Abstract

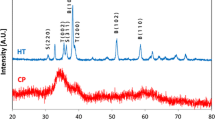

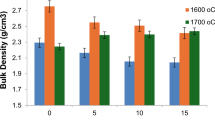

The behavior of hydroxyapatite containing zinc and silicate ions during selective laser melting under irradiation at 10.6 µm was studied for the first time. For comparison, the behavior of the material heated in a high-temperature furnace was investigated. It was found that, in contrast to the slow heating in the furnace, heating of the mechanochemically synthesized material with the degree of substitution x = 0.2 by scanning the laser spot enables its recrystallization with retention of substituent ions in the apatite structure. At high degrees of substitution (x = 1, 2), hydroxyapatites are unstable under both heating regimes. Different heating conditions lead to the formation of different impurity phases.

Similar content being viewed by others

References

3D Printing in Medicine, Ed. Deepak M. Kalaskar, Woodhead Publishing, 2017, 226 pp.

F. Krujatz, A. Lode, J. Seidel, T. Bley, M. Gelinsky, J. Steingroewer, New Biotechnol., 2017, 39, 222; DOI: https://doi.org/10.1016/j.nbt.2017.09.001.

C. M. B. Ho, S. H. Ng, Y. J. Yoon, Int. J. Precis. Eng. Manuf., 2015, 16, 1035; DOI: https://doi.org/10.1007/s12541-015-0134-x.

Z. Chen, Z. Li, J. Li, C. Liu, C. Lao, Y. Fu, C. Liu, Y. Li, P. Wang, Y. He, J. Eur. Ceram. Soc., 2019, 39, 661; DOI:https://doi.org/10.1016/j.jeurceramsoc.2018.11.013.

M. J. Zafar, D. Zhu, Z. Zhang, Materials, 2019, 12, 3361; DOI: https://doi.org/10.3390/ma12203361.

S. M. Barinov, V. S. Komlev, Biokeramika na osnove fosfatov kal’tsiya [Bioceramics Based on Calcium Phosphates], Nauka, Moscow, 2005, 204 pp. (in Russian).

S. V. Dorozhkin, J. Biotechnol. Biomed. Sci., 2018, 1, 25; DOI: https://doi.org/10.14302/issn.2576-6694.jbbs-18-2143.

A. Kumar, S. Kargozar, F. Baino, S. S. Han, Front. Mater., 2019, 6, 313; DOI: https://doi.org/10.3389/fmats.2019.00313.

C. Gao, Y. Deng, P. Feng, Z. Mao, P. Li, B. Yang, J. Deng, Y. Cao, C. Shuai, S. Peng, Int. J. Mol. Sci., 2014, 15, 4714; DOI: https://doi.org/10.3390/ijms15034714.

U. Kalsoom, P. N. Nesterenko, B. Paull, RSC Adv., 2016, 6, 60355; DOI: https://doi.org/10.1039/c6ra11334f.

K. Lin, R. Sheikh, S. Romanazzo, I. Roohani, Materials, 2019, 12, 2660. DOI: https://doi.org/10.3390/ma12172660.

C. Shuai, C. Gao, Y. Nie, H. Hu, Y. Zhou, S. Peng, Nanotechnol., 2011, 22, 285703; DOI: https://doi.org/10.1088/0957-4484/22/28/285703.

C. Shuai, Y. Nie, C. Gao, P. Feng, J. Zhuang, Y. Zhou, S. Peng, J. Exp. Nanosci., 2013, 8, 762; DOI: https://doi.org/10.1080/17458080.2011.606507.

C. Shuai, P. Feng, C. Cao, S. Peng, Biotechnol. Bioprocess Eng., 2013, 18, 3, 520; DOI: https://doi.org/10.1007/s12257-012-0508-1.

P. Feng, M. Niu, C. Gao, S. Peng, C. Shuai, Sci. Rep., 2014, 4, 1; DOI: https://doi.org/10.1038/srep05599.

A. D. Anastasiou, C. L. Thomson, S. A. Hussain, T. J. Edwards, S. Strafford, M. Malinowski, R. Mathieson, C. T. A. Brown, A. P. Brown, M. S. Duggal, A. Jha, Mater. Des., 2016, 101, 346; DOI: https://doi.org/10.1016/j.matdes.2016.03.159.

L. Ferrage, G. Bertrand, P. Lenormand, D. Grossin, B. Ben-Nissan, J. Aust. Ceram. Soc., 2017, 53, 11; DOI: https://doi.org/10.1007/s41779-016-0003-9.

S. Bose, S. Vahabzadeh, A. Bandyopadhyay, Mater. Today, 2013, 16, 496; DOI: https://doi.org/10.1016/j.mattod.2013.11.017.

N. V. Bulina, A. I. Titkov, S. G. Baev, S. V. Makarova, V. R. Khusnutdinov, V. P. Bessmeltsev, N. Z. Lyakhov, Mater. Today: Proc., 2020, 37, 4022; DOI: https://doi.org/10.1016/j.matpr.2020.06.199.

M. Šupova, Ceram. Int., 2015, 41, 9203; DOI: https://doi.org/10.1016/j.ceramint.2015.03.316.

T. Tite, A. C. Popa, L. M. Balescu, I. M. Bogdan, I. Pasuk, J. M. F. Ferreira, G. E. Stan, Materials, 2018, 11, 2081; DOI: https://doi.org/10.3390/ma11102081.

M. A. Zykin, E. O. Anokhin, P. E. Kazin, Russ. Chem. Bull., 2019, 78, 751; DOI: https://doi.org/10.1007/s11172-019-2482-7.

H. M. Rietveld, J. Appl. Crystallogr., 1969, 2, 65; DOI: https://doi.org/10.1107/S0021889869006558.

M. V. Chaikina, N. V. Bulina, I. Yu. Prosanov, O. B. Vinokurova, A. V. Ishchenko, Inorg. Mater., 2020, 56, 402; DOI: https://doi.org/10.1134/S0020168520040044.

N. V. Bulina, M. V. Chaikina, A. S. Andreev, O. B. Lapina, A. V. Ishchenko, I. Yu. Prosanov, K. B. Gerasimov, L. A. Solovyov, Eur. J. Inorg. Chem., 2014, 28, 4810; DOI: https://doi.org/10.1002/ejic.201402246.

R. Z. LeGeros, G. Bonel, R. Legros, Calcif. Tissue Res., 1978, 26, 111. DOI: https://doi.org/10.1007/BF02013245.

R. Ghosh, R. Sarkar, Mater. Sci. Eng. C, 2016, 67, 345; DOI:https://doi.org/10.1016/j.msec.2016.05.029.

I. V. Fadeeva, A. S. Fomin, S. M. Barinov, G. A. Davydova, I. I. Selezneva, I. I. Preobrazhenskii, M. K. Rusakov, A. A. Fomna, V. A. Volchenkova, Inorg. Mater., 2020, 56, 738; DOI: https://doi.org/10.1134/S0020168520070055.

N. V. Bulina, M. V. Chaikina, O. B. Vinokurova, I. Yu. Prosanov, N. Z. Lyakhov, Chemistry for Sustainable Development, 2019, 27, 257; DOI: https://doi.org/10.15372/CSD2019134.

S. Gomes, A. Kaur, J. M. Nedelec, G. Renaudin, J. Mater. Chem. B, 2014, 2, 536; DOI: https://doi.org/10.1039/c3tb21397h.

K. Tõnsuaadu, K. A. Gross, L. Plūduma, M. Veiderma, J. Therm. Anal. Calorim., 2012, 110, 647; DOI: https://doi.org/10.1007/s10973-011-1877-y.

Author information

Authors and Affiliations

Corresponding author

Additional information

Published in Russian in Izvestiya AkademiiNauk. Seriya Khimicheskaya, No. 9, pp. 1682–1689, September, 2021.

This work was carried out within the framework of the State Assignment to the Institute of Solid State Chemistry and Mechanochemistry, Siberian Branch of the Russian Academy of Sciences (Project No. AAAA-A17-117030310277-6) and with the financial support from the Russian Foundation for Basic Research (Project No. 18-29-11064).

This paper does not contain descriptions of studies on animals or humans.

The authors declare no competing interests.

Rights and permissions

About this article

Cite this article

Bulina, N.V., Titkov, A.I., Isaev, D.D. et al. Selective laser melting of Zn-Si-substituted hydroxyapatite. Russ Chem Bull 70, 1682–1689 (2021). https://doi.org/10.1007/s11172-021-3270-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11172-021-3270-8