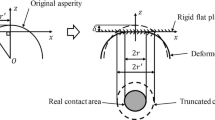

Stiffness characterization of mechanical interfaces is quite crucial for the analysis of several tribological behaviors. In the research of industrial robots, joints exist universally. The stiffness of different machine tools varies greatly, particularly for computer numerical control machine. Therefore, this research aims at providing an assessment of influence factors for stiffness of joint interfaces theoretically. Based on fractal roughness parameters independent of scale and contact mechanics theory, the contact area of joint interface is studied, and a multi-scale normal contact stiffness model and a multi-scale tangential contact stiffness model are proposed. Meanwhile, the problem of the deformation of any contact asperity is considered as three separate regimes. The laws of area-displacement and force-displacement under elastic-plastic regime are established. The transition which is in the deformation mechanism of asperity from elastic to plastic is consistent with classical contact mechanics. The analysis of numerical calculation results indicates the approximate linear relation among dimensionless normal load and key parameters. Moreover, these key parameters have been divided into two main categories for the multiscale model of joint interfaces, namely, fractal parameters, such as fractal dimension D and fractal roughness parameter G, and interfacial parameters. In addition, tangential load and friction factor are two important factors of the tangential stiffness.

Similar content being viewed by others

References

Y. C. Zhou, Y. Xiao, Y. He, et al., Compos. Struct., 236, 111874 (2020).

X. Guo, B. B. Ma, and Y. C. Zhu, J. Mech. Phys. Solids, 133, 103724(2019).

X. Zhang, N. Wang, G. Lan, et al., J. Tribol.-T. ASME, 136, 1–10 (2014).

W. J. Pan, X. P. Li, L. L. Wang, et al., Eur. J. Mech. A/Solids, 66, 94–102 (2017).

W. W. Liu, J. J. Yang, et al., J. Adv. Mech. Des. Syst. Manuf., 9, No. 5, 70–82 (2015).

D. Y. Zhang, Y. Xia, F. Scarpa, et al., Sci. Rep., 7, 12874 (2017).

J. Shen, X. Zhang, et al., Therm. Sci., 23, 2849–2856 (2019).

J. A. Greenwood and J. Williamson, Proc. R. Soc. Lond., Ser. A, 295, 300–319 (1966).

D. J. Whitehouse and J. F. Archard, Proc. R. Soc. Lond., Ser. A, 316, 97–121 (1970).

A. Majumdar and B. Bhushan, J. Tribol.-T. ASME, 113, 1–11 (1991).

B. Bhushan and A. Majumdar, Wear, 153, 53–64 (1992).

M. V. Berry and Z. V. Lewis, Proc. R. Soc. Lond., Ser. A, 370, 459–484 (1980).

A. Majumdar and B. Bhushan, J. Tribol.-T. ASME, 112, 205–216 (1990).

A. Majumdar and C. L. Tien, Wear, 136, 313–327 (1990).

S. Wang, K. Komvopoulos, and B. Bhushan, J. Tribol., 117, 203–215 (1995).

S. Wang and K. Komvopoulos, J. Trib.-T. ASME, 116, No. 4, 824–832 (1994).

W. Yan, K. Komvopoulos, J. Appl. Phys., 84, 3617–3624 (1998).

Y. Morag and I. Etsion, Wear, 262, 624–629 (2007).

X. M. Miao and X. D. Huang, Wear, 309, 146–151 (2013).

W. J. Pan, X. P. Li, and G. Na, Adv. Mech. Eng., 9, No. 3, 1–11 (2017).

Y. S. Zhao, J. J. Xu, and L. G. Cai, ProIMechE, Part C, J. Mech. Eng. Sci., 231, No. 2, 279–293 (2017).

T. Jana, A. Mitra, and P. Sahoo, Appl. Surf. Sci., 392, 872–882 (2017).

J. F. Shen, S. Xu, W. W. Liu, et al., Mechanika, 23, No. 5, 703–713 (2017).

R. Q. Wang, L. D. Zhu, and C. X. Zhu, Int. J. Mech. Sci., 134, 357–369 (2017).

Q. Chen, J. J. Zhou, A. Khushnood A, et al., AIP Adv., 9, No. 1, 1–13 (2019).

S. Xi and A. A. Polycarpou, J. Vib. Acoust., 127, 52–60 (2005).

W. P. Fu, Q. Guo, Y. M. Huang, et al., J. Vib. Acoust., 122, 393–398 (2000).

M. Eriten, C. Lee, and A. A. Polycarpou, Tribol. Int., 50, 35–44 (2012).

L. Kogut and I. Etsion, J. Appl. Mech.-T. ASME, 69, 657–662 (2002).

L. P. Lin and J. F. Lin, J. Tribol.-T. ASME, 127, 666–672 (2005).

W. J. Stronge, in: Impacts in Mechanical Systems, B. Brogliato, Ed., Springer, Berlin; Heidelberg; Cambridge (2000), pp. 189–234.

K. L. Johnson, Contact Mechanics, Cambridge University Press, Cambridge (1985).

D. Josheski, E. Karamazova, and M. Apostolov, AMNS, 4, No. 2, 331–350 (2019).

L. Li, Y. Wang, and X. Li, AMNS, 5, No. 1, 55–60 (2020).

J. L. Liou and J. F. Lin, J. Tribol.-T. ASME, 128, 515–524 (2006).

J. L. Liou and J. F. Lin, J. Tribol.-T. ASME, 74, 603–613 (2007).

W. Chang, I. Etsion, and D. B. Bogy, J. Tribol.-T. ASME, 110, 57–63 (1988).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Izvestiya Vysshikh Uchebnykh Zavedenii, Fizika, No. 7, pp. 81–95, July, 2021.

Rights and permissions

About this article

Cite this article

Liu, W., Shen, J., Cheng, S. et al. A Multi-Scale Stiffness Fractal Model of Joint Interfaces. Russ Phys J 64, 1261–1280 (2021). https://doi.org/10.1007/s11182-021-02453-9

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11182-021-02453-9