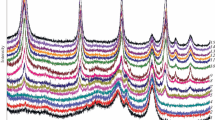

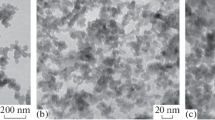

The characteristics of boehmite nanopowders prepared by re-precipitation of aluminum trihydroxide, a sol-gel method by aluminum alkoxide hydrolysis, and hydrothermal synthesis from industrial aluminum powders are investigated. Boehmite nanopowder preparation method has a decisive effect on structure, dispersion, chemical and phase composition, and production properties. It is shown that when preparing products with specified parameters it is necessary to consider the difference in the effect of boehmite nanopowder on functional properties. Examples of the use of boehmite nanopowder from different producers in ceramic and catalyst technologies are provided.

Similar content being viewed by others

References

A. S. Ivanova, “Aluminum oxide and systems based upon it, application,” Linetika Kataliz, 53(4), 446 – 460 (2012).

GOST 8136 – 85. Activated aluminum oxide. Technical specifications. IPK Izd. Stadartov, Moscow (1986).

K. I. Sheferm D. A. Yatsenko, S. V. Tsybulya, et al., “Structural features of very fine pseudo-boehmite prepared by a sol-gel method,” Zh. Strukt. Khim., 51(2), 337 – 341 (2010).

A. V. Bersh, N. N. Zhukov, Yu. L. Ivanov, V. K. Ikonnikov, Yu. A. Mazalov, V. Yu. Ryzhkin, and O. A. Trubachev, RF Patent 2223221, Method for preparing aluminum hydroxide or oxide and hydrogen, Publ. 02.10.2004, Bull. No. 4.

M. Lee, x-ray Diffraction for Materials Research. From Fundamentals to Applications, Apple Academic Press, Inc., Oakville (2016).

V. A. Liopo and V. V. Voina, x-ray Diffractometry [in Russian], Grodno (2003).

GOST 23401 – 90. Metal powders. Catalysts and carriers. Specific surface determination, Izd. Standartov, Moscow (1991)

E. P. Barrett, et al., “The determination of pore volume and area distributions in porous substances. I. Computations from nitrogen isotherms,” J. Am. Chem. Soc., 73, 373 – 380 (1951).

ASTM D6175 – 03(2019). Standard Test Method for Radial Crush Strength of Extruded Catalyst and Catalyst Carrier Particles. Active Standard ASTM D6175 | Developed by Subcommittee: D32.02. Book of Standards Volume: 05.06.

P. A. Vityaz’, A. F. Il’yushenko, L. V. Sudnik, et al., Functional Materials Based on Nano-structured Aluminum Hydroxide Powders [in Russian], Navuka, Minsk Belarus (2010).

V. I. Chernoivanov, Yu. A. Mazalov, A. V. Merenov, A. V. Bersh, A. V. Dunaev, and T. V. Pronskaya, RF Patent 2515727, Method for preparing nano-structured catalytic coatings on ceramic carriers for neutralizing for neutralizing internal engine combustion gases; Publ. 05.20.2014, Bull. No. 14.

A. V. Bersh, A. V. Belyakov, D. Y. Mazalov, et al., “Corundum composite ceramic prepared using boehmite nanoparticles,” Refract. Ind. Ceram., 57(5), 545 – 550 (2017).

A. V. Belyakov, “Synergetic and quasichemical approaches in ceramic technology (a review),” Glass and Ceramics, 60(9/10), 274 – 279 (2003).

A, V. Fedotov, V. I. Vanchurin, and A. V. Belyakov, Aluminum oxyhydroxide nanopowder and field for application,” Proc. IV All-Russia Correspondence Scientific-Practical Youth Conference with International Participation “Contemporary composite material technology,” Ufa, 15 April 2019.

A. V. Bersh, Yu. A. Mazalov, L. V. Sudnik, and A. V. Fedotov, “Influence of nanocrystalline boehmite additive on the properties of non-stick coating,” Technology of Metals, No. 12, 22 – 26 (2010).

A. V. Belyakov, “High-density micro- and nano-grain size ceramics. Transition from open into closed pores. Part 1. Powder preparation, molding mixture, molding,” Refract. Ind. Ceram., 60(6), 574 – 581 (2020).

A. V. Belyakov, “High-density micro- and nano-grain size ceramics. Transition from open into closed pores. Part 2. Binder removal from a workpiece,” Refract. Ind. Ceram., 60(6), 582 – 589 (2020).

A. V. Belyakov, “High-density micro- and nano-grain size ceramics. Transition from open into closed pores. Part 3. Workpiece sintering without external pressure,” Refract. Ind. Ceram., 61(1), 40 – 49 (2020).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Novye Ogneupory, No. 3, pp. 16 – 23, March, 2021.

Rights and permissions

About this article

Cite this article

Belyakov, A.V., Fedotov, A.V. & Vanchurin, V.I. Boehmite Nanoparticles with Different Functional Properties for Preparing Products with Specific Parameters. Refract Ind Ceram 62, 145–152 (2021). https://doi.org/10.1007/s11148-021-00574-9

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11148-021-00574-9