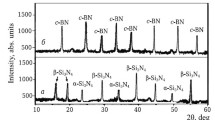

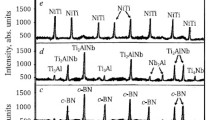

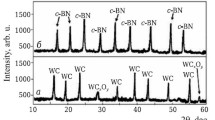

The effects of Wand Mo power additives during spark-plasma sintering of compositions at compression force 60 MPa at 1200 – 1600°C on the phase composition, microstructure, crystalline-phase grain size, relative density, linear shrinkage, physicomechanical properties, and the linear correlation of the elasticity modulus and fracture toughness of mullite–ZrB2–β-SiC–TaC samples were studied. The synthesized ZrB2, β-SiC, and TaC powders were characterized by extensive crystallization of ZrB2, β-SiC, and TaCcub, respectively. Sintered samples withWand Mo powder additives showed extensive mullite formation and more active crystallization of β-SiC, (Zr, Ta)B, C, β-WC, and β-WB than (Ta, Zr)C, B, β-MoC, β-MoB, and MoB2 at 1200 – 1600°C. The microstructure of the sample with the Mo additive at 1500°C was more uniformly and densely sintered and crystalline; contained fewer pores and weakly sintered areas; and was more reinforced at the boundaries of oxide-free oxide and oxide-free crystalline phases. This sample had characteristically smaller grain sizes of the crystalline phases at 1400 – 1600°C and showed uniform growth of the relative density, linear shrinkage, and physicomechanical properties; higher crack resistance (with propagation of microcracks along a meandering path), and a better linear correlation of the elasticity modulus and fracture toughness at 1200 – 1600°C.

Similar content being viewed by others

References

M. Hotta and T. Goto, “Spark-plasma sintering of TiN – cubic BN composites,” J. Ceram. Soc. Jpn., 118(2), 137 – 140 (2010).

L. Silvestroni and S. Diletta, “Densification of ZrB2–TaSi2 and HfB2–TaSi2 ultra-high temperature ceramic composites,” J. Am. Ceram. Soc., 94(6), 1920 – 1930 (2011).

H. Chunfeng, S. Yoshio, and T. Hidehiko, “Microstructure and properties of ZrB2–SiC composites prepared by spark plasma sintering using TaSi2 as sintering additive,” J. Eur. Ceram. Soc., 30(4), 2625 – 2631 (2010).

X. Liu, Q. Xu, and S. Zhu, “Effect of B4C on the mechanical properties and microstructure of ZrB2–SiC based ceramics,” Adv. Mater. Res., 105/106(2), 218 – 221 (2010).

A. V. Hmelov, “Preparation of mullite–TiC–TiN materials by a plasma spark method and their properties,” Refract. Ind. Ceram., 58(4), 418 – 425 (2017).

X. Zhang, X. Li, J. Han, and W. Han, “Effect of Y2O3 on microstructure and mechanical properties of ZrB2–SiC,” J. Alloys Compd., 465(1/2), 506 – 511 (2008).

X. Zhang, W. Li, C. Hong, and W. Han, “Microstructure and mechanical properties of ZrB2-based composites reinforced and toughened by zirconia,” Int. J. Appl. Ceram. Technol., 5(5), 499 – 504 (2008).

J. F. Zhang, R. Tu, and T. Goto, “Spark plasma sintering and characterization of WC–Co–c-BN composites,” Key Eng. Mater., 616(4), 194 – 198 (2014).

X. Y. Ren, Z. J. Peng, Y. Peng, C. B.Wang, et al., “Spark plasma sintered WC–Ni cemented carbides with various contents of ZrC nano-powder,” Key Eng. Mater., 591(3), 75 – 78 (2014).

S. Sugiyama and H. Taimatsu, “Preparation of WC–WB–W2B composites from B4C–W–WC powders and their mechanical properties,” Mater. Trans., 43(5), 1197 – 1201 (2002).

P. Anupam, M. Ragini, and K. Nagarajan, “Development of ZrB2–SiC–Ti by multistage spark plasma sintering at 1600°C,” J. Ceram. Soc. Jpn., 124(4), 393 – 402 (2016).

D. Jiaxin and S. Junlong, “Microstructure and mechanical properties of hot-pressed B4C/TiC/Mo ceramic composites,” Ceram. Int., 35(2), 771 – 778 (2009).

R. Vedant, “Development of ZrB2–B4C–Mo ceramic matrix composite for high temperature applications,” A thesis submitted to the National Institute of Technology Rourkela, 1 – 61 (2014).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Novye Ogneupory, No. 2, pp. 17 – 25, February, 2020.

Rights and permissions

About this article

Cite this article

Hmelov, A.V. Development of Oxide-Free Oxide Materials under Spark-Plasma Sintering Conditions of a Mixture of Oxide-Free Components and Various Metal Powder Additives. Refract Ind Ceram 61, 73–81 (2020). https://doi.org/10.1007/s11148-020-00433-z

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11148-020-00433-z