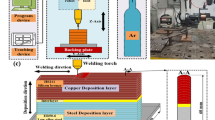

The regularities of structure formation and operational properties of bimetallic functionally graded samples made of nickel-based Udimet500 and bronze CuCr1 have been investigated. The results of obtaining samples with different order of deposited layers on the substrate were obtained. It was found that deposition of nickelbased superalloy on copper alloy forms a gradient zone of less thickness than deposition of copper alloy on nickel-based superalloy. The structure of the transition zone is characterized by a division into a region of mechanical mixing of the components and a region with a smoothly changing composition, extending to the pure alloy. The extended smooth gradient zone is characteristic of the component deposited in the top part of the sample, and the boundary with the component located in the bottom part is sharp. The mechanical properties of the gradient zone of the samples are at the level of the least strong component, bronze CuCr1. Tensile rupture of the samples occurs along the bronze area.

Similar content being viewed by others

References

T. DebRoy, H.L. Wei, J.S. Zuback, et al., Prog. Mater. Sci., 92, 112–224 ( 2018).

P. Ferro, R. Meneghello, S. M. J. Razavi, et al., Phys. Mesomech., 23 (3), 256–262 (2020).

E. G. Astafurova, S. V. Astafurov, K. A. Reunova, et al., Phys. Mesomech., 25 (1), 1–11 (2022).

Z. Li, C. Liu, T. Xu, et al., Mat. Sci. Eng. A, 742, 287–294 (2019).

E. Fereiduni, A. Ghasemi and M. Elbestawi, Mater. Des., 184, 108185 (2019).

E. A. Kolubaev, V. E. Rubtsov, A. V. Chumaevsky and E. G. Astafurova, Phys. Mesomech., 25, No. 6, (2022) (In print).

X. Shu, G. Chen, J. Liu, et al., Mater. Lett., 213, 374–377 (2018).

A. V. Filippov, E. S. Khoroshko, N. N. Shamarin, et al., J. Alloys. Cmpd., 859, 157824 (2021).

K. S. Osipovich, A. V. Chumaevskii, A. A. Eliseev, et al., Russ. Phys. J., 62, No. 8, 1486–1494 (2019).

K. S. Osipovich, E. G. Astafurova, A. V. Chumaevskii, et al., J. Mater. Sci., 55, 9258–9272 (2020).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Chumaevskii, A.V., Kolubaev, E.A., Osipovich, K.S. et al. Obtaining of Bimetallic Product from Nickel Superalloy and Heat-Resistant Bronze by Wire-Feed Electron Beam Additive Manufacturing. Russ Phys J 65, 1231–1238 (2022). https://doi.org/10.1007/s11182-022-02756-5

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11182-022-02756-5