Abstract

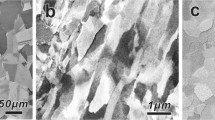

Microstructure evolution and mechanical behavior of ultrafine grained (UFG) commercially pure Ti produced by equal channel angular pressing (ECAP) were investigated. Repetitive pressings of the same sample were performed to six passes at 683 K, using the procedure designated as route B c . After the sixth pass was finished, recrystallized grains were observed as similar as the fourth pass. The average size of the recrystallized grains was approximately 0.3 μm. The hardness value (H v ) continuously increases with decreasing grain size. The H v values are in good agreement with the other experimental data of Ti produced by severe plastic deformation processes. The similar slop k H suggests that these microstructures have similar density of dislocations in the grains produced by the severe plastic deformation processes such as torsion straining, multiple forging, and ECAP. The grain size dependence of k y in the present samples is 7.9 \( MPa\sqrt m \). After six-pass ECAP, the ultimate tensile strength was increased by 60%. This is most likely due to considerable grain refinement through severe deformation by ECAP. The standard Hall–Petch relation for yield strength and hardness in the ECAPed Ti implies that the ECAPed Ti samples have similar texture and that the effect of grain size on strength may prevail over the effect of texture on the strength in Ti.

Similar content being viewed by others

References

R.Z. Valiev, E.V. Kozlov, Y.F. Ivanov, J. Lian, A.A. Nazarov, B. Baudelet, Acta Metall. Mat. 42, 2467–2475 (1994)

A. Yamashita, M. Furukawa, Z. Horita, T.G. Langdon, Metall. Mat. Trans. 29A, 2245–2252 (1998)

Y. Zhu, T. Lowe, T.G. Langdon, Scripta Mater. 51, 825–830 (2004)

W.J. Kim, C.Y. Hyun, H.K. Kim, Scripta Mater. 54, 1745–1750 (2006)

A. Vinogradov, V. Stolyarov, S. Hashimoto, R.Z. Valiev, Mater. Sci. Eng. A318, 163–173 (2001)

A.V. Sergueeva, V.V. Stolyarov, R.Z. Valiev, A.K. Mukherjee, Scripta Mater. 45, 747–752 (2001)

G.A. Salishchev, R.M. Galeyev, S.P. Malysheva, M.M. Myshlyaev, NanoStruct. Mater. 11, 407–414 (1999)

H.K. Kim, W.J. Kim, Mater. Sci. Eng. A385, 300–308 (2004)

H. Hasegawa, S. Komura, A. Utsunomiya, Z. Horita, M. Furukawa, M. Nemoto, T.G. Langdon, Mater. Sci. Eng. A265, 188–196 (1999)

A.A. Salem, S.R. Kalidindi, R.D. Doherty, Scripta Mater. 46, 419–423 (2002)

Y.N. Wang, C.I. Chang, C.J. Lee, H.K. Lin, J.C. Huang, Scripta Mater. 55, 637–640 (2006)

M.F. Ashby, D.R.H. Jones, Engineering Materials 1 (Pergamon Press, Oxford, 1980), p. 105

D.R. Fang, Q.Q. Duan, N.Q. Zhao, J.J. Li, S.D. Wu, Z.F. Zhang, Mater. Sci. Eng. A459, 137–144 (2007)

V.V. Stolyarov, I.V. Alexandrov, Y.R. Kolobov, M. Zhu, Y. Zhu, T. Lowe, in Proc. of 7th Int. Fatigue, Congress, Beijing, P.R. China (Eds: X.R. Wu, Z.G. Wang), Higher Education Press, Beijing, China, 1345, (1999)

A. Vinogradov, S. Hashimoto, Adv. Eng. Mater. 5, 351–358 (2003)

N.G. Turner, W.T. Roberts, Trans. AIME. 242, 1223–1230 (1968)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hyun, CY., Lee, JH. & Kim, HK. Microstructures and mechanical properties of ultrafine grained pure Ti produced by severe plastic deformation. Res Chem Intermed 36, 629–638 (2010). https://doi.org/10.1007/s11164-010-0198-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11164-010-0198-2