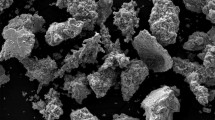

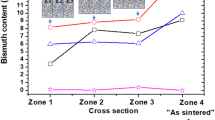

Addition of various reinforcements was studied in an attempt to produce a TiC–Al2O3 composite with high density, homogeneous microstructure, and outstanding mechanical properties for use in aggressive media using self-propagating high-temperature synthesis (SHS). Ductile Ni-metal powder (5 – 20 wt.%) and Al2O3 and ZrO2 (1 mole fraction) dilutions with and without Ni addition were introduced into TiC–Al2O3 composite synthesized by combined SHS and direct consolidation (DC). The influence of the Ni content and dilution with Al2O3 and ZrO2 on the phase composition, densification behavior, microstructure, and mechanical properties of the synthesized TiC–Al2O3 composite was investigated. The best results were obtained by adding Ni(5 wt.%) to the TiC–Al2O3 composite. However, the chemical reactions between the starting precursors were disturbed and the composite characteristics worsened if the Ni content was increased to >5 wt.%. Accordingly, addition of 5 wt.% Ni was suggested to produce a highly dense TiC–Al2O3 composite with a homogenized morphology and unparalleled mechanical properties. Moreover, the produced composites could be used successfully in aggressive media and tribological applications.

Similar content being viewed by others

References

L. J. Kecskes, A. Niller, T. Kottke, K. V. Logan, and G. R. Villalobos, “Dynamic consolidation of combustion-synthesized alumina–titanium diboride composite ceramics,” J. Am. Ceram. Soc., 79, 2687 – 2695 (1996).

Y. G. Elazar and I. Gotman, “Dense high-temperature ceramics by thermal explosion under pressure,” J. Eur. Ceram. Soc., 19, 2381 – 2393 (1999).

D. S. Mao and J. Li, “Mechanical properties and fracture behaviour of Al2O3–TiC–Co advanced ceramics,” J. Mater. Sci. Lett., 16, 537 – 540 (1997).

R. P. Wahi and B. Ilschner, “Fracture behaviour of composites based on Al2O3–TiC,” J. Mater. Sci., 15, 875 – 885 (1980).

A. Goldstein and A. Singurindi, “Al2O3/TiC based metal cutting tools by microwave sintering followed by hot isostatic pressing,” J. Am. Ceram. Soc., 83, 1530 – 1532 (2004).

J. T. Horng, N. M. Liu, and K. T. Chiang, J. Mater. Process. Technol., 532 – 541 (2008).

A. S. Kumar, A. R. Durai, and T. Sornakumar, Int. J. Refract. Met. Hard Mater., 21, 109 – 117 (2003).

M. V. Grigoryev, et al., “Microstructure, mechanical properties and machining performance of hot-pressed Al2O3–ZrO2–TiC composites,” IOP Conf. Ser.: Mater. Sci. Eng., 116, 012002 (2013).

M. Lee and M. P. Borom, “Rapid rate sintering of Al2O3–TiC composites for cutting-tool applications,” Adv. Ceram. Mater., 3, 38 – 44 (1988).

R. P. Wahi and B. Ilschner, “Fracture behaviour of composites based on Al2O3–TiC,” J. Mater. Sci., 15, 875 – 885 (1980).

T. Nagano, H. Kato, and F. Wakai, “Deformation of alumina/titanium carbide composite at elevated temperatures,” J. Am. Ceram. Soc., 74(9), 2258 – 2262 (1991).

S. V. Gedevanishvili and Z. A. Munir, “Field-assisted combustion synthesis of MoSi2–SiC composites,” Scr. Metall. Mater., 31, 741 – 743 (1994).

H. Xue and Z. A. Munir, “Extending the compositional limit of combustion-synthesized B4C–TiB2 composites by field activation,” Metall. Mater. Trans. B, 27, 475 – 480 (1996).

H. C. Yi and J. J. Moore, “Self-propagating high-temperature (combustion) synthesis (SHS) of powder-compacted materials,” J. Mater. Sci., 25, 1159 – 1168 (1990).

S. Gedevanishvili and Z. A. Munir, “Field-activated combustion synthesis in the Nb–Si system,” Mater. Sci. Eng., A, 211, 1 – 9 (1996).

D. A. Hoke, D. K. Kim, J. C. LaSalvia, and M. A. Meyers, “Combustion synthesis/dynamic densification of a TiB2–SiC composite,” J. Am. Ceram. Soc., 79, 177 – 182 (1996).

Y. M. Z. Ahmed, Z. I. Zaki, R. K. Bordia, D. H. A. Besisa, and A. M. M. Amin, “Simultaneous synthesis and sintering of TiC/Al2O3 composite via self propagating synthesis with direct consolidation technique,” Ceram. Int., 42(15), 16589 – 16597 (2016).

L. Wang, M. R. Wixom, and L. T. Thompson, “Structural and mechanical properties of TiB2 and TiC prepared by self-propagating high-temperature synthesis/dynamic compaction,” J. Mater. Sci., 29, 534 – 543 (1994).

H. J. Feng, J. J. Moore, and D. G.Wirth, “Combustion synthesis of ceramic-metal composites materials: the TiC–Al2O3–Al system,” Metall. Trans. A, 23, 2373 – 2379 (1992).

A. Chakraborty, S. V. Kamat, R. Mitra, and K. K. Ray, “Effect of MoSi2 and Nb reinforcements on mechanical properties of Al2O3 matrix composites,” J. Mater. Sci., 35, 3827 – 3835 (2000).

W. G. Fahrenholtz, D. T. Ellerby, and R. E. Loehman, “Al2O3–Ni composites with high strength and fracture toughness,” J. Am. Ceram. Soc., 83, 1279 – 1280 (2000).

B. D. Flinn, M. Ruhle, and A. G. Evans, “Toughening in composites of Al2O3 reinforced with Al,” Acta Metall., 37, 3001 – 3006 (1989).

S. Kasuriya and D. Atong, “The effect of MgO–Y2O3 on Al2O3–TiC composites,” Mater. Sci. Forum, 534 – 536, 605 – 608 (2007).

R. Kumar, A. K. Chaubey, T. Maity, and K. G. Prashanth, “Mechanical and tribological properties of Al2O3–TiC composite fabricated by spark plasma sintering process with metallic (Ni, Nb) binders,” Metals, 8(50), 1 – 12 (2018).

Y. M. Z. Ahmed, Z. I. Zakia, D. H. A. Besisa, A. M. M. Amin, and R. K. Bordia, “Effect of zirconia and iron on the mechanical properties of Al2O3/TiC composites processed using combined self-propagating synthesis and direct consolidation technique,” Mater. Sci. Eng., A, 696, 182 – 189 (2017).

K. Otani, K. Hattori, H. Muraoka, H. Kawazoe, and S. Tsuruta, “Development of ultraheavy gauge (210 mm thick) 800 N/mm2 tensile strength plate steel for racks and jack-up rigs,” Nippon Steel Tech. Rep., 58, 292 (1993).

J. Matsushita, H. Nagashima, and H. Saito, “Preparation and mechanical properties of TiB2 composites containing Ni and C,” J. Ceram. Soc. Jpn., 99, 78 (1991).

G. J. Zhang, Z. Z. Jin, and X. M. Yue, “Effects of Ni addition on mechanical properties of TiB2/SiC composites prepared by reactive hot pressing (RHP),” J. Mater. Sci., 32, 2093 – 2097 (1997).

Y. Choi and S. Rhee, “Effect of precursors on the combustion synthesis of TiC–Al2O3 composite,” J. Mater. Res., 9(7), 1761 – 1766 (1994).

M. Fukuhara, K. Fukazawa, and A. Fukawa, “Physical properties and cutting performance of silicon nitride ceramic,” Wear, 102, 195 – 210 (1985).

D. A. Jerebtsov, G. G. Mikhailov, and S. V. Sverdina, “Phase diagram of the system: Al2O3–ZrO2,” Ceram. Int., 26, 821 – 823 (2000).

G. Liu, J. Li, and K. Chen, “One-step preparation of dense TiC1–xNx–Ni3Ti cermet by combustion synthesis,” Mater. Des., 87, 6 – 9 (2015).

F. Qiu, R. Zuo, S.-L. Shu, Y.-W.Wang, and Q.-C. Jiang, “Effect of Al addition on the microstructures and compression properties of (TiCxNy–TiB2)/Ni composites fabricated by combustion synthesis and hot press” Powder Technol., 286, 716 – 721 (2015).

J. W. McCauley, N. D. Corbin, T. Resetar, and P. Wong,”Simultaneous preparation and self-sintering of materials in the system Ti–B–C,” Ceram. Eng. Sci. Proc., 3, 538 – 554 (1982).

R. A. Cutter, A. C. Hurford, and A. V. Virkar, “Pressurelesssintered Al2O3–TiC composites” Mater. Sci. Eng., A, 105 – 106, Part 1, 183 – 192 (1988).

X. Sun and J. Yeomans, “Optimization of a ductile-particle- toughened ceramic” J. Am. Ceram. Soc., 79, 2705 – 2717 (1996).

Acknowledgments

We gratefully acknowledge support for this work from US National Science Foundation Grant No. 0612063 and Science and Technology Development Fund (STDF), Egypt, Grant No. 323.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Novye Ogneupory, No. 9, pp. 47 – 55, September, 2020.

Rights and permissions

About this article

Cite this article

Besisa, D.H.A., Zaki, Z.I., Amin, A.M.M. et al. Influence of Hardening Additives on the Characteristics of the Tribological TiC–Al2O3 Ceramic Composite Obtained by SHS. Refract Ind Ceram 61, 528–535 (2021). https://doi.org/10.1007/s11148-021-00515-6

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11148-021-00515-6