Abstract

Microbial conversion of CO2 and CO into chemicals is a promising route that can contribute to the cost-effective reduction of anthropogenic green house and waste gas emissions and create a more circular economy. However, the biotechnological valorization of CO2 and CO into chemicals is still restricted by the limited number of model microorganisms implemented, and the small profit margin of the products synthesized. This perspective paper intends to explore the genetic potential for the microbial conversion of CO2 and CO into ectoines, in a tentative to broaden bioconversion platforms and the portfolio of products from C1 gas fermentations. Ectoine and hydroxyectoine can be produced by microorganisms growing at high salinity. They are high-value commodities for the pharmaceutical and medical sectors (1000–1200 €/kg). Currently microbial ectoine production is based on sugar fermentations, but expansion to other more sustainable and cheaper substrates is desirable. In this work, a literature review to identify halophilic microbes able to use CO2 and CO as a carbon source was performed. Subsequently, genomes of this poll of microbes were mined for genes that encode for ectoine and hydroxyectoine synthesis (ectABCD, ask, asd and ask_ect). As a result, we identified a total of 31 species with the genetic potential to synthesize ectoine and 14 to synthesize hydroxyectoine. These microbes represent the basis for the creation of novel microbial-platforms that can promote the development of cost-effective and sustainable valorization chains of CO2 and CO in different industrial scenarios.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

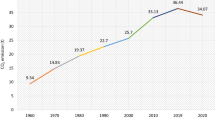

A primary target of a profitable circular economy is the development of new bio-production systems capable of recycling and creating value out of greenhouse gases and industrial off-gas emissions (European commission 2018a). The current chemical market is worth more than 3.6 trillion € per year globally, but less than 5% of the chemicals are produced using biotechnological processes. Most of the existing biotechnologies use sugars as feedstock, whose price accounts for up to 50% of the production costs (Zeng 2019). Besides, utilization of sugars for the production of chemicals directly competes with food markets and is environmentally unsustainable (Ritala et al. 2017). In recent years, the microbial conversion of point source CO2 and CO emissions have received great attention as an alternative to sugar fermentations (Nisar et al. 2021; Naresh Kumar et al. 2022). The availability of these gases is practically unlimited, flue gases are practically free, and the valorization of CO2 and CO acts as an atmospheric pollution and climate change mitigation strategy (Metz et al. 2018). However, despite the potential for sustainable production of added-value compounds from CO2 and CO, current physico-chemical and biological technologies are seldomly cost-effective. Physico-chemical transformation of CO2 into industrial compounds of interest is difficult because it requires high energy input as a result of the oxidized low-energy carbon of the CO2 molecule (Gabrielli et al. 2020). For biological CO2 transformation, photobioreactors are the most studied and developed biological technologies (Anand et al. 2020). However, photosynthesis has a relatively low energy efficiency (less than 3%). Open systems have limitations such as uneven light intensity, evaporative losses, diffusion of CO2 to the atmosphere, undesired contamination and a larger footprint. Closed photobioreactors are expensive and often require nitrogen dosing to improve productivity (Zeng 2019; Bose et al. 2019). CO, instead, is a high-energy molecule and can be converted using chemical synthesis. Nevertheless, chemical catalysis usually requires energy-intensive conditions (e.g. Fischer–Tropsch process), a fixed H2 to CO ratio, and costly removal of syngas impurities to avoid catalyst poisoning (Cordero et al. 2019).

CO2 and CO can be converted using chemolithoautotrophic microorganisms in a process independent from light, known as dark carbon fixation. Chemolithoautotrophic organisms obtain their energy from redox reactions and their carbon from CO2 fixation or/and CO. Technologically, dark carbon fixation can be a cost-effective option to transform CO2 and CO emissions into chemical building blocks (Claassens et al. 2018). Promising cell factories are researched for the production of plastics, diesels, single cell protein and extracellular polysaccharides. Table 1 shows an overview of chemicals produced from CO2 and CO (complete review of microbial compounds produced from CO2 and CO, yields and references in supplementary information 1, Table S1). However, current processes apply a restricted number of model microorganisms, such as acetogens, with a small portfolio of products, mainly alcohols and organic acids (Zeng 2019). Consequently, the development of new biotechnologies that expand microbial catalysts used for transforming CO2 and CO and their product portfolio is of great interest for the transition pathway to a fossil-free circular economy.

2 High-value compounds produced by microbes at high salinities: ectoine and hydroxyectoine

Microorganisms growing in high-salinity environments produce organic osmolytes (also known as extremolytes) to protect cell integrity and ensure survival (Czech et al. 2018a). Industry has spotlighted extremolytes formed at high salinity as an ‘unexploited gold-mine’ with opportunities for the cosmetic, medical, and food industries (Becker and Wittmann 2020). Out of all the extremolytes, ectoines (ectoine and its hydroxyectoine derivative) are highly interesting as they provide protection against an array of stress factors (e.g. salinity, desiccation, oxygen radicals, temperature, UV light) which makes of them multi-functional agents of great market value (Becker and Wittmann 2020; Liu et al. 2021).

Ectoine is a cyclic imino-acid (2-methyl-1,4,5,6-tetrahydropyrimidine-4-carboxylic acid) which molecular structure enhances hydrogen bonding in aqueous solution (Czech et al. 2018a). This allows ectoine to bind water and form an ectoine-hydro-complex that acts as a protective hydro-layer on cell surfaces and macromolecules. This makes ectoine a highly effective stabilizer of proteins, DNA–protein complexes, nucleic acids, cell membranes and tissues (Fig. 1). Current ectoine retail value is of approximately 1000 € kg−1 and market trends indicate that ectoine’s importance in the chemical industry will continue to grow inferred from its novel commercial products (Liu et al. 2021). Bitop AG manufactures 90% of the current market needs (data 2016), but other companies such as Bloomage Biotechnology Corporation are starting to produce ectoine industrially (Becker and Wittmann 2020). The primary application is the cosmetic industry: mainly for skin and hair care products (industrial producers: Bitop AG, DADO-cosmed GmbH, Börlind Gesellschaft für, Jan Dekker). There is also expansion towards the medical industry due to ectoines anti-allergenic and anti-desiccant properties. Companies like Johnson & Johnson, Pari GmbH, and Bitop AG are already incorporating ectoine in nasal sprays, eye drops, mouth and throat spray, anti-dermatitis creams and lung inhalation fluids (Becker and Wittmann 2020).

Gene cluster for ectoine and hydroxyectoine production in Acidiphilum cryptum and general microbial biosynthetic pathway for ectoine and hydroxyectoine production in the cell. ectR encodes a MarR-type regulator; ectA, the protein diaminobutyric acid (DABA) acetyltransferase (EctA); ectB, DABA aminotransferase (EctB); ectC, ectoine synthase (EctC); ectD, ectoine hydroxylase (EctD); ask_ect, a specialized aspartokinase (Ask); Asd stands for l-aspartate-semialdehyde-dehydrogenase. Dotted box with possible mechanisms for ectoine protection in the cells. Figure created with biorender

Although the pathway for ectoine production can vary slightly from one organism to another, it involves three specific enzymes encoded by the conserved gene cluster ectABC (Fig. 1): l-2,4-diaminobutyric acid (DABA) transaminase (EctB), DABA acetyltransferase (EctA) and ectoine synthase (EctC). EctC is considered a marker protein for ectoine producers (Czech et al. 2019). Sometimes an additional gene of aspartokinase (ask_ect) and/or the gene (ectR) for a MarR-type regulator are observed within the ectABC cluster (Czech et al. 2018a).

Members of Halomonas, Brevibacterium and Chromohalobacter genera can naturally accumulate high concentrations of ectoine (15% cdw) when cultured at high salinity with simple sugars and yeast extract. Halomonas elongata is the most widely used strain for industrial ectoine production. Bitop AG uses non-genetically modified ‘superleaky’ mutants of H. elongata to produce tons of ectoines yearly (Kunte et al. 2014; Becker and Wittmann 2020). These mutants excrete ectoine to the medium avoiding the need for hiper and hipo osmotic shocks to recover intra-cellular ectoine from the biomass (bio-milking process). Besides this advantage, the process with ‘superleaky’ strains is still costly due the high amounts of glucose and oxygen required, and the corrosive characteristics of the high salinity medium (Kunte et al. 2014; Liu et al. 2021). Recent research and commercial attempts have focused on cost-effective biotechnology aimed at synthesizing ectoine at lower salinities using engineered microorganisms, however, the preference of using natural non-GMO extremolytes by the cosmetic market calls for other alternative processes (Becker and Wittmann 2020). Table 2 shows some of the high-yield ectoine producers (complete overview of ectoine producers can be found in supplementary information 1, Table S2).

A compatible solute derived from ectoine that has recently received commercial attention is hydroxyectoine (5-hydroxy-2-methyl-1,4,5,6-tetrahydropyrimidine-4-carboxylic acid) (Czech et al. 2019). Hydroxyectoine is produced by a substantial amount of ectoine producers through a position- and stereo-specific hydroxylation catalyzed by an ectoine hydroxylase (EctD) (Czech et al. 2018a). Compared to ectoine, hydroxyectoine confers additional protective properties due to its hydroxylated nature and has a higher price (1200 € kg−1) (Becker and Wittmann 2020). Hydroxyectoine plays an important role in heat stress protection, increasing the melting temperature of DNA, and confers stronger desiccation resistance due to its ability to form glasses (Liu et al. 2019). With the exception of some Marinococcus strains and Pseudomonas stuzeri (Schiraldi et al. 2006; Seip et al. 2011), hydroxyectoine and ectoine are naturally co-produced. Commercial strains for ectoine production, such as H. elongata, can be manipulated to increase its hydroxyectoine content (to a maximum of approximately 50%) via desiccation at extreme salinity and elevated temperature. However, growth under extreme conditions and subsequent chromatographic separation procedures increase production costs. Thus, industrial ectoines are usually sold as mixtures of ectoine and hydroxyectoine (Liu et al. 2021).

As hydroxyectoine is in high demand due to its superior protective properties, current research has focused on the singular production of this analogue. The highest hydroxyectoine production yields have been obtained in cultivations with natural Halomonas species at high salinity. Although some recent research has focused on the genetic modification of non-natural producers with the aim of synthesizing hydroxyectoine as the only osmolite (Table 3; a whole overview of hydroxyectoine producers, conditions, and yields can be found in supplementary information 1, Table S3).

3 C1 compounds as alternative feedstock for ectoine and hydroxyectoine production

Although there has been tremendous progress in ectoine and hydroxyectoine biosynthesis, there is little integration of sustainable feedstock and a lack of studies about the use of renewable carbon and energy sources for ectoine production. In this regard, new bioproduction systems using waste C1 compounds as carbon supply could lower production costs, while mitigating greenhouse gas emissions. Different halotolerant aerobic methanotrophs have been identified as able to accumulate ectoine; most of them belong to the genus Methylomicrobium, e.g. M. alcaliphilum, M. buryatense, M. kenyense or M. japanense, although other bacteria such as, Methylobacter marinus and Methylohalobius cremeensis are also ectoine producers (Kalyuzhnaya et al. 2008). Out of all, M. alcaliphilum is considered the most efficient methanotrophic ectoine producer (achieving ectoine specific yields of 230 ± 20 mg gdcw−1) (Khmelenina et al. 2015). In fact, the process feasibility of M. alcaliphilum in bio-reactors has been demonstrated in aerobic fed-batch fermentation, reaching extracellular concentrations of 253.4 ± 55.1 mg L−1 ectoine and recoveries of ~ 70% of the total intra-cellular ectoine (Cantera et al. 2017). Further on, the use of consortia has been preferred for the production of ectoine from CH4 in continuous, due to their higher resilience and two times higher ectoine productivities (Cantera et al. 2020). In fact, a recent techno-Economic and Sensitivity Analysis of the production of ectoine from biogas in waste treatment facilities has demonstrated that the production of ectoine from biogas has high profitability with a net present value evaluated at 20 years (NPV20) of 33.6 M€ (Pérez et al. 2021). Nevertheless, despite the enormous potential of biogas as feedstock for ectoine production, its large-scale production is still constrained by the limitation of CH4 solubility in liquid medium and gas–liquid mass transfer, eventually resulting in low product titers.

In view of overcoming these rate-limiting factor, a novel approach of using different C1 gases with greater mass transfer, such as CO2, and processes that integrate aerobic and anaerobic microbes able to use CO2 and CO as carbon source could broaden and make more sustainable this bioconversion platform.

Different approaches could be taken for the bio-conversion of CO2 and CO into ectoines. Synthetic co-cultures formed by mesophilic microorganisms able to produce organic acids or ethanol from CO2 or CO, such as acetogens, coupled to heterotrophic ectoine producers, such as Halomonas species, could be used to enhance the valorization process of these C1 gases. Nevertheless, two step fermentations would be required for the implementation of this technology by virtue of operational restrictions. These restrictions include the high salinity needed for ectoine production, the changes in the pH concomitant to the production of organic acids and alcohols, and the anaerobic restrictive conditions characteristic of acetogens. The use of mixotrophs also appears as a solution for ectoine production from CO2/CO. In fact, recently, it was observed that H. elongata anaplerotic flux can support an increase in ectoine production when using glucose as the main carbon source (Hobmeier et al. 2020). In other study, the addition of low concentrations of glucose (0.5 g L−1) to Halomonas stevensii cultures promoted ectoine contents of 15% and 22% at salinities of 6% and 12% NaCl, and supported an abatement of 37.1 mg CO2 L−1 h−1 (Cantera et al. 2022). Besides glucose, other organic compounds, such as acetate and alcohols, could be considered for mixotrophic growth, though they have not yet been experimentally tested.

Nevertheless, a chemoautotrophic biotechnological platform that allows to produce ectoines purely with CO2 as the sole carbon source has a great potential. Although, dark fixation provides less energy than aerobic respiration of sugars, this bioconversion process could use CO2 from industrial flue gases, and waste gases (CO, H2) or liquid waste (sulfur compounds, metals, ammonium) as energy source enhancing the feasibility and expansion of this residue-valorisation technology. Moreover, it could be implemented in both, aerobic and anaerobic conditions. However, CO2 and CO have been disregarded for the production of ectoines, fact that is probably related to the current lack of fundamental studies proving that chemolithoautotrophs can produce ectoines.

4 Potential chemolithoautotrophs able to produce ectoines

Although heat or cold stress can affect ectoine accumulation, salinity is the main trigger for the expression of genes involved in ectoine biosynthesis pathway (Argandoña et al. 2021). Thus, ectoine and hydroxyectoine production is usually observed in halophilic or halotolerant organisms. Several halophiles have the ability to grow on CO2 and/or CO, but their potential to produce ectoines while using these gases is unexplored. Based on literature and genomic databases (supplementary information 2), we gathered a total of 143 species of halophilic chemolithotrophs, carboxydotrophs and carboxydovores. All the identified species that were able to use CO2 and CO aerobically and anaerobically, together with their required energy sources and their optimum salinity for growth are summarized in supplementary information 2, Table S4 and Table S5. Genomes of the identified species were screened for genes encoding for enzymes involved in the ectoine and hydroxyectoine synthesis pathways: specifically ectA, ectB, ectC and ectD (supplementary information 2, Tables S6 and S7). Moreover, the presence of ectR, an important transcriptional regulator of this pathway, and two genes involved in the production of the precursor L-2,4-diaminobutyrate (aspartate kinase: ask and aspartate semi-aldehyde dehydrogenase: asd), were assessed.

In total, 31 microbial genomes were identified with the ectABC gene cluster (Fig. 2). Most of these genomes (22) belonged to aerobic organisms capable of CO2 fixation. Some of them are well described as pure chemolithotrophs that use H2 (Alkalilimnicola ehrlichii, Hydrogenovibrio marinus, Pseudonocardia autotrophica, Pseudonocardia dioxanivorans, Rhodococcus opacus), S2O3− (Guyparkeria halophila, Halothiobacillus neapolitanus, Salinisphaera hydrothermalis, Thiohalomonas denitrificans, Thiomicrospira aerophila, Thiomicrospira halophila), NH4+ (Nitrosococcus halophilus, Pseudonocardia ammonioxydans), NO2− (Nitrococcus mobilis) or Fe2+ and reduced sulfur compounds (Acidihalobacter aeolianus, Acidihalobacter ferrooxidans, Acidihalobacter prosperus) as electron donors. This diversity indicates a broad range of possibilities for application in biotechnological processes. Some anaerobic chemolithoautotrophs also contained the genes for ectoine synthesis. These included Achromobacter ruhlandii and Alkalilimnicola erlichii (CO2 fixation with H2 as electron donor and NO3− as electron acceptor), Desulfatibabacillum aliphaticivorans (CO2 fixation with H2 as electron donor and SO42−as electron acceptor), Desulfocapsa sulfexigens (CO2 fixation with H2 as electron donor and S0, SO32−, S2O32− as electron acceptors), and the methanogen Methanobacterium subterraneum (CO2 fixation with H2 as electron donor). Theoretically, these could be potential candidates for the anaerobic conversion of CO2 into ectoine.

Presence/absence of ectoine biosynthesis genes in halophilic chemolithotrophs. All genomes found with ectC and ectB were interrogated for other relevant genes in the ectoine biosynthesis pathway. All detected ectA and ectD were found within 10 kb of ectB and ectC. All surveyed genomes contained aspartate kinase (ask) genes. Additionally, ask copies found within 10 kb of the ect gene cluster are considered to represent ask_ect orthologs (orange). While most genomes contained genes belonging to the ectR gene family (COG1846; gray), only those found within 10 kb of the ect gene cluster were considered ectR orthologs (red). The phylogeny displayed at the left reflects the relationships between organisms based on their NCBI taxonomy

As less CO-utilizing microbes are known, and therefore screened, their metabolic potential may be less well characterised. However, some aerobic carboxydotrophs such as Hydrogenibacillus schlegelii, and Hahella chejuensis, aerobic carboxydovores, such as Alkalispirillum mobile and Mycobacterium smegmatis, and the facultative anaerobe Alkalilimnicola erlichii were detected as putatively able to consume CO and produce ectoine (Hoeft et al. 2007).

The formation of hydroxyectoine depends on the initial synthesis of ectoine and its subsequent hydroxylation by the enzyme coded by the gene ectD. The ectD gene was found in 14 of the genomes that contained ectABC. Ten of those genomes belonged to aerobic CO2-utilizing microbes (Fig. 2), one to an anaerobic chemolithoautotrophic CO2 consumer (Achromobacter ruhlandii), and three to aerobic CO-utilizing microbes (Mycobacterium smegmatis, Hydrogenibacillus schlegelii, and Hahella chejuensis).

5 Perspectives

This work sheds light in a new direction looking at yet overlooked microbes and strategies that can help in the development of CO2 and CO valorization. The information provided has the potential to propel new research in this topic for different industrial scenarios, using H2, nitrogen and sulfur compounds or metals as the energy source. Moreover, the approaches and results from this review are applicable for the valorization of any CO2-containing gases, including emissions from industrial sites (steel mills, cement producers, electricity plants, etc.); flue gas emissions (natural gas-fired power plants, coal boilers) and syngas. Besides, biotransformations carried out at high salinity can be adapted to reduce cost (use of plastic-based reactors, sea water as medium) and are usually more robust processes due to the low risk of contamination. Therefore, this review offers a completely new strategy that can pave the way for a more cost-effective elimination of GHG and waste gasses, as well as more sustainable and circular chemical production systems.

References

Anand A, Raghuvanshi S, Gupta S (2020) Trends in carbon dioxide (CO2) fixation by microbial cultivations. Curr Sustain/renew Energy Reports 7:40–47. https://doi.org/10.1007/s40518-020-00149-1

Argandoña M, Piubeli F, Reina-Bueno M et al (2021) New insights into hydroxyectoine synthesis and its transcriptional regulation in the broad-salt growing halophilic bacterium Chromohalobacter salexigens. Microb Biotechnol 14:1472–1493. https://doi.org/10.1111/1751-7915.13799

Becker J, Wittmann C (2020) Microbial production of extremolytes — high-value active ingredients for nutrition, health care, and well-being. Curr Opin Biotechnol 65:118–128. https://doi.org/10.1016/j.copbio.2020.02.010

Bethlehem L, Moritz KD (2020) Boosting Escherichia coli’s heterologous production rate of ectoines by exploiting the non-halophilic gene cluster from Acidiphilium cryptum. Extremophiles 24:733–747. https://doi.org/10.1007/s00792-020-01188-8

Bose A, Lin R, Rajendran K et al (2019) How to optimise photosynthetic biogas upgrading: a perspective on system design and microalgae selection. Biotechnol Adv 37:107444. https://doi.org/10.1016/j.biotechadv.2019.107444

Cantera S, Lebrero R, Rodríguez S et al (2017) Ectoine bio-milking in methanotrophs: a step further towards methane-based bio-refineries into high added-value products. Chem Eng J 328:44–48. https://doi.org/10.1016/j.cej.2017.07.027

Cantera S, Phandanouvong-Lozano V, Pascual C et al (2020) A systematic comparison of ectoine production from upgraded biogas using Methylomicrobium alcaliphilum and a mixed haloalkaliphilic consortium. Waste Manage 102:773–781. https://doi.org/10.1016/j.wasman.2019.11.043

Cantera S, Sousa DZ, Sánchez-Andrea I (2022) Enhanced ectoines production by carbon dioxide capture: A step further towards circular economy. J CO2 Utilization 61: 2009 https://doi.org/10.1016/j.jcou.2022.102009.

Chen W-C, Hsu C-C, Wang L-F et al (2019) Exploring useful fermentation strategies for the production of hydroxyectoine with a halophilic strain, Halomonas salina BCRC 17875. J Biosci Bioeng 128:332–336. https://doi.org/10.1016/j.jbiosc.2019.02.015

Claassens NJ, Sánchez-Andrea I, Sousa DZ, Bar-Even A (2018) Towards sustainable feedstocks: a guide to electron donors for microbial carbon fixation. Curr Opin Biotechnol 50:195–205. https://doi.org/10.1016/j.copbio.2018.01.019

Cordero PRF, Bayly K, Man Leung P et al (2019) Atmospheric carbon monoxide oxidation is a widespread mechanism supporting microbial survival. ISME J 13:2868–2881. https://doi.org/10.1038/s41396-019-0479-8

Czech L, Stöveken N, Bremer E (2016) EctD-mediated biotransformation of the chemical chaperone ectoine into hydroxyectoine and its mechanosensitive channel-independent excretion. Microb Cell Fact 15:126. https://doi.org/10.1186/s12934-016-0525-4

Czech L, Hermann L, Stöveken N et al (2018a) Role of the extremolytes ectoine and hydroxyectoine as stress protectants and nutrients: genetics, phylogenomics, biochemistry, and structural analysis. Genes 9:177. https://doi.org/10.3390/genes9040177

Czech L, Poehl S, Hub P et al (2018b) Tinkering with osmotically controlled transcription allows enhanced production and excretion of ectoine and hydroxyectoine from a microbial cell factory. Appl Environ Microbiol 84:e01772-e1817. https://doi.org/10.1128/AEM.01772-17

Czech L, Wilcken S, Czech O et al (2019) Exploiting substrate promiscuity of ectoine hydroxylase for regio- and stereoselective modification of homoectoine. Front Microbiol 10:2745. https://doi.org/10.3389/fmicb.2019.02745

Eilert E, Kranz A, Hollenberg CP et al (2013) Synthesis and release of the bacterial compatible solute 5-hydroxyectoine in Hansenula polymorpha. J Biotechnol 167:85–93. https://doi.org/10.1016/j.jbiotec.2013.02.005

European comission (2018a) EU climate action: 2030 climate & energy framework 2014 (revised 2018). https://ec.europa.eu/clima/policies/strategies/2030_en

European commission (2018b) Smarter, greener, more inclusive? — indicators to support the Europe 2020 strategy, 2018th edn. European Union, Luxemburg

Fallet C, Rohe P, Franco-Lara E (2010) Process optimization of the integrated synthesis and secretion of ectoine and hydroxyectoine under hyper/hypo-osmotic stress. Biotechnol Bioeng 107:124–133. https://doi.org/10.1002/bit.22750

Fatollahi P, Ghasemi M, Yazdian F, Sadeghi A (2021) Ectoine production in bioreactor by Halomonas elongata DSM2581: Using MWCNT and Fe-nanoparticle. Biotechnol Prog 37:e3073. https://doi.org/10.1002/btpr.3073

Frings E, Sauer T, Galinski EA (1995) Production of hydroxyectoine: high cell-density cultivation and osmotic downshock of Marinococcus strain M52. J Biotechnol 43:53–61. https://doi.org/10.1016/0168-1656(95)00119-2

Gabrielli P, Gazzani M, Mazzotti M (2020) The Role of carbon capture and utilization, carbon capture and storage, and biomass to enable a Net-Zero-CO2 emissions chemical industry. Ind Eng Chem Res 59:7033–7045. https://doi.org/10.1021/acs.iecr.9b06579

He Y-Z, Gong J, Yu H-Y et al (2015) High production of ectoine from aspartate and glycerol by use of whole-cell biocatalysis in recombinant Escherichia coli. Microb Cell Fact 14:55. https://doi.org/10.1186/s12934-015-0238-0

Hobmeier K, Goëss MC, Sehr C et al (2020) Anaplerotic pathways in halomonas elongata: the role of the sodium gradient. Front Microbiol 11:2124. https://doi.org/10.3389/fmicb.2020.561800

Hoeft SE, Blum JS, Stolz JF et al (2007) Alkalilimnicola ehrlichii sp. nov., a novel, arsenite-oxidizing haloalkaliphilic gammaproteobacterium capable of chemoautotrophic or heterotrophic growth with nitrate or oxygen as the electron acceptor. Int J Syst Evol Microbiol 57:504–512. https://doi.org/10.1099/ijs.0.64576-0

Kalyuzhnaya MG, Khmelenina V, Eshinimaev B et al (2008) Classification of halo(alkali)philic and halo(alkali)tolerant methanotrophs provisionally assigned to the genera Methylomicrobium and Methylobacter and emended description of the genus Methylomicrobium. Int J Syst Evol Microbiol 58:591–596

Khmelenina VN, Rozova ON, But SYu et al (2015) Biosynthesis of secondary metabolites in methanotrophs: biochemical and genetic aspects (Review). Appl Biochem Microbiol 51:150–158. https://doi.org/10.1134/S0003683815020088

Kumar M, Sundaram S, Gnansounou E et al (2018) Carbon dioxide capture, storage and production of biofuel and biomaterials by bacteria: a review. Biores Technol 247:1059–1068. https://doi.org/10.1016/j.biortech.2017.09.050

Kunte H, Lentzen G, Galinski E (2014) Industrial production of the cell protectant ectoine: protection mechanisms. Process Product 3:10–25. https://doi.org/10.2174/22115501113026660037

Liu C, Baffoe DK, Zhan Y et al (2019) Halophile, an essential platform for bioproduction. J Microbiol Methods 166:105704. https://doi.org/10.1016/j.mimet.2019.105704

Liu M, Liu H, Shi M et al (2021) Microbial production of ectoine and hydroxyectoine as high-value chemicals. Microb Cell Fact 20:76. https://doi.org/10.1186/s12934-021-01567-6

Ma H, Zhao Y, Huang W et al (2020) Rational flux-tuning of Halomonas bluephagenesis for co-production of bioplastic PHB and ectoine. Nat Commun 11:3313. https://doi.org/10.1038/s41467-020-17223-3

Metz B, Davidson O, de Coninck H et al (2018) Sources of carbon dioxide In: Carbon dioxide capture and storage. Cambridge University Press, Cambridge.

Naresh Kumar A, Sarkar O, Chandrasekhar K et al (2022) Upgrading the value of anaerobic fermentation via renewable chemicals production: a sustainable integration for circular bioeconomy. Sci Total Environ 806:150312. https://doi.org/10.1016/j.scitotenv.2021.150312

Nisar A, Khan S, Hameed M et al (2021) Bio-conversion of CO2 into biofuels and other value-added chemicals via metabolic engineering. Microbiol Res 251:126813. https://doi.org/10.1016/j.micres.2021.126813

Onraedt AE, Walcarius BA, Soetaert WK, Vandamme EJ (2005) Optimization of ectoine synthesis through fed-batch fermentation of brevibacterium epidermis. Biotechnol Prog 21:1206–1212. https://doi.org/10.1021/bp0500967

Pérez V, Moltó JL, Lebrero R, Muñoz R (2021) Ectoine production from biogas in waste treatment facilities: a techno-economic and sensitivity analysis. ACS Sustain Chem Eng 9:17371–17380. https://doi.org/10.1021/acssuschemeng.1c06772

Pérez-García F, Ziert C, Risse JM, Wendisch VF (2017) Improved fermentative production of the compatible solute ectoine by Corynebacterium glutamicum from glucose and alternative carbon sources. J Biotechnol 258:59–68. https://doi.org/10.1016/j.jbiotec.2017.04.039

Ritala A, Häkkinen ST, Toivari M, Wiebe MG (2017) Single cell protein—state-of-the-art, industrial landscape and patents 2001–2016. Front Microbiol 8:2009. https://doi.org/10.3389/fmicb.2017.02009

Schiraldi C, Maresca C, Catapano A et al (2006) High-yield cultivation of Marinococcus M52 for production and recovery of hydroxyectoine. Res Microbiol 157:693–699. https://doi.org/10.1016/j.resmic.2006.03.004

Seip B, Galinski EA, Kurz M (2011) Natural and engineered hydroxyectoine production based on the pseudomonas stutzeri ectABCD-ask gene cluster. Appl Environ Microbiol 77:1368–1374. https://doi.org/10.1128/AEM.02124-10

Vyrides I, Stuckey DC (2017) Compatible solute addition to biological systems treating waste/wastewater to counteract osmotic and other environmental stresses: a review. Null 37(7):865–879. https://doi.org/10.1080/07388551.2016.1266460

Zeng A-P (2019) New bioproduction systems for chemicals and fuels: needs and new development. Biotechnol Adv 37:508–518. https://doi.org/10.1016/j.biotechadv.2019.01.003

Zhang L, Lang Y, Nagata S (2009) Efficient production of ectoine using ectoine-excreting strain. Extremophiles 13:717. https://doi.org/10.1007/s00792-009-0262-2

Zhao Q, Li S, Lv P et al (2019) High ectoine production by an engineered Halomonas hydrothermalis Y2 in a reduced salinity medium. Microb Cell Fact 18:184. https://doi.org/10.1186/s12934-019-1230-x

Acknowledgements

This work was supported by a European Commission H2020-MSCA-IF-2019 grant (ENHANCEMENT, ref. 897284), by the Dutch Research Council (NWO) under projects CLIMATIC (6142021100 NWO XS), AMBIENT (6142021490 NWO XS) and SynValue (NWO-GK-07), and by the European Research Council (ERC consolidator grant 817834).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have no relevant financial or non-financial interests to disclose.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Cantera, S., Tamarit, D., Strong, P.J. et al. Prospective CO2 and CO bioconversion into ectoines using novel microbial platforms. Rev Environ Sci Biotechnol 21, 571–581 (2022). https://doi.org/10.1007/s11157-022-09627-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11157-022-09627-y