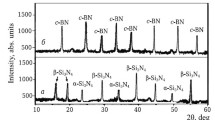

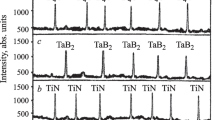

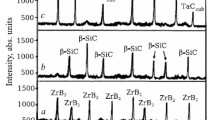

The paper shows the effect of Ti2 AlNb, NiTi, NiNbZr, and NiVTa additives during spark plasma sintering of the compositions under a pressing loading of 60 MPa in the temperature range from 1200 to 1600°C on the phase composition, microstructure, grain sizes of the crystalline phases, relative density, linear shrinkage, physical and mechanical properties, linear correlation of the modulus of elasticity, and fracture toughness of the mullite—(Ti,Mo)(C,N) – c-ZrO2– c-BN and mullite – (Ti,Mo)(C,N) – β-Si3N4– c-BN samples. Synthesized powders of Ti(C0.7N0.3), β-Si3N4, c-BN, Ti2 AlNb, NiTi, NiNbZr, and NiVTa show intensive crystallization of Ti(C0.7N0.3), β-Si3N4, c-BN, Ti2AlNb, NiTi, Ni45Nb35Zr20, and Ni17V61Ta22 phases. Spark plasma sintered c-ZrO2 (at 1400°C) and (Ti,Mo)(C,N) (at 1800°C) show intensive crystallization of c-ZrO2 and (Ti0.7Mo0.3)(C0.7N0.3) phases. The crystalline microstructure of the sintered c-ZrO2 and (Ti,Mo)(C,N) phases consists of variously sintered and compacted grains of different shapes. The Ti2 AlNb, NiTi, NiNbZr, and NiVTa additives contribute to different crystallization of mullite and (Ti,Mo)(C,N), ZrO2, β-Si3N4, and c-BN phases in the temperature range from 1200 to 1600°C. Crystallization of the NiTi phase proceeds more intensively compared to the Ti2 AlNb phase, and samples sintered in the temperature range from 1400 to 1600°C demonstrate higher crystallinity of the Ni(Zr,Nb), Ni45Nb35Zr20, Ni(Ta,V), and Ni17V61Ta22 phases. The NiTi and NiVTa additives enhance sintering and promote the formation of more uniform and densely sintered microstructures of the samples at 1500°C, which results in polydisperse grain compositions of the crystalline phases of the samples in the range from 1200 to 1600°C. Samples containing the NiTi and NiVTa additives show a more active increase and higher physical and mechanical properties, crack resistance, linear correlation of the modulus of elasticity, and fracture toughness in the range from 1200 to 1600°C.

Similar content being viewed by others

Change history

17 November 2022

A Correction to this paper has been published: https://doi.org/10.1007/s11148-022-00690-0

Notes

The stoichiometry of Ni45Nb35Zr20, Ni17V61Ta22, and (Ti0.7Mo0.3)(C0.7N0.3) was determined based on the percentage content of Ni, Nb, Zr, Ni, V, Ta, Ti, Mo, C, and N in these compounds with an error of ±2% by energy dispersive X-ray spectrometer (model JET-2300T).

References

R. Vedant, Development of ZrB2-B4C-Mo ceramic matrix composite for high temperature applications, A thesis submitted to National institute of Technology Rourkela (2014), pp. 1 – 61.

P. Anupam, M. Ragini, and K. Nagarajan, “Development of ZrB2–SiC–Ti by multi stage spark plasma sintering at 1600°C,” J. Ceram. Soc. Jpn., 124(4), 393 – 402 (2016).

M. Naidoo, J. Raethel, I. Sigalas, and M. Herrmann, “Preparation of (Ti,Ta)(C,N) by mechanical alloying,” Int. J. Refract. Met. Hard Mater., 35(2), 178 – 184 (2012).

A. V. Hmelov, Development of dense materials by spark-plasma sintering of oxide – oxide-free components with different mixtures of metal powders, Refract. Ind. Ceram., 61(3), 313 – 321 (2020).

A. V. Hmelov, “Development of oxide-free oxide materials under spark-plasma sintering conditions of a mixture of oxide-free components and various metal powder additives,” Refract. Ind. Ceram., 61(1), 73 – 81 (2020).

J. Yu, G. Shi, O. Li, J. Wu, and L. Zhang, “Dependence of Nb doping on microstructure and mechanical properties of Al2O3/Ti3SiC2 composites,” J. Mater. Sci., 55(17), 7259 – 7267 (2020).

A. V. Hmelov, “Spark-plasma sintering of oxide-non-oxide components with the addition of a TiC–ZrC solid solution and various metal powder mixtures,” Refract. Ind. Ceram., 61(5), 568 – 579 (2021).

X. Ren, Z. Peng, Y. Peng, and C. Wang, “Spark plasma sintered WC-Ni carbides with various contents of ZrC nanopowder,” Key Eng. Mater., 591(1), 75 – 78 (2014).

J. Zhang, R. Tu, and T. Goto, “Spark plasma sintering and characterization of WC–Co–c-BN composites,” Eng. Mater., 616(4), 194 – 198 (2014).

Y. Fei, C. Huang, and H. Liu, “The phase composition and mechanical properties of Al2O3–TiC–TiN ceramic materials with different Ni content,” J. Ceram. Sci. Tech., 10(2), 1 – 8 (2019).

V. Verma and M. Kumar, “Processing of TiCN–WC–Ni/Co cermets via conventional and spark plasma sintering technique,” Trans. Ind. Inst. Met., 70(3), 843 – 853 (2017).

A. V. Hmelov, “Stimulation of spark-plasma sintering of mixtures of oxide-non-oxide components by adding a solid solution TaB2–NbC and through a nickel melt in mixtures of metal powders,” Refract. Ind. Ceram., 62(1), 74 – 88 (2021).

B. K. Karakozov, M. K. Skakov, Sh. R. Kurbanbekov, and A. A. Sitnikov, “Structural and phase transformations in alloys during spark plasma sintering of Ti + 23.5 at.% Al + 21 at.% Nb powder mixtures,” Inorg. Mater., 54(1), 37 – 42 (2018).

T. Tokunaga, S. Matsumoto, H. Ohtani, and M. Hasebe, “Thermodynamic analysis of the phase equilibria in the Ni–Nb–Zr system,” Mater. Trans., 48(9), 2263 – 2271 (2007).

C. Wang, Y. Liang, S. Yang, and J. Zhang, “Phase equilibria in the Ni–V–Ta ternary system,” Metals, 8(10), 762 – 774 (2018).

N. A. Toropov, V. P. Barzakovskii, and R. V. Lapin, Phase Diagrams of Silicate Systems [in Russian], Nauka, Leningrad (1979).

H. Zhang, N. Yan, H. Liang, and Y. Li, “Phase transformation and microstructure control of Ti2AlNb-based alloys: a review,” J. Mater. Sci. Technol., 80(30), 203 – 216 (2021).

M. Ibrahim and N. Bright, “The binary system Nb2O5-SiO2,” J. Am. Ceram. Soc., 45(5), 221 – 222 (2006).

X. Zhang, J. Zhou, Y. Jiang, C. Wu, and C. Lin, “Preparation and characterization of Nb2O5–Al2O3 system ceramics with different Al2O3 additions,” Eng. Mater., 544(4), 60 – 63 (2013).

A. Garcia-Prieto, M. D. Ramos-Lotito, D. Gutierrez-Campos, and C. Baudin, “Influence of microstructural characteristics on fracture toughness of refractory materials,” J. Eur. Ceram. Soc., 35(6), 1956 – 1970 (2015).

B. Phillips, J. J. Hutta, and I. Warshaw, “Phase equilibria in the system NiO–Al2O3–SiO2, J. Am. Ceram. Soc., 46(12), 579 – 583 (2006).

A. Wannagon, N. Mishima, T. Wakasugi, R. Ota, and J. Fukanaga, “Formation and thermal stability in the SiO2–TiO2–ZrO2 system,” J. Ceram. Soc. Jpn., 105(11), 940 – 946 (1997).

M. Ilatovskaia, G. Savinykh, and O. Fabrichnaya, “Thermodynamic description of the Al2O3–TiO2–ZrO2 system based on experimental data,” J. Eur. Ceram. Soc., 37(10), 3461 – 3469 (2017).

J. Zygmuntowicz, P. Falkowski, A. Miazga, and K. Konopka, “Fabrication and characterization of ZrO2/Ni composites,” J. Aust. Ceram. Soc., 54(4), 655 – 662 (2018).

S. H. Choi, B. Ali, S. K. Hyun, and J. J. Sim, “Reaction kinetics and morphological study of TiNb2O7 synthesized by solid-state reaction,” Arch. Metall. Mater., 62(2), 1051 – 1056 (2017).

R. J. Perez and A. R. Massih, “Thermodynamic evaluation of the Nb–O–Zr system,” J. Nucl. Mater., 360(3), 242 – 255 (2007).

G. V. Chuprina and M. I. Shalya, “Reactions of NiTi with oxygen,” Powder Metall. Met. Ceram., 41(1/2), 85 – 89 (2002).

A.-T. Qiu, L.-J. Liu, W. Pang, X.-G. Lu, C.-H. Li, “Calculation of phase diagram of Ti-Ni-O system and application to deoxidation of NiTi alloy,” Trans. Non-ferrous Met. Soc. China, 21(8), 1808 – 1816 (2011).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Novye Ogneupory, No. 10, pp. 26 – 41, October, 2021.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Hmelov, A.V. Development of Dense and Hard Materials Based on Oxide – Non-Oxide Compounds with Added Intermetallic Components During Spark Plasma Sintering. Refract Ind Ceram 62, 570–586 (2022). https://doi.org/10.1007/s11148-022-00645-5

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11148-022-00645-5