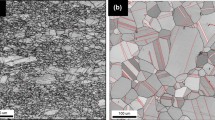

Using transmission electron microscopy, the features of the grain and defect structure of the V–4Ti–4Cr alloy after 16 acts of biaxial and triaxial pressing at room temperature are studied. The microstructure of the alloy after these treatments is a structural composite with the elements of fine-crystalline and submicrocrystalline states. The defect structure is characterized by a crystal lattice curvature from 10 to 30°/μm. It is established that biaxial pressing contributes to a more intensive grinding of the crystallites and a formation of an anisotropic microstructure. The dislocation-disclination mechanism and localization in the direction of maximum shear stresses are thought to be the main mechanisms of structural transformation under conditions of high-strength state, formed as a consequence of dispersion strengthening by the second phase particles. The role of local internal stresses and their gradients in the processes of crystal lattice fragmentation under conditions of severe plastic deformations is discussed.

Similar content being viewed by others

References

R. Z. Valiev, R. K. Islamgaliev, and I. V. Alexandrov, Prog. Mater. Sci., 45, 103 (2000).

M. A. Meyers, A. Mishra, and D. J. Benson, Prog. Mater. Sci., 51, 427(2006).

Y. Estrin and A. Vinogradov, Acta Materialia, 61, 782(2013).

K. Edalati, A. Bachmaier, V. A. Beloshenko, et al., Mater. Res. Lett., 10, No. 4, 163 (2022).

V. Segal, Materials, 11, 1175 (2018).

R. N. Harsha, V. Mithun Kulkarni, and B. Satish Babu, Mater. Today: Proc., 5, 22340 (2018).

K. M. Agarwal, R. K. Tyagi, V. K. Chaubey, and A. Dixit, IOP Conf. Ser.: Mater. Sci. Eng., 691, 012074 (2019).

F. Z. Utyashev, Y. E. Beygelzimer, and R. Z. Valiev, Adv. Eng. Mater., 23, No. 7, 2100110 (2021).

E. Bagherpour, N. Pardis, M. Reihanian, et al,. Int. J. Adv. Manuf. Technol., 100, 1647 (2019).

A. Azushima, R. Kopp, A. Korhonen, et al., CIRP Annals, 57, No. 2, 716 (2008).

Y. Beygelzimer, Y. Estrin, and R. Kulagin, Adv. Eng. Mater., 17, No. 12, 1853 (2015).

B. Verlinden, Metall. Mater. Eng., 24, 165 (2018).

A. N. Tyumentsev, I. A. Ditenberg, A. D. Korotaev, and K. I. Denisov, Phys. Mesomech., 16, 319 (2013).

A. N. Tyumentsev, I. A. Ditenberg, K. V. Grinyaev, et al., J. Nucl. Mater., 413, 103 (2011).

A. D. Korotaev, A. N. Tyumentsev, and Yu. P. Pinzhin, Phys. Mesomech., 1, 21 (1998).

I. A. Ditenberg, A. N. Tyumentsev, K. V. Grinyaev, et al., Tech. Phys., 56, 815 (2011).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Grinyaev, K.V., Smirnov, I.V., Ditenberg, I.A. et al. Microstructure of V-4Ti-4Cr Alloy After Deformation by Multi-Directional Pressing. Russ Phys J 66, 713–720 (2023). https://doi.org/10.1007/s11182-023-02997-y

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11182-023-02997-y