Abstract

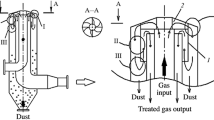

A new method proven under production conditions is proposed for fine cleaning of air in systems of pneumatic transport of loose materials consisting of the use of filters made of porous metals. A production scheme is considered for a test-industrial unit and operating parameters are recommended.

Similar content being viewed by others

References

M. B. Generalov, V. P. Aleksandrov, V. V. Alekseev, et al., Engineering, Encyclopaedia. Machines and Equipment for Chemical Petrochemical production, Vol. IV-12 [in Russian], Mashinostroenie, Moscow (2004).

V. S. Shvydkii and M. G. Ladygichev, Gas Cleaning: Reference Edition [in Russian], Teploenergetik, Moscow (2002).

V. A. Goremykin, Yu. V. Krasovitskii, S. Yu. Panov, et al., Energy Saving Dust Removal During Production of Ceramic Pigments by a “Dry” Method [in Russian], VGO, Voronezh (2001).

V. P. Dobrosotskii, K. S. Gromov, A. V. Malinov, et al., “Commercial and social-economic prospects for highly efficient dust removal during production of building materials and ceramics,” Stroit. Materialy, No. 8 (Business supplement), 12–13 (2005).

V. P. Dobrosotskii, K. S. Gromov, A. V. Malinov, et al., “Evaluation of the economic loss to the main production fund of an enterprise due to dust discharges,” Stroit. Materialy, No. 12, 64 (2005).

V. P. Dobrosotskii, K. S. Gromov, A. V. Malinov, et al., “Rational organization and procedure for dust and gas measurements during production of building materials and ceramics,” Stroit. Materialy, No. 5 (Technology supplement), 12–16 (2005).

V. P. Dobrosotskii, K. S. Gromov,, G. V. Kol’tsov, et al., “Determination of the economic desirability of a specific load in granular filtering barriers with dust removal,” Khim. Neftegaz. Mashinotroenie, No. 5, 36–38 (2005).

V. P. Dobrosotskii, K. S. Gromov, G. V. Kol’tsov, et al., “Future development of dust removal systems in ceramic production,” Khim. Neftegaz. Mashinotroenie, No. 7, 37–38 (2005).

V. P. Dobrosotskii, K. S. Gromov, A. V. Malinov, et al., “Technical and economic indices of catching ceramic dust with granular filters,” Khim. Neftegaz. Mashinotroenie, No. 2, 35–36 (2006).

L. P. Kholpanov, E. P. Zaporozhets, T. K. Zibert, et al., Mathematical Modelling of Nonlinear Thermohydrogasdynamic Processes in Multicomponent Jet Streams [in Russian], Nauka, Moscow (1998).

S. V. Éntin, N. M. Anzheurov, S. Yu. Panov, et al., “Analysis of methods and future directions for regeneration of granular filtering layers,” in: Proc. Internat. Sci. Pract. Conf. “Progressive Technologies of Development,” Tambov (2004).

S. V. Éntin, N. M. Anzheurov, S. Yu. Panov, et al., “New technical solution fir highly effective dry dust removal in refractory production,” Novye Ogneupory, No. 5, 84–86 (2003).

Author information

Authors and Affiliations

Additional information

__________

Translated from Novye Ogneupory, No. 9, pp. 68–72, September 2007.

Rights and permissions

About this article

Cite this article

Éntin, S.V., Kabargin, S.L., Ermolychev, D.A. et al. Dust removal from air in systems of pneumatic transport of loose raw materials. Refract Ind Ceram 48, 387–390 (2007). https://doi.org/10.1007/s11148-007-0101-x

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11148-007-0101-x