Abstract

The growing global population and higher living standards instantly demand the transition in the direction of a sustainable food system. A substantial section of means and agricultural lands are presently committed to protein-rich feed production to rear livestock for human consumption. Conversely, accelerated farming activities and the food industry have rendered a drastic increase in waste which impair the economic and environmental sustainability of the ecosystem. This situation emerges the need for developing an integrated technology for waste management and to improve sustainability footprints. Microbial protein (MP) production based on renewable electron and carbon sources has the potential as a substitute protein source. MP production for animal feed use is growing fast and is derived from bacteria, algae, and fungi including yeast. MP produced from all types of microbes is currently commercialized and in use. However, novel methods and processes are also under investigation to make MP production more economical and sustainable. Current research on MP has concentrated on the valorization of waste materials by using high protein content-containing microorganisms, which can then be used in animal feed. Using such kind of integrated approach, the agroindustry waste resources upcycling can contribute towards finding sustainable, cheaper, and environment-friendly protein sources. This review first describes the potential waste feedstock for MP production and summarizes the recent progress in the application of MP-producing microorganisms including fungus, yeast, bacteria, and phototrophic microbes. Bioprocesses, and production technology advances for MP production have been explored and discussed in detail. Finally, the MP application as animal feed, its challenges, and future perspectives in research have been evaluated.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The growing population and increasing living standards in developed and developing countries globally are anticipated to generate 1,250 million tonnes per year of worldwide meat demand by 2050 (Ritala et al. 2017). Livestock farming is a significant constituent of the agricultural economies of several countries. However, fulfilling the demand for increased meat and dairy products from conventional sources will not be sustainable due to the inferior conversion productivity of feed to protein (Aiking 2011; Alberti et al. 2022). Meat and dairy production is ever-increasing to meet the global demand for animal-derived protein. Livestock farming has long played an important role in sustaining the nutritional requirements of the world’s population. Rapid industrial and population development over the last few decades has led to the development of an emerging livestock industry in most agricultural countries (Mugagga and Nabaasa 2016). Traditional sources such as green fodder, and silage obtained from a variety of plants are not considered sustainable to meet the protein-rich feed requirement for animal farming (Newman et al. 2023). Therefore, new solutions are needed for a sustainable protein supply.

On the other hand, accelerated agriculture farming activities and food industry have rendered a drastic increase in agricultural waste (Garrity et al. 2010; Kesavan and Swaminathan 2008). About 4532 trillion British thermal units (TBtu) of biomass were generated only in the United States (USA), making up about 4.9% of the total primary energy consumption of the USA in 2020 (Dey et al. 2021). Agriculture-based industries also produced a large number of waste materials (Newman et al. 2023). Agriculture waste is originated from diverse waste stream sources across the farms including farms and agro-industries like animal manure, vegetable, and farm waste generated from production to packing activities (Ahmad Khorairi et al. 2021; Asiri and Chu 2022; Díaz-Vázquez et al. 2021). These wastes impair the economic and environmental sustainability of the ecosystem. For public health and wellbeing, valuable and state-of-the-art recycling methods are needed. This situation emerges the need for developing an integrated technology for waste management and to improve sustainability footprints. Currently, utilizing agriculture industry and food waste through recycling for resource recovery and manufacturing of value-added products has shown a great potential. An assimilated bio-refinery concept is steadily developing into an optimistic resolution with various products developments such as biofuels, biomaterials, and other bioactive compounds.

Ding et al. 2023; Gervasi et al. 2018; Jones et al. 2020; Nyyssölä et al. 2022; Raziq et al. 2020; Sharif et al. 2021; Zeng et al. 2022; Zhou et al. 2022a; Zhu et al. 2022). The protein produced in microbial cells also known as MP is an option with the potential to address the issue simultaneously. Microbial strains which are characterized by protein contents higher than 30% in their biomass and essential amino acids are considered more suitable for this purpose (Bourdichon et al. 2012; Jiang et al. 2022; Raziq et al. 2020; Yang et al. 2022; Zhou et al. 2022a). Microorganisms have been traditionally used for centuries in fermented foods. Microalgae and fungal-derived commercial products are already available in the market for human consumption with various commercial names such as Spirulina, Chlorella, Dunaliella salina, Aphanizomenon, QuornTM, and, Algaeon, primarily as health supplements (Ritala et al. 2017). Some strict regulatory frameworks in place are relevant for MP human consumption (Bourdichon et al. 2012). The microbial sources for animal feed production are generally wider compared to those permitted for human consumption. This is because the safety and quality standards for animal feed are typically different from those for human consumption. MP production for animal feed use is growing fast and is derived from bacteria, algae, and fungi (including yeast) (Asiri and Chu 2022; Khoshnevisan et al. 2022; Woolley et al. 2023; Zheng et al. 2023). Animal feed from sugar fermentation was produced in Finland in 1974 and the process was registered with the commercial name “PEKILO®” to be used in the European Union countries. MP produced from microbes is currently commercialized and in use as animal feed from companies like Uniprotein®, and Unibio A/S, Denmark, known as FeedKind® (Alloul et al. 2022). Very recently, Gulf Biotech Qatar, and Unibio, have partnered to establish a production facility in Qatar, the gulf’s first natural gas to protein plant, to produce initially 6,000 tonnes of UniProtein® as a feed for aquaculture livestock (Unibio 2022). While several companies are working on natural-methane-fed and other edible food substrates MP production worldwide, yet, the production processes are expensive and not environment friendly due to the use of fossil and edible resources (Kalyuzhnaya et al. 2013). Therefore, cheaper and sustainable substrates are required resulting in the bacterial protein production roar.

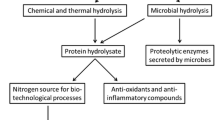

Current research on MP has concentrated on the valorization of organic waste materials by using high protein content containing microorganisms including fungus, yeast, algae, and bacteria, which can then be used in animal feed (Chandra et al. 2021; Hülsen et al. 2022a; Xu et al. 2020; Yang et al. 2022; Zhu et al. 2022). Fig. 1 presents a schematic of MP production from agroindustrial waste using different microorganisms. Microorganisms use inexpensive and plentiful agro-waste for metabolism and to produce biomass, which may decrease the environmental impact. Start-up company eniferBio has recently updated the PEKILO® process using different industrial by-products as a substrate to produce the MP biomass validated for aquafeed and aiming to extend it further for human consumption (eniferBio 2022). The study of optimal fermentation conditions, cheap substrates, and various microorganisms is on the rise. The objective of this review is to perform a comprehensive analysis of the applications and research being carried out in the field of MP production from waste substrates for animal feed production in one place. The potential waste substrates for MP production, suitable microorganisms, bioprocesses, and production technology advances for MP production have been explored and discussed in detail. Finally, the MP application as animal feed, its challenges, and future perspectives in research in MP have been evaluated.

2 Agriculture and food waste as feedstock for MP production

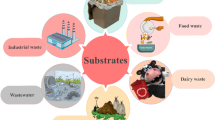

Carbon and nitrogen are required with proper carbon-to-nitrogen ratios for the growth of microorganisms and MP production (Ugalde and Castrillo 2002). Nitrogen from different sources in form of ammonia, ammonium salt, nitrite, and/or nitrate is used by microbes. Typically 45–75% of the total MP production cost comes from the carbon feedstock and 7–15% of the total cost is from nitrogen sources (Nyyssölä et al. 2022). In the case of algal MP, carbon in the atmosphere is free, however, the cost of agitation to dissolve it into dense algal culture is high (Wang et al. 2022; Xu et al. 2021b). Globally a large number of wastes rich in organics and nutrients are produced from agriculture forms, food processing units, restaurants, supermarkets, and consumers including lignocellulose wastes such as corn, rice, and wheat (Capanoglu et al. 2022; Chandra et al. 2021; Rosenboom et al. 2022; Talan et al. 2022; Türker et al. 2022). These waste materials are potential raw feedstock for the production of MP (Yang et al. 2022). Industrial and agricultural wastes have high biological oxygen demand (BOD) which can cause significant environmental pollution (Alloul et al. 2019; Capson-Tojo et al. 2020; Tropea et al. 2022). Although so far, commercially available MP is mostly produced from edible agriculture substrates and carbohydrate-derived materials with carbon as necessary constituents are usually employed for this objective, the current focus is on utilizing waste materials for MP synthesis for a sustainable environment and on making the process cost-effective (Thiviya et al. 2022b; Türker et al. 2022; Yang et al. 2022; Zeng et al. 2023). Waste feedstock selection is done based on their availability in the vicinity of the production site. A variety of agriculture and food-oriented solid wastes including rice straw, corncob starch waste, wheat bran, banana peel, pineapple waste, watermelon, potato bagasse, fermented grass, tofu and cheese wastes, sugarcane bagasse, banana, coconut, grape, and mango waste have been studied and reported as a feedstock for MP production (Asiri and Chu 2022; Chandra et al. 2021; Farhan et al. 2021; Kurcz et al. 2018; Nascimento et al. 2022; Sakarika et al. 2022; Thiviya et al. 2022a; Thiviya et al. 2022b; Tropea et al. 2022; Voutilainen et al. 2021; Zhu et al. 2022). Several liquid substrates are also reported for MP production such as waste milk, non-dairy creamer wastewater, sugar beet pulp, cheese whey, sugar refinery wastewater, pineapple peel juice, pumpkin, farm manure, biogas slurry, rice washing water, latex rubber sheet wastewater, olive mill wastewater, sugarcane molasses, soybean molasses, food waste-derived volatile fatty acids, and municipal wastewater treatment effluent (Acosta et al. 2020; Bertasini et al. 2022; Cao et al. 2021; Ding et al. 2023; Pillaca-Pullo et al. 2023; Yang et al. 2017; Zha et al. 2021).

Annually millions of tons of agricultural and food waste is generated globally and its inadequate management and dumping pose adverse impacts on the environment and are detrimental to the ecosystem (Nyyssölä et al. 2022). Consequently, sustainable and environment-friendly conversion of organic and nutrient-rich waste to valuable products has become an important objective worldwide (Chandra et al. 2021; Dey et al. 2021; Nyyssölä et al. 2022). With proper management and processing, agro-food waste can play a vital role in the sustainability of the ecosystem and energy security. Overall, the choice of waste feedstock for MP production depends on factors such as availability, cost, and suitability for the production process (Awad Saad Allah 2021; Capanoglu et al. 2022; Kumar et al. 2021; Leite et al. 2021; Reihani and Khosravi-Darani 2019). It is important to consider the potential impacts of using agricultural waste feedstocks for MP production on the production process and the environmental impacts of the production process itself. Table 1 presents a list of the most frequently reported agro-food wastes used for MP production along with the type of microbes used. Different waste substrates that can be used for MP production have their advantages and disadvantages. For instance, wheat bran, sugarcane bagasse, and sugar beet pulp are the byproduct of wheat processing and sugar processing, respectively, and can be used as a feedstock for MP production (Aker and Robinson 1987; Puligundla and Mok 2021; Saejung and Salasook 2020; Yunus et al. 2015). These waste feedstocks are relatively inexpensive and abundant, and their use does not compete with their use as a food or feed crop. However, their low protein content may limit their suitability for some MP production processes. Similarly, corn stover and rice straw are byproducts of harvesting that can be used as feedstock for MP production (Voutilainen et al. 2021). Both are relatively abundant and low-cost feedstock. For effective biomass valorization into MP, biodegradation and depolymerization of lignin is required which can be done only by selected microbes capable of producing lignin-degrading enzymes such as Bacillus sp. LD2, Aneurinibacillus sp. and Trichoderma harzianum (Sharma et al. 2022). It is important to consider the potential impacts of using agricultural wastes for MP production on waste reduction and environmental sustainability, as well as the quality and safety of the resulting MP product.

The use of agro-food waste for MP production must comply with relevant regulatory standards, including those related to food and feed safety, environmental protection, and animal feed which depend on several factors, including the type of waste, the source of waste, and the intended use of the MP (Janssen et al. 2022; Nyyssölä et al. 2022; Vethathirri et al. 2021; Voutilainen et al. 2021; Wadhwa and Bakshi 2016). Regulatory standards may differ between countries or regions, and it is important to consult local regulations and guidelines to determine the suitability of specific types of agricultural waste. For instance, in the United States, the Food and Drug Administration (FDA) regulates animal feed and sets standards for animal food ingredients, including MP (Jonaitis et al. 2022). The FDA generally permits the use of MP in animal feed, but it must meet certain requirements for safety and nutrition. In Europe, MP production from organic waste for animal feed must comply with regulations set forth by the European Union (EU)'s regulations which include the General Food Law Regulation (EC) No. 178/2002, which sets out the general principles of food safety, and the Novel Food Regulation (EC) No. 2015/2283, which establishes requirements for novel foods, including MP (EFSA Panel on Dietetic Products et al. 2016; EFSA Panel on Nutrition et al. 2019; Lähteenmäki-Uutela et al. 2021). Similarly in Japan, MP production from agro-food waste and municipal waste must comply with regulations set forth by the Ministry of Agriculture, Forestry, and Fisheries (MAFF) and the Ministry of Health, Labour, and Welfare (MHLW). MAFF regulates animal feed, including MP, and requires that it be manufactured following Good Feed Manufacturing Practices (GFMP) (Kondo and Taguchi 2022). MHLW regulates food safety and requires that MP intended for human consumption meet certain safety standards. Globally, the final product MP as animal feed should be tested for purity, safety, and nutritional value, and it should be labeled and marketed according to applicable regulations and guidelines (Pereira et al. 2022). Overall, the suitability of agricultural waste for animal feed production will depend on a range of factors, and compliance with regulatory standards will be essential to ensure the safety and quality of the feed.

3 Microorganisms for MP production

A wide variety of microorganisms have shown the potential to produce MP including heterotrophic bacteria, fungi, microalgae, chemoautotrophs, and methylotrophs (Nyyssölä et al. 2022). A detailed description of the microbes used for protein-rich biomass production is provided below.

3.1 Yeast and fungi

Yeast and fungi have been exclusively used to carry out the commercial-scale industrial synthesis of MP in the past due to their promising balanced amino acid profile making it a complete protein source. Yeast has been used historically as animal and human food and is an aspiring MP candidate (Nyyssölä et al. 2022). Many fungal species are being used as MP and are available in the market with commercial brand names. For instance, QuornTM extracted from the filamentous fungus F. venenatum was launched decades ago by Marlow Foods (UK) and is utilized for human consumption extensively (Wiebe 2004). The fungal MPs have normally a balanced composition of lipids, protein, fiber, and amino acids meeting the FAO guidelines for food supplements (Groenewald et al. 2014). Yeast and fungal MP can be applied to not only enhance the nutritional quality of food products but can also improve the functional properties such as texture, and emulsifying capability (Barzee et al. 2021; Sharif et al. 2021; Wiebe 2004). Nevertheless, there is a need to consider the possible production of mycotoxins while working with a few species like Fusarium and Aspergillus (Barzee et al. 2021). Furthermore, yeast MP can be utilized as probiotics, has higher vitamin B. composition, and comprises relatively lower nucleic acid (5–12%) as compared to bacterial MP (8–14%) which reduces health dangers and limits the downstream treatment cost (Alkalbani et al. 2022; Sen and Mansell 2020; Yao et al. 2020). Saccharomyces cerevisiae (S. cerevisiae) species have been extensively investigated for different applications, including MP production (Abdelwahab et al. 2020; Dunuweera et al. 2021; Gunun et al. 2022; Li et al. 2022a; Sen and Mansell 2020; Tropea et al. 2022). S. cerevisiae, also known as Brewer’s yeast, is traditionally used for the production of yeast extracts (Dunuweera et al. 2021; Farhan et al. 2021). Yarrowia lipolytica (Y. lipolytica) is another yeast specie that is being applied in the biotechnology industry owing to its ability to utilize numerous carbon substrates and synthesize MP with high-quality lipids (Groenewald et al. 2014; Li et al. 2022a; Yang et al. 2022). European Food Safety Authority (EFSA), consequently, granted and accepted Y. lipolytica MP as a food as requested by the European Commission (EFSA Panel on Nutrition et al. 2019). The filamentous fungus Paecilomyces varioti has long been utilized for a registered PEKILO® process to produce MP for animal feed production (eniferBio 2022). Aspergillus oryzae (A.oryzae) is another filamentous fungus that is most studied and applied at the industrial scale, particularly in Asian countries like Korea, Japan, and China for the production of several fermented products (Ferreira et al. 2016). Yeast Candida utilis (C. utilis) has been approved as safe food and feed supplement by the China Food and Drug Administration and is included in the Generally Recognized as Safe (GRAS) list by the United States (Kurcz et al. 2018). C. utilis is currently being studied a lot to produce MP for safe and robust production of MP and has shown a great perspective for the synthesis of edible MP for human and animal consumption because of its higher yield, protein contents, growth rate, and capability to utilize different substrates as nutrients source (Carranza-Méndez et al. 2022; Ding et al. 2023; Kurcz et al. 2018; Li et al. 2022a; Yang et al. 2021c). C. utilis yeasts have a vitamin B complex and can produce a steroid compound called ergosterol which can immediately be converted to vitamin D2 (Dunuweera et al. 2021). Candida spp. are among the most studied microbes for MP production because of their high growth rates and low energy metabolism at room temperature. C. sorboxylosa, C. Lipolytica, and C. parapsilosis have been recently reported to produce MP using different waste materials as feedstock (Coimbra et al. 2021; Pillaca-Pullo et al. 2023; Rages et al. 2021). Several other yeast strains are under investigation and have shown potential to produce MP for dietary applications such as Galactomyces geotrichum, Candida tropicalis, Debaryomyces hansenii, Pichia guilliermondii, Pichia kudriavzevii, Wickerhamomyces anomalus, Pichia jadinii, Nectaromyces rattus (Dias et al. 2021; Su et al. 2021; Zhang et al. 2021; Zhou et al. 2022a). Hashem et. al. has recently investigated few non-conventional yeast strains like Hanseniaspora guilliermondii, Hanseniaspora uvarum, Issatchenkia orientalis, and Cyberlindnera fabianii for MP production and reported that these newly isolated strains could be promising candidate for MP synthesis (Hashem et al. 2022).

Furthermore, the interest in the use of mixed yeast cultures for MP production is growing (Areniello et al. 2023). The use of mixed culture is advantageous due to the wider range of hydrolytic activities performed by the diverse culture, enhancing the utilization of complex substrates. Such as lignocellulosic raw materials require several enzymes for their efficient hydrolysis and a mixed fungal culture can address this by producing different enzymes (Salazar-López et al. 2022). Moreover, the metabolic products of one species may work synergistically by catabolizing various feedstocks (Vethathirri et al. 2021). Mixed microbial cultures have been reported to increase the nutritional content, by balancing the composition of proteins, vitamins, and lipids. However, controlling and optimizing the operational parameters for MP production in mixed culture may be more complicated and needs careful design and biochemical reaction control (Hashempour-Baltork et al. 2022). Moreover, the production of toxic secondary metabolites and process inhibitors is another challenge that needs to be addressed in the mixed culture production process (Nyyssölä et al. 2022).

3.2 Microalgae and photosynthetic bacteria

Microalgae are considered a great source of MP due to their high protein and amino acid contents. Microalgae can utilize various waste substrates as nutrient sources to produce MP as an alternative to soy feed for protein-rich animal feed (Janssen et al. 2022). Some of the studies of algae biomass for MP production include Chlorella (C.) Vulgaris, C. pyrenoidosa, C. luteoviris, C. robusta, Arthrospira (A.) maxima, A. platensis, Tetraselmis chui, Odontella aurita, Nannochloropsis oceanica, Nannochloropsis gaditana, Dunaliella salina, Euglena gracilis and Galdieria sulphuraria (Abiusi et al. 2022; Muys et al. 2019; Nascimento et al. 2022; Sui and Vlaeminck 2020). Microalgal biomass protein content ranges from 30–80%, for different strains (Sui and Vlaeminck 2020). Microalgae can fix carbon dioxide through photosynthesis (Almomani et al. 2019b). Microalgae like Scenedesmus obliquus (S. obliquus) have the potential to fix higher concentrations of CO2 as shown in a recent study (Molitor et al. 2019). In this study, the growth rate of S. obliquus at 2.5% CO2 surpassed all earlier reported values and growth was not too much affected even at 35% CO2 with amino acid content comparable to that of soy. Cyanobacteria also known as blue-green algae are usually categorized together with microalgae due to their photosynthetic ability and phenotype. Spirulina and Chlorella species are the most famous cyanobacteria having protein contents of up to 50–70% and are currently commercially marketed as human and animal food. Presently, the projected production of Chlorella and Spirulina is about 6600 and 12,000 tons d.m/year worldwide, respectively (García et al. 2017). Cyanobacteria are not rich only in protein but also have the valuable composition of other essential food elements such as small peptides, B12, B2, B1, B3, E-vitamins, lipids, and pigments. Nevertheless, Spirulina MP has lower concentrations of amino acids like cysteine, methionine, and lysine which make it not a favorable protein for human food (Abiusi et al. 2022; Muys et al. 2019). Because of this, most of the current commercial companies' focus is to use Spirulina as a feed product with advantageous features for animal feed and aquaculture (Vethathirri et al. 2021).

Photosynthetic bacteria (PSB) are another group of protein-rich microorganisms that have shown the potential to produce MP with a variety of metabolic abilities (Zhu et al. 2022). PSB can not only produce MP but also other high-quality products including hydrogen and biodiesel (Li et al. 2019). Some of the most studies of PSB biomass for MP production include Rhodobacter capsulatus, Ectothiorhodospira, Rhodopseudomonas faecalis, Rhodobacter sphaeroides, Rhodopseudomonas palustris (Cao et al. 2021; Deseure et al. 2021; Saejung and Chanthakhot 2021; Saejung and Sanusan 2021; Yu et al. 2021, 2022). Although there are many types of PSB microbes based on the metabolism and operational parameters requirements, it comprises four key families including purple non-sulfur bacteria (PNSB) such as Rhodospirillaceae, purple sulfur bacteria (PB) like Chromatiaceae, green sulfur bacteria (GSB) like Chlorobiaceae and gliding filamentous green sulfur bacteria (GFB) such as Chloroflexaceae (Lu et al. 2019). PSB has demonstrated significant MP production efficiency with high protein productivity (about 150 mg/L·d) (Cao et al. 2021). PSB has shown potential as an additive for the synthesis of value added-products because of the presence of several important components like coenzyme Q10, nicotinic acid, pantothenic acid, 5-aminolevulinic acid, carotenoids, and pigments like carotenoid and bacteriochlorin. These pigments can produce red, purple, or orange colors and can be used as natural color additives for dairy and bakery products (Lu et al. 2019).

3.3 Chemoautotrophs and methylotrophs

Although various bacterial species are being studied currently for MP production by heterotrophic bacteria by fermentation, commercial production of bacterial MP has mainly focused on the use of chemoautotrophs and methanotrophic species using gaseous substrates for growth (Martin et al. 2013; Sakarika et al. 2022; Woolley et al. 2023). Methanotrophic species oxidize methane to formaldehyde through ribulose monophosphate or serine pathways. MP production by methanotrophs was long ago started on a commercial scale in the late 1970s nevertheless manufacturing was stopped due to economic issues. However, methanotrophic MP has again come to attention for the production of microbial feed, and currently, various commercial products are marketed with brand names like KnipBio (USA), UniProtein® (Unibio, Denmark), and FeedKind® (Calysta, USA) (Khoshnevisan et al. 2022; Sakarika et al. 2022; Woolley et al. 2023; Xu et al. 2021b). KnipBio is the first genetically modified MP product that has achieved GRAS status from the United States Food and Drug Administration (Nyyssölä et al. 2022). Several methanotrophic microbes are prevalently reported for MP synthesis from biogas including Methylococcales, Methylococcus capsulatus, Methylocystis, Methylophilus, Rurimicrobium, Comamonadaceae, Methylophilale, Methylomicrobium buryatense, Methylocystis parvus, Methylomonas, Methylocapsa acidiphila, Methylomonas methanica, and Methylomicrobium alcaliphilum (Jintasataporn et al. 2021; Woolley et al. 2023; Xu et al. 2021a, 2020; Zha et al. 2021). Moreover, several methanotrophs such as Methyloferula, Methylococcus, and Methylocaldum can fix CO2, making them advantageous to grow on biogas utilizing both CH4 and CO2 (Kim et al. 2022; Kulkarni et al. 2021; Salehi and Chaiprapat 2022). Autotrophically growing hydrogen oxidizing bacteria (HOB) also known as Knallgas bacteria energize their metabolism using hydrogen as the electron donor in presence of oxygen while fixing CO2 to biomass (Jiang et al. 2022). The common HOB employed for biogas-based MP production are Alcaligenes eutrophus Z, Hydrogenomonas, Pseudomonas, Aquaspirillum, Paracoccus denitrificans Y5, Ralstonia eutropha B5786, Cupriavidus necator H16, and Paracoccus versutus D6 (Jiang et al. 2022). Hydrogen is oxidized both by aerobic and anaerobic bacteria. In anaerobic oxidation, CO2 is fixed through the reductive acetyl-CoA pathway, in which carbon is mainly converted to organic co-products such as ethanol and acetate rather than cell biomass. Whereas, in aerobic hydrogen oxidation, carbon dioxide is assimilated through the reverse tricarboxylic acid cycle to produce the cell mass (Muñoz et al. 2015; Pander et al. 2020; Sakarika et al. 2022). Therefore, the current industrial process is focused on the synthesis of value-added chemicals such as ethanol and acetate instead of cell biomass for MP production (Pander et al. 2020). A two-step process has been suggested for MP production by acetogens in which firstly carbon dioxide is reduced to acetate by acetogenic bacteria, followed by the cultivation of heterotrophic yeast or fungal species using produced acetate as the carbon source (Bolognesi et al. 2022).

4 MP production processes

MP is generally produced by the fermentation process using particular microorganisms cultivated on appropriate substrates (Ding et al. 2023). For this purpose, suitable microorganisms are isolated from different sources including water, air, and soil samples, and then growth conditions are optimized for maximum product yields (Kurcz et al. 2018). A detail description is provided below.

4.1 Direct feedstock fermentation by bacteria and yeast

The fermentation process can be divided into submerged, semisolid, and solid-state fermentation. In the submerged fermentation process, the substrate with the required nutrients for microbial growth is always in liquid form (Ding et al. 2023). Submerged fermentation can be carried out in batch mode, fed-batch reactor, and/or in a continuous operating reactor with continuous harvesting of the biomass followed by separation and biomass drying. The fed-batch fermentation process is advantageous as compared to the batch system, for instance, it offers a higher biomass growth rate which can increase the fermentation performance. However, it is important to optimize the different factors affecting the fermentation efficiency, such as pH, temperature, oxygen level, nutrients concentration (e.g. nitrogen and phosphorus), and C/N ratios (Ding et al. 2023; Gervasi et al. 2018; Nyyssölä et al. 2022; Ugalde and Castrillo 2002; Zeng et al. 2022). Heat is generated in this process and aeration is continuously performed to properly cool down the bioreactor system. So usually, the fermenter setup is provided with sensors and regulators for agitation, pH, dissolved oxygen, and temperature. Several organic wastes rich in nutrients are being explored for fungal and yeast biomass production. Candida utilis MP was produced using biogas slurry as ammonia nitrogen and acetate, lactate, and sugar as carbon sources with maximum biomass production of 14.8 g dried biomass/L containing 46.5% protein content. The C/N ratio showed a significant impact on the biomass yield where the increase in C/N ratio from 3 to 15, resulted in the reduction of biomass yield depicting that a controlled C/N ratio of 3, is beneficial (Ding et al. 2023). Controlling the pH is an important factor as it can affect biomass growth by changing enzyme action, and membrane permeability. However, different yeast strains have different pH ranges for optimal microbial growth. For instance, C. utilis can grow in a wide-ranging pH of 3.5–8.0 (Ding et al. 2023), whereas, the optimum pH for Galactomyces candidum and Nectaromyces rattus growth is pH 5.5 (Zhou et al. 2022a).

Another factor that can significantly impact MP production is phosphorus concentration. Phosphorus is an essential nutrient for microorganisms, and it plays a crucial role in various cellular processes, including energy metabolism, nucleic acid, and protein synthesis. However, excess phosphorus in the growth medium can lead to the formation of insoluble phosphates, which can reduce the availability of phosphorus for microbial growth and protein synthesis (Goonesekera et al. 2022). This can negatively affect the yield and quality of the MP produced. On the other hand, inadequate phosphorus levels can also limit MP production by slowing down cell growth and reducing protein synthesis (Goonesekera et al. 2022; Quan et al. 2001; Stern and Hoover 1979; Zhu et al. 2020). Therefore, it is crucial to maintain an optimal phosphorus concentration in the growth medium to maximize MP production. Furthermore, excess phosphorus can lead to environmental pollution, as it can be discharged into water bodies, causing eutrophication and algal blooms (Van Heyst et al. 2022; Zhou et al. 2022b). Therefore, it is essential to develop sustainable methods for MP production that take into account the optimal use of nutrients and minimize environmental impacts.

The digestate from anaerobic digestion (AD) of numerous organic wastes is usually rich in acetate and NH4-N and in a recent study pretreated digestate was investigated as an alternate substrate to produce fungal/yeast MP by fermentation (Zeng et al. 2023). A hybrid electrochemical-membrane fermentation process was employed for the recovery of ammonium and acetate from digestate, followed by fermentation processes using S. cerevisiae yeast. Acetate and ammonium as feedstock were recovered by electrodialysis (ED) and fed to S. cerevisiae for MP productions of about 0.76–0.86 g/L (Fig. 2). The separation process to recover the biomass is chosen based on the type of microbes used for MP production. For instance, filamentous fungi are usually separated by filtration whereas bacteria are collected by the centrifugation process. Moreover, it is important to recover the maximum quantity of nutrient-rich water contents which can be obtained after drying.

A Graphical depiction of acetate and ammonium recovery from anaerobic digestate for MP synthesis by an integrated electrochemical-membrane fermentation system. B Acetate and C ammonia recovery, D & E yeast biomass growth using integrated process (Reproduced from (Zeng et al.) with permission from Elsevier 2023)

In the semisolid fermentation process, the substrate is used in the solid state. The MP production through this process involves the selection of suitable media preparation with an explicit carbon source, accurate media decontamination, careful selection of microbial strain, biomass separation, and final product processing (Ritala et al. 2017; Thiviya et al. 2022b). Various substrates as a carbon source are employed for this objective such as different fruit and vegetable wastes, food industries waste, carbon oxide, polysaccharides, several gaseous hydrocarbons, ethanol, methanol, effluents of different industrial effluents including breweries and other solid organic waste materials (Areniello et al. 2022; Puligundla and Mok 2021; Thiviya et al. 2022b; Zhang et al. 2018). This type of fermentation requires a specific type of bioreactor carefully designed to identify mass and energy conversion and transportation (Selvaraj et al. 2021; Sharif et al. 2021). Biomass cultivation involves several operations such as multiphase mixing using stirring, oxygen transport to microbes from the gaseous bubble phase to the liquid phase, and eventually heat transfer from the aqueous phase to the environs (Molfetta et al. 2022; Sharif et al. 2021; Śliżewska and Chlebicz-Wójcik 2020). This fermentation process needs higher initial capital investment and operating costs.

While fungal MP is usually synthesized in submerged fermentations there is a growing focus on employing solid-state fermentation to provide physical support for the microbial culture and deliver nutrients for the production of various value-added products (Cerda et al. 2019; Kumar et al. 2021; Leite et al. 2021; Melnichuk et al. 2020; Sharif et al. 2021; Vauris et al. 2022). Solid-state fermentation offers the advantages of higher nutritional value, less effluent generation, and lower energy costs (Kumar et al. 2021). MP production in solid-state fermentation can be carried out using various microbes under different environmental conditions in a variety of reactor designs (Godoy et al. 2018; Vauris et al. 2022). The process is not only suitable for the synthesis of MP but also capable of producing various other products such as ethanol, enzymes, organic acids, peptides, several vitamins, and flavors (Aita et al. 2019; Cerda et al. 2019; Godoy et al. 2018; Hashempour-Baltork et al. 2022; Li et al. 2022a; Liu et al. 2018; Melnichuk et al. 2020; Vauris et al. 2022; Zhang et al. 2018). As evident by the name, the process needs feedstock in pure solid form such as agriculture form waste like wheat bran and/or rice bran, orange pulp, molasses, brewer's spent grain, poultry litter; and waste capsicum powder, etc. (Aita et al. 2019; Olukomaiya et al. 2019; Sharif et al. 2021). A feedstock is inoculated with the selected microbes and spread on the flatbeds with controlled operating parameters like proper moisture level (60–65%), continuous oxygen supply, controlled temperature, essential nutrient concentration, and pH (Aita et al. 2019; Kumar et al. 2021). Though, the formation of unexpected toxic secondary byproducts poses a significant risk in using such complex waste materials. Therefore, the recent research focus is to develop novel synthesis processes to improve the utilization efficiency of waste byproducts from further complex waste substrates. In this effort, an integrated approach to employ both solid-state and submerged fermentations have been proposed (Khonngam and Salakkam 2019; Liu et al. 2020; Martău et al. 2021; Olukomaiya et al. 2019; Premalatha et al.; Villegas-Méndez et al. 2022).

Substrate composition, concentration, presence of anions and cations, and operational parameters like reaction time, dissolved oxygen, pH, and temperature strongly influence MP production through the fermentation process. The substrate cost for bioprocessing makes up half of the total production cost (Padoan et al. 2022; Zeng et al. 2022). Current research on MP production is focused on finding less expensive feedstock at large-scale. The cost of the substrate and strict sterilization are two major issues when utilizing pure culture fermentation. Currently, research on the valorization of agriculture and FW is gaining growing interest, and researchers all over the world are working on it by proposing numerous strategies to reuse food waste (Zeng et al. 2022). Organic waste components from the agriculture and food industry have been recognized as low-cost feedstock, to produce several biologically driven value-added products by fermentation. Agriculture residues including rice and wheat straw, cassava waste, orange peel, sugarcane, paper mill waste, sugar industry wastewater (Saejung and Salasook 2020), sawdust, corn cobs, sugar beet pulp, coconut waste, grape waste, mango waste, etc. have been studied as substrates for MP production employing various microorganisms (Cao et al. 2021). Sugar industry effluents are highly polluted and generated from different processes including sugarcane washing, crushing, evaporation, crystallization, molasses preparation, and end products refining. Sugar-industry wastewater is largely composed of organic carbon with high chemical oxygen demand (COD) and therefore can be a good feedstock for MP production by cultivating microbes (Kushwaha 2015). Chewapat et. al. studied MP production using sugar industry wastewater as a carbon source and reported R. faecalis biomass with more than 50% protein contents which are suitable to be used as animal feed while simultaneously reducing 80% of the COD (Saejung and Salasook 2020). The experimental setup involved batch cultivation of R. faecalis in a 3 L photo-bioreactor using sugar industry waste as a co-substrate. The biomass produced was reported to have high concentrations of essential amino acids like leucine and lysine.

Waste generated from agroindustry and some other waste streams are rich in short-chain and long-chain organic acids, however, the utilization of these organic acids by different microbes to produce MP is still not well understood. There is a need to understand the biomass composition and protein contents of the MP produced by waste feeds tock rich in organic acids content. Recently, Zeng et al. employed different organic acids to produce S. cerevisiae MP production and reported 0.94 g/L MP at 20 g/L of acetate COD (Zeng et al. 2022). S. cerevisiae biomass and protein concentration were found to increase with increasing acetate concentration. Moreover, acetic acid and lactic acid were described as suitable short-chain organic acids for S. cerevisiae MP production. In another set of experiments, it was found that a mixture of acetate with lactate, oleate, or linoleate enhanced MP production. Long-chain fatty acids linoleate and oleate are commonly found in the anaerobic digestate of food waste and can be a good co-substrate for MP production as shown in this study.

While these waste materials are excellent raw feedstock for the synthesis of MP, there is a need to pretreat it to improve its physicochemical and biological characteristics (Chandra et al. 2021; Dey et al. 2021; Hashem et al. 2022; Hashempour-Baltork et al. 2022; Ugalde and Castrillo 2002; Yang et al. 2022). Several physicochemical and biological processes are employed for the treatment. It is important to find out the optimal conversion process that can liberate maximum monomers from the organic waste to get the highest availability of secondary metabolites like carbon sources, nutrients, phenols, starch and cellulose, proteins, and lipids (Godoy et al. 2018; Hashempour-Baltork et al. 2022; Sakarika et al. 2022; Suriyapha et al. 2020; Vauris et al. 2022; Yang et al. 2022; Zeng et al. 2023). These compounds are the secondary substrate for enzymatic hydrolysis and fermentation in the later stages of the MP production process. To achieve this, several approaches are being applied including combined physical/chemical and biological treatment of the substrate (Khonngam and Salakkam 2019; Li et al. 2022a; Newman et al. 2023; Xu et al. 2021a). Mechanical grinding, microwave, steam explosion, and hot water treatments are the method being used for physical pretreatments (Leite et al. 2021; Molfetta et al. 2022; Zhu et al. 2022). Whereas chemicals including strong acids are used to hydrolyze the biomass structure in chemical treatment. Biological pretreatment is carried out by employing commercial enzymes and/or selected microbes. However, recently researchers are working to use organic waste substrates directly for fermentation without pretreatments to reduce the costs (Gervasi et al. 2018). For instance, Teresa et al. (Gervasi et al. 2018) used S. cerevisiae to produce MP by aerobic fermentation from mixed fruit and vegetable FW without any pretreatments. The MP produced from the process has a protein content of 39.8% which was higher than many earlier reported studies. Another approach to avoid costly pretreatment is to use the digestate obtained after the digestion of waste materials. The anaerobic digestate comprising organic acids like acetate, lactate, and other long-term VFAs can be directly consumed by several fungal and bacterial strains such as S. cerevisiae with little pretreatment (Zeng et al. 2022).

4.2 Phototrophic processes

Microalgae, photosynthetic bacteria (PSB), and cyanobacteria are grown in open ponds or photobioreactors under control environment and operational parameters (Capson-Tojo et al. 2020; Janssen et al. 2022). High-intensity light exposure is the major requirement to cultivate microalgae and cyanobacteria in any kind of production setup. Algae cultivation in open ponds is generally considered suitable and economical, however, it has some drawbacks including low productivity and potential contamination issues. The growth of microbes in a photobioreactor can be affected by several factors including carbon and nitrogen sources, temperature, pH value, the chemical composition of the feedstock, light intensity, oxygen saturation level, and hydraulic retention time (Alloul et al. 2019; Almomani et al. 2019a; Capson-Tojo et al. 2020; Laskowska et al. 2017). The light-oxygen state is the most important operational parameter for phototrophic microbes. It is reported that a high NH4+−N concentration (2000 mg NH4+−N/L) improved the protein contents of PSB to 65.0% because it supplied suitable nitrogen resources for cell growth and synthesis of protein (Yang et al. 2017). Numerous agri-industrial wastewaters have been used for MP production in photobioreactors with reasonable protein contents (Alloul et al. 2019; Capson-Tojo et al. 2020; Hülsen et al. 2018a). The objective of current research is to produce microalgae biomass with high protein contents and recently few studies have investigated microalgae biomass even in extreme growing environments such as acidic pH 0 to 4 and temperature above 40 °C (Montenegro-Herrera et al. 2022). In another study, a combined microalgae Chlorella vulgaris and the methanotrophic system was investigated to convert biogas into MP (Wang et al. 2022).

In laboratory-scale investigations, flasks and small glass reactors (transparent acrylic material) are typically used for microbial growth experiments with magnetic stirring, artificial light, pumps for influent and effluent flows, pH, and thermometers for temperature monitoring (Liu et al. 2016; Meng et al. 2017; Yang et al. 2018). Several photobioreactor designs and operations strategies are proposed to enhance biomass yields. Flat panel photobioreactors with transparent flat vessels for suspended biomass growth have been used for both PBS and microalgae cultivation (Carone et al. 2022; Chen et al. 2011; Gabrielyan et al. 2022; Hülsen et al. 2022b; Lim et al. 2023; Maia et al. 2022; Ravi Kiran and Venkata Mohan 2022). A flat-panel photobioreactor was tested for growing Tetradesmus sp. SVMIICT4 algae biomass using diary wastewater as feedstock (Ravi Kiran and Venkata Mohan 2022). The bioreactor showed substantial carbon and nutrient utilization for biomass assimilation with protein contents of 19.52 mg/g. Figure 3A shows the graphical presentation of the flat panel photobioreactor utilized for the selected algae biomass growth. A pilot scale flat-panel vertical photobioreactor (70 L) has been employed for the cultivation of Chlorella sorokiniana algae biomass in semi-continuous mode with a biomass growth of 2.8 g dw/L (Fig. 3B and C) (Gabrielyan et al. 2022). Microalgae-based biotechnological processes are gaining importance for direct CO2 capture and high-quality biomass production for numerous industrial applications (Montenegro-Herrera et al. 2022). To capture atmospheric CO2 and improve microalgae growth, CO2 gas with controlled bubble size is fed to photobioreactors (Carone et al. 2022; Lim et al. 2023). Carone et. al. designed a new 1.3 cm thick alveolar flat panel photobioreactor to fix the CO2 and produce algae biomass of Acutodesmus obliquus aiming to increase the gas–liquid mass transfer coefficient (Fig. 3D) (Carone et al. 2022). The designed reactor achieved 64% CO2 fixation efficiency and biomass growth of 1.9 g dw/L under a controlled environment (Fig. 3E).

Different flat panel photobioreactors design and performance for algae biomass production. A Graphical presentation of flat panel photobioreactor using dairy wastewater for algal biomass production (Reproduced from (Ravi Kiran and Venkata Mohan 2022) with permission from Elsevier 2023) B General scheme of A flat-panel vertical photobioreactor for Cultivation of Chlorella sorokiniana and C photo of the main reactor units consisting of a reservoir, bottom, lid, Suspension, LED module, LED, power supply, platform, temperature indicator & sensor, supply tube, and sprayer (Reproduced from (Gabrielyan et al. 2022) with permission from the MDPI 2022). D Process diagram of the flat panel photobioreactor with microbubble for CO2 fixation E Algal biomass concentration in the flat panel photobioreactor (Reproduced from (Carone et al. 2022) with permission from Elsevier 2022)

Bio-electrochemical systems (BESs) have been applied for various applications including water/wastewater treatment and resource recovery. The application of BESs for microalgae growth has also gained attention in the last few years. The membranes provide an access to migrate the nutrients and can separate microalgae from aqueous phase solutions. BESs studies usually focus on single- and two-chamber microbial fuel cells and microbial electrochemical systems with high efficiency in organics utilization and nutrient recovery. Few researchers have investigated the use of the BESs system for protein-rich microalgae cultivation to produce MP (Pan et al. 2021). For instance, Pan et. al. reported the cultivation of Chlorella vulgaris in a three-chamber microalgal BES while using agro-industry wastewater for MP production and obtained a biomass growth of 0.87–1.11 g dw/L under an optimal operating environment. Similarly, several other studies have reported the potential of different BESs for microalgae growth with high protein contents (Bolognesi et al. 2022; Cevik et al. 2020; Elmaadawy et al. 2022; Elshobary et al. 2021; Jadhav et al. 2019; Sharma et al. 2020; Yang et al. 2021b).

Higher economic costs, light penetration, long microbial acclimatization period, and seasonal weather variations are among some of the obstacles inhibiting extensive MP generation by phototrophs from waste feedstock (Ayre et al. 2017). Because of the recent developments in PBS growth technology, MP production by PSB can address some of the issues that come upon in phototrophic systems. PSB are photo heterotrophs, using organic carbon as an anabolic substrate and infrared (IR) light spectrum for energy generation (Hülsen et al. 2018b). PSB has a faster growth rate as compared to algae and can utilize nutrients and organics from waste feedstock, simultaneously (Capson-Tojo et al. 2020). PSB has a unique metabolism pathway as it can execute photosynthesis, aerobic, and anaerobic fermentation depending upon the growth environment. Generally, dark-aerobic and light-anaerobic environment are considered suitable light-oxygen conditions for PSB growth. PSB can be produced in small households or large plants by maintaining the temperature around 23–39 °C, pH range 6.0–9.0, and light at about 100–200 μmol/m2/s in the bioreactors constructed of transparent glass containers, plastic bags, and/or ponds. PSB is produced by two different processes. The first is closed light-anaerobic cultivation mode and the second is known as the open light-micro aerobic process. In the anaerobic process, the medium is sterilized and inoculated with 20–50% PSB culture in the reactor containers where PSB is grown for 5–10 days under continuous stirring to keep the biomass flowing up to obtain light. In the open light-micro aerobic process, air stones are applied to provide a suitable micro aerobic environment under controlled light intensity, temperature, and pH like the anaerobic process. The oxygen concentration needs to be carefully controlled in this process as a higher oxygen level may impair the PSB photosynthesis leading to a decrease in biomass quality and quantity (Laskowska et al. 2017). The focus of most of the earlier studies was on the lab-scale operation to optimize the reactor design and operational parameters, however, there is a need to upscale the designed technology in an outdoor environment and demonstrate the technical performance in terms of biomass production and substrate utilization. In a recent study, a horizontal flat plate photobioreactor (10 m long) with 0.95 m3 volume was supplied with poultry processing wastewater for an extended period of 253 days under different operational schemes to grow PSB (Fig. 4A) (Hülsen et al. 2022b). The reactor was operated in microaerobic, and anaerobic modes and it was found that the anaerobic process showed higher performance in terms of PSB growth, whereas carbon and nutrient utilization was recorded maximum in anaerobic/aerobic integrated performance (Fig. 4B). The total relative abundance of PPB in the mixed microbial culture was over 56.0% when the reactor was operated under an optimal working environment (Fig. 4C).

A Schematic depiction of the photobioreactor for PSB growth on poultry wastewater (top) and pictures of the bioreactor with and without the UV–VIS absorbing foil (bottom). B biomass production during the whole operation period C Microbial community structure in the bioreactor during the different phases fed on poultry wastewater (Reproduced from (Hülsen et al. 2022b) with permission from Elsevier 2022). D Relative abundances based on 16S analysis for the 100 L photobioreactor fed with piggery wastewater (Reproduced from (Hülsen et al. 2022a) with permission from Elsevier 2022)

PSB can also grow at low light intensities and can acclimatize to low temperatures under anaerobic conditions. PSB tolerance towards high ammonia concentration and capacity to grow in outdoor systems make PSB a potential microbe for agri-industrial waste to produce MP. Illumination is the critical factor that enhances the overall phototrophic system cost, prohibiting its use for MP production. Recent studies are addressing this factor by employing sunlight as an energy source to reduce MP production costs by PSB (Capson-Tojo et al. 2020). Though, there are limited studies on actually using the mixed PSB culture in an outdoor environment for MP production (Hülsen et al. 2022a). Most of the experiments done are labs scale under controlled environmental conditions and the results from these studies cannot be directly generalized to real MP production systems from organic waste substrates. The use of organic waste as substrate for mixed PSB culture may not only impact biomass growth but also can significantly affect the produced biomass quality to be utilized as MP-based animal feed (Capson-Tojo et al. 2020).

4.3 Gas-based processes

Although direct fermentation is a well-established technology for MP production, there is a risk of potential bioaccumulation of heavy metals, pesticides, and chlorinated hydrocarbons present in agro-industrial waste (Luo et al. 2012; Martin et al. 2013; Puligundla and Mok 2021; Sakarika et al. 2022; Salehi and Chaiprapat 2022). This issue associated with the toxicity of these contaminants can be addressed by converting the wastes into a non-toxic substrate that can be easily used by microorganisms for example biogas production by AD of organic biomass (Acosta et al. 2020; Kim et al. 2022; Pander et al. 2020; van der Ha et al. 2012; Verbeeck et al. 2019). This approach is commercially more attractive as it can utilize different waste streams together for MP production. Figure 5 depicts the process integration of biogas production and liquid streams of the AD process to synthesize MP for animal feed production. The first step in this process is AD (co-digestion in case of more than one substrate) of the organic waste and subsequently MP production by fermentation of biogas with selected methanotrophs in a closed bioreactor (Bertasini et al. 2022; Tsapekos et al. 2021; Zha et al. 2021). Biogas fermentation is performed in a sterile medium comprising the necessary nutrient for microbial growth. The optimization of the production process is controlled by several factors including bio-methane to oxygen ratio, AD digestate nutrient concentration, temperature, reaction time, biogas concentration, moisture, and pH (Martin et al. 2013; Puligundla and Mok 2021; Sakarika et al. 2022; Tsapekos et al. 2021). In this process, biogas composition can considerably affect the growth of methanotroph microbial cultures (Cantera et al. 2016). Different microbial strains have different growth and substrate utilization and it is important to understand the conditions necessary to select the most suitable microbial culture and waste streams to be utilized as substrate (Areniello et al. 2023; Banks et al. 2022; Li et al. 2022b). The generated biomass is then processed for protein extraction which requires biomass separation and drying. Finding suitable separation techniques for cost-effectively harvesting biomass, as well as drying studies is a key process for preparing the final product (Lee and Stuckey 2022; Sakarika et al. 2022). Several separation techniques have been reported including flocculation with gravity settling. Spray and solar drying are being studied currently as sustainable and cost-effective techniques (Hu et al. 2022; Lee and Stuckey 2022). The dried product will is finally analyzed to find out the content of total proteins, amino acids, vitamins, salts, and other parameters of interest (Bonan et al. 2022; Lee and Stuckey 2022; Salehi and Chaiprapat 2022).

Process integration of anaerobic digestion of farm organic waste and fermentation of produced biogas to produce MP for animal feed. The combination of both processes reflects the integrated valorization of agriculture waste streams towards renewable feed/food products. The process includes the demonstration and analysis that the produced feed is both safe and beneficial compared with currently used animal feed

To warrant the sustainability and economic viability of MP as animal feed, bio-methane as a feedstock could be an attractive alternative. Bio-methane is a viable substrate, as it is a major by-product of the AD of organic wastes (farm manure, organic agriculture waste, landfills, food waste, etc.) (Acosta et al. 2020; Muñoz et al. 2015; Puligundla and Mok 2021; Sakarika et al. 2022; Woolley et al. 2023; Xu et al. 2021a). Current research is focused on innovating the technology for coupling the biogas generation with gas fermentation using the selected methanotrophs such as Methylocystis parvus and Methylococcus capsulatus (Comesaña-Gándara et al. 2022; Gęsicka et al. 2021; Salehi and Chaiprapat 2022; Tsapekos et al. 2021; Zha et al. 2021). Moreover, nutrient-rich digestate, a product of anaerobic digestion, can provide nitrogen and phosphorus instead of using expensive chemical nutrients. Using such kind of integrated approach, organic waste resources upcycling can considerably contribute to finding sustainable, cheaper, and environment-friendly protein sources (Tsapekos et al. 2021). However, there is a lack of research on the industrial-scaled production of MP from AD streams as most of the work earlier was focused on the use of natural gas, and conventional nutrient sources. Upcycling of biogas and nutrient recovery from agricultural organic waste is the only viable method for large-scale MP production without requiring an associated increase in energy consumption.

The MP produced by aerobic fermentation of methane gas has distinctive benefits. Methanotrophic microbes are protein-rich biomass with greater than 75% protein content and have the potential to replace conventional protein sources (Angelidaki et al. 2018; Puligundla and Mok 2021; van der Ha et al. 2012; Verbeeck et al. 2019; Wang et al. 2022; Xu et al. 2021a). The ability to use a variety of wastes with a wide range of organic compounds, under different environmental conditions of temperature, humidity, etc. is the key advantage of this process (Li et al. 2022b; Martin et al. 2013; Puligundla and Mok 2021; Sakarika et al. 2022; Tsapekos et al. 2021). However, this process emits CO2 from the biogas into the air which is a shortcoming because CO2 is the main contributor to climate change. Additionally, there is a risk of explosion because of the formation of a mixture of biogas and O2 directly in the bioreactor culture medium (Molitor et al. 2019; Muñoz et al. 2015; Van Peteghem et al. 2022; Yang et al. 2021a).

To overcome the issue of CO2 emissions, several alternative strategies are proposed as a possible solution including the co-cultivation of autotrophic HOB with methanotrophs in a single-stage process (Areniello et al. 2023; Chen et al. 2022; Hu et al. 2022; Lin et al. 2022). However, the application of HOB requires H2 gas which is generally produced by an energy-demanding water electrolysis method with a risk of an explosion raising safety issues as well. Another promising replacement process is the integration of methanotrophic and algal biomass production in a phototrophic bioreactor in which the CO2 generated is fixed by algae while O2 produced by algae is utilized as an electron acceptor by methanotrophs (Areniello et al. 2023; Azarpour et al. 2022; Balagurunathan et al. 2022; Wada et al. 2022). This process is advantageous over the methanotrophic and methanotrophs-HOB processes as it can all together convert CH4 and CO2 in the biogas without the requirement of any external O2. Hydrogen and methane gases need to be dissolved in the aqueous media for their availability to microbes, however, poor solubility of these gases is a bottleneck in their application for MP production (Areniello et al. 2023). Several bioreactor configurations such as with controlled stirring systems and shapes like U-loop have been designed as an alternative to conventional reactors to address the solubility issues (Nizovtseva et al. 2022; Nyyssölä et al. 2022; Tyagi et al. 2022). Natural gas is generally used as a source of methane gas for MP production. However, in the AD process, hydrogen is produced in the acidogenesis stage as an intermediate product which is rapidly transformed into methane by methanogenic archaea. Therefore, biogas-based MP production by HOB is not considered a suitable process unless the methane formation is inhibited intentionally to produce bio-hydrogen which is not viable commercially so far (Khoshnevisan et al. 2022; Nyyssölä et al. 2022).

An alternative strategy to address the issues related to the use of biogas is to upgrade it to get the needed characteristics (Khoshnevisan et al. 2022). Biogas upgradation can be done by several physicochemical and biological processes such as absorption and adsorption which are already commercially available and can be utilized for MP production (Luo et al. 2012). It can also be done using biological processes which involve electrochemical means to perform the in situ or ex-situ reduction of the substrates for instance conversion of CO2 to CH4 in presence of methanogens (Martin et al. 2013; Muñoz et al. 2015; Verbeeck et al. 2019). For instance, the production of MP from upgraded biogas was reported by Acosta et. al., (Acosta et al. 2020) in which an electrochemical process was applied to separate CO2 and CH4 from the biogas stream produced from anaerobic digestion. The electrochemically upgraded biogas having a blend of CH4 with H2 exhibited the high quality and quantity of MP production demonstrating the electrochemical separation as a viable option for biogas upgradation to produce MP as shown in Fig. 6. CO2 in the biogas can be efficiently separated from CH4 by solar energy driven electrochemical process while generating H2 and O2, simultaneously (Kumar et al. 2016; Matassa et al. 2016). A quantitative analysis on the potential of renewable photovoltaic-driven biomass production showed that MP produced using such renewable resources has production efficiently higher than that of conventional crops Fig. 6C (Leger et al. 2021). In this study, the efficiency of applying solar power for conversion of CO2 in the air into microbial biomass was investigated and it was showed that the MP based food production leave behind the cultivation of staple crops like soybean in terms of protein yields and caloric value per unit land area (Fig. 6D). The study concluded that MP food could considerably contribute to the growing food demand and can help in sharing future inadequate land resources.

Overview of the integrated process scheme involving anaerobic digestion and electrochemical biogas upgrade A Schematic of the MP production process by electrochemically upgraded biogas B CO2 flux in the biogas stream with the corresponding removal and current efficiencies (Acosta et al. 2020). PV-driven MP production C schematic depiction of energy transfer of MP from solar energy. Each conversion step is associated with an energetic efficiency corresponding to the electricity fraction used for electrosynthesis of the carbon-substrate, D Protein yield of PV-driven MP production as a function of irradiance. Different electron donors and assimilation pathways were analyzed in comparison with conventional crops like soybean the highest protein-yielding staple food (Reproduced from (Leger et al. 2021) with permission from Elsevier 2021)

The application of organic wastes as carbon and nitrogen source is considered a viable option. The supernatant of the AD process is considered a rich source of nitrogen for the subsequent methanotrophs to produce MP. However, supernatant from the AD process has a high ammonium concentration ranging from 1,000–3,000 mg-NH4 +−N/L, which needs to be diluted to meet the desired ammonium concentration (Acosta et al. 2020). The protein contents of the biomass produced in the methanotrophic bioreactor are reported in the range of 40–60% on a dry cell weight (DCW) basis, which is higher than the protein contents of commonly used soybean meal for animal feed. Hence, MP-based feed can be an alternative to conventional protein sources for animal feed additives.

H2S is usually a component of the biogas produced from AD and its concentration can vary depending on the substrates used (Angelidaki et al. 2018; Miltner et al. 2017; Salehi and Chaiprapat 2019). Recently, several studies have reported the detrimental effects of H2S on the protein contents of the MP (Xu et al. 2020). It is reported that biomass production with natural gas is significantly higher than that of using raw biogas containing H2S. Xu et. al. reported the growth inhibition of M. acidiphila and a decrease in amino acid contents in the produced biomass at approximately 1000 ppm of H2S in crude biogas as shown in Fig. 7 (Xu et al. 2020). Moreover, the quality of MP produced is also affected by the H2S in the biogas. So, it is very important to desulfurize raw biogas before using it for MP production. In MP production, the source and concentration of nitrogen have an important role in synthesizing protein by microbes. Expensive synthetic nitrogen-rich media like ammonium mineral salts (AMS), nitrate mineral salts (NMS), etc. are generally used to grow MP-producing microbes including algae, methanotrophs, and HOB. Organic waste has nitrogen in different forms such as ammonia, ammonium salts, nitrite, and nitrate, and can be used as a source of nitrogen and carbon, simultaneously. In anaerobic digestion, ammonia nitrogen (NH4+-N) rich biogas slurry is produced which becomes a grave environmental and economic issue given that about 1 billion tons of biogas slurry per year are only produced in China (Ding et al. 2023). Therefore, using waste streams as a nitrogen source for the growth of MP-producing microbes has shown the potential to minimize the cost. pH has a significant impact generally on microbial growth. Regulation of pH in MP production is crucial to get the maximum yield (Zeng et al. 2022). It was observed that keeping an acidic environment in the bioreactor was essential to get higher biomass and MP synthesis. Biogas and nutrient-rich liquid products of AD of organic wastes can serve as a solution. Traditionally, biogas is used for combined heat and power generation and the nutrients rich digestate of the AD process is supplied to plants as fertilizer, however, it is not safe and its storage could result in fugitive emissions of greenhouse gases including methane and ammonia (Haraldsen et al. 2011; Matassa et al. 2015; Styles et al. 2018). The assimilation of nutrients by methanotrophs to produce protein-rich biomass seems to be a favorable substitute (Khoshnevisan et al. 2020; Matassa et al. 2015). Therefore, effective biotechnology for protein-rich microbial biomass production using both liquid and gas streams of farm organic waste AD process will improve the economic value of the overall process. Yet, this 2nd generation's concept of MP production from biogas is not established. There are questions about the efficiency of the AD process, biogas fermentation, and quality of the MP produced. Also, it is a subject of research whether biogas-fed MP can substitute traditional animal feed sources such as soybean and fishmeal (Suriyapha et al. 2020). MP can be produced locally from organic-rich food waste, is easy to trace source and quality, and can be capable of providing all necessary amino acid and vitamin requirements for animal growth (Alloul et al.). Furthermore, compared to other sources of protein, the environmental burdens in terms of energy, greenhouse gases, water footprint, and land area are claimed to be much lower for MP, although limited scientific literature is available in this area (Sillman et al. 2020). However, the selection of bacteria with comparatively higher growth rates, protein content, and healthy amino acid composition are the most important factors to produce high-quality cell biomass for animal feed production.

Growth inhibition of methanotrophs by H2S: a OD410 with reaction time; b CH4 profile over time; c sulfide profile with reaction time; d amino acid profile analysis as a percentage of dry biomass (Reproduced from (Xu et al. 2020) with permission from Elsevier 2020)

While the concept of direct biogas fermentation to MP has many potential benefits, several challenges must be overcome to make this process viable, efficient, and safe. Different challenges are associated with the direct conversion of gases into MP including mass transfer limitations, quality of gas feed gas, the need for microbial catalysts, and safety(Khoshnevisan et al. 2022; Salehi and Chaiprapat 2022; Wang et al. 2022; Xu et al. 2021a; Zha et al. 2021). Limiting gas-to-liquid mass transfer is still regarded as one of the main obstacles to the commercialization of gas-based fermentation systems (Sakarika et al. 2022). A useful parameter for comparing the mass transfer capacities of various reactor layouts is the volumetric mass transfer coefficient, which is a direct evaluation of a reactor's hydrodynamic state (Li et al. 2021). Improvements in impeller designs, fluid flow patterns, aerated power efficiency, mixing time, baffle design, and the utilization of microbubble dispersers are some of the traditional methods investigated in literature to overcome mass transfer constraints (Dupnock and Deshusses 2019; Lai et al. 2021; Rodríguez et al. 2020; Soto et al. 2021). Before being added to the fermentation process, the feed gas needs to be clean. To guarantee optimal production, appropriate gas cleanup techniques should be utilized before gas-based fermentation processes (Acosta et al. 2020; Golmakani et al. 2022; Naquash et al. 2022). Another crucial step in commercializing the process is the discovery of anaerobic bacteria that can convert biogas into MP with greater product yields (Leu et al. 2020; Thamdrup et al. 2019). Several safety challenges must be considered and addressed to minimize the risks associated with biogas fermentation to MP. Some of the key safety challenges include explosion hazards, toxic gas emissions, and fire hazards (Salehi and Chaiprapat 2022; Xu et al. 2021a; Zha et al. 2021). Biogas is a combustible gas that can pose an explosion hazard if it is not handled properly. Bioreactors and other equipment used in the fermentation process must be designed and operated to minimize the risk of explosion. Appropriate safety measures, such as gas detection systems, explosion-proof equipment, and adequate ventilation, must be in place to prevent accidents (Stolecka and Rusin 2021). Also, biogas fermentation can produce toxic gases such as hydrogen sulfide and carbon monoxide, which can pose health risks to workers and the environment (Tayou et al. 2022; Xu et al. 2020). Proper ventilation, gas detection systems, and personal protective equipment must be used to prevent exposure to these gases.

Another issue related to the conversion of biogas to MP is its competition with other biogas end uses. Biogas is a versatile fuel that can be used for electricity generation, heating, and transportation (Abanades et al. 2022). As such, the biogas market is highly competitive, and the cost of producing biogas for use in MP production would need to be competitive with other uses of biogas. Moreover, the production of MP requires a significant amount of energy, including the energy needed to maintain the bioreactor temperature and supply nutrients to the microorganisms. This energy must be supplied from renewable sources to ensure that the process has a low carbon footprint. The MP production requires a high level of nutrients, including nitrogen and phosphorus, which may not be readily available in the substrate used for biogas fermentation. So additional nutrient supplementation may be required to achieve high yields of MP. The production of MP from biogas must be economically viable to compete with other sources of protein. The cost of production must be low enough to make the final product competitive with other protein sources on the market.

5 MP in animal feed

MP produced from microbes is currently commercialized and in use as animal feed from companies like Uniprotein®, and Unibio A/S, Denmark, known as FeedKind® (Alloul et al.). These commercial products are produced by aerobic fermentation of methane in natural gas. In this process, the fermentation of methane is carried out by methanotrophs while assimilating nitrogen compounds such as ammonium, ammonia, and nitrate in their proteinaceous cells. MP produced by methanotrophic fermentation has distinctive benefits and can be utilized as cattle feed as an alternative to plant-based protein due to its higher contents of protein (> 75% dry weight) (Ritala et al. 2017). Few selected species of bacteria and fungus have been employed to produce MP as animal feed for the last two decades. Recently, the production of MP for animal feed applications has gained momentum. Animal feed from sugar fermentation was produced in Finland in 1974 and the process was registered with the commercial name “PEKILO®” to be used in the European Union countries. This process utilizes the filamentous fungus Paecilomyces varioti using sugar as a substrate to produce MP (Ritala et al. 2017). Start-up company eniferBio has recently updated the PEKILO® process using different industrial by-products as a substrate to produce the MP biomass validated for aquafeed and aiming to extend it further for human consumption (eniferBio 2022). Imperial Chemical Industries UK, developed an MP using methanol as a substrate for animal feed with the brand name Pruteen, by employing Methylophilus methylotrophus bacteria up to 70% protein (Johnson 2013). Nevertheless, Pruteen production became commercially unviable because of the availability of other inexpensive protein sources such as soybean, and Pruteen production was discontinued in 1970. Pruteen was produced from methanol, but lately, methane gained interest as a substrate for MP production. Several multinational companies including UniBio A/S and Calysta Inc. have developed a U-loop fermenter technology employing fermentative methanotroph bacteria to convert natural gas to MP. UniBio commercialized the MP by the brand name UniProtein® with ~ 70% protein, which is already approved for use in animal feed (Petersen et al. 2017). Similarly, Calysta Inc. introduced its MP with the commercial name FeedKind®, in the UK market in 2016 as animal feed has partnered with Cargill USA to build a larger production facility. The biotechnology companies in Qatar have already shown interest and ambition to adopt new technologies. Very recently, Gulf Biotech Qatar, and Unibio, have partnered to establish a production facility in Qatar, the gulf’s first natural gas to protein plant, to produce initially 6,000 tonnes of UniProtein® as a feed for aquaculture livestock (Unibio 2022).

The biotechnology companies like Calysta Inc. and UNIBIO are producing MP by employing pure microbial cultures that necessitate comparatively pure sources of co-substrates and nutrients to avoid contamination risks. However, the supply of chemical grade nutrients (micro and macronutrients) and natural gas as methane sources increase the operational costs and are the bottlenecks to decreasing the production costs of the MP. Furthermore, the usage of natural gas is not sustainable and environmentally friendly. Therefore, the sustainability of MP production by natural gas-fed fermentation process is under question (Kalyuzhnaya et al. 2013). To address the above-mentioned issues, cheaper and sustainable sources of both substrates (methane and nutrients), are required resulting in the bacterial protein production roar.

Yeast and methanotrophs-based MP produced using waste substrates have been tested as animal, fish, and shrimp meal (Sharif et al. 2021; Woolley et al. 2023; Zheng et al. 2023). The yeast C. utilis MP was used as a feed supplement for weaned piglets in a study by Yang et. al (Yang et al. 2021c). It was observed that C. utilise-based MP has the potential to substitute the use of antibiotics in the growth of weaned piglets. Additionally, MP enhanced the overall growth, and intestinal health with a reduction in diarrhea, and enhanced cecal microflora diversity and richness in piglets. MP produced by PSB has been applied for many years as the poultry and pig feed to enhance the egg laying rate, yolk pigment content, chicken health fineness, and animal weight (Lu et al. 2019).