Abstract

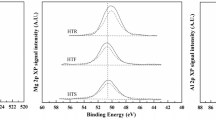

Cu–Mn–Al mixed oxides were prepared by calcination of carbonate layered double hydroxides. Four materials were prepared with nominal Cu/Mn ratios in the 0.5–2.0 range and 0.19 nominal Al atom fraction relative to metal ions. Reduction of the oxide precursors was followed by in situ X-ray absorption and X-ray diffraction and showed that copper was totally reduced, and manganese reduced mainly to Mn2+. Copper metal surface area by N2O decomposition after in situ reduction showed that the dispersion increased with decreasing copper content in Mn–Cu–Al catalysts. In methanol synthesis from syngas, the methanol productivity and selectivity achieved values up to 35 mol kg−1 h−1 and 94% with Cu–Mn–Al catalysts. In the direct syngas to DME reaction, using γ-alumina as the methanol dehydration component, the productivity of the Cu–Mn–Al catalyst with 0.5 Cu/Mn ratio stood-out from that of the remaining catalysts.

Similar content being viewed by others

References

Bepari S, Kuila D (2020) Steam reforming of methanol, ethanol and glycerol over nickel-based catalysts-a review. Int J Hydrogen Energy 45:18090–18113. https://doi.org/10.1016/j.ijhydene.2019.08.003

Dos Santos RG, Alencar AC (2020) Biomass-derived syngas production via gasification process and its catalytic conversion into fuels by Fischer–Tropsch synthesis: a review. Int J Hydrogen Energy 45:18114–18132. https://doi.org/10.1016/j.ijhydene.2019.07.133

Sousa-Aguiar EF, Noronha FB, Faro A Jr (2011) The main catalytic challenges in GTL (gas-to-liquids) processes. Catal Sci Technol 1:698–713. https://doi.org/10.1039/C1CY00116G

Jadhav SG, Vaidya PD, Bhanage BM, Joshi JB (2014) Catalytic carbon dioxide hydrogenation to methanol: a review of recent studies. Chem Eng Res Des 92:2557–2567. https://doi.org/10.1016/j.cherd.2014.03.005

Ali KA, Abdullah AZ, Mohamed AR (2015) Catalytic carbon dioxide hydrogenation to methanol: a review of recent studies. Renew Sustain Energy Rev 44:508–518. https://doi.org/10.1016/j.rser.2015.01.010

Çelik MB, Özdalyan B, Alkan F (2011) The use of pure methanol as fuel at high compression ratio in a single cylinder gasoline engine. Fuel 90:1591–1598. https://doi.org/10.1016/j.fuel.2010.10.035

Joghee P, Malik JN, Pylypenko S, O’Hayre R (2015) A review on direct methanol fuel cells—in the perspective of energy and sustainability. MRS Energy Sustain 2:1–31. https://doi.org/10.1557/mre.2015.4

Galadima A, Muraza O (2015) From synthesis gas production to methanol synthesis and potential upgrade to gasoline range hydrocarbons: a review. J Nat Gas Sci Eng 25:303–316. https://doi.org/10.1016/j.jngse.2015.05.012

Bakhtyari A, Rahimpour MR (2018) Methanol. In: Basile A, Dalena FBT-M (eds) Methanol to dimethyl ether. Elsevier, Amsterdam, pp 281–31

Prabowo B, Yan M, Syamsiro M, Setyobudi RH, Biddinika MK (2017) State of the art of global dimethyl ether production and its potentional application in Indonesia. Proc Pak Acad Sci Part B 54:29–39

Arcoumanis C, Bae C, Crookes R, Kinoshita E (2008) The potential of di-methyl ether (DME) as an alternative fuel for compression-ignition engines: a review. Fuel. 87:1014–1030. https://doi.org/10.1016/j.fuel.2007.06.007

Zhu Y, Wang S, Ge X, Liu Q, Luo Z, Cen K (2010) Experimental study of improved two step synthesis for DME production. Fuel Process Technol 91:424–429. https://doi.org/10.1016/j.fuproc.2009.05.001

Nakyai T, Saebea D (2019) Exergoeconomic comparison of syngas production from biomass, coal, and natural gas for dimethyl ether synthesis in single-step and two-step processes. J Clean Prod 241:118334. https://doi.org/10.1016/j.jclepro.2019.118334

Takeishi K (2010) Dimethyl ether and catalyst development for production from syngas. Biofuels 1:217–226. https://doi.org/10.4155/bfs.09.16

Saravanan K, Ham H, Tsubaki N, Bae JW (2017) Recent progress for direct synthesis of dimethyl ether from syngas on the heterogeneous bifunctional hybrid catalysts. Appl Catal B 217:494–522. https://doi.org/10.1016/j.apcatb.2017.05.085

Ogawa T, Inoue N, Shikada T, Ohno Y (2003) Direct dimethyl ether synthesis. J Nat Gas Chem 12:219–227

Blanco H, Lima SH, Rodrigues V, Palacio LA, Faro A Jr (2019) Copper–manganese catalysts with high activity for methanol synthesis. Appl Catal A 579:65–74. https://doi.org/10.1016/j.apcata.2019.04.021

Kagan YB, Rozovskij AY, Liberov LG, Slivinskij EV, Lin GI, Loktev SM, Bashkirov AN (1975) Study of mechanism of methanol synthesis from carbon monoxide and hydrogen using radioactive carbon isotope C14. Dokl Akad Nauk SSSR. 224:1081–1084

Studt F, Behrens M, Kunkes EL, Thomas N, Zander S, Tarasov A, Schumann J, Frei E, Varley JB, Abild-Pedersen F, Nørskov JK, Schlögl R (2015) The mechanism of CO and CO2 hydrogenation to methanol over Cu-based catalysts. ChemCatChem 7:1105–1111. https://doi.org/10.1002/cctc.201500123

Lee S, Sardesai A (2005) Liquid phase methanol and dimethyl ether synthesis from syngas. Top Catal 32:197–207. https://doi.org/10.1007/s11244-005-2891-8

Sun J, Yang G, Yoneyama Y, Tsubaki N (2014) Catalysis chemistry of dimethyl ether synthesis. ACS Catal 4:3346–3356. https://doi.org/10.1021/cs500967j

Ramos FS, De Farias MD, Borges LEP, Monteiro JL, Fraga M, Sousa-Aguiar EF, Appel LG (2005) Role of dehydration catalyst acid properties on one-step DME synthesis over physical mixtures. Catal Today 101:39–44. https://doi.org/10.1016/j.cattod.2004.12.007

Venugopal A, Palgunadi J, Deog JK, Joo OS, Shin CH (2009) Dimethyl ether synthesis on the admixed catalysts of Cu–Zn–Al–M (M = Ga, La, Y, Zr) and γ-Al2O3: the role of modifier. J Mol Catal A 302:20–27. https://doi.org/10.1016/j.molcata.2008.11.038

Baltes C, Vukojević S, Schüth F (2008) Correlations between synthesis, precursor, and catalyst structure and activity of a large set of CuO/ZnO/Al2O3 catalysts for methanol synthesis. J Catal 258:334–344. https://doi.org/10.1016/j.jcat.2008.07.004

García-trenco A, Martínez A (2012) Direct synthesis of DME from syngas on hybrid CuZnAl/ZSM-5 catalysts: new insights into the role of zeolite acidity. Appl Catal A 411–412:170–179. https://doi.org/10.1016/j.apcata.2011.10.036

Ginés MJL, Amadeo N, Laborde M, Apesteguía CR (1995) Activity and structure-sensitivity of the water–gas shift reaction over Cu single bond Zn single bond Al mixed oxide catalysts. Appl Catal A 131:283–296. https://doi.org/10.1016/0926-860X(95)00146-8

Kowalik P, Antoniak-Jurak K, Bicki R, Próchniak W, Wiercioch P, Michalska K (2019) The alcohol-modified CuZnAl hydroxycarbonate synthesis as a convenient preparation route of high activity Cu/ZnO/Al2O3 catalysts for WGS. Int J Hydrogen Energy 44:913–922. https://doi.org/10.1016/j.ijhydene.2018.11.051

Lima SH, Forrester AMS, Palacio LA, Faro AC (2014) Niobia-alumina as methanol dehydration component in mixed catalyst systems for dimethyl ether production from syngas. Appl Catal A 488:19–27. https://doi.org/10.1016/j.apcata.2014.09.022

Rocha AS, Aline AM, Lachter ER, Sousa-Aguiar EF, Faro AC (2012) Niobia-modified aluminas prepared by impregnation with niobium peroxo complexes for dimethyl ether production. Catal Today 2012:104–111. https://doi.org/10.1016/j.cattod.2012.02.062

Lang Y, Du C, Tang Y, Chen Y, Zhao Y, Chen R, Liu X, Shan B (2020) Highly efficient copper–manganese oxide catalysts with abundant surface vacancies for low-temperature water-gas shift reaction. Int J Hydrogen Energy 45:8629–8639. https://doi.org/10.1016/j.ijhydene.2020.01.108

Tanaka Y, Utaka T, Kikuchi R, Takeguchi T, Sasaki K, Eguchi K (2003) Water gas shift reaction for the reformed fuels over Cu/MnO catalysts prepared via spinel-type oxide. J Catal 215:271–278. https://doi.org/10.1016/S0021-9517(03)00024-1

Qi G, Fei J, Zheng X, Hou Z (2001) DME synthesis from CO/H2 over Cu–Mn/Ă-Al2O3 catalyst. React Kinet Catal Lett 73:245–256. https://doi.org/10.1023/A:1014194804329

Palgunadi J, Yati I, Jung KD (2010) Catalytic activity of Cu–Zn–Al–Mn admixed with gamma-alumina for the synthesis of DME from syngas: manganese effect or just method of preparation? React Kinet Mech Catal 101:117–128. https://doi.org/10.1007/s11144-010-0205-z

Tan Y, Xie H, Cui H, Han Y, Zhong B (2005) Modification of Cu-based methanol synthesis catalyst for dimethyl ether synthesis from syngas in slurry phase. Catal Today. 104:25–29. https://doi.org/10.1016/j.cattod.2005.03.033

Tang Q, Huang X, Chen Y, Liu T, Yang Y (2009) Characterization and catalytic application of highly dispersed manganese oxides supported on activated carbon. J Mol Catal A 301:24–30. https://doi.org/10.1016/j.molcata.2008.11.003

Ghosh SK (2020) Diversity in the family of manganese oxides at the nanoscale: from fundamentals to applications. ACS Omega 5:25493–25504. https://doi.org/10.1021/acsomega.0c03455

Holse C, Elkjær CF, Nierhoff A, Sehested J, Chorkendorff I, Helveg S, Nielsen JH (2015) Dynamic behavior of CuZn nanoparticles under oxidizing and reducing conditions. J Phys Chem C 119:2804–2812. https://doi.org/10.1021/jp510015v

Šťastný M, Issa G, Popelková D, Ederer J, Kormunda M, Kříženecká S, Henych J (2021) Nanostructured manganese oxides as highly active catalysts for enhanced hydrolysis of bis(4-nitrophenyl)phosphate and catalytic decomposition of methanol. Catal Sci Technol 11:1766–1779. https://doi.org/10.1039/d0cy02112a

Zhang QC, Liu ZW, Zhu XH, Wen LX, Zhu QF, Guo K, Chen JF (2015) Application of microimpinging stream reactors in the preparation of CuO/ZnO/Al2O3 catalysts for methanol synthesis. Ind Eng Chem Res 54:8874–8882. https://doi.org/10.1021/acs.iecr.5b01775

Nijs H, Jacobs PA (1980) New evidence for the mechanism of the Fischer–Tropsch synthesis of hydrocarbons. J Catal 411:401–411. https://doi.org/10.1016/0021-9517(80)90043-3

Andersson MP, Remediakis IN, Bligaard T, Jones G, Lytken O, Horch S, Nielsen JH, Sehested J, Chorkendorff I (2008) Structure sensitivity of the methanation reaction: H2-induced CO dissociation on nickel surfaces. J Catal 255:6–19. https://doi.org/10.1016/j.jcat.2007.12.016

Acknowledgements

The authors acknowledge the XRD at IQ-UFRJ for sample analysis. To the Laboratório de Petróleo e Meio Ambiente (LCPMA) at UERJ for making available the equipment to perform the TPR and N2O decomposition measurements. We acknowledge LNLS (Campinas, Brazil) for provision of synchrotron radiation facilities for XAS measurements at XAFS2 beamline (Project 20190122) and XRD measurements at XPD (Project 20190118) beamline. The authors also thank Conselho Nacional de Desenvolvimento Científico e Tecnológico—CNPq (Grant 426600/2018-5) Brazil, for the financial support. ACFJ thanks CNPq for a productivity research scholarship. This study was financed in part by the Coordenação de Aperfeiçoamento de Pessoal de Nível Superior-Brasil (CAPES)—Finance Code 001. HB thanks CAPES for a D.Sc. scholarship.

Funding

Funding was provided by Conselho Nacional de Desenvolvimento Científico e Tecnológico (Grant No. 426600/2018-5), Coordenação de Aperfeiçoamento de Pessoal de Nível Superior (Grant No. 001).

Author information

Authors and Affiliations

Contributions

The manuscript was written through contributions of all authors. All authors have given approval to the final version of the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors have no competing interests to declare that are relevant to the content of this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Blanco, H., Palacio, L.A., Rodrigues, V. et al. Cu–Mn–Al based catalyst for the direct syngas to dimethyl ether conversion. Reac Kinet Mech Cat 137, 913–934 (2024). https://doi.org/10.1007/s11144-024-02581-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11144-024-02581-6