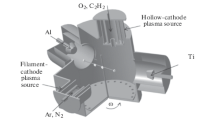

The paper presents X-ray diffraction data analysis of the phase composition of heat-resistant coatings based on Ti−Al−C and Y−Al−O systems. These coatings are deposited onto molybdenum substrates using cathodic-arc deposition using two single-component titanium and aluminum cathodes in a mixture of acetylene and argon gases. It is found that the deposited coatings have the amorphous structure. After annealing, the formation of the Ti2AlC MAX phase and Ti−Al intermetallic compounds occurs in the Ti−Al−C system, whereas in the Y−Al−O system, the formation of Y2O3, YAlO3, Y4Al2O9 oxides is observed.

Similar content being viewed by others

References

X. Chen, et al., J. Eur. Ceram. Soc., 39, No. 13, 3778−3787 (2019).

C. Gatzen, et al., Coatings, 9, No. 10, 609 (2019).

L. R. Turcer, et al., J. Eur. Ceram. Soc., 38, No. 11, 3905–3913 (2018).

M. W. Barsoum and M. Radovic, Annu. Rev. Mater. Res., 41, 195−227 (2011).

M. Radovic and M. W. Barsoum, Am. Ceram. Soc. Bull., 92, No. 3, 20−27 (2013).

I. M. Low, ed., MAX Phases and Ultra-High Temperature Ceramics for Extreme Environments, IGI Global, (2013).

M. W. Barsoum, J. Electrochem. Soc., 8, 148−156 (2001).

X. H. Wang, Oxid. Met., 59, 303−320 (2003).

M. Sundberg, Ceram. Int., 30, 1899−1904 (2004).

J. W. Byeon, et al., Oxid. Met., 68, 97−111 (2007).

A. Pazniak, et al., Mater. Des., 183, 108143 (2019). https://doi.org/10.1016/j.matdes.2019.108143.

A. Pazniak, et al., Ceram. Int., 45, No. 2, 2020−2027 (2019). https://doi.org/10.1016/j.ceramint.2018.10.101.

O. Berger, Surf. Eng., 36, No. 3, 225−267 (2020).

O. Berger, Surf. Eng., 36, No. 3, 268−302 (2020).

O. Berger, Surf. Eng., 36, No. 3, 303−325 (2020).

P. Eklund, et al., Thin Solid Films, 518, No. 8, 1851−1878 (2010).

P. Eklund, et al., J. Phys. D: Appl. Phys., 50, No. 11, 113001 (2017).

Y. M. Manawi, et al., Materials, 11, No. 5, No. 5, 822–858 (2018).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Izvestiya Vysshikh Uchebnykh Zavedenii, Fizika, No. 11, pp. 99–106, November, 2022.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Maslov, A.A., Nazarov, A.Y., Ramazanov, K.N. et al. Advanced Heat-Resistant Y–Al–O and Ti–Al–C Coatings. Russ Phys J 65, 1900–1907 (2023). https://doi.org/10.1007/s11182-023-02849-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11182-023-02849-9