraction intensities for Rietveld refinement, in order to provide reasonable phase contents and structural details. With reference to Fig. 11, I 0 is the diffraction intensity of a unit volume sample at angle 2θ under the condition of zero absorption, S is the cross-sectional area of the direct beam at position x in a sample of thickness t,x and d are the path lengths of the X-ray in the sample before and after diffraction, and μ is the linear absorption coefficient of the sample. The diffracted intensity from the volume element Sdx with diffraction angle, 2θ, is:

X-ray paths in the sample for normal-beam-transmission diffraction. S is the cross sectional area of the X-ray beam after being shaped by the pinhole collimator. Parameter t is sample thickness, X is the distance the X-rays travel before diffraction, and d is the path of the diffracted beam in the sample. Parameter dx is the thickness of the volume element, and 2θ is the diffraction angle. The total diffracted intensity at any angle 2θ is the integration of the volume element over the sample thickness

The total diffracted intensity at diffraction angle 2θ is the integration of dI at the same angle over the range of sample thickness x∈[0,t].

Relative intensities are used instead of absolute intensities in Rietveld refinement, in both the analytical profile fitting and fundamental parameter method, and therefore the intensities at diffraction angle 2θ can be normalized to the intensities at 2θ=0:

The normalization factor for the intensity correction is

Beryl-Quartz Mixture Results

Diffraction data were obtained in the CheMin FM instrument for a 97 % beryl, 3 % quartz mixture by integration of the Debye rings on the 2-D diffraction image. Intensities were corrected for sample absorption according to Eq. (4). During Rietveld refinement, data in the range 5–8∘ 2θ were excluded to remove the contribution from the Kapton® window. Data above 53∘ 2θ were also excluded, as data in this region originate from the edges of the CCD detector and resultant Debye rings are poorly represented. The quality of the fit for the four minor peaks at high diffraction angles is comparatively poor, probably for the same reason. Both structural parameters and instrumental parameters were refined using the FM instrument diffraction data and the fundamental parameters method. Sample linear absorption coefficients, sample thickness, and sample packing factors were also refined. The refinement converged to a weighted profile or agreement factor (“Rwp”) of 12.6 %. Beryl is the major phase in the sample and quartz is only a minor phase, with a refined wt.% of 1.9. These data were also fit using the analytical profile fitting method, using the popular modified Thompson-Cox-Hasting pseudo-Voigt function (Young 1993). The refinement converged to a larger Rwp factor of 18.2 %, with a large difference between calculated and experimental intensities, particularly for the first beryl peak. Although the phase content of quartz resulting from this refinement (2.6 %) is more accurate than the result obtained with the fundamental parameters method, the fit quality is significantly inferior and it is not possible to obtain information on sample-related broadening effects. For this reason, the fundamental parameter approach will be used in the refinement of the CheMin instrumental broadening function and the analysis of CheMin data.

1.8 Measurement of the Energies of Individual Photons

The CCD-224 directly detects individual X-ray photons that are absorbed by the active silicon, producing a number of electron-hole pairs equal to the energy of the X-ray in electron volts, divided by 3.65 (the energy of an electron-hole pair in the silicon structure). For example, a Co Kα X-ray with an energy of 6.93 keV will produce 1,899 electron-hole pairs. XRD and XRF data products are described in 1.9 below. The X-ray fluorescence requirement was descoped from the CheMin instrument for technical and budgetary reasons. However, energy discrimination is still required for the energy binning that will segregate Co Kα and other energies critical to XRD. Although of secondary importance to the energy resolution of primary Co X-rays, qualitative elemental information from sample-generated secondary X-ray fluorescence will also be important for supporting mineral identification by pinpointing the elements to be included or excluded in mineral search/match routines.

1.9 XRD and XRF Data Products

In order to retain energy information from individual X-ray photons, it is necessary to operate the CCD in “single photon counting mode.” This is accomplished by exposing the CCD to the X-ray flux for only a brief interval between read cycles. During a nominal 5–30 second single-frame exposure, the likelihood is low that more than one photon (characteristic, Bremsstralung or fluorescent) will be collected in any single pixel of the array (most of the nearly 360,000 pixels will contain background). Raw data consist of 600×582 arrays that store charge collected from individual CCD frames. The data are stored as “Digital Numbers” or “DN” that are transformed to energy (in keV) subsequent to downlink. During a CheMin analysis, individual CCD images are stored in memory (up to a total of 2,730 images or frames of 600×582 pixels). Ideally, all raw frames would be transmitted to ground for processing. However the data volume is too large for this to be feasible. The raw CCD frames are therefore processed into a number of higher-level data products by the Rover Compute Element (RCE) and selected data products are subsequently transmitted to ground. However, a small number of individual raw frames will be downlinked to monitor background before the X-ray tube is powered on, at intervals during the analysis, and after the X-ray tube is powered off. These raw frames will be utilized to assess the health of the CCD over time and to choose DN values suitable for background and high and low DN limits for energy-selected diffraction products (such as CoKα). If for whatever reason, the background or high and low limit DN values have changed between analyses or even between individual minor frames, the quality of the higher-level data products will have been compromised. In this event, the correct DN values can be determined on the ground from the raw frame data and uplinked to the spacecraft on a following Sol. The full complement of raw frames from an analysis are retained in CheMin’s flash memory and can be reprocessed by the RCE using the correct DN values, and a corrected set of higher-level data products can be retransmitted to ground. Ten to 200 raw frames are collected and processed by the RCE to produce “Minor Frame” data products (described below). Five to 20 minor frames collected within a single sol, typically at night, are referred to as a “Major Frame.” A complete analysis of an individual sample, which may require one or more sols, is called an “Observation.” Major frames and Observations are assembled on the ground from downlinked Minor Frame products.

Figure 12 shows data obtained from the CheMin FM instrument during ThermoVac testing. Background-subtracted single raw frames (Fig. 12, left) contain all photons detected by the CCD during a single 30-second exposure. Various minor frame products are generated from raw frames by the RCE and transmitted to ground. Figure 12 (middle) shows an energy-selected Co Kα data product, summed from ∼200 single frame images. Figure 12 (right) shows a major frame product, assembled on the ground from 7 minor frame images.

2-D diffractograms from the Gore Mountain amphibole (obtained from the CheMin Flight Model (FM) during ThermoVac testing). Left: A single 30-second frame of raw data containing all detected photons (characteristic and continuum radiation from the X-ray tube plus sample-generated secondary fluorescence). Middle: Minor frame of energy-selected Co Kα data, summed from 200 single frames. Right: Major frame of energy-selected Co Kα data, summed from 7 minor frames

Minor frame and major frame 1-D patterns are constructed on the ground by summing the images circumferentially around the central beam, resulting in a 1-D diffractogram similar to that obtained by conventional XRD instruments (e.g., Fig. 13). Phase identification and quantitative analysis are performed on the 1-D data.

1-D diffractograms from the Gore Mountain amphibole. At incremental radii 2-D patterns as in Fig. 12 are summed circumferentially about the central nondiffracted beam to yield a one-dimensional plot of 2θ versus intensity comparable to conventional XRD data. Left: Minor frame Co Kα diffractogram. Right: Major frame Co Kα diffractogram. Intensity in arbitrary units

CheMin’s XRF detector was descoped from the instrument due to perceived cost and risk factors. However, limited XRF data from the CCD detector will be provided to the extent they are available. Figure 14 shows single frame, minor frame and major frame XRF data from the Gore Mountain amphibole. The instrument is only sparingly sensitive to elements below atomic number 19 (K) as a result of sample self-absorption, the aluminized light shield, and Mars atmosphere absorption. However, even the limited XRF data provided by the CCD detector will be useful in the discrimination of mineral phases.

XRF Energy-Dispersive Histograms (EDH). Left: Single frame EDH from Gore Mountain amphibole. Right: Minor frame EDH, sum of 200 single frame EDH. Middle: Major frame EDH, sum of 7 minor frame EDH. Elements detected from the sample include Fe, Ti and Ca. Cobalt originates from the X-ray tube, argon from the 7 Torr argon atmosphere of the test chamber, silicon from self-fluorescence of the CCD detector and aluminum from the CCD light shield, and only in part from the amphibole

“Fully Processed” Data

“Fully processed” data are comprised of 600×582 two-dimensional (2-D) arrays of energy-selected Co Kα and Co Kβ X-rays, plus a one-dimensional (1-D) Energy-Dispersive Histogram (EDH). The integer value in a particular x,y position in a Co Kα or Co Kβ array represents the number of Co Kα or Co Kβ X-rays that were detected in the corresponding x,y pixel of the CCD array (a DN value in the array is considered to represent a Co Kα or Co Kβ photon if its background-subtracted value fits within upper and lower values ground-specified for Co Kα or Co Kβ events). Co Kα and Co Kβ diffraction events can be treated separately; in practice the Co Kα pattern is significantly stronger and will be the primary product. The 2-D patterns are transformed into 1-D diffractograms on the ground by the CheMin science team by summing circumferentially about the central beam. The resulting 1-D patterns are normalized for number of pixels versus 2θ and normalized to account for variable arc length. The energy histograms provide performance-check information on CCD function and may be used to aid in constraining search/match procedures in XRD analysis. Several ground-selectable Minor Frame products that utilize the energy-discriminating capability of the CCD can be calculated by the RCE and transmitted to ground. These include:

- “XRD energy-selected mode”::

-

If the background-subtracted DN value in an x,y pixel falls between ground-specified low and high values, a 2-D counting number array is incremented by one at that x,y location in the counting number array. The result is a 2-D array that represents all of the detected X-ray events that lie within a specified energy window. Windows may be chosen for the energies of Co Kα and Co Kβ photons (these constitute Co Kα or Co Kβ diffraction patterns); as noted above the general case will be selection of Co Kα. Two further refinements of this mode can be selected:

- “Single pixel mode”::

-

If the background-subtracted DN value in an x,y pixel falls between ground-specified low and high values, and nominal zero values are present in the four pixels immediately above, below, right and left of the x,y pixel of interest, a 2-D counting number array is incremented by one at that x,y location in the counting number array. This mode differs from the general case in that X-ray “split pixel” events, in which charge from a single photon is shared within two or more adjacent pixels, will not be counted. Single pixel mode Co Kα patterns have fewer peak artifacts in their patterns because in normal energy-selected mode, Co Kβ photons which split a small amount of charge into an adjacent pixel may be counted as Co Kα photons.

- “Summed Split Pixel mode”::

-

If the background-subtracted sum of the DN values of an x,y pixel plus the four pixels immediately above, below, right and left of the x,y pixel of interest falls between ground-specified low and high values, a 2-D counting number array is incremented by one at that x,y location in the counting number array. This mode attempts to count single pixel events as well as split pixel events. Summed split pixel mode patterns will maximize the number of Co Kα counts while removing Co Kβ photons which have split a small amount of charge into an adjacent pixel.

- “XRF (all photons) mode”::

-

All of the background-subtracted DN values in the 600×582 CCD array are summed into a 1-D histogram of DN value vs. number of counts. This array amounts to an energy-dispersive histogram (EDH) of the sample, plus characteristic and Bremsstrahlung photons from the X-ray tube. XRF all photons mode EDH have a higher background and poorer energy resolution due to split pixel events that broaden the energy distribution of observed peaks. Two further refinements of this mode can be ground-selected:

- “XRF single pixel mode”::

-

Background-subtracted DN values from each x,y pixel that have nominal zero values in the four pixels immediately above, below, right, and left of the pixel of interest are summed into a 1-D histogram of DN value vs. number of counts. This array amounts to an energy-dispersive histogram (EDH) of the sample, plus characteristic and bremsstrahlung photons from the X-ray tube, excluding split pixel events. XRF single pixel mode EDH provide for the lowest background and highest energy resolution because split pixel events, which broaden the energy distribution of observed peaks, are removed.

- “XRF split pixel mode”::

-

Background-subtracted DN values from each x,y pixel plus the DN values in the four pixels immediately above, below, right and left of the pixel of interest are summed into a 1-D histogram of DN value vs. number of counts. This array amounts to an energy-dispersive histogram (EDH) of the sample, plus characteristic and bremsstrahlung photons from the X-ray tube, including reconstituted split-pixel events. XRF split pixel mode processing will provide the maximum count rate but will provide poorer resolution because of split events, which when summed, show some energy losses relative to the charge deposited by the incoming photon.

“Modified Raw” Patterns

Modified raw patterns are produced by background subtracting a frame, setting CCD pixels below a specified DN value to zero and run-length encoding the data. The DN cutoff can be near zero or just below the most useful energies (Fe Kα to Co Kβ). Following downlink, the 2-D patterns are reconstructed, transformed into 1-D diffractograms, and treated as in the fully processed mode.

“Film-Mode” Patterns

In film mode, background values are subtracted from each frame and the DN values in the frame are then summed into a 600×582 counting number array. The resulting Minor Frame acts similarly to a piece of photographic film, detecting all photon events, including diffraction, fluorescence, bremsstrahlung, etc. This data product maximizes the number of counts that can contribute to the pattern, but background can be raised substantially if the sample exhibits strong fluorescence. There is a higher background associated with film-mode patterns and interpretation of film-mode diffraction is complicated by presence of both Co Kα and Co Kβ characteristic diffraction, as well as diffraction from tungsten L-line radiation that is produced as the cathode of the X-ray tube sputters onto the anode (this problem increases in severity as the tube ages). An additional complication arises when poor grain movement in the sample cell results in “spottiness” in the pattern due to multiple photon detections in the same pixel from grains that remain in the diffraction orientation. Indeed, film-mode images are used to diagnose grain movement problems if anomalous peak intensities are suspected in 1-D patterns. The 2-D patterns that are downlinked in film mode are transformed into 1-D patterns as in the previous data types but the multiple diffraction energies produce a pattern that is more difficult to interpret uniquely. Mixed intensities and multiple peaks for each d-value can preclude accurate phase identification or quantification in some samples. Film mode generally will not be used because of these problems and because of the high and irregular background, which degrades detection limits and removes any capability of detecting and quantifying amorphous components. However, under certain circumstances (e.g., extensive neutron damage from the RTG) the energy-dispersive function of the CCD may degrade to the point where separation of Co Kα and Co Kβ XRD patterns is not possible. In such cases, XRD will still be possible in film mode.

Once a 1-D plot of 2θ versus intensity is obtained, standard methods of analysis for laboratory XRD data are applicable. The baseline approach for MSL XRD data will be to use the mineral identification utilities in programs such as Jade® (MDI, Pleasanton, CA), TOPAS (Bruker Corp.), and Xpowder® (Martin 2004), typically using ICDD or AMCSD library data and operator knowledge to identify minerals based on analysis of the 1-D diffraction pattern. Qualitative chemical information obtained from the EDH can be used to include or exclude certain elements, refining the search. Following identification of all minerals detectable in the sample, mineral abundances will be quantified. Quantification will be accomplished using either a program such as FULLPAT (Chipera and Bish 2002) or Rietveld methods (reconstruction of the full 1-D pattern from fundamental crystallographic properties of all phases present). The presence of amorphous material will be determined from broad scattering reflecting the radial distribution properties of the amorphous material.

2 CheMin Science and Measurement Requirements

2.1 CheMin Science Requirements

The overarching science requirement of the CheMin instrument is that it be able to “…utilize X-ray Diffraction to establish the mineralogy of rocks and soils, allowing the MSL science team to infer the formation and alteration histories of samples acquired by the mission.” The CheMin measurement objectives are to provide: (1), mineral identification and quantitative mineralogy of rock and soil samples utilizing powder X-ray diffraction; (2), qualitative elemental composition of rocks and soils utilizing energy dispersive histograms (EDH); and (3), analyses of as many as 74 samples supplied by SA/SPaH CHIMRA during the nominal one-Mars-year surface mission.

2.2 CheMin Measurement Requirements

The CheMin measurement requirements are listed below. Critical source and detector requirements necessary to achieve these measurements are shown in Table 3.

-

Detection limit of 3 wt.%. “The CheMin instrument shall have the ability to achieve a detection limit of better than 3 wt.% for crystalline phases (demonstrated by showing a minimum detection limit (MDL) of less than or equal to 3 weight percent abundance of quartz in a quartz-beryl mixture).”

The rationale for this requirement is based on MER A (Spirit) observations of mineralogy at Gusev Crater (Ming et al. 2006; Morris et al. 2006, 2008). With a 2 % detection limit, CheMin would not detect halides (NaCl, KCl, MgCl2), indicators of groundwater action or deposition by acid fog (∼2 % abundance at Clovis outcrop). With a 5 % detection limit, CheMin would not detect goethite (FeOOH), a positive indicator of basalt altered by water at oxidizing conditions (∼5 % abundance at Clovis outcrop) and hematite (Fe2O3), a probable indication of aqueous alteration (∼4 % abundance at Paso Robles outcrop). With a 10 % detection limit, CheMin would not detect sulfates (gypsum/anhydrite and magnesium sulfates), positive indicators of aqueous alteration and soil forming processes (Clovis outcrop).

With a 3 % MDL, the phases observed by CheMin are sufficient to identify the suite of sulfates at Clovis as well as phosphates, with local information bearing on outcrop vs. soil origins. In concert with APXS results, inferences could be made about the halide associations.

-

Measurement accuracy of 15 % relative and precision of 10 % relative. “The CheMin instrument shall have the ability to determine the abundance of crystalline mineral phases present in the sample at 4 times the MDL to an accuracy of 15 % relative (1σ) and a precision of 10 % relative. This will be demonstrated by determining the abundance of quartz in a quartz-beryl mixture having 12 wt.% quartz (4 times the required MDL).” This test is specifically written for the FM, but extended calibration using the DM will use a broad suite of natural and synthetic mineral mixtures of known abundance.

The rationale for this requirement is as follows: 15 % relative accuracy and 10 % relative precision for the measurement of 12 % quartz in a quartz-beryl mixture is representative for many mineral mixtures and is a realistic goal for quantitative XRD in polyphase mixtures. However, the presence of amorphous or X-ray amorphous materials, or poorly crystalline materials such as clay minerals and Fe-Ox-hydroxide phases is expected to reduce both the precision and accuracy of analyses. This level of accuracy and precision in mineralogical measurements will be critical for mass-balance calculations of both igneous and sedimentary systems on Mars. There is an extensive literature of mass balance determinations for soils and sediments based solely on chemical (XRF or APXS) data using “assumed” mineral mixtures; a quantum improvement in these calculations will be attained when both mineral presence and abundance are constrained.

-

Distinguish minerals at abundances above detection limits in a rock matrix. “The CheMin instrument shall, with an integration time of 10 hours, have the ability to distinguish unique minerals at abundances above detection limits in a rock matrix (e.g., calcite, gypsum and jarosite in an evaporite; apatite in a basalt). This will be demonstrated by measurement of the full-width at half-maximum (FWHM) intensity showing angular (2θ) resolution of better than or equal to 0.35∘ over the 2θ range from 24∘ to 45∘ (Co Kα), for quartz and beryl peaks in a mixture of 12 wt.% quartz and 88 wt.% beryl.”

The rationale for this requirement can be illustrated using a model of the complex mineralogy thought to be present in Peace Outcrop, Columbia Hills (case 2 from Table 5 of Ming et al. 2006) on the basis of seven minerals modeled from APXS data. The modeled mineralogy includes forsterite, augite, labradorite, magnetite, chlorapatite, kieserite and gypsum. In Fig. 15 (upper) the principal lines for these seven minerals are shown over the 2θ range detectable by the CheMin instrument. There are clearly many close or overlapping lines in the important range from 30∘ to 45∘ 2θ. Figure 15 (lower) shows the same stick diffractogram of 7 minerals, but with patterns that have been given artificial resolutions ranging from 0.30∘ to 0.60∘ 2θ. Clearly, the decrease in 2θ resolution yields cases in which some minerals will not be identified in the analysis. Figure 16 shows the range from 30∘ to 32∘ 2θ, a region in which labradorite, kieserite, apatite and augite peaks overlap. Although the kieserite (−111) peak is still identifiable at 21.5∘ 2θ, identification of the kieserite triplet at 30∘ to 32∘ 2θ is lost as the FWHM goes from 0.35∘ to 0.40∘. The presence of kieserite is suspected but not confirmed if the FWHM is worse than 0.35∘. The presence of kieserite vs. gypsum in an otherwise igneous rock has implications for the activity of activity of water, and the salinity of the hydrous fluid involved.

Fig. 15 (Upper): Positions of the major diffraction peaks of 7 minerals inferred from APXS data to be present in the Peace Outcrop, Columbia Hills by Ming et al. (2006), over the 2θ range detected by the CheMin instrument. Positions and intensities of the peaks were obtained from the ICDD powder diffraction database. Lower: as above, but showing the effect of instrumental 2θ resolution on modeled patterns. Resolution varies from 0.30∘ to 0.60∘ 2θ

Fig. 16 A portion of the diffractogram shown in Fig. 15 (lower), showing the region between 30∘ and 32∘ 2θ. As 2θ resolution is degraded below 0.30∘ 2θ, the ability to identify kieserite is lost. The presence of kieserite is suspected but not confirmed if the FWHM is worse than 0.35∘ 2θ

-

Provide an energy-dispersive histogram (EDH) with specified energy range and resolution. The CheMin instrument shall have the ability to return an energy-dispersive histogram (EDH) over the 0–15 keV range with energy resolution sufficient to separate Fe Kα, Co Kα and Co Kβ. This requirement can be met by analysis of an Fe-containing amphibole standard for 10 hours showing energy resolution of 250 eV at Fe Kα or Co Kα.

The rationale for this requirement is as follows: The full 0–15 keV energy range is needed for characterization of split events and to diagnose the quality of sample cell vibration by characterization of the incidence of double Co Kα photon detections. A FWHM energy resolution <250 eV is a first priority requirement, needed to separate diffracted primary Co Kα photons from fluoresced Fe Kα (iron will be present as a major element in virtually all samples). As the FWHM of the detector increases above 250 eV, there will be an increase in the number of Fe Kα photons that are included in the energy window chosen for Co Kα detection. This will result in a decrease in the peak/background ratio in diffraction patterns, and a degradation of the minimum detection limit. As a second level priority, while XRF analysis has been descoped, a simple determination of the presence or absence of an element will greatly aid in search/match mineral determinations.

2.3 List of Available Flight, Demonstration, and Testbed Instruments and Components

In addition to the Flight Model (FM) and Demonstration Model (DM) CheMin instruments, several prototype and testbed instruments or components have been and are being used during the calibration and characterization process. These are discussed below with a brief description of how each will be used in calibration and characterization.

2.3.1 CheMin IV Testbeds

CheMin IV instruments, fitted with a 1200×1152 pixel E2V 5530 CCD rather than the CCD-224 used in the FM and DM, but having comparable 2θ resolution, are currently operational at Ames Research Center, Jet Propulsion Laboratory and Johnson Space Center. These testbeds were used for early evaluation of candidate FM standards and evaluation of quantitative XRD performance using synthetic rocks, and are presently in use for the development of an XRD pattern library appropriate to the CheMin configuration. For example, Fig. 17 and Table 4 show CheMin IV results obtained from a synthetic mixture of phyllosilicate and evaporite minerals. In Fig. 17 (left), the ∼15 Å d-value from nontronite (7∘ 2θ) is seen as the first spatially distinct bright ring of intensity around the undiffracted beam (a silhouette of the beam stop is seen at the center of the lower edge of the image). Figure 17 (right) shows the conventional 1-D diffractogram that results from summing the 2-D pattern circumferentially around the central undiffracted beam. Table 4 shows a quantitative analysis of this sample using the program FULLPAT. These results and others were used to establish and validate the required mineral detection level, analytical precision and accuracy of mineralogical results from the flight instrument.

(Left): 2-D image of diffraction pattern from a synthetic clay-bearing evaporite sample. The direct beam is at the lower center of the image; 2θ increases radially with distance from this point. Right: 1-D 2θ diffractogram derived from the 2-D image. The low angle detection capabilities of the CheMin IV instrument (which match the 2θ range and 2θ resolution of the CheMin flight instrument) are capable of detecting the basal spacing of all known natural phyllosilicates

2.3.2 Inel Testbed