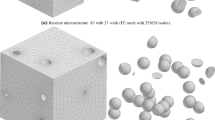

Using the finite element method, a numerical investigation of the initial stage of crack propagation in a material containing spherical pores under multiaxial compression (constrained conditions) was carried out. The influence of the pore spacing and the mechanical properties of the material on fracture location and crack-propagation direction was analyzed for brittle and ductile materials. Material properties and the arrangement of defects were found to significantly influence the direction of crack propagation initiating on stress concentrators (structure defects), even in mutually perpendicular directions (for uniaxial compression). Numerical estimates were obtained for the characteristic sizes of the influence region of spherical pores on each other, beyond which the stress fields of the neighboring structural elements do not overlap. The dependence of the size of this influence region on the elastic characteristics of the matrix material was studied. The obtained results are important for numerically estimating the durations of the initial stages of the quasibrittle fracture of ceramic-based heterophase materials, particularly refractory materials.

Similar content being viewed by others

References

K. Andreev, V. Tadaion, Q. Zhu, et al., “Thermal and mechanical cyclic tests and fracture mechanics parameters as indicators of thermal shock resistance—case study on silica refractories,” J. Eur. Ceram. Soc., 39, 1650 – 659 (2019). https://doi.org/10.1016/j.jeurceramsoc.2018.12.062.

K. Andreev, V. Tadaion, Q. Zhu, W. Wang, et al., “Role of fatigue in damage development of refractories under thermal shock loads of different intensity,” Ceram. Int., 46, 20707 – 20716 (2020). https://doi.org/10.1016/j.ceramint.2020.04.235.

K. Andreev, Y. Yin, B. Luchini, and I. Sabirov, “Failure of refractory masonry material under monotonic and cyclic loading — Crack propagation analysis,” J. Constr. Build. Mater., 299, Article 124203 (2021). https://doi.org/10.1016/j.conbuildmat.2021.124203.

V. A. Perepelitsyn, F. L. Kapustin, K. G. Zemlyanoi, et al., “Crack genesis in refractories,” Refract. Ind. Ceram, 57(4), 394 – 400 (2016).

A. V. Zabolotsky, L. M. Axelrod, “Application of the cell automata method to the brittle material thermal fatigue fracture simulation,” Int. J. Math. Comput. Methods, 2, 284 – 291 (2017).

A. V. Zabolotsky, A. N. Borzov, V. T. Khadyev, and K. P. Andreev, “Digitalization of industrial thermal processes and units,” Chern. Metallurg.: Byul. Nauch.-Tekhnich. Ekonomich. Inform., 77(2), 209 – 214 (2021).

Y. Murakami, Stress Intensity Factors Handbook, 2, ed. by Y. Murakami, Pergamon Press, Oxford (1987).

N.-S. Choi, T.-W. Kim, and K. Y. Rhee, “Kaiser effects in acoustic emission from composites during thermal cyclic-loading,” NDT & E Int., 38(4), 268 – 274 (2005). https://doi.org/10.1016/j.ndteint.2004.09.005.

J. Kaiser, An Investigation into the Occurrence of Noise in Tensile Tests or a Study of Acoustic Phenomena in Tensile Tests, Ph. D. Thesis, Munchen, Germany (1950).

S. V. Astafurov, E. V. Shilko, and S. G. Psakhie, “The possibilities and limitations of the homogenized description of inelastic behavior of brittle porous materials under constrained conditions,” PNRPU Mech. Bull., 1, 208 – 232 (2017).

E. V. Shilko, A. V. Dimaki, and S. G. Psakhie, “Strength of shear bands in fluid-saturated rocks: a nonlinear effect of competition between dilation and fluid flow,” Sci. Rep., 8, Article No. 1428 (2018).

R. J. Cuss, E. H. Rutter, “Holloway the application of critical state soil mechanics to the mechanical behavior of porous sandstones,” Int. J. Rock Mech. Min., 40(6), 847 – 862 (2003).

H. Fossen, R. A. Schultz, Z. K. Shipton, et al., “Deformation bands in sandstone : a review,” J. Geol. Soc. Lond., 164(4), 755 – 769 (2007).

B. Menendez, W. Zhu, and T.-F. Wong, “Micromechanics of brittle faulting and cataclastic flow in berea Sandstone,” J. Struct. Geol., 18, 1 – 16 (1996).

T.-F. Wong, C. David, and W. Zhu, “The transition from brittle faulting to cataclastic flow in porous sandstones,” J. Geophys. Res., 102, 3009 – 3025 (1997).

C. Jaeger, Rock Mechanics and Engineering, Cambridge University Press, Cambridge (2009).

T.-F. Wong, R. Baud, “The brittle-ductile transition in porous rock: a review,” J. Struct. Geol., 44, 25 – 53 (2012).

E. H. Rutter, C. T. Glover, “The formation of porous sandstones; are Byerlee friction and the critical state line equivalent,” J. Struct. Geol., 44, 129 – 140 (2012).

Y. P. Stefanov,M. A. Chertov, G. R. Aidagulov, and A. V. Myasnikov, “Dynamics of inelastic deformation of porous rocks and formation of localized compaction zones studied by numerical modeling,” J. Mech. Phys. Solids, 59, 2323 – 2340 (2011).

A. S. Grigoriev, S. V. Danil’chenko, A. V. Zabolotsky, et al., “Characteristics of destruction of linings in equipment of different sizes,” Nov. Ogneup., No. 12, 3 – 11 (2022).

D. C. Drucker, W. Prager, “Soil mechanics and plastic analysis for limit design,” Q. Appl. Math., 10, 157 – 165 (1952).

E. Oztekin, S. Pul, and M. Husem, “Experimental determination of Drucker – Prager yield criterion parameters for normal and high strength concretes under triaxial compression,” Constr. Build. Mater., 112, 725 – 732 (2016). https://doi.org/10.1016/j.conbuildmat.2016.02.127.

V. D. Kuliev, E. M. Morozov, “The gradient deformation criterion for brittle fracture,” Doklady Phys., 61, 502 – 504 (2016). https://doi.org/10.1134/S1028335816100062.

R. V. Gol’dshtein, N. M. Osipenko, “The model of a structured medium under compression conditions,” Mekhan. Tverd. Tela, No. 6, 86 – 97 (2010).

R. V. Gol’dshtein, N. M. Osipenko, “Model of brittle fracture of porous materials under compression,” Matematich. Modelir. Sistem Protsessov, No. 17, 47 – 58 (2009).

A. V. Zabolotsky, V. T. Khadyev,M. Yu. Turchin, and A. O. Migashkin, “Numerical study of the stress-strain state of a brittle porous material under multiaxial loading,” Physical Mesomechanics of Materials. Physical principles of formation of a multilevel structure and mechanisms of non-linear behavior, abstracts of reports of the International conf. (Tomsk, September 5 – 8, 2022), NGU, Novosibirsk, 291, 292 (2022). https://doi.org/10.25205/978-5-4437-1353-3-176.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Novye Ogneupory, No. 3, pp. 13 – 20, March, 2023.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zabolotsky, A.V., Migashkin, A.O., Grigor’ev, A.S. et al. Simulation of Crack Nucleation in Materials with Regularly Arranged Spherical Pores Under Multiaxial Loading Conditions. Refract Ind Ceram 64, 119–125 (2023). https://doi.org/10.1007/s11148-023-00813-1

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11148-023-00813-1