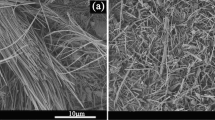

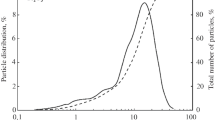

Porous ceramics made by burning out a pore-former during the sintering process were investigated by stepwise isothermal dilatometry (SID), x-ray diffraction (XRD) phase identification, scanning electron microscopy (SEM), and mechanical-property analysis. SID data obtained by the Makipirtti-Meng method was analyzed and was found to fit well with data on shrinkage obtained by means of the rate equation proposed for use with this method. Kinetic parameters were evaluated and it was established that sintering takes place through two main mechanisms. These mechanisms are related to the generation and sintering of oxidation products and have activation energies of 55.4 and 325.4 kJ/mole. The sintering temperature greatly affects such properties of sintered specimens as open porosity and ultimate flexural strength. The results obtained in the investigation were well-supported by microstructural analysis of the sintered specimens.

Similar content being viewed by others

References

W. W. Chen and Y. Miyamoto, “Fabrication of porous silicon carbide ceramics with high porosity and high strength,” J. Eur. Ceram. Soc., 34(3), 837 – 840 (2014).

Z. Li, T. J. Shi, and Dexin Tan, “Conversion of a wood flour-SiO2-phenolic composite to a porous SiC ceramic containing SiC whiskers,” J. Serb. Chem. Soc., 78(8), 1213 – 1223 (2013).

L. S. Sigl and H. J. Kleebe, “Core rim structure of liquid-phasesintered silicon carbide,” J. Amer. Ceram. Soc., 76, 773 – 776 (1993).

J. H. She, T. Ohji, and S. Kanzaki, “Oxidation bonding of porous silicon carbide ceramics with synergistic performance,” J. Eur. Ceram. Soc., 24, 331 – 334 (2004).

T. Ohji and M. Fukushima, “Macro-porous ceramics: processing and properties,” Int. Mater. Rev., 57(2), 115 – 131 (2012).

A. Dey, N. Kayal, and O. Chakrabarti, “Evaluation of air permeation behavior of porous SiC ceramics synthesized by oxidation- bonding technique,” Int. J. Appl. Ceram. Tec., 10(6), 1023 – 1033 (2013).

B. Paul, S. Koley, and A. K. Surey, “A novel approach to determine oxidation kinetics of Mo–16Cr–xSi (x = 4–6 wt. %) using stepwise isothermal thermo-gravimetry,” Thermochim. Acta, 549(10), 57 – 62 (2012).

T. A. G. Restivo and S. R. H. Mello-Castanho, “Cu–Ni–YSZ anodes for solid oxide fuel cell by mechanical alloying processing,” Int. J. Mater. Res., 101(1), 128 – 132 (2010).

B. Paul, “Sintering kinetics of submicron sized cobalt powder,” Thermochim. Acta, 488, 54 – 59 (2009).

B. Paula, D. Jainb, and S. P. Chakrabortya, “Sintering kinetics study of mechanically alloyed nanocrystalline M–30 wt.% W,” Thermochim. Acta, 512(10), 134 – 141 (2011).

C. Y. Bai, X. Y. Deng, and B. Li, Ceram. Int., “Fabrication and properties of cordierite-mullite bonded porous SiC ceramics,” 40, 6225 – 6231 (2014).

X. B. Zhang, X. Q. Liu, and G. Y. Meng, “Sintering kinetics of porous ceramics from natural diatomite,” J. Amer. Ceram. Soc., 88, No. 7, 1826 – 1830 (2005).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Novye Ogneupory, No. 11, pp. 62 – 66, 2014

Rights and permissions

About this article

Cite this article

Liu, J., Zhang, X., Wu, H. et al. Evaluating the Sintering Kinetics of Porous Sic Ceramics. Refract Ind Ceram 55, 545–548 (2015). https://doi.org/10.1007/s11148-015-9761-0

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11148-015-9761-0