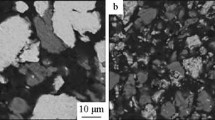

The structural features of the surface of a TiNi-based powder alloy produced by diffusion sintering are studied. Two-dimensional porous samples based on a TiNi powder alloy are manufactured for the experimental investigation of their structural features by the methods of non-destructive testing. It is determined that the phase composition of the TiNi-based powder alloy is represented by the TiNi (B2) austenitic phase and precipitates of the secondary phases enriched with nickel – Ti3Ni4 and titanium – Ti2Ni. The chemical compositions of the TiNi compound and the Ti2Ni secondary-phase particles are determined. A three-dimensional reconstruction of the surface of the TiNi-based powder alloy is performed by optical profilometry. It is shown that, depending on the sintering temperature regime and particle size distribution of the TiNi powder, it is possible to obtain a developed rough surface with a roughness coefficient within Ra = 64–87 μm. An analysis of the surface microstructure of the resulting material indicates the existence of several types of terraced relief — hexagonal islands of regular shape 5–10 μm and large terraced structures up to 30– 40 μm in size.

Similar content being viewed by others

References

V. A. Lanshakov, V. E. Gunther, G. L. Plotkin, et al., Medical materials and shape-memory implants. Shapememory implants for traumatology and orthopeadics [in Russian], Volume 2 (Ed. V.E. Gunther], NPP MITS Publ., Tomsk (2010).

P. G. Sysolyatin, V. E. Gunther, S. P. Sysolyatin, et al., Medical materials and shape-memory implants. Shape-memory implants in oral surgery[in Russian], Vol. 4 (Ed. V. E. Gunther), NPP MITS Publ., Tomsk (2012).

M. Z. Mirgazizov, V. E. Gunther, V. G. Galonskii, et al., Medical materials and shape-memory implants. Shape-memory implants in stomatology [in Russian], Vol. 5 (Ed. V. E. Gunther), NPP MITS Publ., Tomsk (2011).

Biological Responses to Metal Implants [Electronic resource], Food and Drug Administration (FDA) (2019). URL: https://www.fda.gov/media/131150/download (date of reference: 17.01.2020).

S. M. Barinov, Chemistry. Uspekhi, 79, No. 1, 15–32 (2010).

I. A. Kirilova, M. A. Sadovoi, and V. T. Podorozhnaya, Khirurg. Pozvonoch, No. 3, 72–83 (2012).

S. N. Kulkov and S. P. Buyakova, Nanotechnologies in Russia, 2, No. 1–2, 119–132 (2007).

I. A. Kirilova, et al., Khirurg. Pozvonoch, No. 4, 52–62 (2013).

Yu. I. Nyashin, G. I. Rogozhnikov, A. G. Rogozhnikov, et al., Ross. Zh. Biomekh., 16, No. 1(55), 102–109 (2012).

I. A. Kirilova, M. A. Sadovoi, and V. T. Podorozhnaya, Khirurg. Pozvonoch., No. 4, 52–62 (2013).

Q. Chen, C. Zhu, and G. A. Thouas, Progress in Biomaterials, No. 1, 2 (2012).

T. G. Volova, E. I. Shishatskaya, and A. J. Sinskey, Degradable Polymers: Production, Properties and Applications, Nova Sci. Publ. Inc., N. Y. (2013).

T. G. Volova and E. I. Shishatskaya, Degradable Polymers: Production, Properties and Applications [in Russian], Krasnoyarskii Pisatel, Krasnoyarsk (2011).

E. I. Shishatskaya, Izvestiya VUZov. Fiz., 56, No. 12/3,58–64 (2013).

T. G. Volova, Izvestiya VUZov. Fiz., 56, No. 12/3, 27–32 (2013).

V. E. Gunther, Methodological Peculiarities of Deformation Behavior of Metallic Medical Materials and Implants [in Russian], a study guide, NPP MITS Publ., Tomsk (2014).

V. N. Khodorenko, S. G. Anikeev, and V. E. Gunther, Russ. Phys. J., 57, No. 6, 723–730 (2014).

A. V. Kasimtsev and Yu. V. Levinskii, Calcium Hydride Powders of Metals, Intermetallics, Heat-Resistant Compounds and Composite Materials [in Russian], MITKHT Publ., Moscow (2012).

S. G. Anikeev, N. V. Artyukhova, V. N. Khodorenko, et al., Russ. Phys. J., 61, No. 6, 1039–1046 (2018).

S. G. Anikeev, A. S. Garin, N. V. Artyukhova, et al., Russ. Phys. J., 61, No. 4, 749–756 (2018).

Ya. E. Geguzin, Living Crystal [in Russian], Nauka, Moscow (1987).

L. Kang Suk-Joong Sintering, Densification, Grain Growth and Microstructure, Oxford University, Oxford (2005).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Izvestiya Vysshikh Uchebnykh Zavedenii, Fizika, No. 3, pp. 124–130, March, 2020.

Rights and permissions

About this article

Cite this article

Anikeev, S.G., Artyukhova, N.V., Khodorenko, V.N. et al. The Surface Structure of a TiNi-Based Powder Alloy Manufactured by the Method of Diffusion Sintering. Russ Phys J 63, 484–490 (2020). https://doi.org/10.1007/s11182-020-02060-0

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11182-020-02060-0