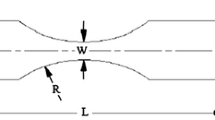

Metastable austenitic steels refer to materials that have numerous engineering applications. Operation of equipment components at different temperatures proceeds under both static and dynamic loads. It is well known that the combined temperature and deformation action can cause martensitic transformations in metastable austenitic steels. This simultaneously strengthens and embrittles the material. In this work, dumbbell-shaped specimens are tested for strength and plasticity after quasi-static uniaxial tension in the temperature range from +65 to –90°C. Structural investigations are performed after plastic deformation. The martensite phase fraction formed in the surface of fractured specimens is defined after tests. It is shown that deformation in a wide temperature range affects phase transformations in metastable austenitic steels. The temperature dependence is found for the volume fraction of the martensite phase and the microhardness of the steels.

Similar content being viewed by others

References

M. Takahashi, Development of high strength steels for automobiles, Nippon Steel Technical Report No. 88, 2– 7 (2003).

O. A. Bannykh, A. M. Sorokin, I. O. Bannykh, and E. I. Lukin, Russian Metallurgy (Metally), No. 6, 528–532 (2018).

S. L. Li, Y. L. Wang, H. L. Zhang, et al., J. Nucl. Mater., 433, Nos. 1–3, 41–49 (2013).

K. G. Farkhutdinov, R. G. Zaripova, and N. A. Breikina, Mater. Sci. Eng. A, 174, No. 2, 217–223 (1994).

S. Y. Shin, B. Hwang, S. Lee, et al., Mater. Sci. Eng. A, 458, No. 2, 281–289 (2007).

R. V. Sundeev, A. M. Glezer, A. P. Menushenkov, et al., Mater. Des., 135, 77–83 (2017).

A. M. Glezer, I. A. Timshin, I. V. Shchetinin, et al., J. Alloys Compd., 744, 791–796 (2018).

A. Hedayati, A. Najafizadeh, A. Kermanpur, and F. Forouzan, J. Mater. Proc. Technol., 210, No. 8, 1017–1022 (2010).

R. J. Moat, S. Y. Zhang, J. Kelleher, et al., Acta Mater., 60, No. 20, 6931–6939 (2012).

A. Das, J. Magn. Magn. Mat., 361, 232–242 (2014).

E. Cakmak, S. Vogel, and H. Choo, Mater. Sci. Eng. A, 589, 235–241 (2014).

L. B. Zuev, G. V. Shlyakhova, S. A. Barannikova, and S. V. Kolosov, Russ. Met. J., No. 3, 229–234 (2013).

S. V. Kolosov, A. M. Nikonova, and S. A. Barannikova, AIP Conference Proceedings, 2310, 020153 (2020).

T. Yu. Sablina, I. N. Sevostyanova, and G. V. Shlyakhova, Russ. Phys. J., 65, No. 4, 635–642 (2022).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Barannikova, S.A., Kolosov, S.V. & Shlyakhova, G.V. Influence of Temperature and Deformation on Structure and Mechanical Properties of Stainless Steel. Russ Phys J 66, 38–42 (2023). https://doi.org/10.1007/s11182-023-02902-7

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11182-023-02902-7