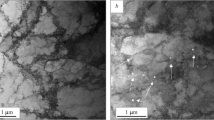

The phase composition, plastic deformation and fracture micromechanisms of Fe–(25–26)Cr–(5–12)Mn–0.15C–0.55N (wt.%) high-nitrogen chromium-manganese steel, manufactured by electron-beam 3D-printing (additive manufacturing) and subjected to heat treatment (at a temperature of 1150°C followed by quenching), are studied. In order to identify the effect of the electron-beam 3D-printing process on the phase composition, microstructure and mechanical properties of high-nitrogen steel, the data obtained are compared with those for Fe–21Cr–22Mn–0.15C–0.53N austenitic steel (wt.%) formed by traditional methods (casting and heat treatment) and used as a material for additive manufacturing. It is experimentally observed that in the specimens formed by additive manufacturing, the depletion of the steel composition in manganese during the electron-beam 3D-printing and post-built heat treatment contributes to the formation of a macro- and microscopically inhomogeneous two-phase structure. The steel specimens contain irregularly shaped macroscopic regions with large ferrite grains or with a two-phase austenite-ferrite structure (microscopic inhomogeneity). Despite the change in the concentration of the basic elements (chromium and manganese) in additive manufacturing, there remains a high concentration of interstitial atoms (nitrogen and carbon). This contributes to a macroscopically heterogeneous distribution of interstitial atoms in the specimens – the formation of a supersaturated interstitial solid solution in the austenitic regions due to the low solubility of nitrogen and carbon in the ferrite regions. This inhomogeneous heterophase (ferrite-austenite) structure exhibits high strength properties, good ductility and work hardening, which are close to those of the specimens of the initial high-nitrogen austenitic steel used as the raw material for additive manufacturing.

Similar content being viewed by others

References

W. E. Frazier, Metal Additive Manufacturing: A Review. JMEPEG, 23 (6), 1917 (2014).

N. Li, S. Huang, G. Zhang, et al., J. Mater. Sci. Tech., 35, 249 (2019).

D. Ding, Z. I. Pan, D. Cuiuri, and H. Li, Int. J. Adv. Manuf. Technol., 81, 465 (2015).

E. G. Astafurova, M.Yu. Panchenko, V. A. Moskvina, et al., J. Mater. Sci., 55, 9211 (2020).

S. Yu. Tarasov, A. V. Filippov, N. N. Shamarin, et al., J. Alloys Compd., 803, 364 (2019).

A. V. Kolubaev, S. Yu. Tarasov, A. V. Filippov, et al., Russ. Phys. J., 61, No. 8, 1491 (2018).

E. V. Melnikov, E. G. Astafurova, S. V. Astafurov, et al., Lett. Mater., 9(4), 460 (2019).

X. Chen, J. Li, X. Cheng, et al., Mater. Sci. Eng. A, 715, 307 (2018).

P. Bajaj, A. Hariharan, A. Kini, et al., Mater. Sci. Eng. A, 772, 138633 (2020).

X. Zhang, Q. Zhou, K. Wang, et al., Mater. Des., 166, 107611 (2019).

V. E. Panin, N. A. Narkevich, V. G. Durakov, and I. A. Shulepov, Phys. Mesomech., 23(2), 15 (2020).

V. G. Gavriljuk and H Berns, High Nitrogen Steels, Springer Verlag, Berlin (1999).

D. Yang, Y. Huang, J. Fan, et al., J. Manuf. Proc., 61, 261 (2021).

J. Boes, A. Röttger, and W. Theisen, Additive Manuf., 32, 101081 (2020).

E. A. Lass, F. Zhang, and C. E. Campbell, Metallurg. Mater. Trans. A, 51, 2318 (2020).

X. Zhang, K. Wang, Q. Zhou, et al., Mater. Today Comm., 27, 102263 (2021).

K. A. Reunova, E. G. Astafurova, S. V. Astafurov, et al., AIP Conf. Proc., 2310, 020275 (2020).

K. A. Reunova, E. G. Astafurova, S. V. Astafurov, et al., AIP Conf. Proc., 2310, 020276 (2020).

E. G. Astafurova, V. A. Moskvina, G. G. Maier, et al., Mater. Sci. Eng. A, 745, 265 (2019).

Yu. I. Chumlyakov, I. V. Kireeva, E. G. Zakharova, et al., Russ. Phys. J., 45, No. 3, 274 (2002).

H. A. Wriedt, N. A. Gokcen, and R. H. Nafziger, Bull. Alloy Phase Diagr., 8(4), 355 (1987).

S. J. Lee and Y. K. Lee, Scripta Mater., 52, 973 (2005).

T. Ping, J. Gong, Y. Wang, et al., Results Phys., 11, 377 (2018).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Izvestiya Vysshikh Uchebnykh Zavedenii, Fizika, No. 7, pp. 10–17, July, 2021.

Rights and permissions

About this article

Cite this article

Astafurova, E.G., Reunova, K.A., Astafurov, S.V. et al. The Effect of Phase Transformations During Electrom-Beam 3D-Printing and Post-Built Heat Treatment on Plastic Deformation and Fracture of Additively Manufactured High Nitrogen Cr–Mn Steel. Russ Phys J 64, 1183–1190 (2021). https://doi.org/10.1007/s11182-021-02442-y

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11182-021-02442-y